DAV TECH DA 250 Product manual

DIAPHRAGM VALVE DA 250

DAV TECH SRL

Via Ravizza, 30 - 36075 Montecchio Maggiore (VI) - ITALIY

Tel. 0039 0444 574510 - Fax 0039 0444 574324

Installation and

maintenance guide

Index

1 INTRODUCTION pag. 3

1.1 The manual

1.2 Warranty

1.3 Goods receiving

2 TECHNICAL DESCRIPTION pag. 3

2.1 Valve operation

2.2 Technical specifications

2.3 Connection diagram

3 INSTALLATION pag. 4

3.1 Mounting on the machine

3.2 Drive the valve

3.3 Fluid connection

3.4 Setting of the valve

3.5 Setting of the material quantity

4 MAINTENANCE pag. 6

4.1 General rules

4.2 Valve Disassembly - Re-assembly

5 TROUBLESHOOTING pag. 6

5.1 Problems and solutions

6 BREAKDOWN AND DIMENSIONS pag. 7

6.1 Overall dimensions

6.2 Breakdown (old version) pag. 8

6.3 Components (old version)

6.4 Breakdown (updated version)

6.5 Componenti (updated version)

Installation and maintenance guide

DIAPHRAGM VALVE DA 250

pag.3

1 INTRODUCTION

1.1 The manual

The user guide is the document that accompanies the valve from the time of its construction and throughout the period of

use, it is therefore an integral part of the valve. It requires reading the manual before taking any action involving the valve. The

manual must be readily available for use by staff and maintenance of the valve. The user and the attendant use are required

to know the contents of this manual.

Reproduction of any part of this manual, in any form, without the express written permission of DAV Tech. The text and

illustrations in this manual are not binding, the DAV tech reserves the right, at any time and without notice, the right to make

any changes to improve the product or for reasons of character manufacturing or commercial.

1.2 Warranty

The warranty is valid for a period of 12 months from the date of commissioning and no later than 15 months from the

date delivery. The interventions carried out during the warranty period does not extend in any way the validity period of the

guarantee. The seller is not liable for defects caused by normal wear of parts which by their nature are subject to wear.

1.3 Goods receiving

The original configuration of the valve must never be changed.

Upon receipt of the goods, check that:

• The packaging is intact

• The exact correspondence of the material ordered.

2 TECHNICAL DESCRIPTION

2.1 Valve Operation

DA250 dosing valve is designed and manufactured in compliance with current safety standards.

The DA250 should only be used for the application of anaerobic, cyanoacrylic or other aggressive fluids at a maximum

pressure of 10 bar. Only qualified personnel are authorized to install and use the DA250 dispensing valve. Read and understand

this manual before installing and using the valve. For the dosing valve DA250 only and exclusively the use fields listed in this

manual are provided. All data and parameters in this manual must be respected. You can only use DAV Tech’s additional or

auxiliary equipment. Any other use is not contemplated.

2.2 Technical Specification

Model DA 250

Drive Simple or Double Acting

Max fluid pressure 10 bar

Operating pressure 5-7 bar

Thread inlet 1/8 BSP

Thread outlet Luer Lock or others on request

Speed Up to 200 cycles / min

Adjustment Micrometric screw adjustment

Used materials Anodized aluminum, stainless steel, PTFE, membrane co-molded with non-reactive materials

Fluids used Cyanoacrylate glue, anaerobic fluids, low viscosity fluids in general (even aggressive)

We reserve the right to modify at any time, without notice, the specifications, dimensions and weights in this datasheet. The illustrations are not binding.

TANKS FOR FLUID FEEDING

The DAV Tech PT tanks are ideal to feed the valve DA 250.

They are available in 3 sizes 2, 5 and 10 liters and in different variations.

The tank PT2.0 in particular is designed to accommodate inside the 250 cc

oval containers used by the major manufacturers of anaerobic fluids such

as Loctite and Loxeal.

NOZZLES FOR VALVE DA 250

The valve DA 250 is designed to accommodate outlet nozzles with luer lock thread.

DAV Tech will be happy to advise and give you to test various types of nozzles in different materials and dimensions.

On request it is also possible to create special nozzles with various shapes.

DRIVE VALVE DA 250

The valve 250 DA have to be drived by solenoid 5/2 or 3/2 (depending on whether you want to work double-acting or

simple acting) for a time setted by the PLC of the customer.

We are available for the supply of timing systems such as the DA 1000 T controller or even with the creation of

electrical control panels to manage the various I / O you need to check.

Connection diagram

S.V. 5/2

(ALSO POSSIBLE SINGLE

ACTING)

PLC

PRESSURIZZABLE

TANK

2.3 Connection diagram

3 INSTALLATION

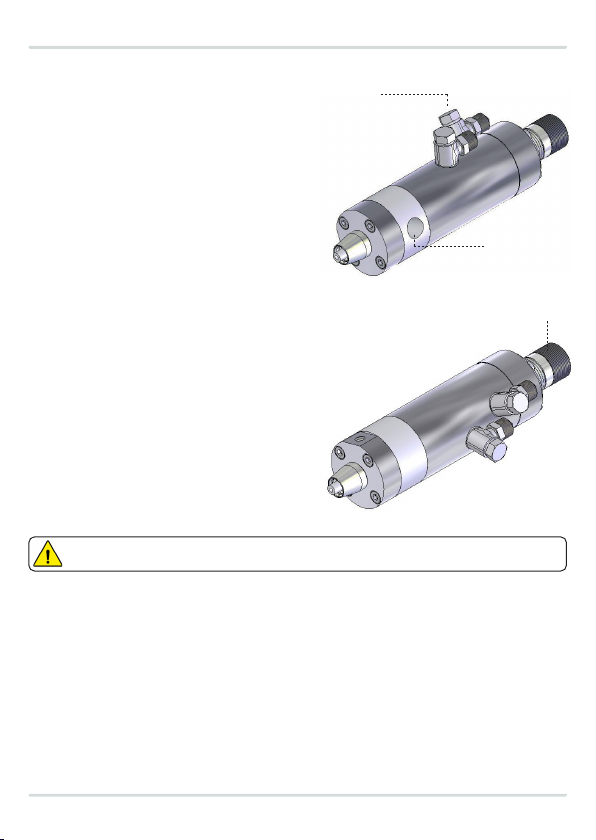

3.1 Mounting on the machine

The dosing valve must be mounted on a support by means of the special threaded hole (M5) on the valve, or by an

ad-hoc collar.

A good fixing of both the dosing valve to the support and the machine should be guaranteed without vibration and with

good accessibility for adjustment, cleaning and maintenance.

The ideal working position of the dosing valve is the vertical one, with the nozzle facing down.

Other positions are possible with the approval of DAV Tech

Threaded hole M5 for fastening

Installation and maintenance guide

pag.5

3.2 Drive the valve

The dosing valve DA250 is a dispensing valve that can work

both in a simple and a double effect, as there is a safety

spring that keeps the valve normally closed.

3.3 Fluid connection

The dispensing valve must be connected to a power supply

unit (pressure tank).

A hose must be connected to the fitting located at the

bottom of the dispensing valve.

Air inlet

Material input

3.4 Setting of the valve

Adjustment of the membrane travel determines the amount

of product delivered.

To adjust the stroke, act on the adjuster knob located at the

top of the dispensing valve.

Rotate clockwise to decrease the membrane stroke and

consequently the amount of product. Turning clockwise,

reaching the end of the stroke, the dispensing valve will be

completely closed, so it will not produce the product.

Rotate counterclockwise to increase the membrane stroke

and then the amount of product.

3.5 Setting of the material quantity

Adjusting the amount of material is determined by:

> The diameter of the nozzle

> Material pressure

> Adjustment of membrane travel

Acting on these factors, you can adjust the amount of material you want.

Adjustment knob

Do not tighten the needle adjustment too firmly to avoid damaging the membrane.

DIAPHRAGM VALVE DA 250

4 MAINTENANCE

4.1 General rules

Minimal, simple, accurate, and constant maintenance allow for long-lasting and smooth operation in the dosing valve

time, while maintaining performance.

4.2 Valve Disassembly - Re-assembly

If it is necessary to disassemble the DA 250 valve, proceed as follows:

1) Disconnect the pneumatic supply

2) Disconnect the fluid supply after discharge

3) Remove the valve from the support to which it is attached

4) Remove the four M4 Allen screws on the front

5) Remove the front part of the PTFE section and clean them carefully

6) Remove the membrane by unscrewing it

7) Remove the 4 screws on the back

8) Pull out the piston, making sure not to squeeze the cylinder

Before reassembling, following the procedure listed here replace the damaged parts (in addition to all the o-rings) by

helping with the explosion shown below.

5 TROUBLESHOOTING

5.1 Problems and solutions

Installation and maintenance guide

PROBLEM POSSIBLE CAUSE SOLUTION

Nothing or little adhesive Valve does not receive the command Check the control (solenoid) of valve. Perform

a manual test.

The pressure of the adhesive is too low

or absent.

Check the pressure of the power supply fluid

and possibly increase it.

The nozzle is clogged

Remove and clean the nozzle.

The filter is dirty (if any) Clean or replace the filter.

A tube is bent Check the fluid supply pipe

Actuating pressure is not sufficient Verify the actuation pressure (6 bar)

Residual fluid in the system to clean Remove any solid particles

Flow of adhesive

compass Moulded gasket damaged Replace the molded seal

The nozzle drips also

if the valve is not pilot Presence of dirt in the nozzle Clean or replace nozzle

The valve opens late Pressure drive is not enough Check the operating pressure (6 bar)

O-ring on the piston damaged tire Replace O-ring on the piston pneumatic

pag.7

6.1 Overall dimensions

These are the indicative dimensions of the DA 250 valve. Download 3D models from our web-site.

6 BREAKDOWN AND DIMENSIONS

DIAPHRAGM VALVE DA 250

NOTE!

The “old” and “updated” versions differ in their external appearance due to the presence or absence of

the dowel placed in the center of component no. 2 (old version) and no. 5 (updated version).

On the following pages you will find the complete exploded views of both versions.

13

14

13

15

6

16

5

8

7

1

4

3

2

11

9

12

10

Old version Uodated version

6.2 Breakdown (old version)

POS CODE QUANTITY DESCRIPTION

102130320 8Screw

225001 1Adjustment block

325002 1Spring

425003 1Piston

592010702 1O-ring

692011401 1O-ring

725004 1Lip seal

825005 1Washer

925009 1Body

10 25006 1Diaphragm

11 25010 1Body Teflon

12 25007 1Frontal body

13 25008 1Ferrule

14 95121502 2Air connection

6.3 Components

Installation and maintenance guide

pag.9

DIAPHRAGM VALVE DA 250

13

14

13

15

6

16

5

8

7

1

4

3

2

11

9

12

10

12

5

15

6

16

8

71

13

13

14

4

10

3

2

11

9

6.4 Breakdown (updated version)

POS CODE Q.TY DESCRIPTION

1BG000450 8Valve body DA 250

2BG000451 1Frontal body DA 250

3M25010 1Body PTFE DA 250

4DH000450 1Diaphragm DA 250

5MDC000450 1Full micrometric adjustment

6PST000450 1Piston Ø 18

7WSH000450 1Washer

8M25004 1Lip seal DA 250

9M25008 1DA 250 ferrule for syring

nozzle

10 RRBF0252 1Push-in fitting in nickel-pla-

ted brass

11 SC00030251 1Stainless steel screw

12 SC00030161 1Stainless steel screw

13 RNG00015E 1O-ring

14 RNG040X10E 2O-ring

15 CCS000450 1Cylindrical compression

spring

16 SGG501801 2Seeger for Ø 18 holes

6.5 Components

DAV TECH SRL Via Ravizza, 30 - 36075 Montecchio Maggiore (VI) - ITALY - Tel. 0039 0444 574510 - Fax 0039 0444 574324

We reserve the right to modify at any time, without notice, the specifications, dimensions and weights in this manual.

The illustrations are not binding.

Table of contents

Other DAV TECH Control Unit manuals

DAV TECH

DAV TECH DA 400 Product manual

DAV TECH

DAV TECH DAV 150 Product manual

DAV TECH

DAV TECH DAS 50N Product manual

DAV TECH

DAV TECH DA 600 Product manual

DAV TECH

DAV TECH DAS 90 Product manual

DAV TECH

DAV TECH DAV 300 MAN Product manual

DAV TECH

DAV TECH DA 400 EV Product manual

DAV TECH

DAV TECH DAS 30 Product manual

DAV TECH

DAV TECH DA 400 EVO Product manual