The supervised edge system is designed to provide status information to the installer or maintenance personnel in order to assist in

troubleshooting. There are three indicators in the receiver unit to observe: the green “heartbeat” LED, the red “fault” LED, and an

integral trouble sounder.

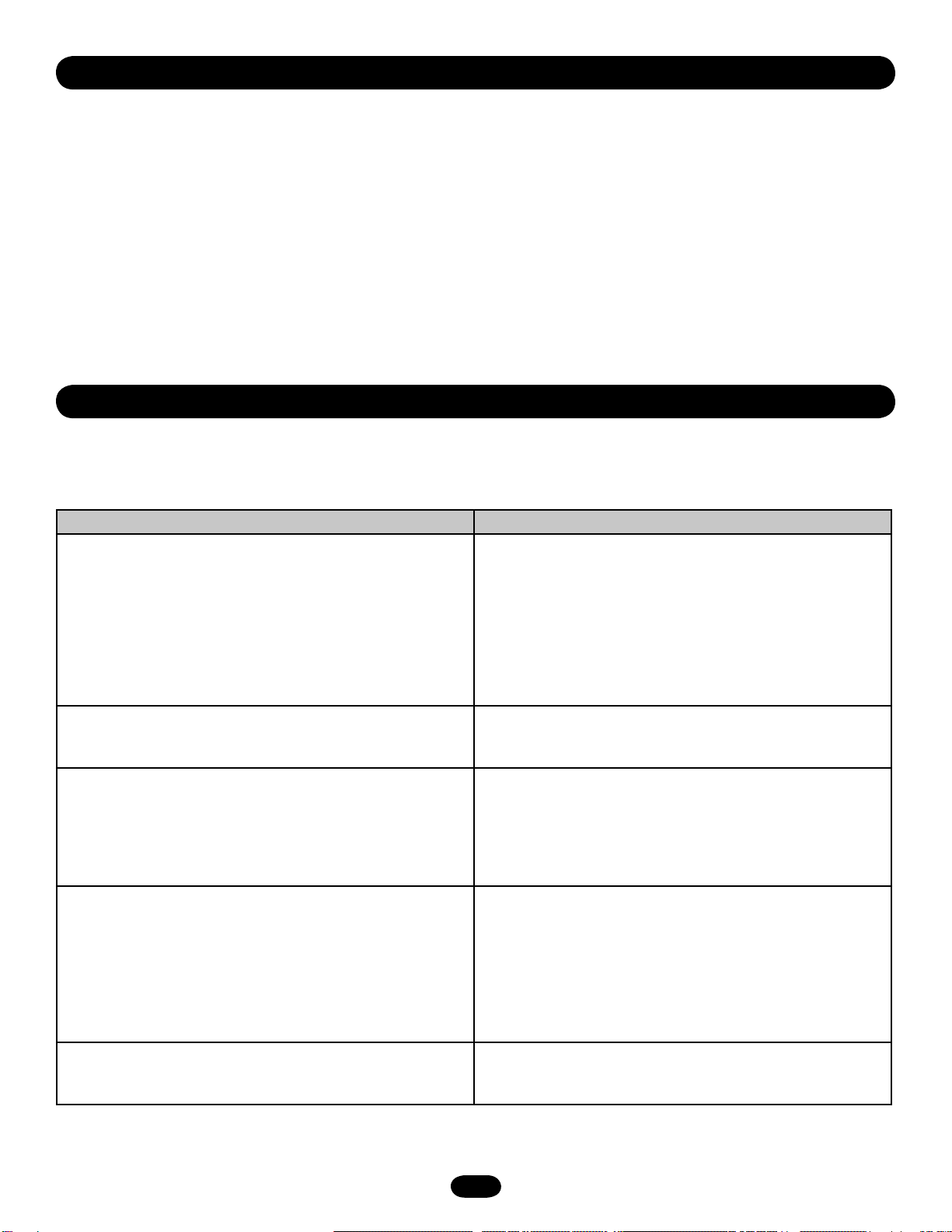

CONDITION SOLUTION

• Red LED on

• 3 beeps repeated every 2 seconds

• Green LED does not flash

Transmission path failure. Make sure there is a direct line of sight

between transmitter and receiver. Transmitter LED or receiver

may be dirty.

OR

The battery was not properly inserted into the transmitter unit.

Open the transmitter unit and make sure the battery is inserted

with the correct polarity.

• Red LED on

• 3 beeps repeated every 2 seconds

• Green LED flashes about every second

One unit is set to channel A while the other is set to channel

B. Open one of the units and change the channel jumper as

described in channel election section.

(ELECTRIC EDGE ONLY)

• Red LED on

• 3 beeps repeated every 2 seconds

• Green LED flashes about every second

Safety edge open fault. Open the transmitter unit and make sure

connections are tight.

The safety edge is open or does not have an 8.2k Ohm resistor

embedded. Use a multimeter to check the resistance on the edge,

it should be between 7.5k Ohms and 15k Ohms.

• Red LED on

• 3 beeps repeated every 2 seconds

• Green LED flashes about every second

The door/grill is closed on an uneven surface. This is a normal

condition if continuously depressed.

(ELECTRIC EDGE ONLY)

Safety edge is shorted or partially shorted. Check the edge

connections in transmitter, and then measure the safety edge

resistance. Correct tolerance is 7.5k Ohms to 15k Ohms. Replace

edge if out of tolerance.

• Red LED Off

• Sounder sounds 2 beeps every ten seconds

• Green LED flashes about every second

Low battery indication. Replace the battery in the transmitter unit

with a 3V Lithium battery.

IMPORTANT - Test system thoroughly before the door is put

into normal operation. Stand clear of the door until it is fully

tested. If any failure occurs during the test procedure, turn all

power to the operator off and follow the suggestions in the

Diagnostics section of this guide.

1. Turn power on to the operator.

2. The system should remain quiet and the green LED should

flash briefly once a second.

3. Cover the protruding LED on the transmitter unit. The red LED

on the receiver unit should come on and be accompanied by a

3-beep warning from the trouble sounder every 2 seconds.

Uncover the LED.

4. Partially open the door. Squeeze the safety edge. The red LED

on the receiver unit should come on and be accompanied by a

3-second continuous warning from the trouble sounder.

Release the safety edge.

5. Begin closing the door. Being careful to stand clear of the door,

squeeze the safety edge. The door should stop its downward

motion and begin to open.

6. Allow door to open completely. The system should remain quiet

and the green LED should flash briefly once a second. Both

units should have an unimpeded path throughout the range of

motion of the door. Strain relief should be used on both cables

as well as additional cable ties as necessary.

TESTING

DIAGNOSTICS

7