Chargery BMS8P User manual

Revised : 28/2/2020

BMS8P

for 2S-8S LiPo/Li-ion, LiFe & LiTO

Low power consumption

High accuracy

2.8” TFT LCD display

Programmable

Chargery BMS8P

attery Management System for 2S-8S LiPo/Li-ion, LiFe & LiTO

Low power consumption, High accuracy, 2.8” TFT LCD display, Programmable

Owners Manual

V .3

Main Unit Software Version .05

LCD Unit Software Version .03

LiPo & LiFe, LiTo attery Management System MS8P V4.3

www.chargery.com

page 2 total 62

Thank you for choosing the Chargery MS8P as your attery Management System. This versatile

MS is designed to be suitable for Electric Vehicles and mobile / fixed Energy Storage Systems

providing extensive flexibility for your specific application.

Please read the ENTIRE instruction manual to become familiar with the features and functions and

capabilities of the device before operating. Please see Video References for additional installation

& operational tips.

Overview:

The Chargery MS8P is designed especially for LiPo, LiFe and LiTo battery packs applied to Energy

Storage Systems and Electrical Vehicles including E-Motorcycle, E-Scooter and so on. The unit can

measure or detect the battery voltage, cell voltage, charge & discharge current, battery

temperature, and battery SOC (State of Charge), with the information displayed on the TFT color

LCD screen. It has an Internal balancing function to balance cells to maintain optimal operations

of the battery pack being managed.

Feel free to send an email to jasonwang[email protected] or call at 86 755 2643 6165 should you have

any questions and suggestions.

Jason Wang

LiPo & LiFe, LiTo attery Management System MS8P V4.3

www.chargery.com

page 3 total 62

Table of Contents

Safety Notes .................................................................................................................................................................. 5

Warning ................................................................................................................................................................... 5

Copyright ................................................................................................................................................................ 5

Specifications ................................................................................................................................................................ 6

Protection functions .................................................................................................................................................... 6

Over current protection ............................................................................................................................................. 6

Version History ............................................................................................................................................................. 7

Update / Change log .................................................................................................................................................. 8

Order information ........................................................................................................................................................ 9

Standard accessories (included in MS unit) .......................................................................................... 9

Current Shunt ..................................................................................................................................................... 10

DC Contactor ....................................................................................................................................................... 11

DCC main Specification ........................................................................................................................... 12

ISO board ..................................................................................................................................................... 13

Chargery DC Contactor (DCC) configuration in Common and Separate Port..................................... 14

Alternator Saver ......................................................................................................................................................... 16

Operational Description ........................................................................................................................................... 19

Special Features ......................................................................................................................................................... 20

Interface ........................................................................................................................................................................ 21

Hardware Setup ......................................................................................................................................................... 23

Absolute maximum or Minimum ratings (Always refer to Manufacturer specifications) ........ 23

Software Configuration ............................................................................................................................................ 24

Parameters Setting----Configuration Values ................................................................................................... 25

Operating guideline ................................................................................................................................................... 28

SOC Calibration .......................................................................................................................................................... 31

alancer ........................................................................................................................................................................ 33

alancing Indicator ........................................................................................................................................... 34

Cell internal resistance (Impedance) test ........................................................................................................ 35

Charge and discharge relay lectotype for MS8P ......................................................................................... 37

Current Calibration (Shunt) ................................................................................................................................... 38

Firmware Upgrades via US Port......................................................................................................................... 40

Update MS main unit ..................................................................................................................................... 41

Continue to update LCD unit ......................................................................................................................... 41

Typical Cell Connections .......................................................................................................................................... 43

2S-4S configuration and 8S configuration ............................................................................................... 43

4s & 4s with single MS8P configuration example. .............................................................................. 44

6P4S 24 cells with single MS8P configuration example. .................................................................. 45

Nissan Leaf battery 6P8S with MS8P configuration example ....................................................... 45

Separate Port Configuration example—with Mechanical relay or DCC. ................................................ 46

Common Port Configuration example—with two Mechanical relay or one CHARGERY DCC. ....... 47

4p4s Cell configuration with MS8P-600 example ....................................................................................... 48

Related parts ............................................................................................................................................................... 49

Total solution on E-Vehicle application—1500W 60A 8S battery charger ............................................ 50

Supplemental: Solid State Relay supplemental information .................................................................... 51

Supplemental: Single Relay with 2 channel Opti-Coupler ......................................................................... 52

LiPo & LiFe, LiTo attery Management System MS8P V4.3

www.chargery.com

page 4 total 62

Supplemental:Equipment Voltage Calibration .............................................................................................. 53

Supplemental: Reference Documents & Video links .................................................................................... 55

Supplemental: MS power consumption .......................................................................................................... 56

Frequent questions ................................................................................................................................................... 57

Improve cell voltage accuracy .............................................................................................................................. 59

Improve current reading fluctuation from Steve ........................................................................................... 60

Over Current protection resume operation ..................................................................................................... 61

Warranty and Service ............................................................................................................................................... 62

LiPo & LiFe, LiTo attery Management System MS8P V4.3

www.chargery.com

page 5 total 62

Safety Notes

Please read the entire manual completely before using, to ensure safe and efficient use.

1.

Ensure the MS program and settings match your battery pack, otherwise the battery may be damaged

and a dangerous situation may arise, especially for Lithium based batteries, which may catch fire.

2.

Use the attery Cell Manufacturers specifications and information when configuring your MS.

3. For Energy Storage System and Electric Vehicle applications, there are many different requirements,

please adjust those key parameters carefully for your application, or contact us for more details.

4. Do not allow water, moisture, metal wires or other conductive materials to come in contact the device.

5. Never charge or discharge any battery having evidence of leaking, expansion/swelling, damaged outer

cover or case, color-change or distortion.

6. Do not try to charge “non-rechargeable” dry cells.

7. Do not mix batteries of different types, different capacities or from different manufacturers, all cells used

should be of matching specifications.

8. Do not exceed the battery manufacturer’s suggested maximum charge and discharge rates.

9. Carefully follow the battery pack manufacturer’s recommendations and safety advice.

Warning

1. The Current shunt must not make contact with any metal including the MS case

2. The MS case should not be in direct contact to any metal

3. External power supply ground don’t connect to battery negative (cell 1 negative) directly

4. Current shunt must connected to the attery Pack Negative !

5. Prevent MS from vibrations and shaking

6.

Ensure the MS case does not make contact with battery wiring in any way.

Copyright

Copyright@Chargery Power Co., Ltd. All rights reserved.

Without prior written consent by Shenzhen Chargery Power Co., Ltd, any units or individual extract and copy

parts or entire contents of this manual, and transmission in any form is illegal and strictly prohibited.

The product described in this manual, may include copyright software ownership belongs to Shenzhen

Chargery Power Co., Ltd and its licensee, except getting the permission from relevant rights holders,

otherwise any copy, distribute, modify, excerpt, decompile, disassemble, decrypt, reverse engineering, lease,

transfer, sub-license, as well as other acts of infringement of software copyright is strictly prohibited, but

apart from the restrictions prohibited by applicable law.

LiPo & LiFe, LiTo attery Management System MS8P V4.3

www.chargery.com

page 6 total 62

Specifications

1. attery range: 2S-8S LiPo & LiFe, LTO battery pack

2. Accurate scope of the cell voltage: -5mV/+5mV

3. Cell Voltage display range: 0.10~4.99V

4. The voltage of external power:15-60V, 3A.

5. alance current:1.2A per cell continuously

6. Temperature display range:-20℃~150℃,

7. SOC indicator:

RED area @ 0~15% of SOC

YELLOW area @ 16~35% of SOC

GREEN area @ 36~100% of SOC

8. uilt-in cooling fan, start automatically upon internal temperature

9. Main module Size: 122×88×38 (L×W×T, mm) or 4.8×3.5×1.5 (L×W×T, inch)

10. Main module weight: 270g excluding accessories

11. Display module size:96×80×24 (L×W×T, mm) or 3.8×3.2×0.95 (L×W×T, inch)

12. Display module weight:130g

13. Warning LED: 11000mCd, @ 2.0V, 20mA

14. Warning beeper: 85d @ 12V, 25mA

15. Package: AL alloy case

Protection functions

1. Cell count error protection

2. Over charge protection

3. Under voltage protection

4. Over current protection when charge or discharge

5. High temperature protection

6. Low temperature protection (on LCD unit V3.03 and higher version)

7. Over differential cell voltage protection in discharge

8. Over differential battery temperature protection

9. Under SOC protection

Over current protection

When charge or discharge current reach over charge current setting or over discharge current setting, MS

will cut off charge or discharge, to resume charge or discharge, please press SET/START button shortly. ut

the over current reason should be removed first.

LiPo & LiFe, LiTo attery Management System MS8P V4.3

www.chargery.com

page 7 total 62

Version History

Software Version of LCD

unit

Description

V4.03

Released first time

Software Version of

main unit

Description

V4.05

first released

Hardware Description

lack mental case with cooling fan

LiPo & LiFe, LiTo attery Management System MS8P V4.3

www.chargery.com

page 8 total 62

Update / Change log

MS8P v4.05 has the following changes that is compared with MS8T,

o

Add intelligent cooling fan, start automatically and speed is controlled by internal

temperature, so MS8T cannot update to MS8P only by update software. And

the MS can balance cell voltage continuously, to save balance time by speed up

balancing even at 1.2A per cell.

o

Minimum current 0.5A measurement capacity on 300A / 600A shunt

o

Minimum current 0.3A measurement on 100A shunt

o

Improve cell voltage detection accuracy

o

Improve AH reading accuracy

o

Add Discharge End voltage of cell, and charge, discharge status send out -----

Protocol v1.26

LiPo & LiFe, LiTo attery Management System MS8P V4.3

www.chargery.com

page 9 total 62

Order information

Model

Description

Accessories

MS8P-100

100A charge and discharge

100A shunt, and standard accessories

MS8P-300

300A charge and discharge

300A shunt, and standard accessories

MS8P-600

600A charge and discharge

600A shunt, and standard accessories

Standard accessories (included in MS unit)

US data cable: Update main

unit and LCD unit

Cell alance wire: connect cell

to MS balance port, 600mm

DCC/Relay controller wire:

cut off charge /discharge ,

600mm.

Temperature sensor: 600mm,

monitor battery temperature.

Warning LED, 300mm Warning eeper, 300mm

Current sensor wire, 600mm,

monitor charge /discharge

current

Communication wire (4.5

meters), connect main unit to

LCD unit

COM3 Data line: connect to

external device, send out all

data

LiPo & LiFe, LiTo attery Management System MS8P V4.3

www.chargery.com

page 10 total 62

Current Shunt

A single shunt is used for the MS8P, it is delivered with MS and other standard accessories. The MS8P

detects the charge and discharge currents using the same shunt. All supplied shunts are voltage and current

calibrated prior to delivery. If you exchange the shunt, 75mV or less is recommended, and need calibrate

again.

LiPo & LiFe, LiTo attery Management System MS8P V4.3

www.chargery.com

page 11 total 62

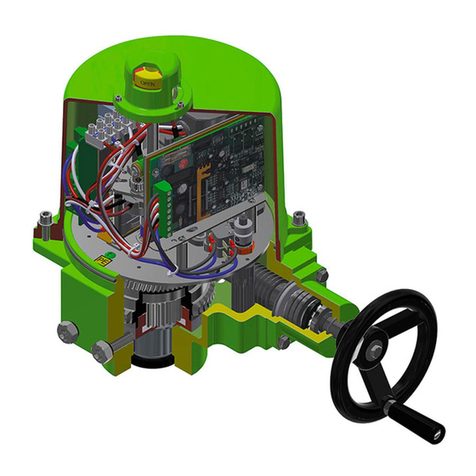

DC Contactor

CHARGERY designed the special DC contactor or named as SSR to fit with all MS, DCC is used for cut off

charge or discharge when any cell voltage reach settings to prevent any cell from damage and possibly fire.

The DCC must be installed on battery positive with ISO board, the board will be ship with DCC, on next

generation DCC, the board will be built-in DCC.

efore using DCC, please note the charge and discharge is on common port or separate port. The DCC has

different hardware on both type port.

Notes

If without DCC, MS will only warn by eeper sound and LED flash.

One DCC can be used in a Common port such as a Solar system, instead of two SSR's or relays.

The Relay Delay Time board (op is to avoid a surge current when start to charge or discharge. If using a

CHARGERY DCC, the delay board is not required, because it has a uilt-in the surge suppressing circuit.

For other SSR or mechanical relay, please consider the surge current seriously and make a suitable plan.

For more detailes please download and read DCC manual V1.2 carefully

http://chargery.com/doc/Chargery_DC_contactor_manual_V1.2.pdf

LiPo & LiFe, LiTo attery Management System MS8P V4.3

www.chargery.com

page 12 total 62

DCC main Specification

DC Contactor (DCC) model

DCC-100HB DCC-200HB DCC-300HB DCC-600HB

Driving voltage

12V

Holding current (Avg.) at 12V

9mA 11mA 11mA 11mA

Rated Operating Voltage

100V

Continuous (Carry) Current, Typical

100A 200A 300A 600A

Maximum current, at 85°C for 2 seconds

200A 300A 500A 1000A

Maximum Contact voltage drop at 100A

200mV 136mV 80mV 40mV

Fan start Temperature

>42°C >42°C >42°C

Over temperature protection---- Turn off

temperature

>90°C >90°C >90°C

Turn on temperature automatically

<80°C <80°C <80°C

Current mode

bi-directional

Size(L*W*H, mm)

105*55*40 105*64*55 105*90*55 142*105*55

Weight(Kg)

0.3 0.45 0.7 1.2

Operating Ambient Temperature

-40 to +85 °C

Cold pressing copper tube terminal

10-6 25-6 50-8

Screws

M6*16 M8*20

Wire Area(mm

2

) requirements

18 30 50 70

Ambient Temperature

-10--45℃

Ambient Humidity

5%--95%

Storage Temp.

-20℃--70℃

Storage Humidity

30%--90%

Status Indicator

Red LED is ON at DCC closed, and OFF at DCC open.

Power Indicator

Red LED is ON, The unit is ON. Red LED is OFF, means MS cut off charge

and/or discharge, or if High/Low temperature protection has been

triggered, or Temperature sensor is disconnected from the MS.

Driven Port

Status Indicator

Po er S itch

Po er Indicator

LiPo & LiFe, LiTo attery Management System MS8P V4.3

www.chargery.com

page 13 total 62

ISO board

The board is designed special for DCC, as we know the DCC install on the positive side is

better and safer than install on negative, so we designed the board.

The board should connect between MS relay controller port and DCC. There is two LEDs, One

indicate charge control signal, another indicate discharge control signal. As below.

When

over charge triggered, MS cut off charging, the charge LED on ISO board and Status

LED on DCC will be off.

When

over discharge triggered, MS cut off discharging, the discharge LED on ISO board and

Status LED on DCC will be off.

Charge control signal

Discharge control signal

Charge control signal

Discharge control signal

LiPo & LiFe, LiTo attery Management System MS8P V4.3

www.chargery.com

page 14 total 62

Chargery DC Contactor (DCC) configuration in Common and Separate Port

BMS Current sensor

shunt

Battery Pack

fuse

Charger/

Inverter

Chargery DCC

ISO board

Battery (-)

Battery

BMS relay controll

er

DCC on Common port connection

BMS Current sensor

Battery Pack

ISO board

Battery (-)

Battery (+)

BMS

Relay controller

DCC on Separate port connection

Charger

Inverter/load

Chargery DCC

Chargery DCC

fuse

LiPo & LiFe, LiTo attery Management System MS8P V4.3

www.chargery.com

page 15 total 62

BMS Current sensor

Battery Pack

ISO board

Battery (-)

Battery (+)

BMS Relay controller

DCC on Separate and common port connection

Inverter as load and charger, Solar panel charge

battery too

Solar Charger

Inverter/charger

Chargery DCC

(Common port)

Chargery DCC

(Separate Port)

fuse

Charge control signal

Dis

c

harge

control signal

ISO board

BMS

LiPo & LiFe, LiTo attery Management System MS8P V4.3

www.chargery.com

page 16 total 62

Alternator Saver

The alternator on a car or boat needs 12V or 24V in order to magnetise the field on the

alternator. Without that it will produce no current at all. Regulating this current is used in the

internal regulation on an alternator to regulate the output of the alternator. The same

capability is used on external regulators as almar or Grassder Smart Charge one or Sterling

ProReg-D. When the batteries have reached floating level they will send less current through

the magnetising field of the alternator in order to limit the output.

When MS cut off charging by “open” DCC or relay directly, this will burn the diodes in the

alternator.

The Alternator saver can switch off the magnetising current to the field of the alternator just 3

seconds before the contactor switch off, so protect the diodes of the alternator.

A small isolated relay cutting the power to the magnetising field could do the trick, the relay

will be “open” first by the Saver board before DCC cut off charging.

The feature could be useful for many boaters and others who charges with alternators.

LiPo & LiFe, LiTo attery Management System MS8P V4.3

www.chargery.com

page 17 total 62

Common port DCC connection diagram with 2 8S batteries.

LiPo & LiFe, LiTo attery Management System MS8P V4.3

www.chargery.com

page 18 total 62

Separate port DCC connection diagram with 2 8S batteries.

LiPo & LiFe, LiTo attery Management System MS8P V4.3

www.chargery.com

page 19 total 62

Operational Description

The MS8P includes a Main Unit and a Display Module. Once the hardware installation is completed and ready,

power on the MS8P to finish setting up all of the parameters using the Display Module. The MS8P will use

the saved settings even if the Display Module is disconnected from the Main Unit. Removing the Display

Module disables the data display, beeper and warning LED but the MS will still function properly and can cut

off charge / discharge when any set condition requires it. You can connect an external device such as a

computer to the COM3 port on the Main Unit to receive all RS232 data. To modify the parameters in setup,

please reconnect the Display Module, no data can be written to the MS from an external application at this

time.

The MS8P can be used with any lithium battery charger, when any cell is over charged, the MS8P will open

the charge relay to cut off charge, if used with a CHARGERY charger, the charge control is handled by

connecting the CHARGERY charger to the MS8P on COM1, when any cell reach OVP, the charge current will

decrease automatically to prevent any cell damage. This feature can save charge relay cost and shorten

charge time.

More information on the RS232 Data Interface can be found in Supplemental: Reference Documents & Video

links

Special NOTE: The RS232 output is wired in a Cross Over fashion. Refer to RS232 Document for pin out. This

can be wired to any type of adapter being used, such as RS232, RJ-11, RJ-45. Pin outs must be observed

accordingly.

LiPo & LiFe, LiTo attery Management System MS8P V4.3

www.chargery.com

page 20 total 62

Special Features

1. The MS8P uses advanced ADC measurement technology, high accuracy, high voltage and high current

detection circuit. The maximum voltage measurements tolerance is within 5mV at up to 8S LiPo battery

(34V)

2. Supports regenerative braking, during braking operation it can charge the battery pack and the discharge

power (Wh) will increase in response to the braking power.

3. Charge/discharge current up to 600A. Larger current support can be custom ordered.

4. 1.2A per cell balance current is very useful for large capacity battery pack, this feature can restore all

cell voltage balance in the shortest time. Over temperature protection ensures the system safety during

balancing.

5. MS8P calculates and displays the charge and discharge power (Wh), generally the battery rated power is

rated voltage multiplied by rated battery capacity.

6. TFT LCD screen provides rich information including current, voltage, power, capacity, battery status, SOC

and temperature and so on.

7. MS8P features maximum safety protections, within the range parameters that can be setup, MS8P will

alarm and cutoff charge or discharge according to users’ setup, out of range parameters and triggered

absolute maximum settings MS8P will force cutoff charge / discharge to protect the battery.

8. Minimize the power consumption by draw current from all cells or external power supply.

9. Dual power design, the unit can be powered by all the cells or an external power supply.

10. Detect cell count at any time, and compare with the count detected when switched on first time. If

inconsistent, the device will alarm and cutoff charge or discharge according to user setup, this is a safety

feature is if a cell becomes loose.

11. Sound alarm and LED alarm will be triggered if any warning events occur, it will wait several seconds,

then disconnect charge / discharge if required. The delay time can be programmed.

12. The Charge and Discharge relays are controlled independently.

13. Two temperature sensors monitor battery temperature for different positions on the pack.

14. Supports upgrading the firmware program by US port.

15. MS8P provide users the maximum flexibility, key parameters can be programmed.

16. MS8P displays battery SOC as a dial gauge. Cell count, battery pack voltage and battery gauge (%)

temperature is displayed simultaneously.

17. In case the battery pack is not to be charged / discharged and put into storage mode, Press STOP

button enter into Sleep Mode to save energy consumption, Charge / Discharge are disabled and the LCD

back light is turned off. Press any key to resume normal work mode.

18. LCD back light ON time can be programmed to save energy, when it is OFF, press any key to activate.

This manual suits for next models

1

Table of contents

Other Chargery Controllers manuals