TABLE

OF

CONTENTS

I.

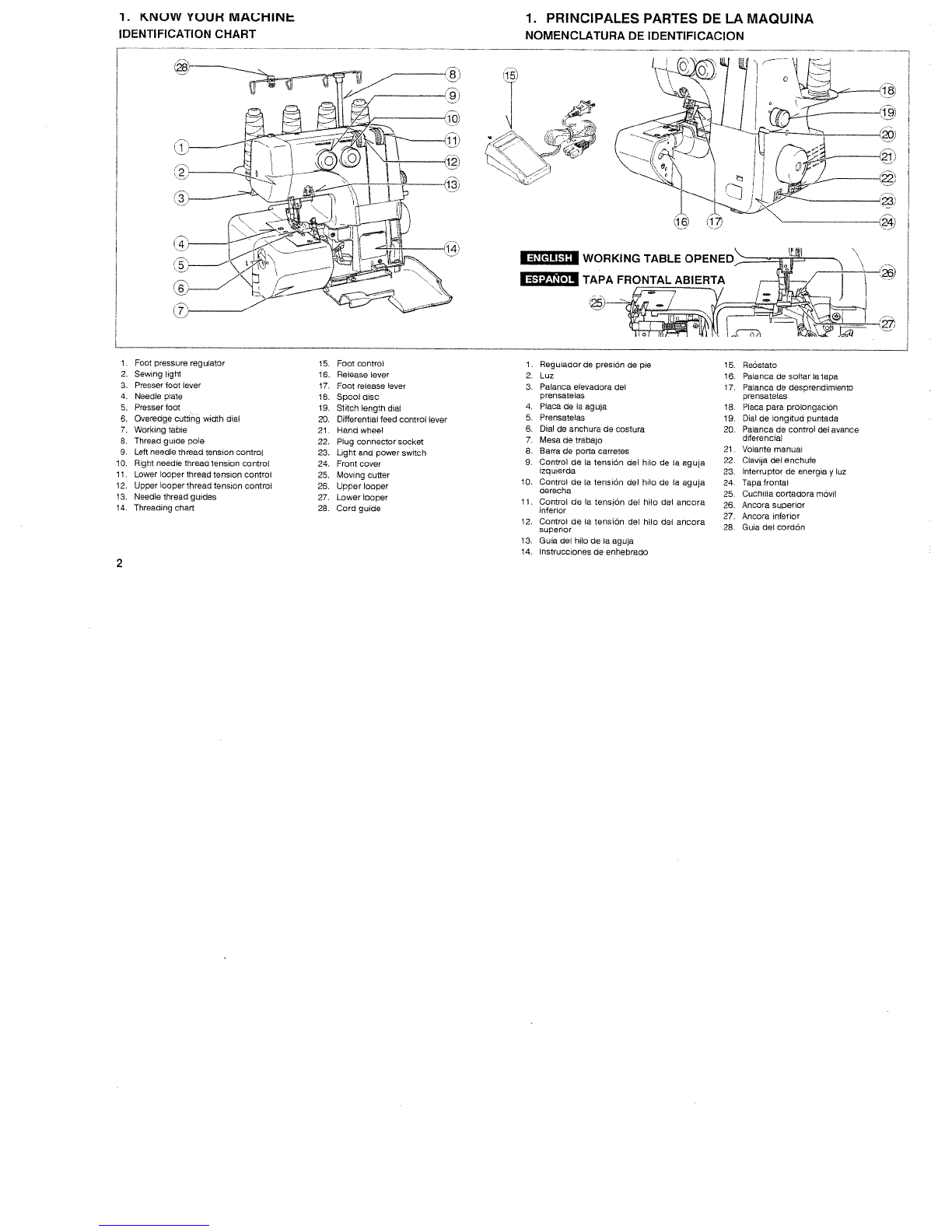

KNOW

YOUR

MACHINE

Identification

chart

Accenaonen

Setting

up

your

macnineS

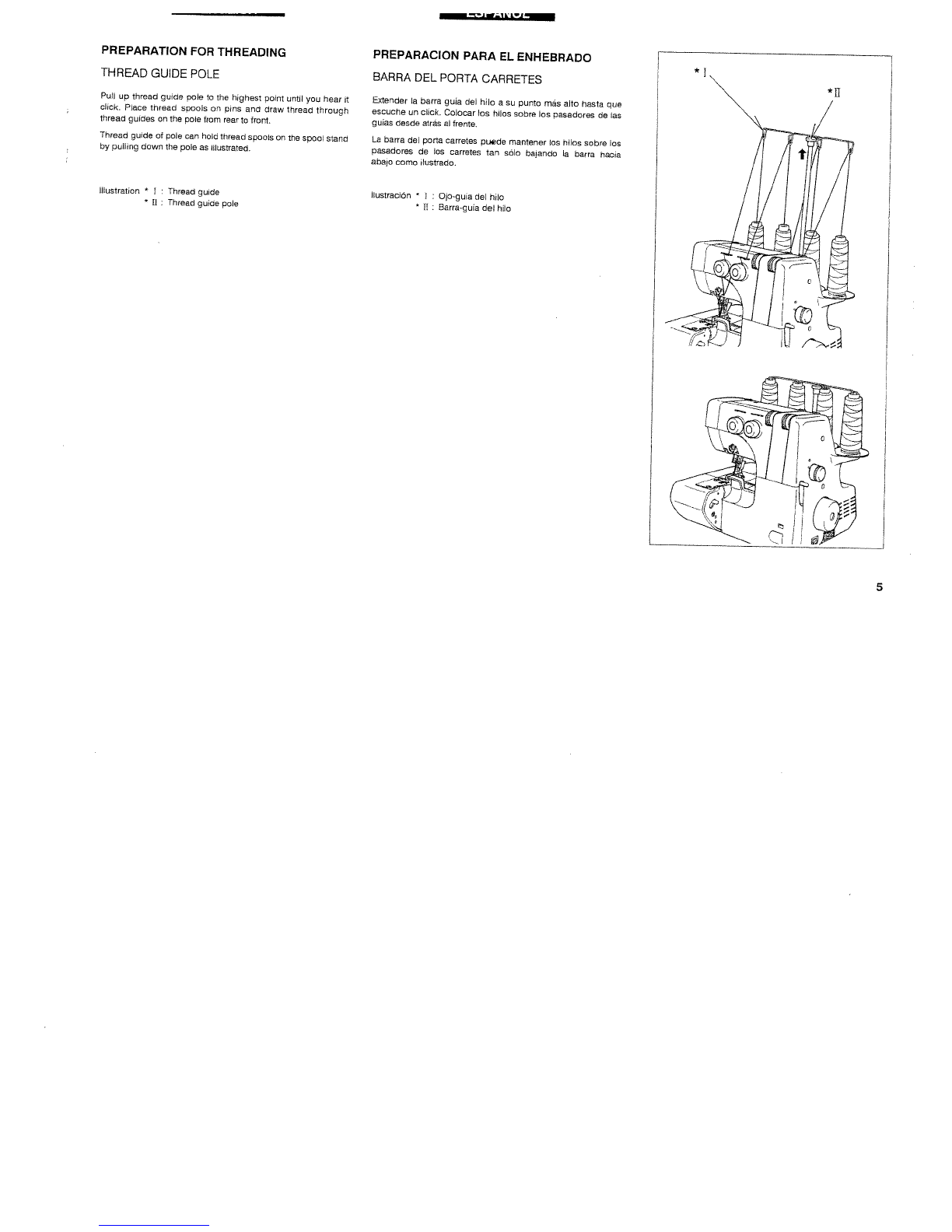

Preparation

for

threading

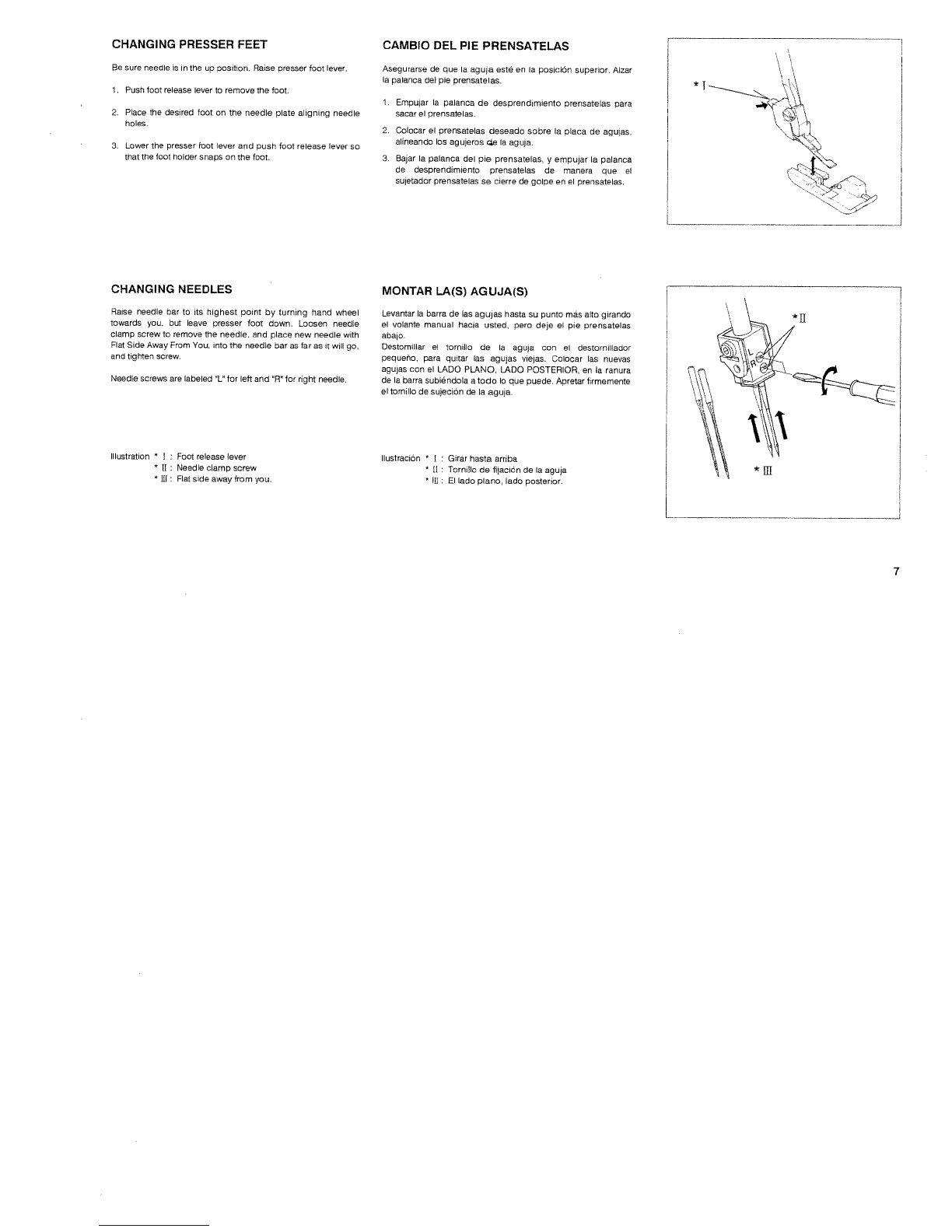

Changing

preaaer

feet.

Cf

Needle

thread and

fabric

2.

STARTING

TO

SEW

Threading

yuui

8-6

-machine

10-12

t-ieiprai

nints

13

Teat ntdch

oneriach atitchen 14

Sernngchart

in-Id

Three-thread

cuerlanir

with

one

needle

r

7

Narrow

and

rolled

new,

picat

stdca 18-

19

Ad

1

ushng

threaa

tenaiann

20

-

21

Adjusting stitch length.

Aduating

oneredge

caning

wid

22

Stitch finger

181

(Narrow)

22

Differential

teed

23

24

Font

pressure

regaiam

Sewing

with

eetre

aeanyweght

fabric

or

multiple

layers

of

fabric

24

Basic

tenhnipuea

Turning

outside corners

without

cuffing

threedu,

Turning

corned

edgen

25

Remaning

stitches

from

newn fabric 25

Corded

one

rionli

26

Denaratine

effects 27

Differential

feeo applications

“—“

28

3.

CARING FOR

YOUR

MACNINE

Replacing

moning

cutter,

Disengaging

wourng

caine

29

Rewaning

lace

cone 39

Cleaning

and

oiling

3D

4.

CHECKING PERFORMANCE PROBLEMS

31

5.

OPTIONAL

ACCESSORIES

32

-

3ó

INDICE

DE

CONTENIDOS

1.

FRINCIPALES

PARTE,S

GE

LA

MAQUINA

7

Cambia

del

pie

prensetelas,

Mactar

8

Materials,

hilan

y

aguen

2,

5-6

EMPEZAR

A

COSER

Enhebrer

so

wanarna

Suoerencias

de

anode

1D-

12

13

Cawprabar

Ins

uonrehiladoa Id

Table

De

filacian

18

-

16

Soarenf

eons

de

cnn

hilns

non

one

agaa”’

17

Dabledilledan enrolladon.

estrenhas

yoe

farm

18-19

Ajaster

las

tensianes

de

Ins

hilan

3D

-

21

Ajaster

la

longitad

oe

panraoa.

Ajaster

Ia

enchura

ae

le

casrare

22

Dnda de

pantede

(8)

22

Trensparfe

aiferennial

23

Regiador de

prenion

do

pie 34

Caser

can

materiel

de

genera

graesa

n

capes

waltipea

de

materiel 24

Tinnines

bbsices

Direr

ei

materiel

sin

carter

Ian

hilas,

Direr

Ian

borden narvedan

28

Eliminer las

sabrehiledan

del

material

casida

28

Pespante

esnardaneao

26

Planrns

decarerinns

27

29

Aplicaciones

del

Irenapane

difernnniel

3.

CUIOAOOS

PARA

SU

MAOUINA

Cemnier

le

nannilla macu 39

Desengrener

la

nanhille

macil,

Gaiter

Ia

cabienafrantel

39

Limpieze

p

engrane

3D

4.

VERIFICANDO

LOS

PROBLEMAS

08

EJECUCION

31

5,

ACCESORIOS

OPCIONALES

32-

3-6

SPECIFICATION

OF MACHINE

Laawner

at

tnreads

3

ore

tnreads

[pyfffpdnp,ytirns

wiggtjm

lien

needle)

end3.8wp(jpn(eedle

jppgie

HA1-SP,

HA

I

li30l705H)’

Catch

lepggt,,,,,,

1-

bmw

—

________

Stitching

speed

Up

In

t3an

stitches nar

rninnre

Dimensions

33n

mm(w)

7280

mwiD)

.‘.

280 nrw)H

rwaignr

BRan

(176

lad

ESPECIFICACION

DE

LA

MAQUINA

Peale

3a4irilsn

i

dwmla

aain

cmido

3.8wipjaqpjauernrn,,,,

HAl-SF.

HA

1

Il3ai7OnHl