Champtek IG300BT User manual

1

IG300BT

C1/C2 Area image Barcode Scanner

User’s Manual

2

Conents

Conents .................................................... 2

1. Introduction......................................... 5

1.1 Safety & Caution .............................. 5

1.2 FCC Warning .................................... 6

2. General Description ............................. 7

2.1 Product Description .......................... 7

2.2 Illustration ......................................... 7

3. Installation .......................................... 8

3.1 Unpacking ....................................... 8

3.2 Mounting .......................................... 8

4. Set up Bluetooth Communication ..... 11

4.1 Pairing ............................................. 11

4.2 Set up Master Mode Communication

11

4.3 Set up Slave Mode Communication12

4.4 Scanner Slave/Master Mode ........... 12

4.4.1 Set Scanner Pin Code Mode ....... 13

4.4.2 Set Pin Code Character ............... 13

4.5 Bluetooth Cradle Setup .................. 14

4.5.1 Set Cradle Security Mode ............ 14

4.5.2 Set Cradle Pin Code ..................... 14

5. Configuring ....................................... 15

5.1 Preface ........................................... 15

5.2 Changing Scanner Settings with

Programming Codes ...................... 15

5.3 Changing Scanner Settings with Utility

Tool ................................................. 16

5.4 Factory Default Settings ................ 16

6. Operating Settings ............................. 17

3

6.1 Factory Default ............................... 17

6.2 Scanning Triggering ...................... 17

6.3 Trigger Time Out ............................ 19

6.4 Good Read Mode .......................... 20

6.5 Buzzer Beep Tone ......................... 20

6.5.1 Beep Tone Setup ........................ 20

6.5.2 Good Read Beeps ...................... 21

6.5.3 Beep Duration ............................. 21

6.5.4 Timing .......................................... 22

6.5.5 Good Read Duration .................. 22

6.5.6 Error Beep ................................... 22

6.5.7 Setup Beep ................................. 22

7. Imager Settings .................................. 23

7.1 Imager Mode .................................. 23

7.2 Sleep Mode .................................... 24

7.3 Batch Mode .................................... 25

7.4 Firmware Version ........................... 26

7.4.1 Engine Firmware Version ........... 26

7.4.2 Scanner Decoder Firmware Version

26

7.4.3 Cradle Decoder Firmware Version

26

7.4.4 Scanner Bluetooth MAC Address26

7.4.5 Cradle Bluetooth MAC Address. 26

7.5 Set Cradle Interface Barcode ........ 27

7.6 Cradle RS232 Communication

Parameter ....................................... 27

7.6.1 Cradle Baud Rate ....................... 27

7.6.2 Cradle Data Bits.......................... 28

7.6.3 Cradle Stop bits .......................... 28

7.6.4 Cradle Parity ............................... 28

7.6.5 Cradle Hand Shaking ................. 29

7.6.6 Cradle Keyboard Wedge Mode

Parameters ..................................... 30

7.7 Decoding Selection ........................ 35

7.7.1 Symbologies Selection ............... 35

7.7.2 Disable All Symbologies. .......... 44

7.7.4 Activates user defined symbology

identifier (UDSI) transmission for all

symbologies.................................... 46

4

7.7.5 Postambles ................................. 48

Appendixes ............................................ 49

A. Decimal Value Table .................... 49

B. ASCII Table .................................... 50

C. Readable Symbologies ............... 51

D. Technical Specifications............. 52

E. Scan Map ....................................... 55

F. Test Symbologies ........................ 56

5

1. Introduction

Thank you for purchasing this brand-new designed

2D imager hand held barcode scanner.

This is a cutting-edge gun-type Area Imaging

barcode scanner which is designed specifically for

retailer, entertainment coupons, medical environment,

shipping industry and etc. That adds on more user

friendly functions and has replaceable cable that

makes it more easily to be operated by the

customers.

This high performance gun-type scanner provides the

customer with the most cost effective solution in the

market. It is perfectly suitable and definitely the best

choice for you.

1.1 Safety & Caution

1) Please read the following safety statement

carefully.

2) Please preserve this user manual for reference

sometime.

3) Before cleaning the device, the users must cut off

all AC power. Do not use liquid or spray type of

detersive to clean the device. Please use

dampish cotton cloth to clean the device.

4) The outlet must set nearby the device for

connecting power easily.

5) Keep the device dry to avoid short circuit.

6) During installation you must fix the equipment at

solid table to avoid damage caused by falling.

7) Before inserting power please ensure the voltage

is healthy to the equipment.

8) For safety please tie wire well and don’t put

anything on the wire.

9) If you don’t use this equipment for long time,

please cut off the power to avoid damage from

surge power.

10) Don’t spray any liquid on this scanner because it

may cause a fire or short circuit.

11) Please do not open the equipment. For safety

only the qualified serviceman can open the

equipment.

6

12) If there are the following situations please

contact with the qualified serviceman to check

this equipment.

13) The damage of wire or pin of power supply.

14) Some Liquid infiltrate into the equipment.

15) The equipment has been exposed to wet

environment.

16) The equipment can’t work well.

17) The equipment has any obvious damage,

making the device working abnormally.

18) Don’t storage the device at the temperature

lower than -20°C (-4°F) or higher than +70°C

(158°F) to avoid any damage.

1.2 FCC Warning

This equipment complies with the requirements in

Part 15 of FCC.

Any operation must comply with the conditions

below:

1) The equipment will not cause any severe

interference.

2) The equipment can avoid any interference

from environment.

Statement:

This product is classified as B class product.

In environment this product may cause some

interference. In this situation the user may do

something to avoid interference.

7

2. General Description

2.1 Product Description

IG300BT is a high performance wireless 2D imager

barcode scanner supporting liner, area imager

barcode scanning.

This device is very easy to configure by this manual,

you can set up by scanning all necessary

programming codes one time that meet applications,

the settings are directly saved permanently, and all

settings can be disabled after scan reset factory

default.

2.2 Illustration

IG-300BT Series

8

3. Installation

3.1 Unpacking

1) Take device and its accessories out of the box.

2) Remove the packing material.

3) Check the standard shipment packing list to make

sure you have received all of the items ordered.

Wireless 2D Imager Scanner

Bluetooth Cradle or Charger (optional)

Power Adaptor (if applied)

Communication Cable

Skip resistant pad

Iron panel of cradle and screw

Quick Start Guide

4) Visually inspect the device and accessories for

any evidence of physical damage.

5) If anything is missing or appears to be damaged,

immediately contact your dealer.

ATTEN

T

ION:

Store the packing material and boxes: It should

be used whenever the device is transported for

servicing.

3.2 Mounting

Once you have unpacked all components, you can

start installing the device as below steps:

IG300BT Scanner

1) The Scanner must be charged for a minimum

of 8 hours before the scanner can be placed

in full operation for the first time.

2) The cradle will indicate in red light when the

scanner is being charged.

3) Once the battery is full, green LED of scanner

will be ON. And green light will be OFF when

the scanner leaving from cradle. The battery

will over charged when battery full charged

again, red and green LED will flashing.

4) If the battery power capacity is too low, the

9

scanner will indicate with red LED and beeper

warning.

IG300BT Cradle

1) Connect the supplied communication cable at

the bottom side of the scanner and you will

hear a “click” when the connection is made.

2) Turn off the host system.

3) Connect the other side of the communication

cable to the right connector of your Host

system.

4) Plug the external power supply into the power

jack on the bottom of the cradle.

5) Plug the power supply into the AC outlet.

6) Turn on your Host system.

7) To set up Bluetooth Communication between

the scanner and cradle. (see chapter 4)

10

Cable Installation

Connect cable and adaptor to Cradle. The other

end of cable will be connected with Host device.

Lock the iron panel of Cradle by screwdriver.

Skip resistant pad position

11

4. Set up Bluetooth

Communication

Before the operation, Bluetooth Communication must

be set up between the scanner and cradle.

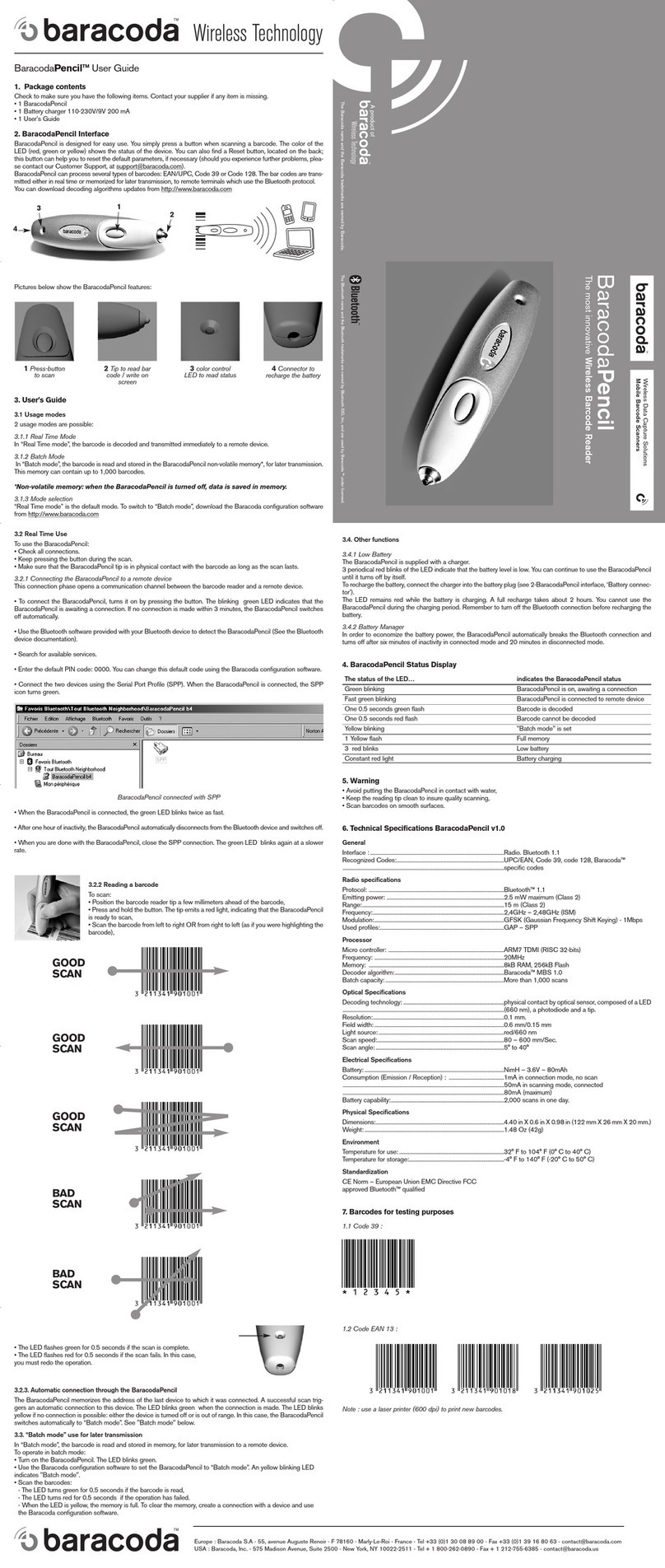

4.1 Pairing

Each scanner has to be linked or paired to a cradle

by scanning the unique Bluetooth MAC address code

located on the bottom of cradle. The pairing between

scanner and cradle is one to one that is one scanner

can be paired to a cradle only.

4.2 Set up Master Mode

Communication

Please follow the steps to set up the communication

between the scanner and cradle.

1) The scanner must scan “Scanner Master Mode”

barcode, to set the scanner in Master mode.

2) Scan the Bluetooth MAC address code located on

the bottom of the cradle.

3) When the Bluetooth MAC address code was

successfully scanned, scanner will sound 2 short

beeps with blue and red LED flash once.

4) Wait approximately five seconds, for completing

the connection process with a long beep sound.

5) If successful, Blue LED of scanner will slow flash

and the cradle will be continued on.

6) If the connections failed the scanner indicates

with 3 shot beeps and the cradle with blinking

blue LED.

12

ATTENTION:

It is important to know that the scanner will only

communicate with the cradle with the unique Bluetooth

MAC address. Other scanner can not pair with that

cradle until the original connection is broken. If the

cradle pairs with another scanner, the cradle will

disconnect with the first scanner and then re-connect

with another scanner.

4.3 Set up Slave Mode Communication

Please follow the below steps to set up the

communication between the scanner and Bluetooth

application device.

1) The scanner must scan “Scanner Slave Mode”

barcode, to set the scanner in Slave mode.

2) Enter the pin code (default 000000) to setup

comport when control the Bluetooth device to

search the scanner.

3) When the scanner is successful connected,

scanner will sound 1 long beep.

4) If successful, Blue LED of scanner will slow flash.

5) If the connections failed the scanner indicates

with 3 shot beeps.

4.4 Scanner Slave/Master Mode

Scanner Slave Mode

<Scanner Master Mode>

13

4.4.1 Set Scanner Pin Code Mode

Set Default Security Code

<PINCODE = 000000>

Set Security Code ON

<Set Security code OFF>

4.4.2 Set Pin Code Character

(PINCODE max. 6 digits/0-9and A-Z ASCII CODE)

Set Default Security Code Barcode

<PINCODE = 000000>

1) Begin to Set PINCODE

2) Go to the ASCII Tables in Appendixes; scan 6

labels that represent the PINCODE.

3) Complete to Set PINCODE

14

4.5 Bluetooth Cradle Setup

4.5.1 Set Cradle Security Mode

Set Default Security Code Barcode

<PINCODE = 000000>

Set Security ON

<Set Security OFF>

4.5.2 Set Cradle Pin Code

(PINCODE max. 6 digits ,0-9,A-Z ASCII CODE )

Set Default Security Code Barcode

<PINCODE = 000000>

1) Begin to Set PINCODE

2) Go to the ASCII Tables in Appendixes; scan

6 labels that represent the PINCODE.

3) Complete to Set Cradle BT PINCODE

15

5. Configuring

5.1 Preface

How to configure this device: The Barcode

Programming Feature gives the possibility to change

the scanner settings with use programming codes.

5.2 Changing Scanner Settings with

Programming Codes

You can setup your device by scanning all necessary

programming codes for parameters that meet

applications. After these scans, the device will save

directly and permanently. To go back to the factory

default settings, just scans the programming code

factory default.

In order to change the scanner settings please follow

the sequence below:

1) Power-up the scanner.

2) Change scanner settings by scanning any of the

programming code that meet applications.

An Example:

For changing the Baud rate to 38400 only scan the

programming code that represents this.

After reading a valid programming code the scanner

will give Di-Du beeps and red-blue LEDs indicator will

flash. And the cradle will give green LED indicator

flash.

At any moment, you can stop your programming and

read programming code factory default to go back to

default.

16

5.3 Changing Scanner Settings with

Utility Tool

Manufacturer has setup this scanner with the most

common used programming codes, It could be

possible that you need more advanced settings to

use the scanner without any problems into your

application.

In this case you can setup your scanner by using the

advanced Utility Tool. This tool can be used with the

following operation systems: Windows98,

Windows2000, Windows XP en Windows Vista.

This Utility Tool can be delivered on request. Please

contact your dealer

5.4 Factory Default Settings

The factory default settings are shown with <> and

bold in the followings sections

The readable and default enable symbologies list,

please see Appendixes C.

17

6. Operating Settings

6.1 Factory Default

Set Scanner /Cradle factory default

The scanner and cradle factory default settings are

shown with bold < > in the following pages.

Reset all configuration parameters to their factory

default setting. After this reset you must select all

required parameters that meet applications.

6.2 Scanning Triggering

<Level>

A reading session begins (lighting and decode

processing on) when beam is activated and stops

when beam is deactivated.

Continuous Scanning

When the scanner is turned on a continuous reading

session begins (lighting and decode processing on).

Pulse

A reading session begins when beam is activated

and stays on until a period of inactivity lasting the

time specified by the timeout.

After the timeout, the scan engine turns off.

18

Flashing

Flashing mode allows power up the lighting and

decoding are on (no need to activate the trigger line)

and after a period of inactivity lasting the time

specified by the trigger timeout, the scanner starts

flashing, checking for a bar code to be read.

When a bar code is detected, the lighting and

decoding automatically turn on and stay on until

another period of inactivity (timeout), after the timeout

the scanner starts flashing again.

Autostand

This mode allows you to switch from Flashing trigger

mode to Level trigger mode.

Autostand begins in flashing mode: At power up the

lighting and decoding are on (no need to activate the

trigger line) and after a period of inactivity lasting the

time specified by the trigger timeout, the scanner

starts flashing.

To switch to Level trigger mode activate the trigger

line (press the trigger).

When in Level trigger mode, after a period of

inactivity lasting the time specified by the trigger

timeout, the scanner switches back to flashing mode.

Toggle

This mode allows lighting and decoding toggle when

the trigger line is activated.

First trigger activation = lighting and decoding on,

second trigger activation = lighting and decoding off.

19

Presentation

This mode allows power up lighting and decoding are

on. After a period of inactivity lasting the time

specified by the trigger timeout, the lighting turns off

or is dimmed. When a new bar code is presented the

lighting and decoding restart and stay on until

another period inactivity.

6.3 Trigger Time Out

<2 sec>

4 sec

6 sec

20

6.4 Good Read Mode

When active, the scan engine stops the reading

session after a successful decoding.

Note: This parameter is NOT used with continuous

and continuous + flashing modes.

<Active >

Not Active

6.5 Buzzer Beep Tone

6.5.1 Beep Tone Setup

<High >

Medium

Low

Other manuals for IG300BT

1

Table of contents

Other Champtek Barcode Reader manuals

Champtek

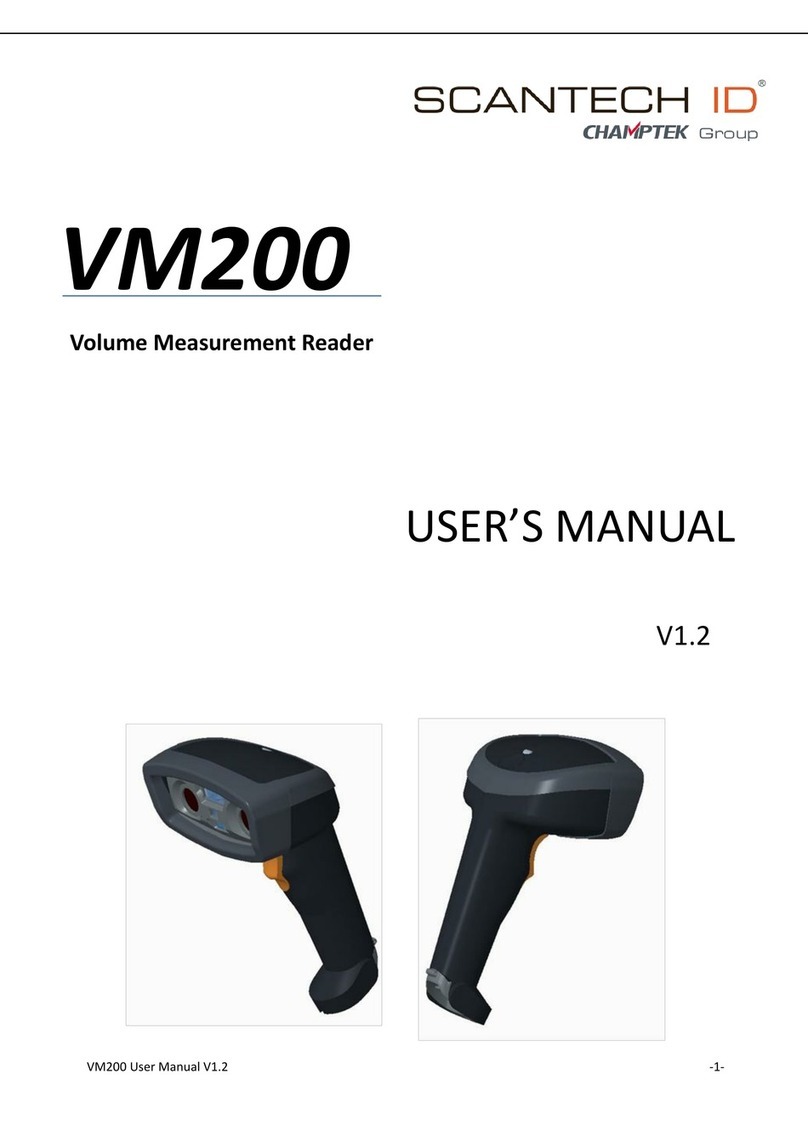

Champtek VM200 User manual

Champtek

Champtek IG300BT User manual

Champtek

Champtek SG700BT User manual

Champtek

Champtek SLIM S-9080i User manual

Champtek

Champtek SG700BT Operating instructions

Champtek

Champtek IG500 User manual

Champtek

Champtek IG-300 User manual

Champtek

Champtek SCANTECH ID VM200 User manual

Champtek

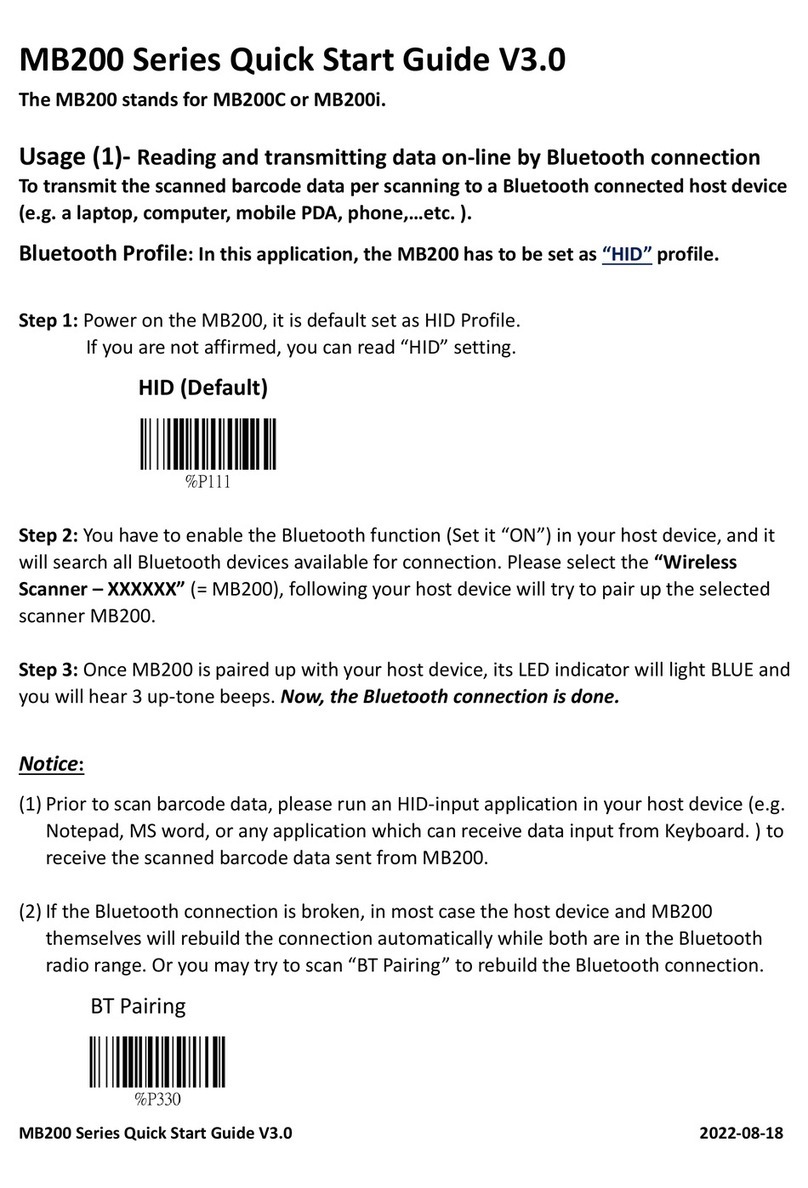

Champtek MB200 Series User manual