1.0 Introduction

3

TABLE OF CONTENTS

1.0 Introduction ...................................................................................................................................... 2

2.0 Safety............................................................................................................................................... 4

2.1 Precautions...................................................................................................................................4

2.2 Power Lockout Procedure ............................................................................................................4

2.3 Warning Label Definitions.............................................................................................................5

3.0 Packing List...................................................................................................................................... 6

4.0 Specifications................................................................................................................................... 7

5.0 Accessories...................................................................................................................................... 8

6.0 Installation Guide ............................................................................................................................. 9

6.1 Inspecting Shipment.....................................................................................................................9

6.2 Unpacking.....................................................................................................................................9

6.3 Leveling.........................................................................................................................................9

6.4 Cleaning........................................................................................................................................9

6.5 Power Hook-up (SCM Models Only) ............................................................................................9

6.6 Knife and Die Installation..............................................................................................................9

7.0 User’s Guide .................................................................................................................................. 10

7.1 SCM/MSCM Diagrams .............................................................................................................. 10

7.2 SCM (Power Model) Operation ................................................................................................. 12

7.3 MSCM (Manual Model) Operation............................................................................................. 12

7.4 Side and Back Gauge Adjustment............................................................................................. 12

7.5 Knife and Die Change................................................................................................................ 12

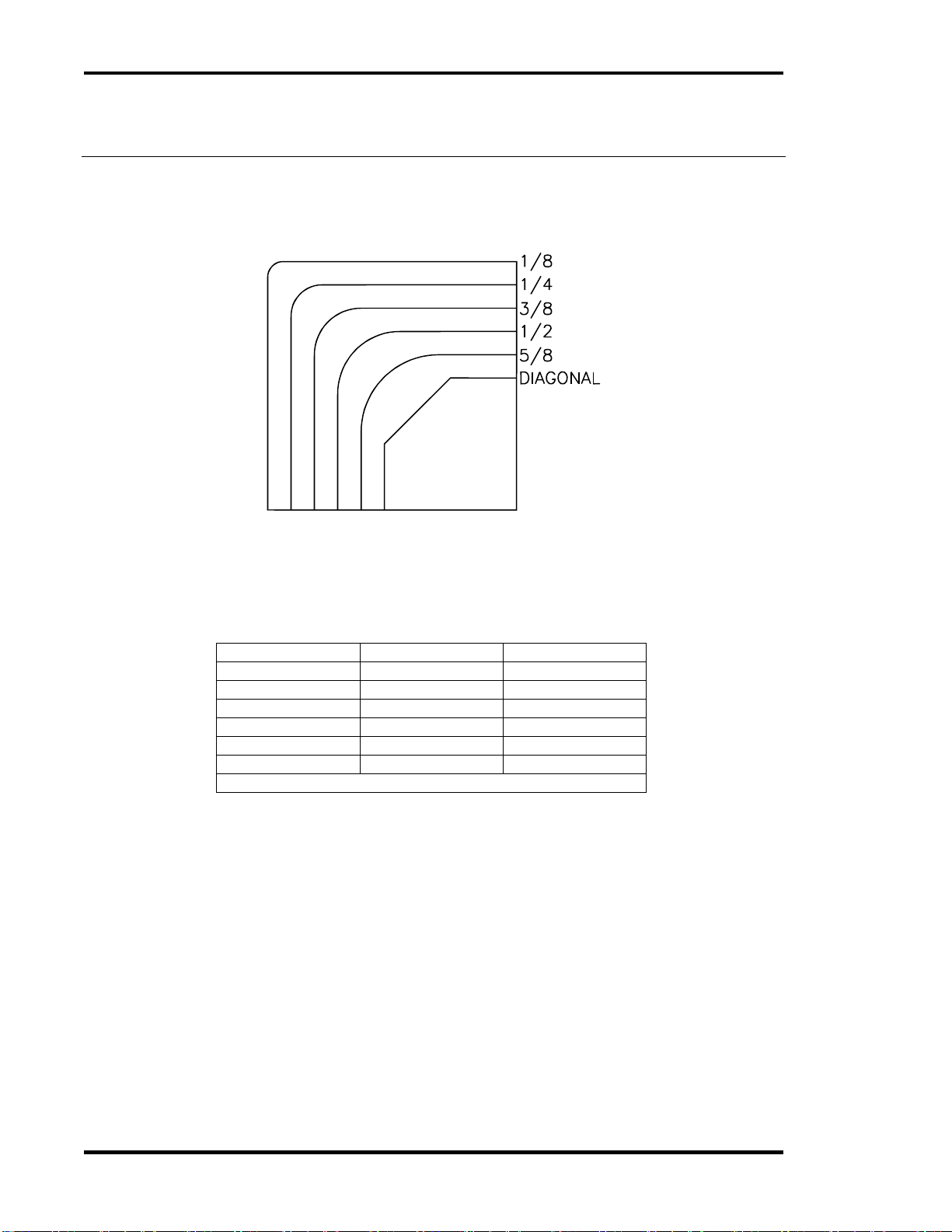

7.6 Straight Diagonal Cutting........................................................................................................... 15

7.7 Lubrication ................................................................................................................................. 16

7.8 Operating Tips ........................................................................................................................... 17

8.0 Appendix A - Maintenance Guide .................................................................................................. 18

8.1 Mechanical System.................................................................................................................... 19

8.1.1 Knife Return Springs .......................................................................................................... 19

8.1.2 Dovetail Gib........................................................................................................................ 20

8.2 Hydraulic System (SCM Models Only)...................................................................................... 21

8.2.1 Hydraulic Fluid Check ........................................................................................................ 21

8.2.2 Replacing Hydraulic Fluid................................................................................................... 22

8.2.3 Hydraulic Fluid Compatibility List ....................................................................................... 22

8.3 Electrical System (SCM Models Only)....................................................................................... 22

8.3.1 Circuit Breaker Check ........................................................................................................ 22

9.0 Appendix B–Parts List.................................................................................................................... 24

9.1 Mechanical................................................................................................................................. 24

9.1.1 A-8300-3 Main Assembly- Knife Head............................................................................. 24

9.1.2 A-8300-3 Main Assembly- Knife Head (Rear).................................................................. 26

9.1.3 A-8300-3 Main Assembly- Underside .............................................................................. 28

9.1.4 A-8300-3 Main Assembly- Hood ...................................................................................... 30

9.1.5 A-8300-3 Main Assembly- Base....................................................................................... 32

9.1.6 A-8300-3 Main Assembly- MSCM, S/N’s 142609M & Up ................................................ 36

9.1.7 83001-1 Hydraulic Power Unit Assembly- SCM, Rev. A.................................................. 38

9.2 Electrical .................................................................................................................................... 40

9.2.1 E-3356-1 Basic Machine Schematic ................................................................................. 40

9.2.2 E-3357-1 Interconnection Diagram ................................................................................... 41

9.2.3 EE-3358-1 Terminal Rail Assembly .................................................................................. 42

10.0 Appendix C- Troubleshooting ...................................................................................................... 44