Champtek VM200 User manual

Volume Measurement Reader

VM200/ VM200BT

Quick Start Guide

V1.9

2

VM200 Quick Start Guide

1. The first time to use VM200

Device inspection and initialization

When a VM200/ VM200BT is been powered on, it will

immediately beep 2 times quick Be-Be-Be, following it

will take about 5seconds to do

the hardware inspection and system initialization,

during this period its LED indicator will blink Green.

Once the inspection and initialization are successful, it

will beep 1 time Be-Be-Be and turn off the Green LED.

You can start your work now !

If it is fail, the VM200 will keep the Be-Be-Bi-Bi beeping

and to flash Red LED. You have to plug again or check.

Note: this manual is applicable to VM200 and VM200BT.

Data output

You have to connect to a data display tool to receive

and display the dimension data transmitted from the

VM200.

There are 3 selections,

(1) VMView tool (for RS-232/USB Virtual com setup, please

note it is not applicable to USB-HID interface). or

(2) your own implemented application, or

(3) [for VM200 USB-HID interface] Windows Notepad or any

tool can receive the keyboard input, or

[for VM200 RS-232/USB Virtual com setup] a RS232

terminal tool (e.g. Terminal2010, Putty, teraterm, etc.)

3

2. Set up the Device

VM200 with USB Interface

1.

Connect the Interface Cable(RJ45 end) to the VM200.

2.

Connect the USB Interface cable to a PC/host.

3.

Plug the power adaptor into the Power outlet.

4.

Connect the power adaptor plug in the injector on the

cable to power it on if required.

Note

: It won’t necessary to do step 3 and 4 if the power

supplied from the USB interface cable is sufficient to

power on the VM200.

VM200 with RS-232 Interface

1.

Connect the Interface cable(RJ45 end) to the VM200.

2.

Connect the RS-232 Interface cable to a PC/host.

3.

Plug the power adaptor into the Power outlet.

4.

Connect the power adaptor plug in the injector on the

RS232 cable to power it on.

VM200BT with USB/RS-232 Interface

4

3. Configurable Button Setting

VM200 consists of two buttons. One “Trigger”button

(A) and another “Touch”button (B).

The two buttons are configurable in one of 6 optional

combinations to be best fit to your application.

Note: VM is Volume measurement

The default buttons setting is <4>.

<4> Trigger (A) button is for measurement, to touch (B)

button to switch (A) button function in between

barcode reading or measurement.

<1> Trigger (A) button to read a barcode, touch (B) button

to do measurement.

<2> Trigger (A) button to do measurement, touch (B) button

to read a barcode.

<3> Trigger (A) button is for barcode reading, to touch (B)

button to switch (A) button function in between

measurement or barcode reading.

<5> Trigger (A) barcode scan first then VM scan, touch (B)

button to redo the scan.

<6> Trigger (A) VM scan first then barcode scan, touch (B)

button to redo the scan.

5

Note: VM is Volume measurement, 2D is barcode reading,

Switch is to switch (A)-button in between VM and 2D

barcode reading.

Button Behavior Setting

A:2D / B:Switch

A:2D / B:VM

A:VM / B:2D

<A:VM / B:Switch>

A:barcode then VM

scan, B:redo scan

A:VM then barcode

scan, B:redo scan

6

3. Reading Mode

There are 3 measuring ways,

Pitch scan- Appropriate to scan a cuboid

shape with horizontal placement on

the longer side of this object.

Vertical scan- Appropriate to measure an

irregular shape and its dimension

output is the minimum cuboid shape

can cover this irregular object. Also

appropriate to scan the cuboid shape

with vertical placement on the longer

side of this object.

Auto scan (Default) –it will automatically

switch in between “Pitch scan” and

“Vertical scan”according to the

reading type it detects.

7

4. Patenting Guiding Aimer

How to aim and measure an object -Pitch scan

When a user triggers a VM200 to measure (e.g.) a

carton, he/she can manipulate it (move closer to or far

from the carton) to lead the cross-shaped “+” laser

aimer aims at the middle area of the front-upper edge

(Abbr. F-Edge) of the measured face of this carton.

Once the width of the Horizontal line of “+” is close to

or longer than the width of F-Edge, the Vertical line of

“+” is located around the middle area of F-Edge, the

whole carton will be inside the “field of view”of

VM200, and its dimensions are immediately measured.

Intelligent Reading Zone Detection

With VM200’s smart reading zone detection, it will

alarm continuous beep with flashing red LED when no

object is detected inside the good reading zone.

8

How to aim and measure an object- Vertical scan

When a user triggers a VM200 to measure (e.g.) a

carton, he/she can manipulate it (move closer to or far

from the carton) to lead the cross-shaped “+” laser

aimer aims at the middle area above this carton.

Once the width of the Horizontal line of “+” is close to

or longer than the width of the carton, the Vertical line

of “+” is located around the middle area above the

carton, the whole carton will be inside the “field of

view”of VM200, and its dimensions are immediately

measured.

Intelligent Reading Zone Detection

With VM200’s smart reading zone detection, it will

alarm continuous beep with flashing red LED when no

object is detected inside the good reading zone.

9

5. Correct and Incorrect Reading

Pitch scan

CORRECT

The width of the Horizontal line of “+” is close to or

longer than the width of F-Edge on the measured

face of the carton, and the Vertical line of “+” is

aimed at around the middle area of the F-Edge.

INCORRECT

Case A: too close to the carton, the width of the

horizontal line of “+” is far less than F-edge.

Cases B: too leftward or C: too rightward, the

vertical line of “+” is NOT aimed at around the

middle area of the F-Edge of the measured face of

the carton.

10

Vertical scan

CORRECT

The width of the Horizontal line of “+” is close to or

longer than the width of the carton, the Vertical line

of “+” is located around the middle area above the

carton

INCORRECT

Cases A: too rightward or B: too leftward, the

vertical line of “+” is NOT aimed at around the

middle area above the carton.

Case C: too close to the carton, the width of the

horizontal line of “+” is far less than the carton.

11

6. Reading distance and angle

Pitch scan

The best reading distance is read from 40cm~150 cm to the

surface of a carton / object.

The best pitch (forward/backward) reading angle is 35°~65°.

35°

65°

The best skew (leftward/rightward) reading angle is ±7°.

12

Vertical scan

The best reading distance is read from 40cm to the upper

surface of a carton / object and within 150cm from the

ground.

Keep vertical to the upper surface of the carton when

measuring, and the best pitch (forward/backward) reading

angle and best tilt (leftward/rightward) reading angle is ±10°

from the ground.

13

Reading zone detection alarm setting

<Alarm Enable>

Alarm Disable

14

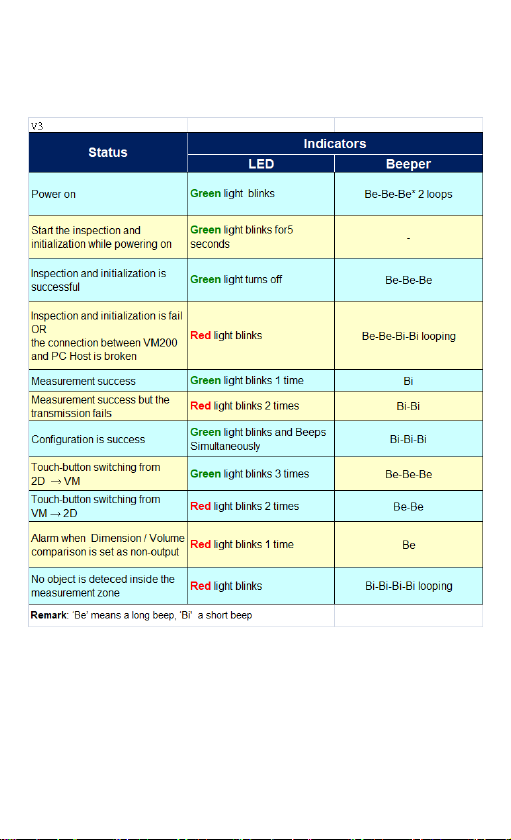

7. Indicators - LED and Beeper

General Operation

15

Power and Bluetooth LED and Beeper for VM200BT

16

8. Default Data Output

The default data output is fixed length described as table,

a space is in between each data column.

‘<2D>’presents the barcode data,

‘<3D>’presents the measurement data;

For example,

<3D> VM200 835DMT900338 CM 27.40 17.70 20.50

27.00 18.00 21.00 66.00 10206.00

<2D>7311271448044

NO.

Data Output

Bytes

of data

Value is

(Example)

Outputted as

(presents a

space)

1

Data Type

identifier

4

<3D> or <2D>

<3D>

2

Model

6

VM200

VM200

3

Serial number

12

835DMT900338

835DMT900338

4

Unit of

measurement

4

CM or INCH

CM

INCH

5

W-Width

(before rounded)

6

20.1

102.4

20.10

102.40

6

H-Height

(before rounded)

6

7

L-Length

(before rounded)

6

17

NO.

Data Output

Bytes of

data

Value is

(Example)

Outputted as

(presents a

space)

8

W-Width (rounded)

6

20.1

102.4

20.00

102.00

9

H-Height (rounded)

6

10

L-Length (rounded)

6

11

Sum of dimension

7

202

202.00

12

Volume

10

10102

10102.00

13

Dimensional weight

7

14

Carriage Return

1

15

Line Feed

1

(Above examples of “Values is”are not relevant to each other, just

for explanation purpose.)

Note:

1. Data values are outputted in fixed length.

2. The output data will be filled a space (presents a

space) ahead in the Integer to comply with the defined

length, filled 0 at the decimal places.

3. If a data-separator is set, the data-separator will be

output in between every two consecutive data.

4. All data are concatenated as an output string and be

transmitted.

5. Customer can configure the data (column no. 5~13) to

be outputted and its sequence in VMSet.

18

9. Configuration Bar Code

Set All Default

USB-VCOM

Interface Selection

<RS232>

Version Information

19

<CR+LF>

Select Terminator

CR

LF

None

Reading Mode

<Good read off>

Trigger On/Off

20

Unit of Measurement

<CM>

INCH

This manual suits for next models

1

Table of contents

Other Champtek Barcode Reader manuals

Champtek

Champtek IG500 User manual

Champtek

Champtek SG700BT Operating instructions

Champtek

Champtek MB200 Series User manual

Champtek

Champtek IG300BT User manual

Champtek

Champtek IG-300 User manual

Champtek

Champtek SLIM S-9080i User manual

Champtek

Champtek IG300BT User manual

Champtek

Champtek SG700BT User manual

Champtek

Champtek SCANTECH ID VM200 User manual