CHAODA Pigging Ball Valve User manual

10633 W Airport Blvd. STE 200 Chaoda Group USA Co., LTD Tel: +1 (832) 939-9944

Stafford, TX 77477 Fax: +1 (832) 939-9942

Page1

Chaoda Group USA Co., LTD

CHAODA Pigging Ball Valve

Installation & Operation Manual

10633 W Airport Blvd. STE 200 Chaoda Group USA Co., LTD Tel: +1 (832) 939-9944

Stafford, TX 77477 Fax: +1 (832) 939-9942

Page2

Chaoda Group USA Co., LTD

Table of Contents

1. Prior to installation3

2. Installation ...................................................................................................................................... 4

2.1 Flange end valve installation......................................................................................................... 6

3. The operation, Launching and Receiving ........................................................................................ 9

3.1 Launching ....................................................................................................................................10

3.2 Receiving .....................................................................................................................................12

4. Maintenance .................................................................................................................................15

5. Hanging and Supporting................................................................................................................16

6. General Assembly Drawing ...........................................................................................................18

6.1 4’’ Pig valve .................................................................................................................................18

6.2 6’’ and above............................................................................................................................... 21

7. Troubleshooting............................................................................................................................24

10633 W Airport Blvd. STE 200 Chaoda Group USA Co., LTD Tel: +1 (832) 939-9944

Stafford, TX 77477 Fax: +1 (832) 939-9942

Page3

Chaoda Group USA Co., LTD

CHAODA Pigging Valve Installation & Operation Manual

This manual provides relevant valve installation, operation, and maintenance

information. All drawings in this manual show standard general construction details.

1. Prior to installation

1. Upon receipt, each valve should be inspected for damage due to transportation and

handling.

2. All packing, packaging, and protection used for each valve should be maintained in

place until the time of installation.

3. End Flange and BW surfaces are properly protected at the factory. End protection

shall be maintained to avoid having foreign material entering the valve body cavity.

4. Make sure the piping system is clean before installing the valve into the pipeline.

Foreign materials, such as sand or welding items will damage the ball and seat ring

seating surfaces.

5. If the valve is stored for a long period of time, all bare surfaces should be coated with

anti-rust oil or lubricant. It is suggested to put the valve in a dry and well-ventilated

location. A valve stored for a very long time should be cleaned and re-pressure tested

before installation.

6. Pig Valve and all accessories MUST be suitable for the service conditions.

10633 W Airport Blvd. STE 200 Chaoda Group USA Co., LTD Tel: +1 (832) 939-9944

Stafford, TX 77477 Fax: +1 (832) 939-9942

Page4

Chaoda Group USA Co., LTD

2. Installation

1. It is highly recommended to install the pigging valve with the stem in the vertical

position.

2. Ensure the Pig Valve matches the nominal size and pressure rating of the piping

system.

3. Check and clean all sealing surfaces and they MUST be free of foreign materials or

damage.

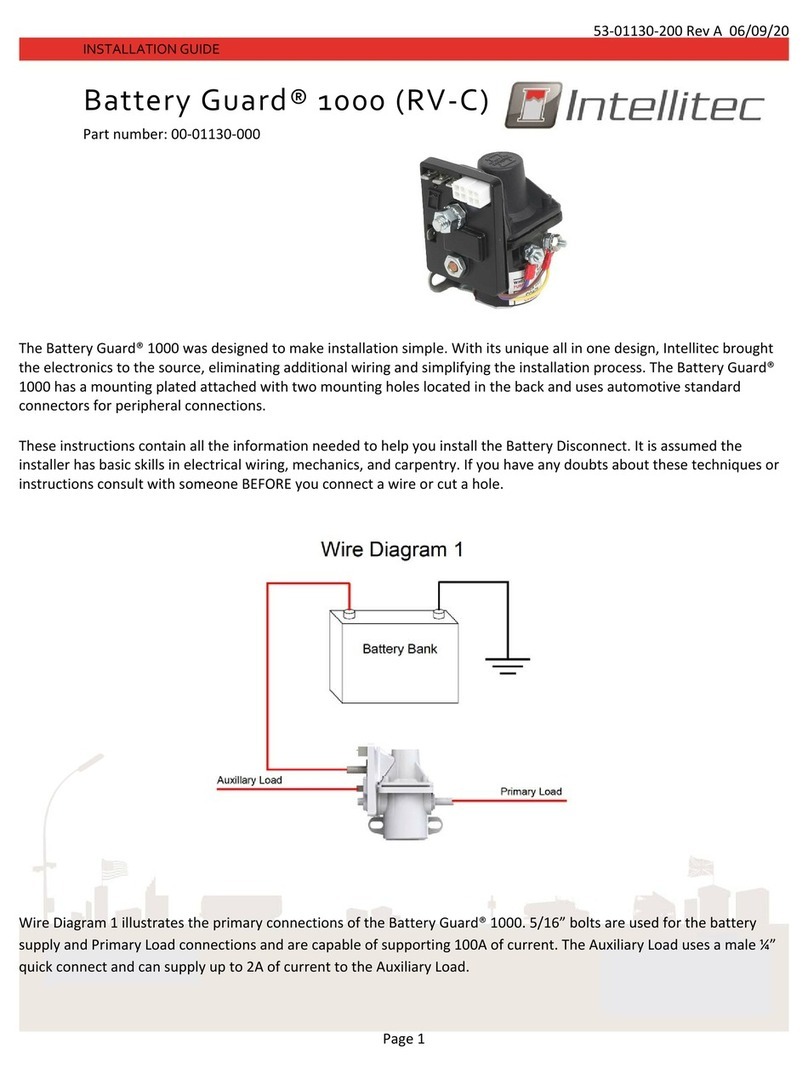

4. Identify the ‘’launcher’’ / ‘’receiver” pigging valve and flow direction. On the marking

side of the body (opposite the closure) there is a flow arrow. If the catcher plate (An

indicated tag located on the flange) is installed on the body at the head (point) end

of the arrow it is a receiver valve and if the catcher plate is installed on the body at

the tail end of the arrow it is a launcher valve (please refer to the figure 1). Ensure

the correct flow direction.

5. The valve should be properly supported to not add weight or stress to the piping

system. The added valve weight can cause distortion of the pipeline and/or valve

body.

6. Do not attempt to correct pipeline misalignment by means of flange bolting

adjustments.

7. Do not allow the valves to carry the weight of the pipeline to avoid distortion and

jamming.

8. Pigging Valve MUST be installed in the “Fully Open” position.

10633 W Airport Blvd. STE 200 Chaoda Group USA Co., LTD Tel: +1 (832) 939-9944

Stafford, TX 77477 Fax: +1 (832) 939-9942

Page5

Chaoda Group USA Co., LTD

10633 W Airport Blvd. STE 200 Chaoda Group USA Co., LTD Tel: +1 (832) 939-9944

Stafford, TX 77477 Fax: +1 (832) 939-9942

Page6

Chaoda Group USA Co., LTD

The Catcher plate, Launcher and Receiver Options

Figure 1

2.1 Flange end valve installation

1. Make sure that both the flange gasket and fastener are suitable for field operation

2. Insert the valve (fully open position) along with suitable gasket between the mating

flange, align the flange bolt holes & hold it in place.

3. Hold the nut first on the backside of the valve flange and then insert the bolts

4. Tighten all the bolts by finger, use two spanners to tighten the joint in sequence as

shown in figure 2 (Corner across corner)

10633 W Airport Blvd. STE 200 Chaoda Group USA Co., LTD Tel: +1 (832) 939-9944

Stafford, TX 77477 Fax: +1 (832) 939-9942

Page7

Chaoda Group USA Co., LTD

10633 W Airport Blvd. STE 200 Chaoda Group USA Co., LTD Tel: +1 (832) 939-9944

Stafford, TX 77477 Fax: +1 (832) 939-9942

Page8

Chaoda Group USA Co., LTD

Bolting Sequence Chart

Figure 2

10633 W Airport Blvd. STE 200 Chaoda Group USA Co., LTD Tel: +1 (832) 939-9944

Stafford, TX 77477 Fax: +1 (832) 939-9942

Page9

Chaoda Group USA Co., LTD

3. The operation, Launching and Receiving

The below video shows the Chaoda Pig Valve demonstration.

Caution:

1. Flush the pipeline carefully once more when the valves are mounted to remove all

the possible impurities. Before, and during, flushing keeps the valve in open fully

2. Open and close the valve slowly to avoid the hammering effect on the valve pipeline.

3. Valves should be fully opened and fully closed to prevent damage to the seat and ball.

4. The valve is intended for on-off service only. It should not be used for throttling

service.

5. Chaoda Pigging valve is ninety degrees shut off the ball valve. Valves open by gear

operator handwheel in a counterclockwise and close by gear operator in a clockwise

direction

6. Care must be taken when opening any fittings, plugs or closure. Proper safety

procedures and (Personal Protective Equipment) PPE must be used. Do not pollute

the ground or atmosphere when open the drain valve. Open the fittings slowly and

do not face it directly.

10633 W Airport Blvd. STE 200 Chaoda Group USA Co., LTD Tel: +1 (832) 939-9944

Stafford, TX 77477 Fax: +1 (832) 939-9942

Page10

Chaoda Group USA Co., LTD

The Below video shows how to Open and Close the Closure/Entry Cap of Chaoda Pig Valve,

check it out first.

3.1 Launching

1. Fully close the pig valve by using the gear operator to achieve shut-off in both

directions. Slowly open the vent/drain fittings/valves located on the Body of the

valve.

2. Open the secondary safety needle vent/bleed valve located at the front of the

closure door. This will vent any excess pressure, releasing the mechanical stop, and

unlocking the closure door(entry cap).

For 4’’ pigging valve. Turn the handle to fully open the safety needle bleeder on

the closure. Then remove the locking bolt and closure. Only after these safety

devices have been removed (to make sure the cavity vented), the closure can be

opened by turning the handle.

For 6’’ and above pigging valve. Turn the handwheel to fully open the safety

needle bleeder on the closure. Only after these safety devices fully

10633 W Airport Blvd. STE 200 Chaoda Group USA Co., LTD Tel: +1 (832) 939-9944

Stafford, TX 77477 Fax: +1 (832) 939-9942

Page11

Chaoda Group USA Co., LTD

opened (to make sure the cavity vented), the closure can be opened by turning

the handle.

3. Open the closure door and insert the Pig.

Note: It won’t let you turn the handle to open the closure if the safety needle valve is

not fully opened.

4. Reinstall the closure -- align and adjust the closure with the entry bore, close it and

turn the handle to lock it. Then, fully close the secondary safety needle valve at the

front of the closure and the vent/drain fittings/valves on the body.

Note: Ensure the safety needle valve is fully closed before going to the next step.

5. Open the pig valve by using the gear operator and the pig will be launched

downstream.

10633 W Airport Blvd. STE 200 Chaoda Group USA Co., LTD Tel: +1 (832) 939-9944

Stafford, TX 77477 Fax: +1 (832) 939-9942

Page12

Chaoda Group USA Co., LTD

Launching

Figure 3

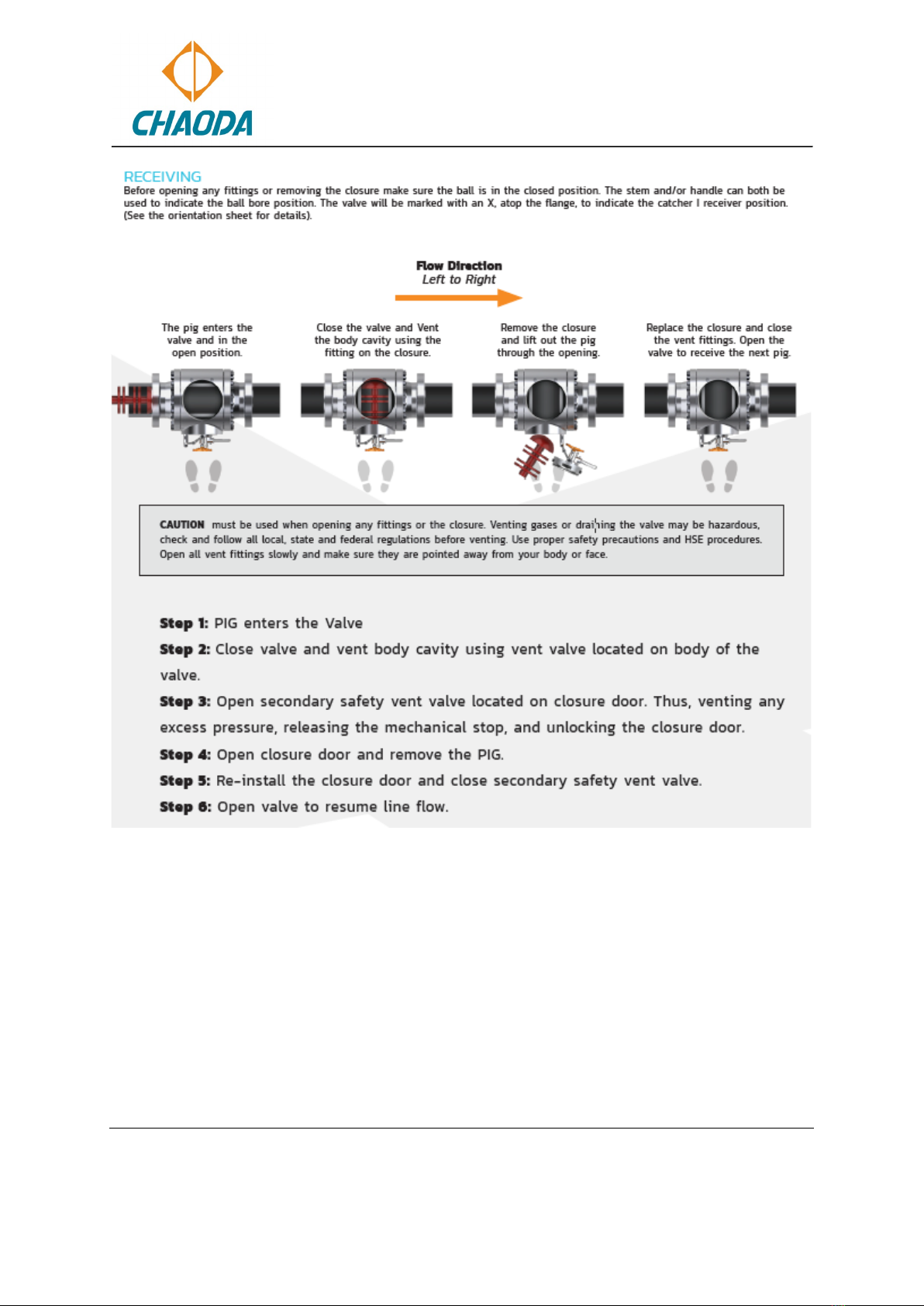

3.2 Receiving

1. The Pig enters the pig valve and it will be stopped by the catcher plate in the open

position.

2. Fully close the pig valve by using the gear operator to achieve shut-off in both

directions. Slowly open the vent/drain fittings/valves located in the Body of the valve.

10633 W Airport Blvd. STE 200 Chaoda Group USA Co., LTD Tel: +1 (832) 939-9944

Stafford, TX 77477 Fax: +1 (832) 939-9942

Page13

Chaoda Group USA Co., LTD

3. Open the secondary safety needle vent/bleed valve located at the front of the closure

door. This will vent any excess pressure, releasing the mechanical stop, and unlocking

the closure door(entry cap).

For 4’’ pigging valve. Turn the handle to fully open the safety needle bleeder on

the closure. Then, remove the locking bolt and closure. Only after these safety

devices have been removed (to make sure the cavity vented), the closure can be

opened by turning the handle.

For 6’’ and above pigging valve. Turn the handwheel to fully open the safety

needle bleeder on the closure. Only after these safety devices fully opened (to

make sure the cavity vented), the closure can be opened by turning the handle.

Note: It won’t let you turn the handle to open the closure if the safety needle valve

is not fully opened

4. Open the closure and remove the pig.

5. Reinstall the closure -- align and adjust the closure with the entry bore, close it and

turn the handle to lock it. Then, fully close the secondary safety needle valve at the

front of the closure and the vent/drain fittings/valves on the body.

Note: Ensure the safety needle valve is fully closed before going to the next step.

6. Open the pig valve by using the gear operator to resume line flow/receive the next

pig.

10633 W Airport Blvd. STE 200 Chaoda Group USA Co., LTD Tel: +1 (832) 939-9944

Stafford, TX 77477 Fax: +1 (832) 939-9942

Page14

Chaoda Group USA Co., LTD

Receiving

Figure 4

10633 W Airport Blvd. STE 200 Chaoda Group USA Co., LTD Tel: +1 (832) 939-9944

Stafford, TX 77477 Fax: +1 (832) 939-9942

Page15

Chaoda Group USA Co., LTD

4. Maintenance

1. After installation and the pressure test of the pipeline or the system, the ball must

be fully opened or fully closed.

2. Dust, grease and medium residual tend to accumulate at the surfaces of the body,

and moving parts such as stem, gearbox, the guide of the yoke, etc., wear and erode

the valve, and even generate friction heat that is dangerous in an explosive

atmosphere, and shall be cleaned frequently according to the working conditions.

3. After putting into service, the valve shall be checked and maintained periodically

especially for the condition of seating surfaces and, the age of packing, and the

corrosion of the body. In the event that sealing will be impaired, the valve shall be

repaired or replaced. It is suggested that the inspection and maintenance of the valve

shall be performed every three months provided the fluid is gas, water or oil. For other,

more abrasive media, at least once a month is recommended.

4. When performing Repair/maintenance operations, the user shall use valve O-rings,

gaskets, bolts, and nuts of the same size and material as the original ones. Valve O-

rings and gaskets may be (alignment of all of this)ordered as spare parts for

maintenance and replacement. It is forbidden to open the closure or replace the bolts,

nuts or O-rings when the valve contains pressure. After replacement of O-ring, gasket,

bolt, and nut, the valve shall be closure test prior to reuse.

5. If stem leak develops inject sealant via emergency sealant injection fitting. If the

stem leakage cannot be stopped then replace of stem packing is necessary.

6. If the body seal leak develops, do not overtighten the body end cover stud and nuts.

This may damage the valve. Instead, the body seal should be removed and replaced

by disassembling the affected end connection

10633 W Airport Blvd. STE 200 Chaoda Group USA Co., LTD Tel: +1 (832) 939-9944

Stafford, TX 77477 Fax: +1 (832) 939-9942

Page16

Chaoda Group USA Co., LTD

7. If the cover flange leak occurs, do not try to excessively tighten the body and bonnet,

this may damage the valve. Instead, the cover flange should be replaced by a new one.

5. Hanging and Supporting

Proper ways of lifting

Proper way of lifting Improper way of lifting

Figure 5

10633 W Airport Blvd. STE 200 Chaoda Group USA Co., LTD Tel: +1 (832) 939-9944

Stafford, TX 77477 Fax: +1 (832) 939-9942

Page17

Chaoda Group USA Co., LTD

Improper method of support Proper method of support

Proper method of support Proper method of support

Figure 6

10633 W Airport Blvd. STE 200 Chaoda Group USA Co., LTD Tel: +1 (832) 939-9944

Stafford, TX 77477 Fax: +1 (832) 939-9942

Page18

Chaoda Group USA Co., LTD

6. General Assembly Drawing

6.1 4’’ Pig valve

10633 W Airport Blvd. STE 200 Chaoda Group USA Co., LTD Tel: +1 (832) 939-9944

Stafford, TX 77477 Fax: +1 (832) 939-9942

Page19

Chaoda Group USA Co., LTD

10633 W Airport Blvd. STE 200 Chaoda Group USA Co., LTD Tel: +1 (832) 939-9944

Stafford, TX 77477 Fax: +1 (832) 939-9942

Page20

Chaoda Group USA Co., LTD

Table of contents

Popular Control Unit manuals by other brands

GONANO

GONANO GV-1625 operating instructions

Microdyn Nadir

Microdyn Nadir Bio-Cel L-1 Technical instructions

DAV TECH

DAV TECH DA 250 Installation and maintenance guide

HYDAC FILTER SYSTEMS

HYDAC FILTER SYSTEMS FluidControl FCU 8111 Operating and maintenance instructions

KSB

KSB DANAIS 150 operating instructions

Edwards

Edwards PVEK Series instruction manual

JYEBAO

JYEBAO SMA3200PA-0085/4*f manual

GEMAR Lumitec

GEMAR Lumitec IRIDIUM 113886 user manual

Honeywell

Honeywell VE4000 Series instruction sheet

Viessmann

Viessmann VITOTRONIC 100 GC1B Installation and service instructions

Intellitec

Intellitec Battery Guard 1000 installation guide

Avalue Technology

Avalue Technology ECM-APL2-A user manual