24”

WARNING

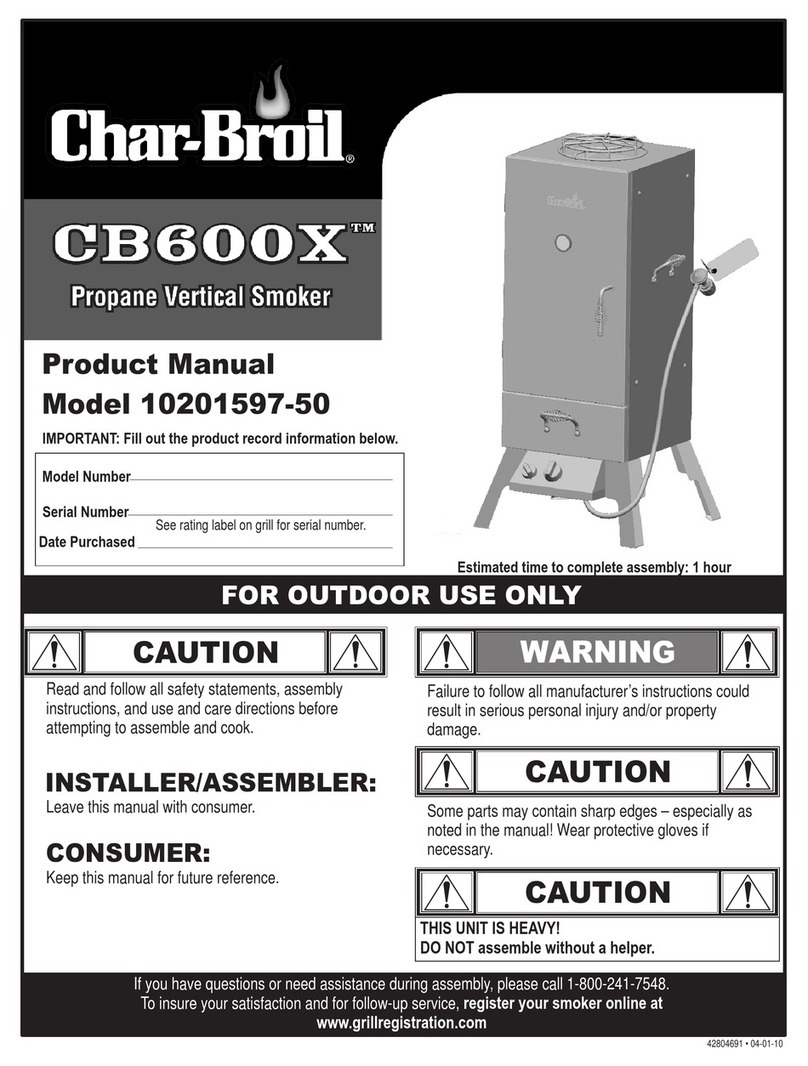

3 ft.

For Safe Use of Your smoker and to Avoid Serious

Injury:

• The use of alcohol, prescription or non-prescription

drugs may impair the consumer's ability to properly

assemble or safely operate the appliance.

• When cooking, the appliance must be on a level, stable

noncombustible surface in an area clear of combustible

material. An asphalt surface (blacktop) may not be

acceptable for this purpose.

• Do not leave appliance unattended. Keep children and

pets away from the appliance at all times.

• Do not place empty cooking vessel on the appliance

while in operation. Use caution when placing anything in

cooking vessel while the appliance is in operation.

• Do not move the appliance when in use. Allow the

cooking vessel to cool to 115°F (45°C) before moving or

storing.

• This appliance is not intended for and should never be

used as a heater.

• This appliance will be hot during and after use. Use

insulated oven mitts or gloves and long-handled

barbecue utensils for protection from hot surfaces or

splatter from cooking liquids.

• Keep appliance area clear and free from materials that

burn.

• Keep appliance area clear and free from combustible

materials, gasoline and other flammable vapors and

liquids.

• Keep fuel supply hose away from any heated surfaces.

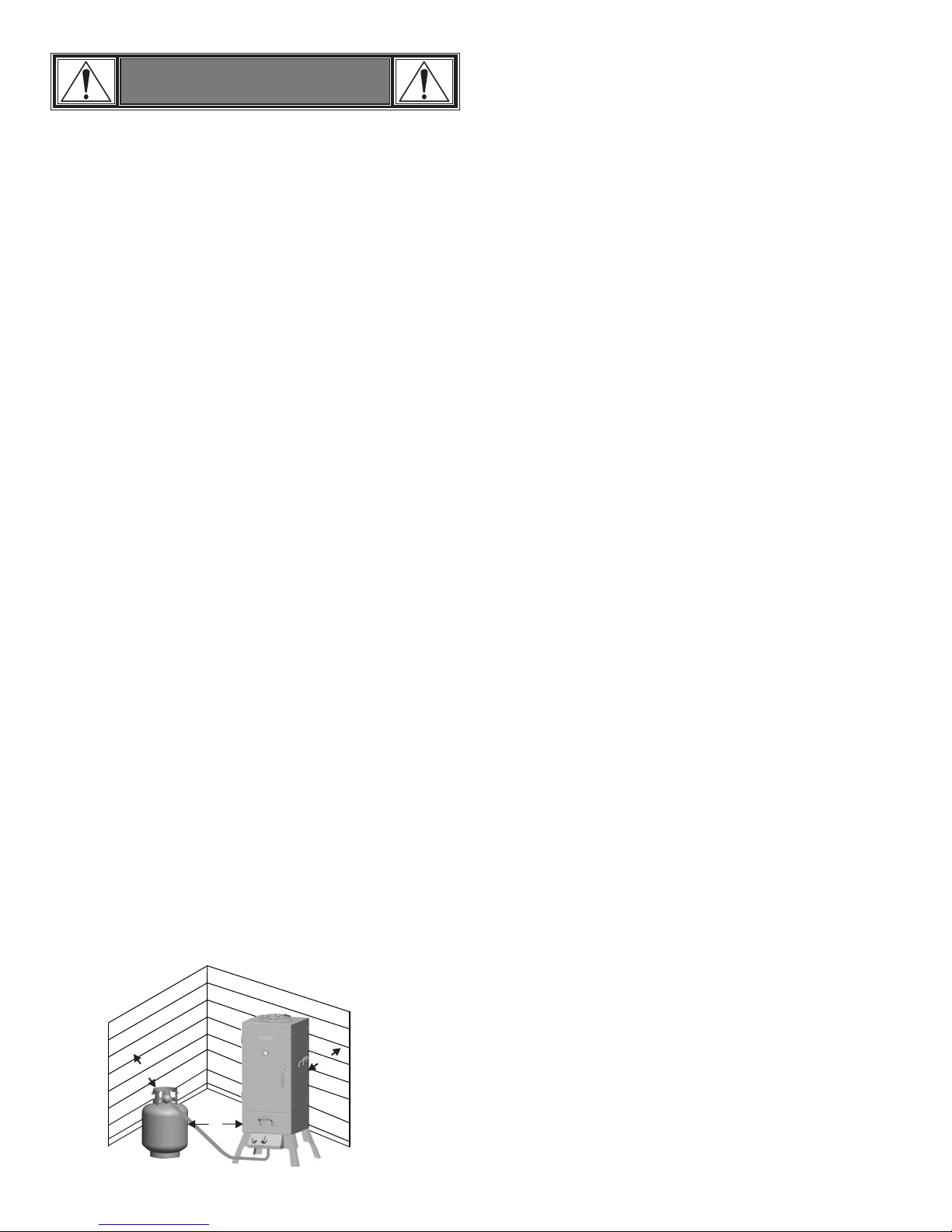

• Use only in well-ventilated space. NEVER use appliance

in enclosed space such as carport, garage, porch,

covered patio, or under an overhead structure of any

kind.

• Use appliance at least 3 ft. from any wall or surface.

Maintain 10 ft. clearance to objects that can catch fire or

sources of ignition such as pilot lights on water heaters,

live electrical appliances, etc.

• Apartment Dwellers:

Check with management to learn the requirements and

fire codes for using an LP gas appliance in your

apartment complex. If allowed, use outside on the ground

floor with a three (3) foot clearance from walls or rails. Do

not use on or under balconies.

• NEVER attempt to light burner with any type of

closed cover . A buildup of non-ignited gas inside a

closed appliance is hazardous.

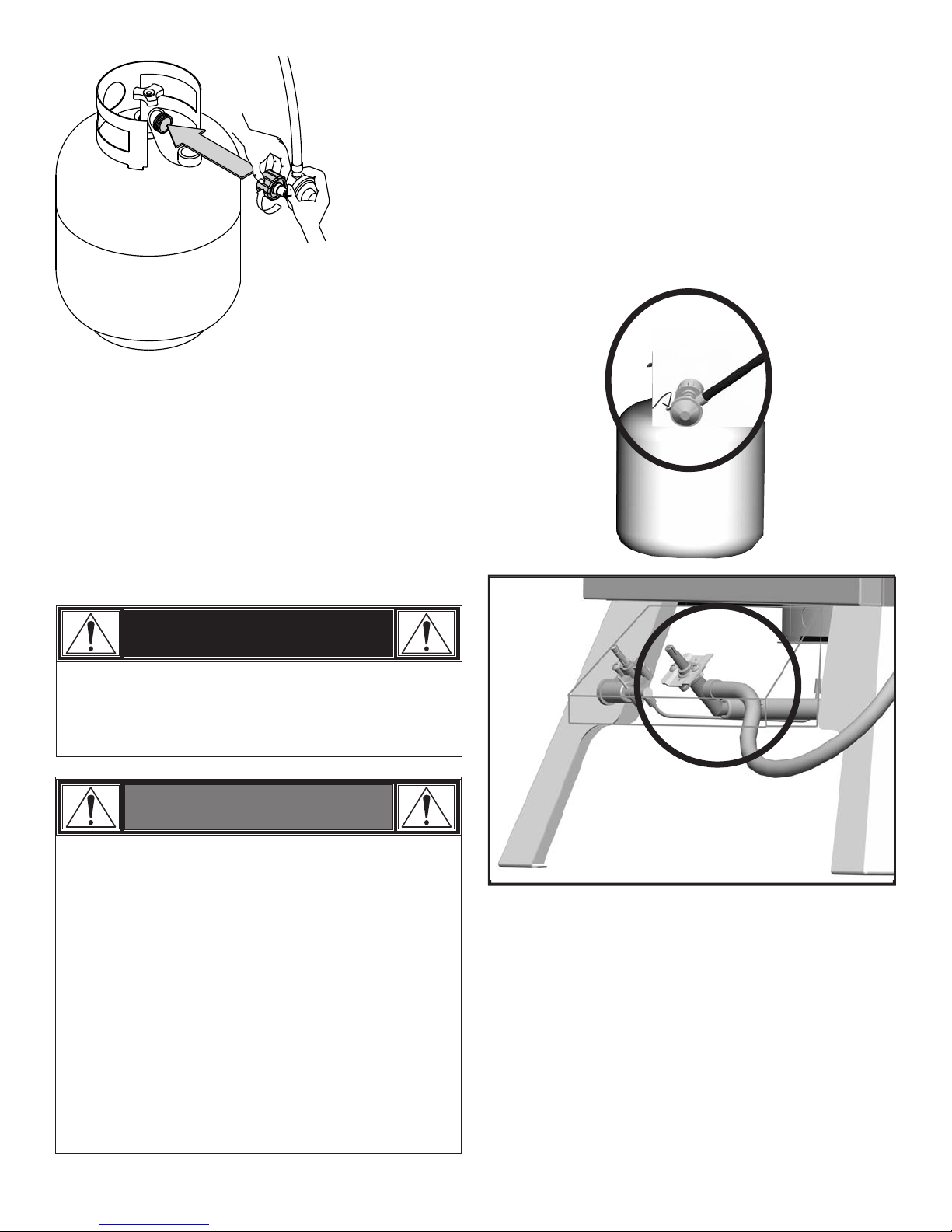

• Never operate appliance with LP cylinder out of

correct position specified in assembly instructions.

• Always close LP cylinder valve and remove coupling

nut before moving LP cylinder from specified

operation position.

Safety Tips

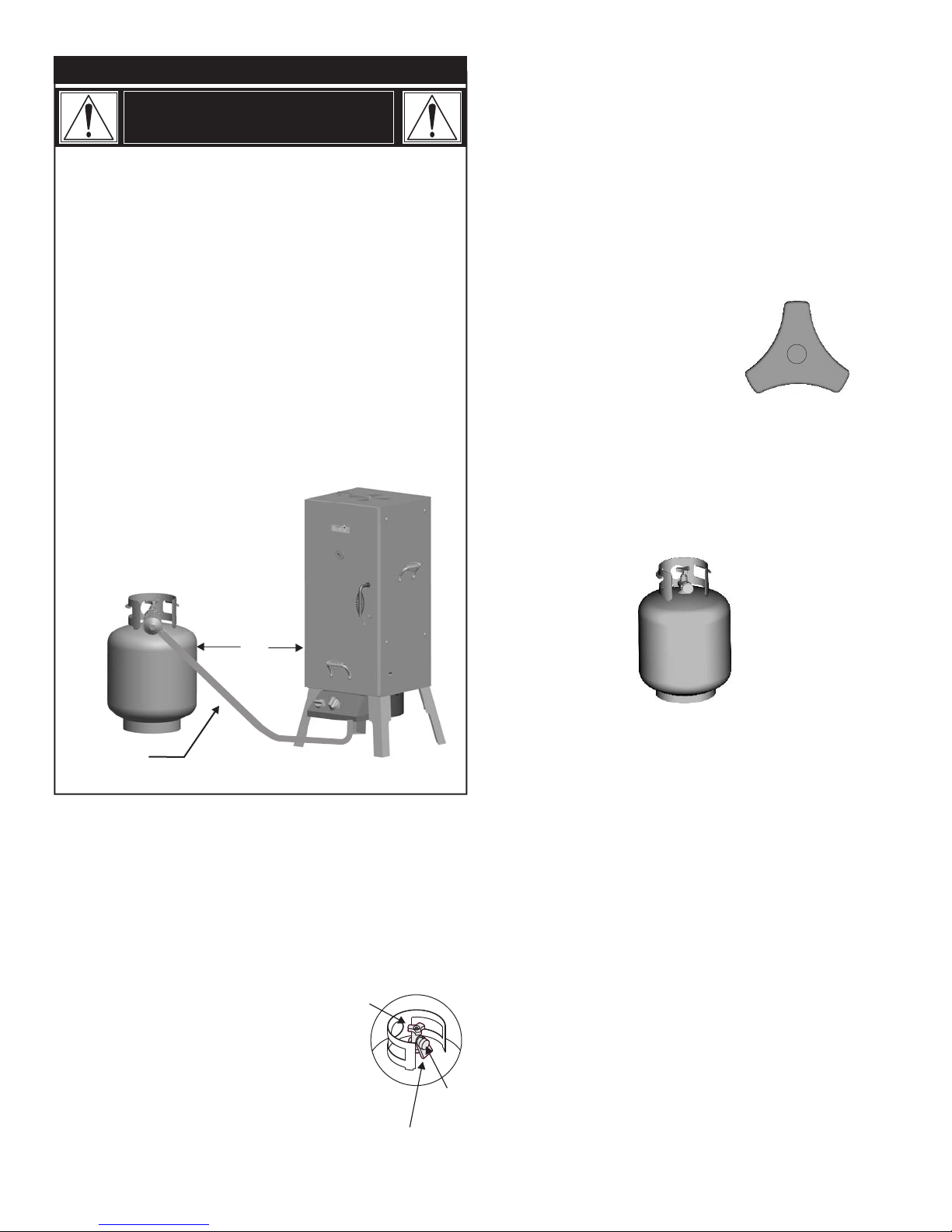

• Before opening LP cylinder valve, check the coupling nut for

tightness.

• When appliance is not in use, turn off control knob and LP

cylinder valve.

• Smoker Chamber door should be open while attempting

to light the burner.

• The grease tray must be inserted into appliance and

emptied after each use. Do not remove grease tray until

appliance has completely cooled.

• If you notice grease or other hot material dripping from

appliance onto valve, hose or regulator, turn off gas

supply at once. Determine the cause, correct it, then

clean and inspect valve, hose and regulator before

continuing. Perform a leak test.

• Do not store objects or materials under the appliance

enclosure that would block the flow of combustion air to

the underside of either the control panel or the firebox

bowl.

• The regulator may make a humming or whistling noise

during operation. This will not affect safety or use of grill.

• If you have an appliance problem see the

"Troubleshooting Section".

• If the regulator frosts, turn off appliance and LP cylinder

valve immediately. This indicates a problem with the

cylinder and it should not be used on any product. Return

to supplier!

• Clean grill often, preferably after each cookout. If a bristle

brush is used to clean any of the grill cooking surfaces,

ensure no loose bristles remain on cooking surfaces prior

to grilling. It is not recommended to clean cooking

surfaces while grill is hot.

3 ft.