aci FREEZE STATS Series Installation instructions

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 1

Version: 10.0

I0000298

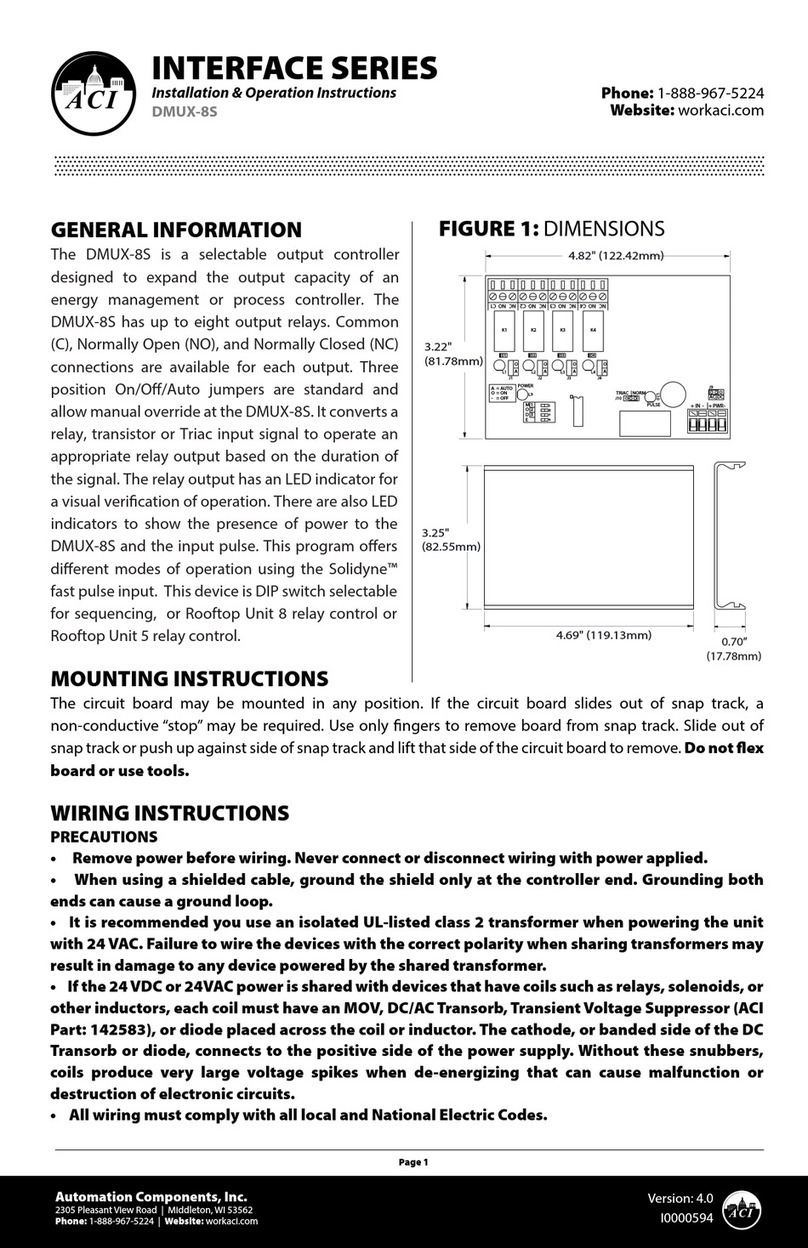

FIGURE1: DIMENSIONS

FREEZE STATS SERIES

Installation & Operation Instructions Phone: 1-888-967-5224

Website: workaci.com

GENERAL INFORMATION

The FS Series are low limit controllers, also

known as "Freeze Stats". These devices were

designed for use on HVAC equipment that

require low-temperature cutout protection to

prevent cooling coils from freezing. They should

be mounted between the heating and cooling

coils on the supply side of the fan unit and

respond to the lowest temperature sensed

along any one foot section of the sensing

element. The FS Series has manual and

automatic reset versions, as well as, models that

feature one or two sets of SPDT contacts.

Numerous capillary lengths are also available.

MOUNTING INSTRUCTIONS

• Do not uncoil more element or capillary

than is required for the application.

• Do not sharply bend the element or

capillary more than necessary bending

hardens the element and makes it brittle. If

the element or capillary can be subjected to

vibration, protect any surface that makes

contact.

Strap the element on a coil; for example, in an

area where freezing can occur, or mounted in a

duct. Use as much of the element as necessary

for maximum protection. Use metal straps to

fasten the element to the coil to be controlled.

Use clips for mounting the element in a duct.

Locate the sensing element where it can sense

the average temperature of the space to be

controlled.

Locate the thermostat case where the ambient

temperature is always warmer than the set

point.

FS-1

FS-2

FS-3

FS-4

FS-50 4.53”

(115.01mm)

Available with 6’, 10’, 20’

& 50’ Capillary Lengths

4.35” (110.49mm)

2.18”

(55.25mm)

FS-5

FS-6

4.53”

(115.01mm)

Ø0.375”

(9.53mm)

3.65”

(92.71mm)

4.35” (110.49mm)

2.18”

(55.25mm)

Thermostat enclosure to be surface mounted; avoid locations subject to excessive vibration.

Mount to at surface using oval holes only. (See Wiring Diagrams) Mounting with round holes in middle of

freeze stat may damage the instrument and cause improper operation.

Install the capillary sensing element across the face of the coil, horizontally serpentine only. If too much of

the element is vertical, it will not operate properly.

Avoid sharp bends or kinks in the sensing element.

Install the thermostat in an upright position so that the bellows point down and the capillary tube exits

the bottom of the unit..

WIRING INSTRUCTIONS

All wiring should comply with National and Local Electrical Codes.

A M20 watertight tting is installed in the ½” conduit knockout. If the ½” knockout is needed, remove the

M20 tting and install the appropriate conduit tting in the 0.830” knockout in the bottom of the

enclosure.

Maximum wire size is 14 AWG (2.5mm) two copper wires. Use a screwdriver to loosen the terminal

connections screws. Strip wire ends 3/8” and insert into box connectors on the switch block and securely

retighten the screws.

Now replace the cover and tighten the screw on the front cover.

Note: The Freeze Thermostat is factory set at 39°F. This is the ideal setting that will provide the best

protection while avoiding nuisance trips.

FIGURE 2: MOUNTING

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 2

Version: 10.0

I0000298

GENERAL INFORMATION

The FS Series are low limit controllers, also

known as "Freeze Stats". These devices were

designed for use on HVAC equipment that

require low-temperature cutout protection to

prevent cooling coils from freezing. They should

be mounted between the heating and cooling

coils on the supply side of the fan unit and

respond to the lowest temperature sensed

along any one foot section of the sensing

element. The FS Series has manual and

automatic reset versions, as well as, models that

feature one or two sets of SPDT contacts.

Numerous capillary lengths are also available.

MOUNTING INSTRUCTIONS

• Do not uncoil more element or capillary

than is required for the application.

• Do not sharply bend the element or

capillary more than necessary bending

hardens the element and makes it brittle. If

the element or capillary can be subjected to

vibration, protect any surface that makes

contact.

Strap the element on a coil; for example, in an

area where freezing can occur, or mounted in a

duct. Use as much of the element as necessary

for maximum protection. Use metal straps to

fasten the element to the coil to be controlled.

Use clips for mounting the element in a duct.

Locate the sensing element where it can sense

the average temperature of the space to be

controlled.

Locate the thermostat case where the ambient

temperature is always warmer than the set

point.

Thermostat enclosure to be surface mounted; avoid locations subject to excessive vibration.

Mount to at surface using oval holes only. (See Wiring Diagrams) Mounting with round holes in middle of

freeze stat may damage the instrument and cause improper operation.

Install the capillary sensing element across the face of the coil, horizontally serpentine only. If too much of

the element is vertical, it will not operate properly.

Avoid sharp bends or kinks in the sensing element.

Install the thermostat in an upright position so that the bellows point down and the capillary tube exits

the bottom of the unit..

WIRING INSTRUCTIONS

All wiring should comply with National and Local Electrical Codes.

A M20 watertight tting is installed in the ½” conduit knockout. If the ½” knockout is needed, remove the

M20 tting and install the appropriate conduit tting in the 0.830” knockout in the bottom of the

enclosure.

Maximum wire size is 14 AWG (2.5mm) two copper wires. Use a screwdriver to loosen the terminal

connections screws. Strip wire ends 3/8” and insert into box connectors on the switch block and securely

retighten the screws.

Now replace the cover and tighten the screw on the front cover.

Note: The Freeze Thermostat is factory set at 39°F. This is the ideal setting that will provide the best

protection while avoiding nuisance trips.

CAUTION!

FIGURE 2: WIRING

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 3

Version: 10.0

I0000298

(BLUE)

(WHITE)

(RED)

(BLUE)

(WHITE)

(RED)

FS-1

FS-1A

FS-3

FS-3A

FS-5

FS-5A

FS-6

FS-2

FS-2A

FS-4

FS-4A

FS-6

FS-6A

FS-50

FS-50A

Note: Falling Temperature and attained low cut-out point

Contact Connection: Red to Blue

White

Red

Blue

N/C

Common

N/O

Schematic Diagram

Note: Falling Temperature and attained low cut-out point

Contact Connection: Red to Blue

White

Red

Blue

N/C

Common

N/O

Schematic Diagram

White

Red

Blue

N/C

Common

N/O

PRODUCT SPECIFICATIONS

WARRANTY

The Freeze Stat Series is covered by ACI’s Two (2) Year Limited Warranty, which is located in the front of ACI’S

SENSORS & TRANSMITTERS CATALOG or can be found on ACI’s website: www.workaci.com.

W.E.E.E. DIRECTIVE

At the end of their useful life the packaging and product should be disposed of via a suitable recycling

centre. Do not dispose of with household waste. Do not burn.

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 4

Version: 10.0

I0000298

Self-contained, electromechanical

Vapor-lled capillary

Temperature in air

14°F to 54°F (-10°C to 12°C)

392°F (200°C), maximum 60 minutes

To lowest temperature sensed by any 1 ft section of the capillary element

Copper

Duct and across coil mounted

Ø0.08 in. (2 mm) (6’ Length models have a larger bulb at the end)

ON/OFF, low-level single-stage or cut-out control, with One (1) microswitch output

At 39°F (4°C), and safety-lock secured

14°F to 54°F

Over full operating range, via screwdriver slot

Form 1C (SPDT Contact)

250 VAC

15 (8) A

1.8°F (1°K), auto- or manual reset

14°F to 131°F (-10°C to 55°C)

0 to 95% RH, non-condensing

14°F to 158°F (-10°C to 70°C)

Steel, galvanized

ABS, re retardant

NON-SPECIFIC INFORMATION

Thermostat Type:

Sensing Element:

Sensing Media:

Sensing Temperature Operating Range:

Sensing Capillary Overload

Temperature:

Sensing Response:

Sensing Capillary Material:

Sensing Capillary Length:

Sensing Capillary Diameter:

Type of Control:

Low-Level Setpoint (Factory Set):

Low-Level Setpoint Visual Range:

Low-Level Setpoint Adjustment:

Contact Form:

Maximum Contact Switching Voltage:

Maximum Contact Switching Current:

Switching Differential:

Enclosure Operating Temperature

Range:

Operating Humidity Range:

Storage Temperature Range:

Enclosure Base Material:

Enclosure Cover Material:

This manual suits for next models

5

Other aci Controllers manuals

Popular Controllers manuals by other brands

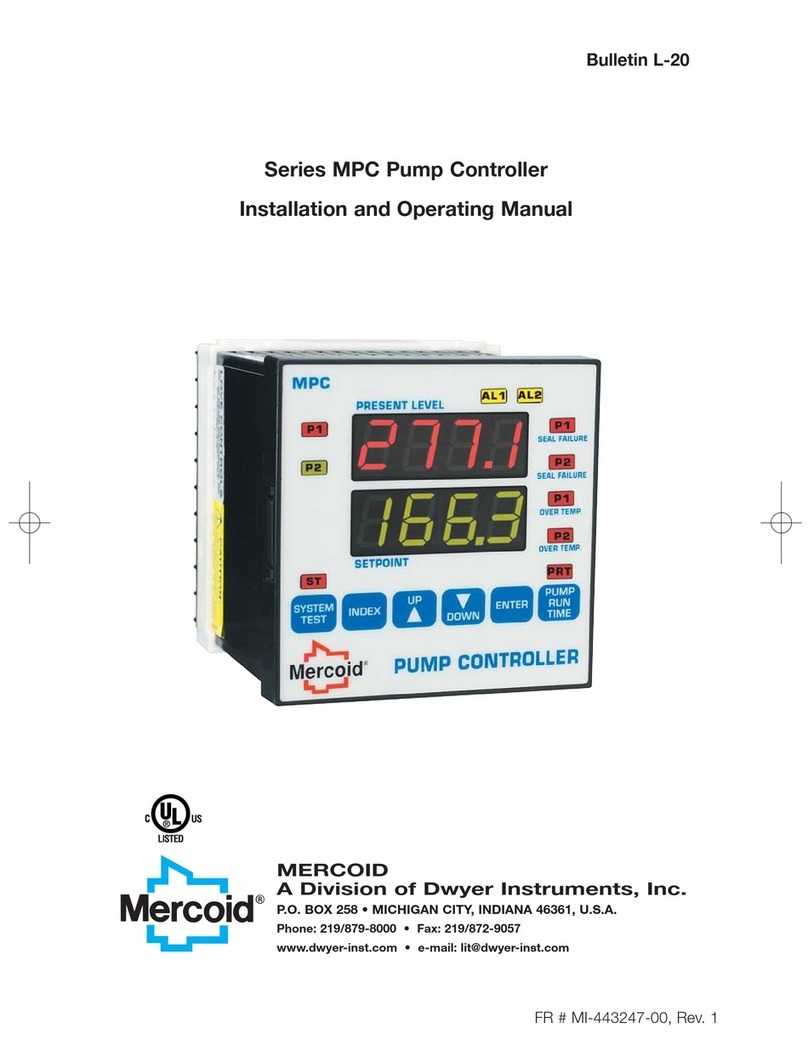

Mercoid

Mercoid Series MPC Installation and operating manual

dixell

dixell XR03CX Installing and operating instructions

Samson

Samson 3273 Mounting and operating instructions

GESTRA

GESTRA NRR 2-50 installation instructions

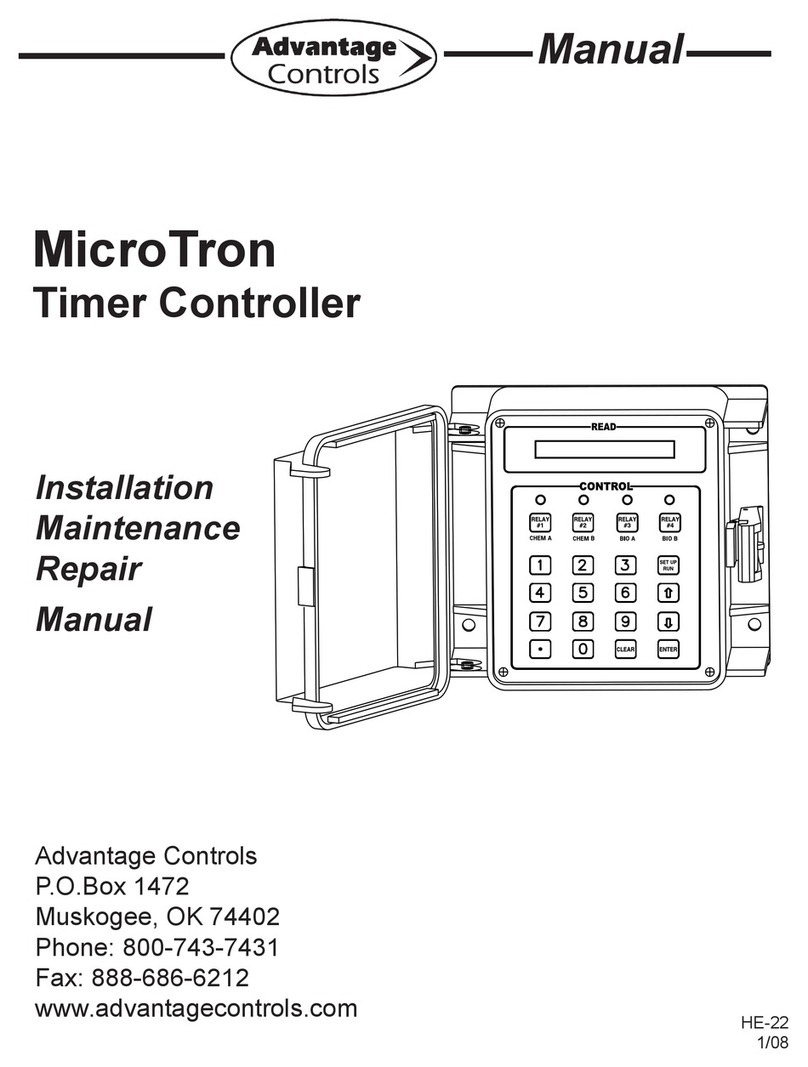

Advantage

Advantage MicroTron installation manual

Johnson Controls

Johnson Controls M4-CGM Series installation guide

PROSPERITY GROUP

PROSPERITY GROUP TRAXON e:cue 3 mx INFORMATION FOR USE

Bosch

Bosch Rexroth Diax 04 instruction manual

Gigabyte

Gigabyte Network Device GA-7N400 user manual

Lincoln Electric

Lincoln Electric MAXsa 19 MSA Operator's manual

Linak

Linak Deskline DL7 system user manual

BitFenix

BitFenix 6+6 CONTROLLER introduction