Charmilles E110-D10 User manual

1

r

r

2

-

-

[)

)

Published

by

ATELIERS

DES

CHARMILLES

S.A.

GENEVA

-

SWITZERLAND

The

handing

over

to

a

third

party,

the

publication

or

the

reproduction

even

partial

of

this

document

without

any

authorization

are

forbidden.

All

rights

for

modifications

reserved.

Printed

in

tzerl

MD10222370E

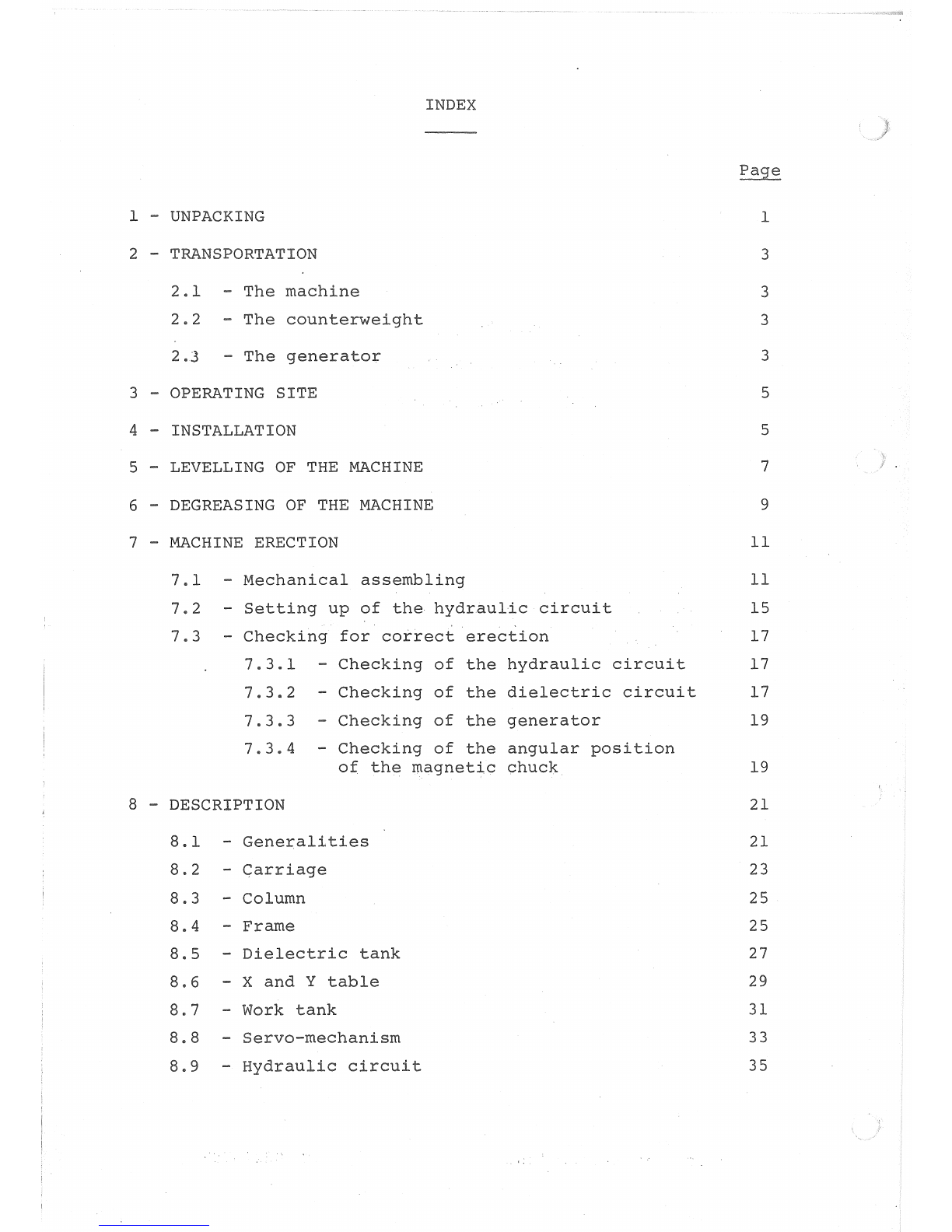

INDEX

1

-

UNPACKING

2

-

TRANSPORTATION

2.1

-

The

machine

2.2

-

The

counterweight

2.3

-

The

generator

3 -OPERATING

SITE

4 -INSTALLATION

5 -LEVELLING

OF

THE

MACHINE

6

-

DEGREASING

OF

THE

MACHINE

7

-

MACHINE

ERECTION

7.1

-Mechanical

assembling

7.2

-

Setting

up

of

the

hydraulic

circuit

7.3

-Checking

for

correct

erection

7.3.1

-

Checking

of

the

hydraulic

7.3.2

-

Checking

of

the

dielectric

7.

3.

3 -

Checking

of

the

generator

circuit

circuit

7.

3.

4

--

Checking

of

the

angular

position

of

the

magnetic

chuck

8

-

DESCRIPTION

8.1

-

Generalities

8.2

-

Carriage

8.3

-

Column

8.4

-

Frame

8.5

-

Dielectric

tank

8.6

-

X

and

y

table

8.7

-

Work

tank

8.8

-

Servo-mechanism

8.9

-

Hydraulic

circuit

1

3

3

3

3

5

5

7

9

ll

ll

15

17

17

17

19

19

21

21

23

25

25

27

29

31

33

35

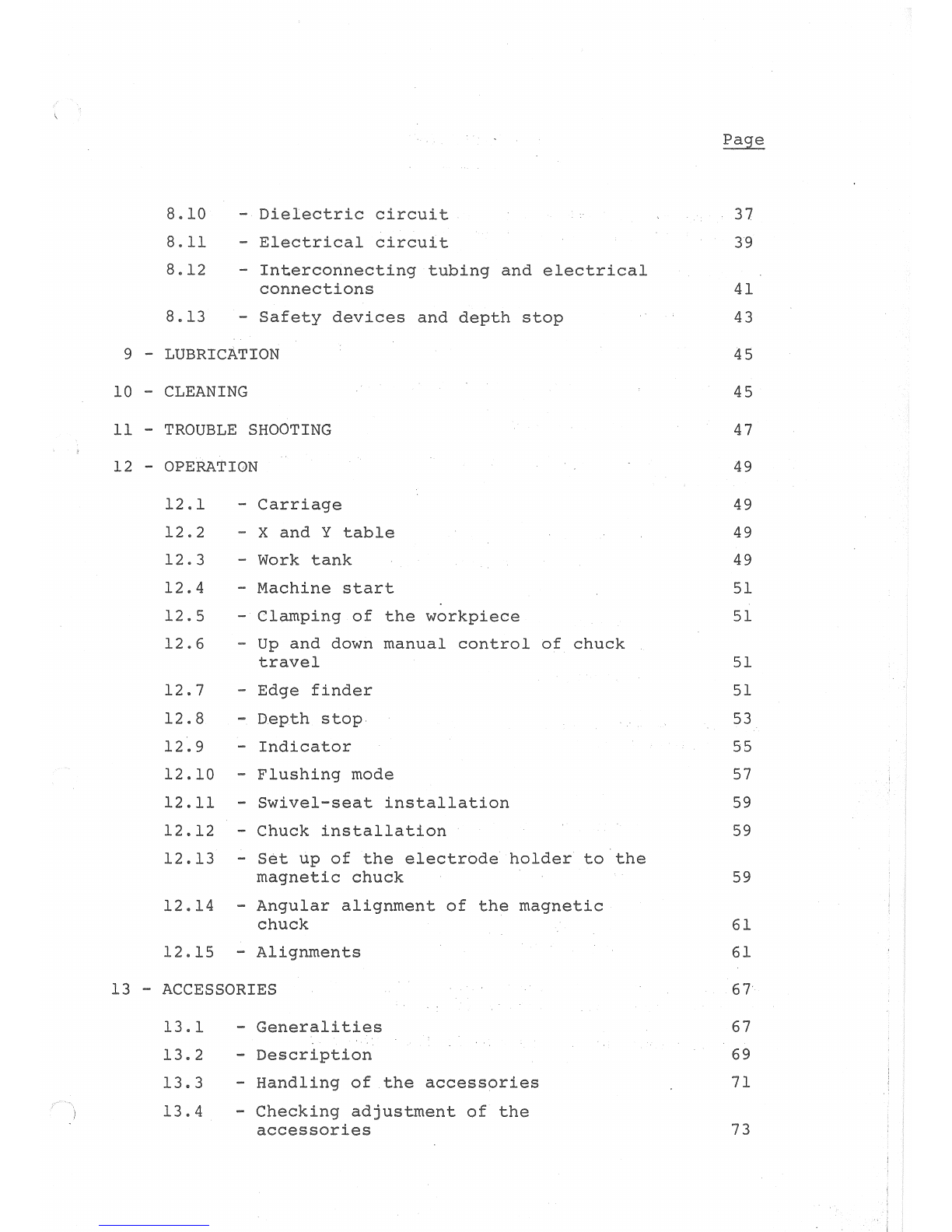

-

Dielectric

circuit

-

Electrical

circuit

8.10

8.11

8.12

-

Interconnecting

tubing

and

electrical

connections

8.13

-

Safety

devices

and

depth

stop

9

-

LUBRICATION

10

-

CLEANING

ll

-

TROUBLE

SHOOTING

12

-

OPERATION

12.1

-

Carriage

12.2

--

X

andY

table

12.3

-Work

tank

12.4

-

Machine

start

12.5

-Clamping

of

the

workpiece

12.6

--

Up

and

down

manual

control

of

chuck

travel

12.7

- Edge

finder

12.8

-

Depth

stop

12.9

-

Indicator

12.10

-

Flushing

mode

12.11

-

Swivel-seat

installation

12.12

- Chuck

installation

12.13

-

Set

up

of

the

electrode

holder

to

the

magnetic

chuck

12.14

-Angular

alignment

of

the

magnetic

12.15

-Alignments

13

-

-

13.1

13.2

13.3

-

Generalities

-

Description

--

Handling

of

the

acces

es

13.4

-

Checking

adjustment

of

the

accessories

37

39

41

43

45

45

47

49

49

49

49

51

51

51

51

53

55

57

59

59

59

61

61

67

67

69

71

73

-

1 -

l

--

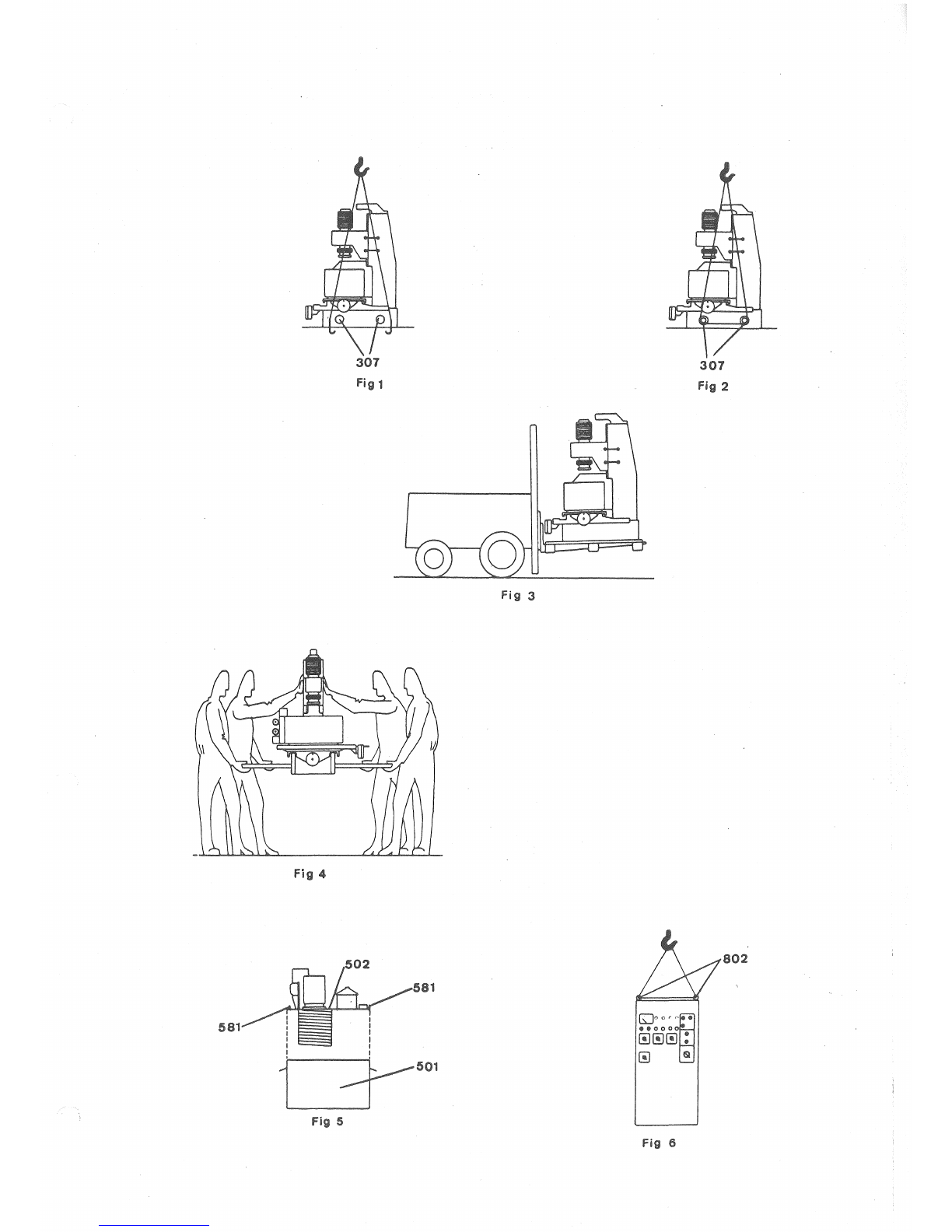

UNPACKING

It

is

recommended

that

the

following

procedure

observed

for

removal

of

the

machine

from

the

packing

crate:

l.

Remove

the

top

cover

of

the

crate

(fig.

1)

.

2 •

Remove

the

two

beams

that

hold

the

machine

(fig.

2)

•

3.

Remove

the

two

long

side-flats

of

the

case

(fig.

3)

•

4 •

Remove

the

two

lateral

head-pieces

(fig.

4)

•

5.

Cut

the

hoop-iron

strips.

This

will

expose,

from

left

to

right

on

the

bottom

of

the

crate

(fig.

5):

- 1

machine,

type

D

10,

- 1

case

containing

accessories,

- l

generator

(800),.

- 1

tank

for

the

dielectric

fluid

(500)

2

pipes

(G &

H)

,

-

several

hose

clamps.

6.

Remove

the

above

units

from

the

bottom

of

crate

in

the

following

order:

(first

loosen

the

hold-down

beams)

the

case

of

accesso~ies,

-

the

generator

(800)

(refer

to

paragraph

on

uTRANSPORTATION"),

-the

pipes

(G

&

H),

-

the

tank

(500)

(refer

to

paragraph

on

''TRANSPORTATION"),

7.

Remove

the

two

wood

beams

that

clamp

down

the

metal

bars

used

to

secure

machine

(fig.

6).

8.

Lift

the

machine

and

remove

it

from

the

base

of

the

crate.

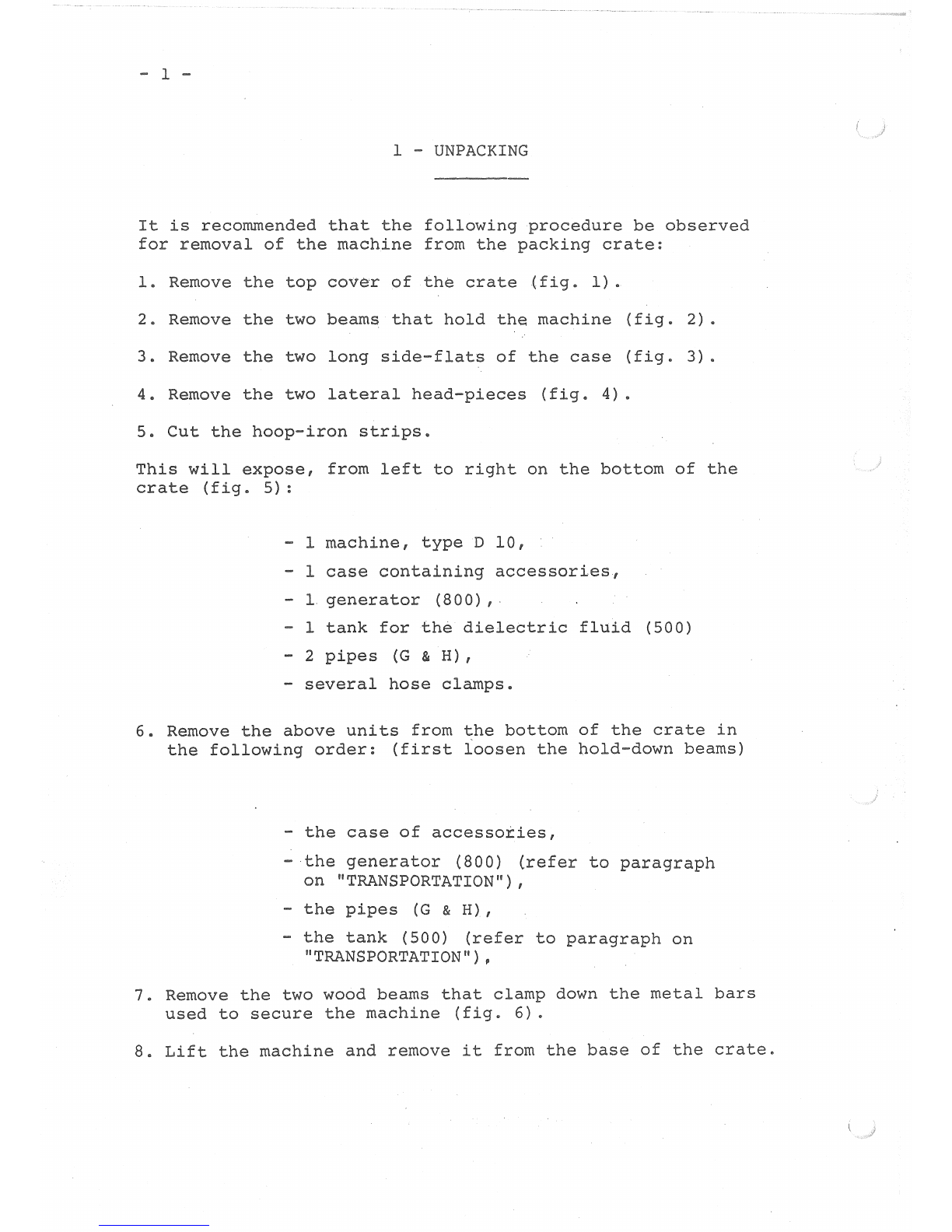

Fig

2

Fig

4

800

Fig

5

Fig

6

-

3

-

2

-

TRANSPORTATION

The

various

units

contained

within

the

crate

can

be

trans-

ported

in

the

following

manner:

2.1

The

machine:

2.2

The

dielectric

tank:

2.3

The

generator:

wei~ht:

soo

lb

(230'Kg)

2

through-holes

(307),

diameter

1~"

(30

mrn),

have

been

provided

to

permit

of

transportation

by

different

means:

a)

by

means

of

a

crane

(figs.

1 & 2)

b)

by

means

of

a

fork-lift

(fig.

3)

c)

manually,

by

4

persons

(fig.4)

weight:

260

1b

(120

Kg)

remove

the

tank-cover

(502)

by

means

o~

the

loop-handles

(581),

(fig.

5),

and

transport

the

tank-cover

separately

Irom

the

tank

itself

(501).

weight:

Pl2

P25

180

lb

(80

Kg)

270

lb

(125

Kg)

the

generator

can

be

transported

quite

easily

by

fastening

a

rope

through

the

holes

of

the

two

screws

(802)

(fig.

6)'

Fig

4

581

Fig 5

301

fig

1

Fig

3

Fig

6

307

Fig

2

802

-

5

-

3

-

OPERATING

SI.TE

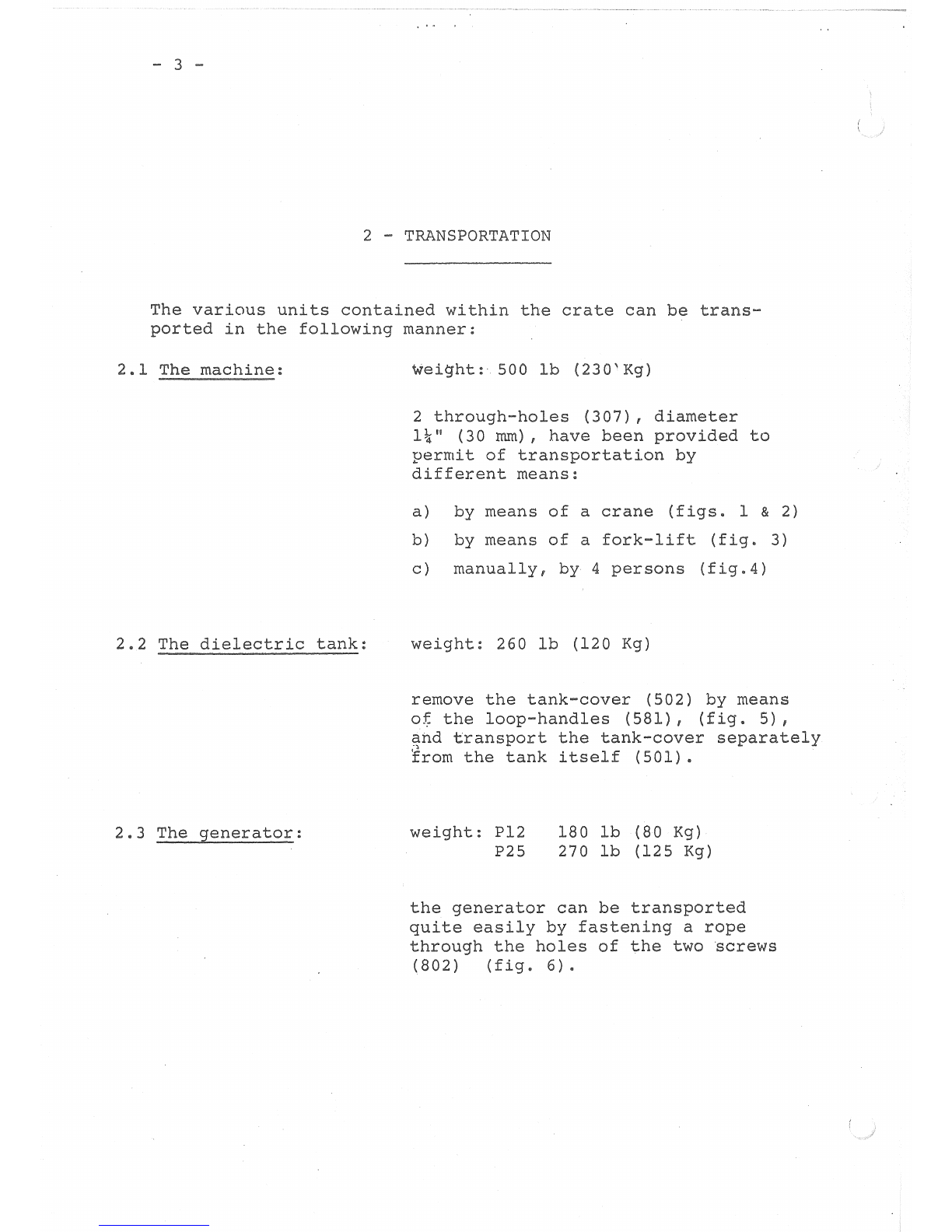

We

recommend

that

the

machine

installed

in

a

clo

and

clean

room,

or

at

least,

that

it

located

in

a

site

is

well

protected

against

dirt,

dust

and

grit

usually

encoun-

tered

in

workshops.

~he

floor

plan

(fig.

1)

takes

care

of

not

only

the

actual

space

taken

up

by

the

machine,

the

generator

and

the

dielectric

tank,

but

also

the

space

required

for

their

correct

location

in

relation

to

each

other

and

the

space

necessary

for

normal

operating

and

maintenance

of

the

complete

installation.

The

dotted

line

refers

to

cases

in

which

the

dielectric

tank

is

located

in

the

rear

of

the

machine

(refer

to

paragraph

on

11

INSTALLATION

11

).

On

the

site

chosen,

provision

must

be

made

for

:

-

A

3-phase,

3

KVA

electrical

supply

outlet,

complete

with

all

necessary

protective

devices

(fuses,

over-

load

relays),

to

power

the

installation.

- A

suitable

system

for

-

supply

and

disposal

of

coolant

water

at

a

pressure

not

to

exceed

120

PSI

(10

Kg/cm2),

pipe

~

3/8"

(10

mm).

-

Efficient

ventilation

or

an

installation

for

the

exhaust

of

fumes.

-

An

adequate

lighting

installation.

4

-

INSTALLATION

It

is

necessary

to

comply

with

two

very

important

considerations

a)

The

dielectric

tank

must

always

be

located

at

a

lower

level

than

the

machine.

b)

The

generator

must

be

located

as

close

as

possible

to,

and

on

the

right-hand

side

of

the

machine.

1§~

possibility

:

on

a

single

workbench.

Minimum

dimensions

2~~

possibility

of

the

bench

area:

60"

x

32"

(1500

x

800

mm).

If

the

dielectric

tank

(500)

is

located

immediately

underneath

the

machine,

the

height

available

below

the

workbench

must

be

of

at

least

33"

(830

mm)

(fig.

2).

on

two

workbenches.

Minimum

dimensions

of

the

area

of

each

workbench:

30"

x

32"

(1500

x

800

mm).

If

the

dielectric

tank

(500)

is

located

immediate

underneath

the

machine,

the

height

available

below

the

workbench

must

be

of

at

t 33

11

(830

mm)

(fig.

3).

The

tank

for

the

dielectric

fluid

may

be

installed

either

a)

immediately

underneath

the

machine

(fig.

4)

b)

in

the

rear

or

at

the

side

of

the

machine

(figs.

5 &

6).

60

em

\

-

3KVA

-

.J

/

----

Fig

5

50

cm

150

em

Fig

1

Fig

3

E

co

60

em

E

rnm

Fig

2

Fig

4

Fig

6,

co

E

-

7

-

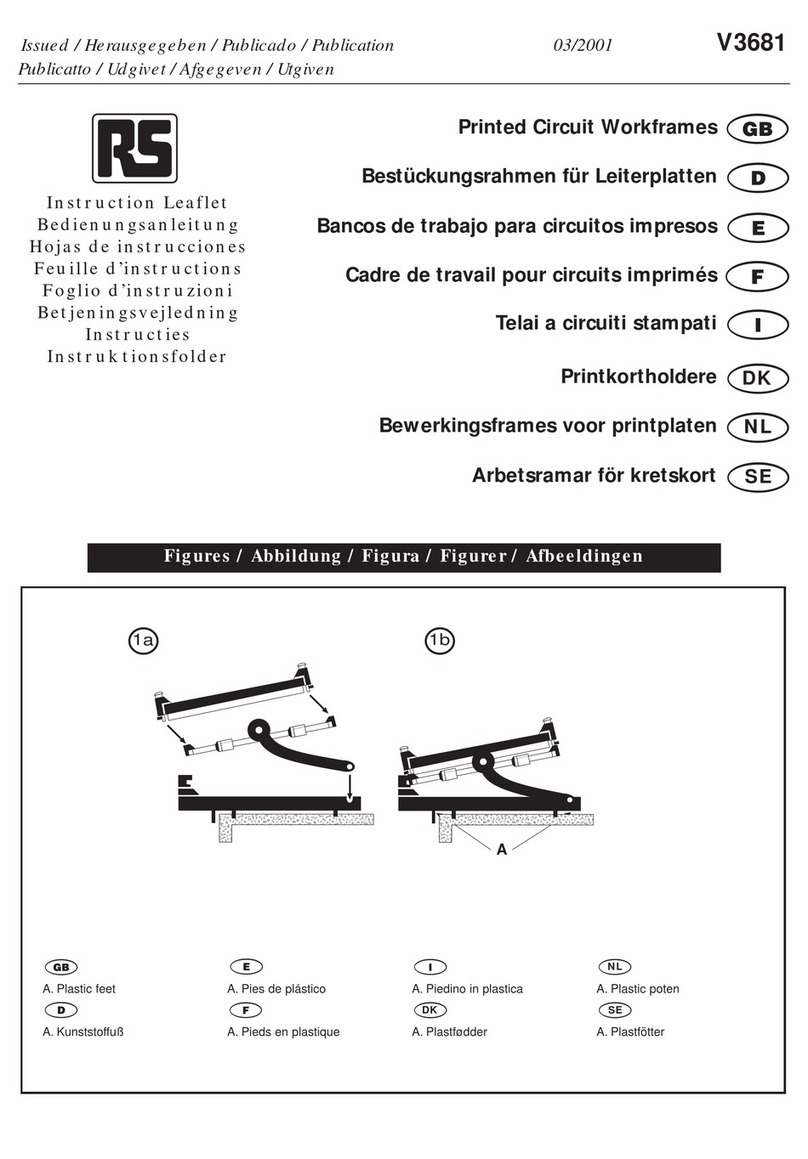

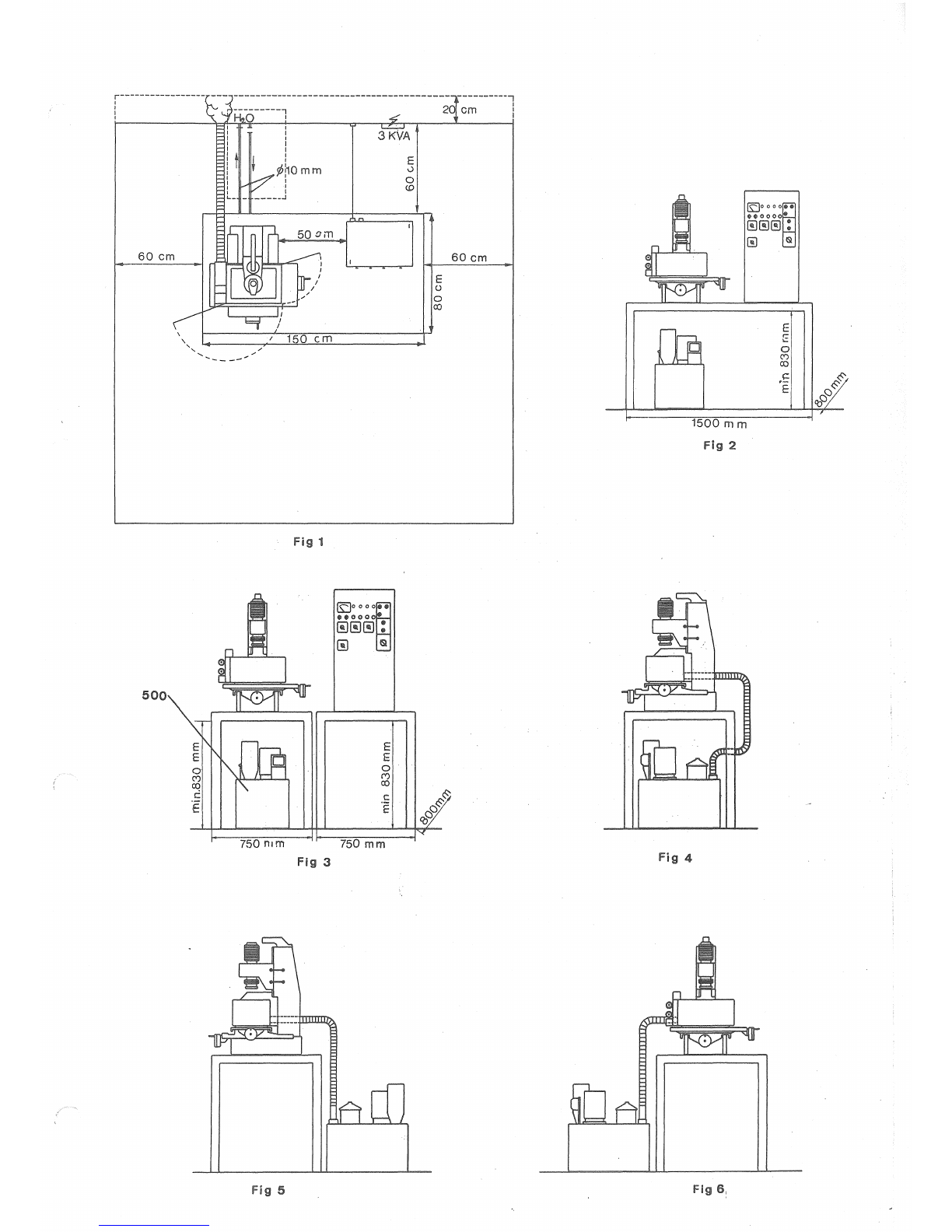

5

-

LEVELLING

OF

THE

MACHINE

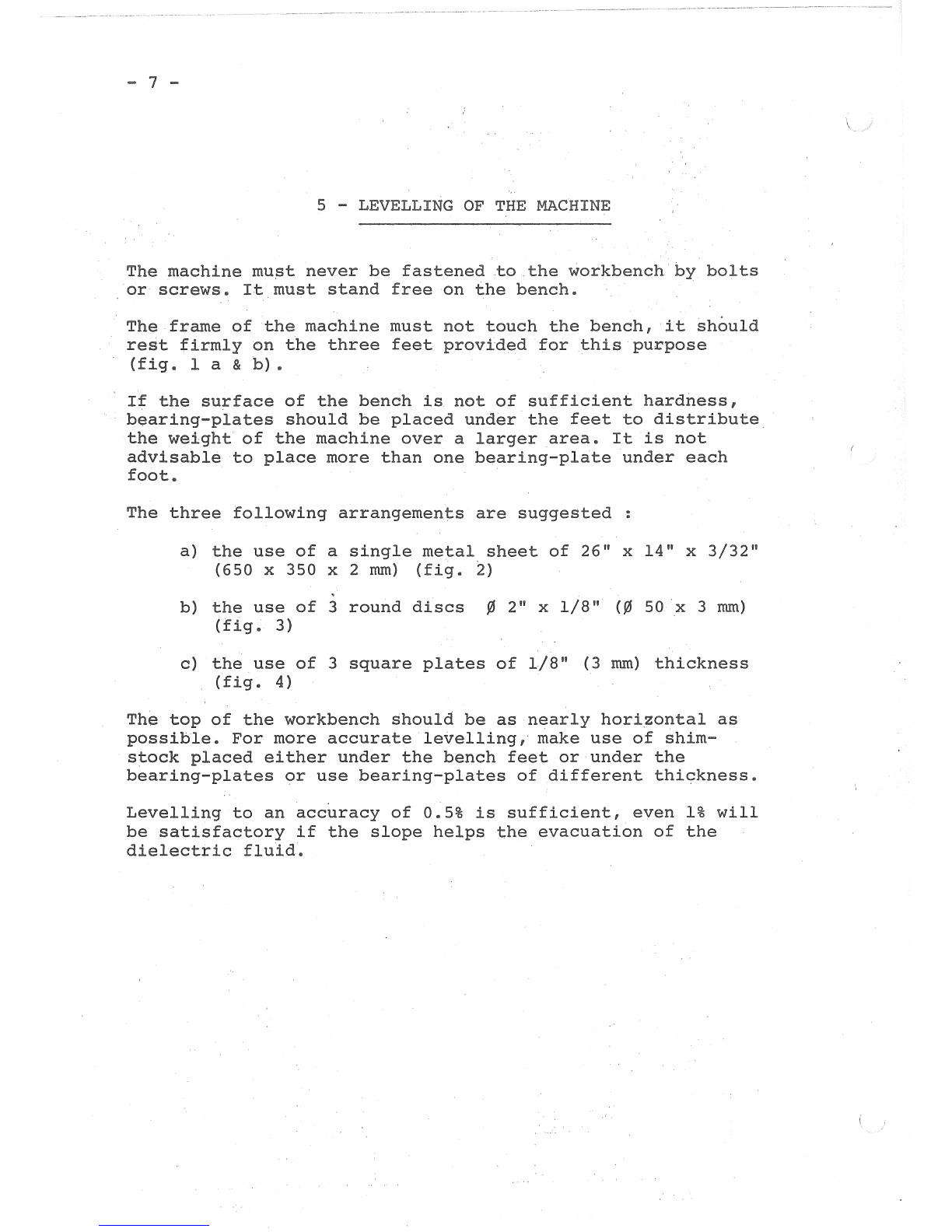

The

machine

must

never

fastened

to

the

workbench

by

bolts

or

screws.

It

must

stand

free

on

the

bench.

The

frame

of

the

machine

must

not

touch

the

bench,

it

should

rest

firmly

on

the

three

feet

provided

for

this

purpose

(fig.

1 a &

b)

.

If

the

surface

of

the

bench

is

not

of

sufficient

hardness,

bearing-plates

should

be

placed

under

the

feet

to

distribute

the

weight

of

the

machine

over

a

larger

area.

It

is

not

advisable

to

place

more

than

one

bearing-plate

under

each

foot.

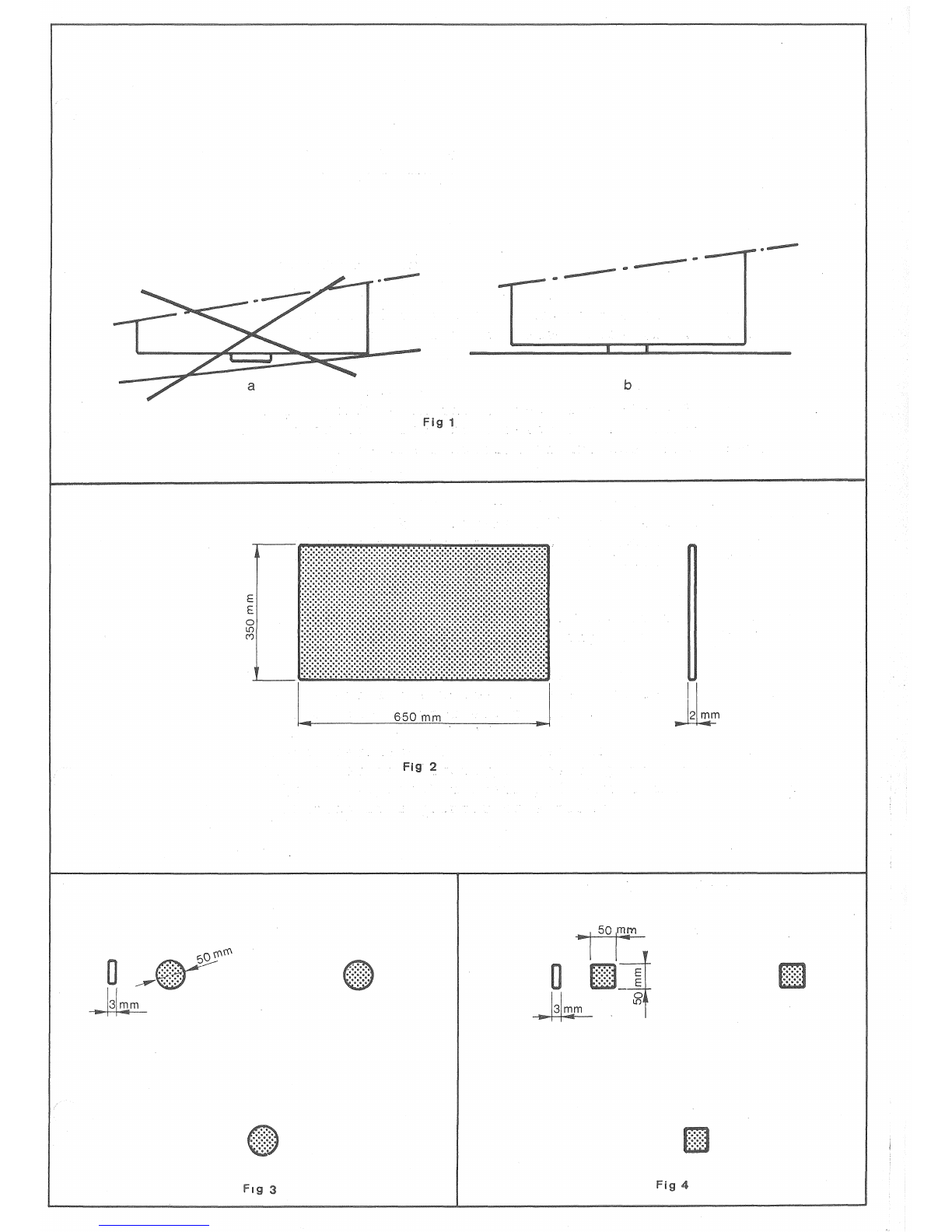

The

three

following

arrangements

are

suggested

a)

the

use

of

a

single

metal

sheet

(650

X

350

X 2

rom)

(fig.

2)

26"

X

14"

X

3/32"

b)

the

use

of

3

round

discs

~

2"

x

1/8"

(~

50

x 3

mm)

(fig.

3)

c)

the

use

of

3

square

plates

of

(fig.

4)

8"

(3

mm)

thickness

The

top

of

the

workbench

should

be

as

nearly

horizontal

as

possible.

For

more

accurate

levelling,

make

use

of

shim-

stock

placed

either

under

the

bench

feet

or

under

the

bearing-plates

or

use

bearing-plates

of

different

thickness.

Levelling

to

an

accuracy

of

0.5%

is

sufficient,

even

1%

will

be

satisfactory

if

the

slope

helps

the

evacuation

of

the

dielectric

fluid.

E

E

Fig

fig

2

-

b

Fig

4

9

-

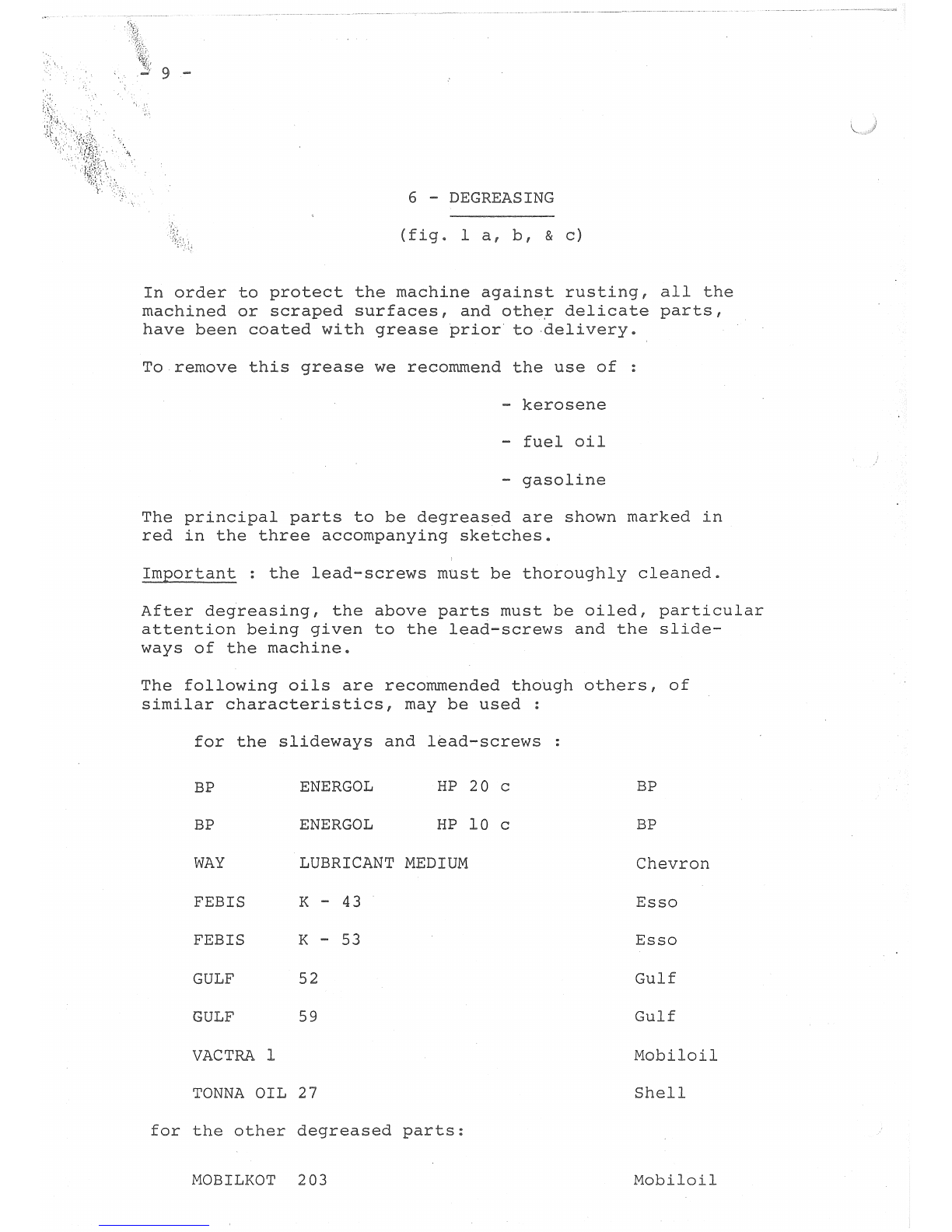

6

-

DEGREASING

(fig.

l

a,

b,

&

c)

In

order

to

protect

the

machine

against

rusting,

all

the

machined

or

scraped

surfaces,

and

othe~

delicate

parts,

have

been

coated

with

grease

prior

to

-delivery.

To

remove

this

grease

we

recommend

the

use

of

-

kerosene

-

fuel

oil

-

gasoline

The

principal

parts

to

be

degreased

are

shown

marked

in

red

in

the

three

accompanying

sketches

Important

:

the

lead-screws

must

be

thoroughly

cleaned.

After

degreasing,

the

above

parts

must

be

oiled,

particular

attention

being

given

to

the

lead-screws

and

the

slide-

ways

of

the

machine.

The

following

oils

are

recommended

though

others,

of

similar

characteristics,

may

be

used

:

for

the

slideways

and

lead-screws

BP

ENERGOL

HP

20

c

BP

BP

ENERGOL

HP

10

c

BP

WAY

LUBRICANT

MEDIUM

Chevron

FEB

IS

K - 43

Esso

FEB

IS

K -

53

Esso

GULF

52

Gulf

GULF

59

Gulf

VACTRA

1

Mobiloil

TONNA

OIL

27

Shell

for

the

other

degreased

parts:

MOBILKOT

203

Mobiloil

F1g 1

-

11

-

7

-

MACHINE

ERECTION

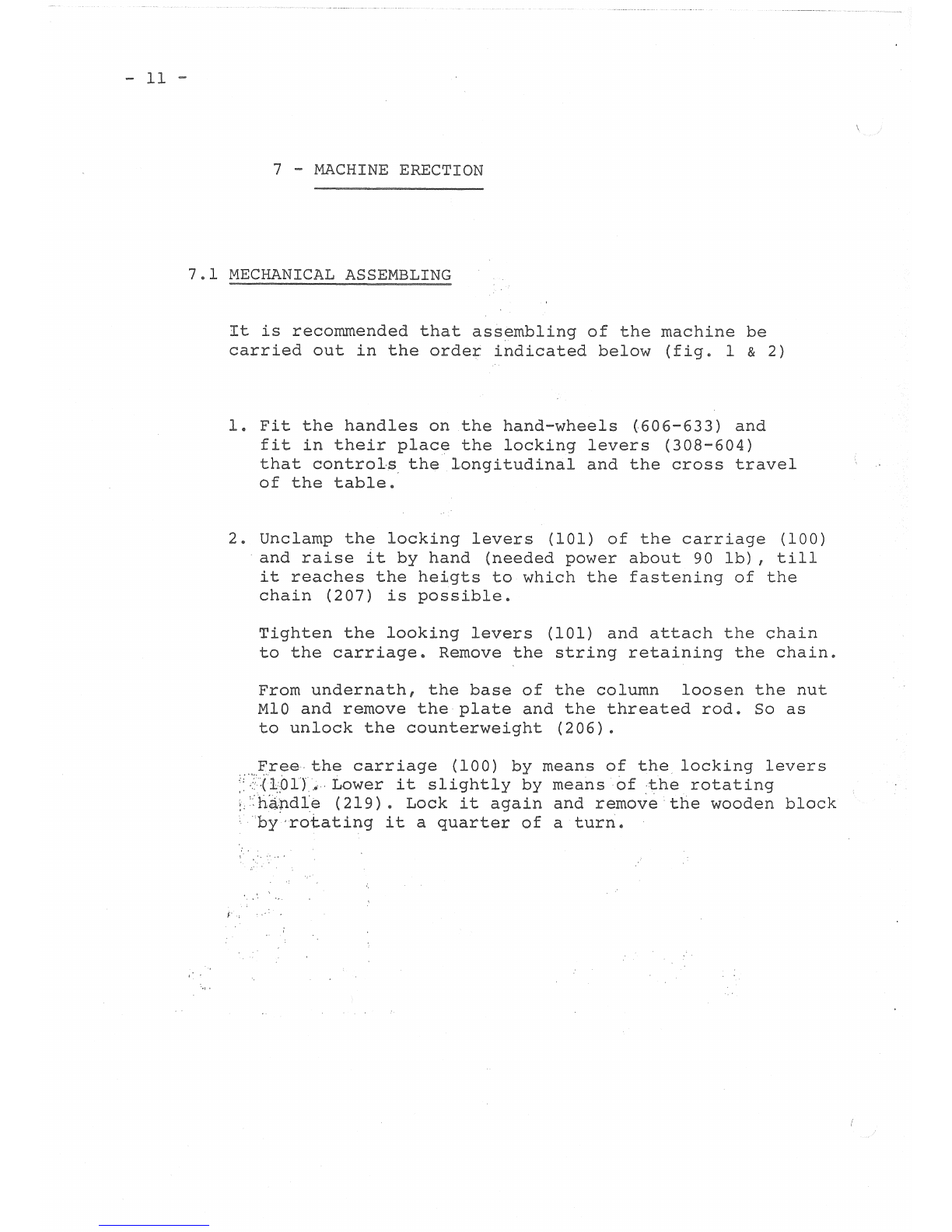

7.1

MECHANICAL

ASSEMBLING

It

is

recommended

that

assembling

of

the

machine

be

carried

out

in

the

order

indicated

below

(f

. 1 & 2)

1.

Fit

the

handles

on

the

hand-wheels

(606-633)

and

fit

in

their

place

the

locking

levers

(308-604)

that

controls

the

longitudinal

and

the

cross

travel

of

the

table.

2.

Unclamp

the

locking

levers

(101)

of

the

carriage

(100)

and

raise

it

by

hand

(needed

power

about

90

lb),

till

it

reaches

the

heigts

to

which

the

fastening

of

the

chain

(207)

is

possible.

Tighten

the

looking

levers

(101)

and

attach

the

chain

to

the

carriage.

Remove

the

string

retaining

the

chain.

From

undernath,

the

base

of

the

column

loosen

the

nut

MlO

and

remove

the

plate

and

the

threated

rod.

So

as

to

unlock

the

counterweight

(206).

Freethe

carriage

(100)

by

means

of

the

locking

levers

(

1:01)

...

Lower

it

slightly

by

means

of

the

rotating

:'handle

(219).

Lock

it

again

and

remove

the

wooden

block

by·rotating

it

a

quarter

of

a

turn.

219

206

606

--

13

-

*

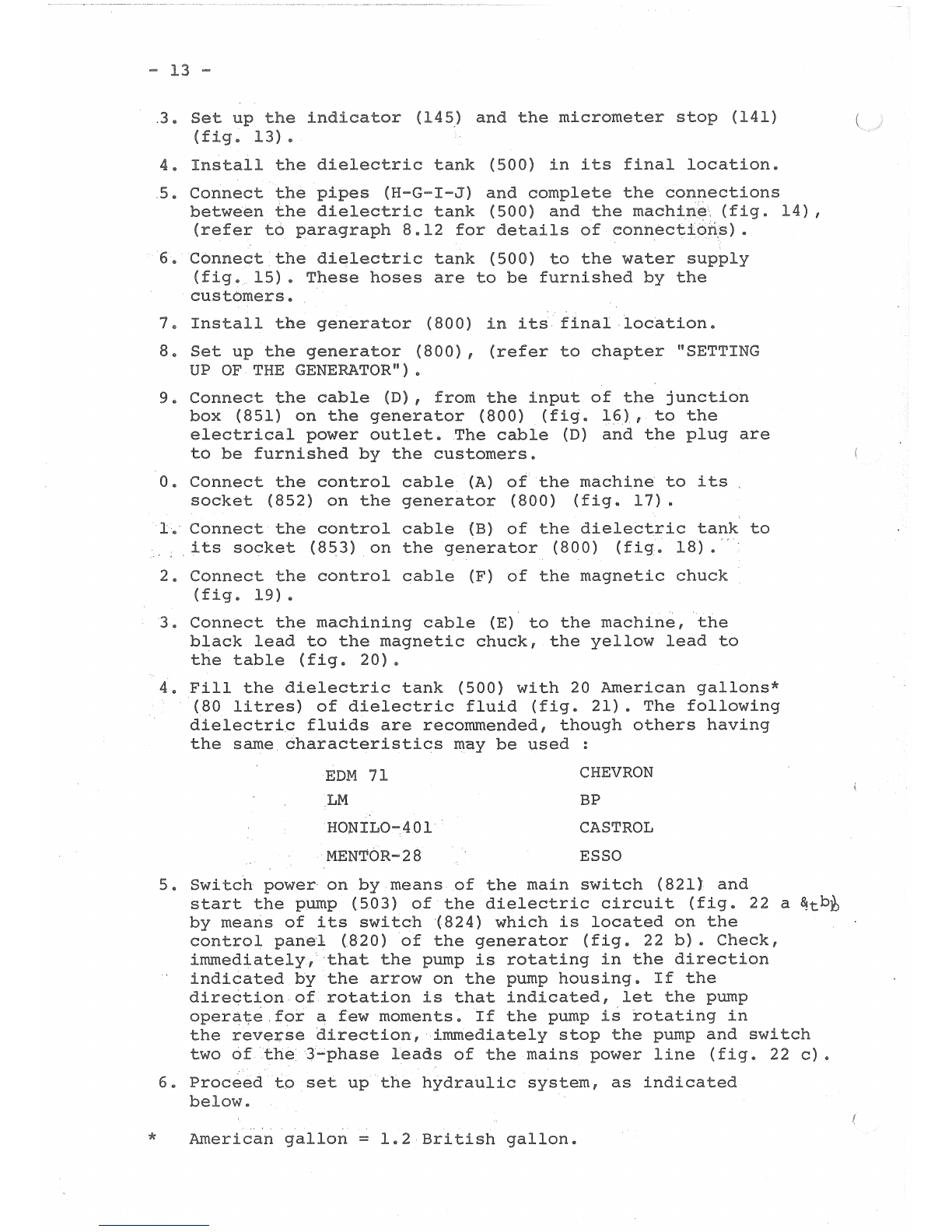

.3.

Set

the

indicator

(145)

and

the

micrometer

stop

(141)

(fig.

13).

4.

Install

the

dielectric

tank

(500)

in

its

final

location.

5.

Connect

the

pipes

(H-G-I-J)

and

complete

the

connections

between

the

dielectric

tank

(500)

and

the

machine

(fig.

14),

(refer

to

paragraph

8.12

for

details

of

connections).

6.

Connect

the

dielectric

tank

(500)

to

the

water

supply

(fig.

15).

These

hoses

are

to

be

furnished

the

customers.

7.

Install

the

generator

(800)

in

its

final.location.

8.

Set

up

the

generator

(800),

(refer

to

chapter

11

SETTING

UP

OF

THE

GENERATOR").

9.

Connect

the

cable

(D),

from

the

input

of

the

junction

box

(851)

on

the

generator

(800)

(fig.

16),

to

the

electrical

power

outlet

•.

The

cable

(D)

and

the

plug

are

to

be

furnished

by

the

customers.

0.

Connect

the

control

cable

(A)

of

the

machina

to

its

socket

(852)

on

the

generator

(800)

(fig.

17).

1.

Connect

the

control

cable

(B)

of

the

dielectric

tank

to

its

socket

(853)

on

the

generator

(800)

(fig.

18).

2.

Connect

the

control

cable

(F)

of

the

magnetic

chuck

(fig.

19).

3.

Connect

the

machining

cable

(E)

to

the

machine,

the

black

lead

to

the

magnetic

chuck,

the

yellow

lead

to

the

table

(fig.

20).

4.

Fill

the

dielectric

tank

(500)

wi

20

American

gallons*

(80

litres)

of

dielectric

fluid

(fig.

21).

The

following

dielectric

fluids

are

recommended,

though

others

having

the

same

characteristics

may

be

used

EDM

71

LM

HONIL0-401

MENTOR-28

CHEVRON

BP

CASTROL

ESSO

5.

Switch

power

on

means

of

the

main

switch

(821)

and

start

the

pump

(503)

of

the

dielectric

circuit

(fig.

22

a

& b

by

means

of

its

switch

(824)

which

is

located

on

the

control

panel

(820)

of

the

generator

(fig.

22

b).

Check,

immediately,

that

the

pump

is

rotating

in

the

direction

indicated

the

arrow

on

the

pump

housing.

If

the

direction

of

rotation

is

that

indicated,

let

pump

operate

for

a

moments.

If

the

pump

i~

totating

in

the

reverse

direction,

immediately

stop

the

pump

and

switch

two

the

3-phase

leads

of

the

mains

power

line

(fig.

22

c).

6.

Proceed

to

set

up

the

hydraulic

system,

as

indicated

below.

American

gallon

=

1.2

British

gallon.

145

Fig

15

Fig

13

Fig

14

800

:

852

: B

800

:

:

853

'

Fig

17

Fig

18

Fig

Hi

F

Fig

19

Fig

20

821

Fig

22

-

15

-

7.2

-

UP

OF

THE

HYDRAULIC

CIRCUIT

1.

Remove

the

metal

plug

fro~

the

free

end

the

rubber

pipe

but

leave

the

diaphragm

plug

on

rubber

pipe

(K)

(fig.

23).

2.

Fill

a

very

clean

can

wi

l.

5

American:

gallon*

( 5

li

tres)

of

hydraulic

oil.

We

recommend

the

use

of

the

following

oils

though

others

having

similar

characteristics

be

used:

ENERGOL-HYDRAULIC-40

CHEVRON

5 X

SPINESSO

-

34

VELOCIT 6

PENNOL

GC

-

34

TELLUS

OIL

-

15

PURFINA-HYDRAU

-

125/12

BP

Chevron

Esso

Mobiloil

Pennsylvania

Shell

Socal

3.

Insert

the

ends

of

the

rubber

pipes

(M

&

K)

into

the

can,

without

removing

the

diaphragm

plug

from

pipe

(K),

then

pour

a

small

quantity

of

oil

into

the

filter

(593)

(fig.

24).

4.

Start

up

the

pump

(590)

(fig.

25

a)

of

the

hydraulic

circuit

by

means

of

the

switch

(823)

(fig.

25

b)

located

on

the

control

panel

(820)

of

the

generator,

make

sure

that

the

direction

of

rotation

of

the

pump

is

correct

and

then

let

the

oil

circulate

for

at

least

two

hours

in

order

to

filter

out

any

impurities

it

may

contain.

5.

Having

let

the

oil

circulate

for

a

period

of

two

hours,

switch

off

the

hydraulic

pump

(590)

by

means

of

the

switch

(823).

6.

Remove

the

adhesive

tapes

covering

the

openings

(108-109-

125)

and

also

the

rubber

guard

placed

as

protection

over

the

nozzle

(104)

(fig.

26).

7.

Remove

the

diaphragm

plug

from

the

end

of

pipe

(K)

and

fit

this

rubber

pipe

onto

nozzle

(104)

(fig.

27).

Start

up

the

pump

(590)

again

by

means

of

tch

(823).

The

piston

(121)

will

then

rise

automatically

to

the

highest

point

of

its

stroke.

8.

As

soon

as

the

oil

within

the

indicator

tube

(107)

reaches

a

level

intermediate

between

5"

(125

mm)

(minimum)

and

5~

(

14

0

mm)

(maximum)

(fig.

28)

,

switch

off

pump

(

590)

of

the

hydraulic

circuit

by

means

of

switch

(823).

9.

Remove

the

rubber

guard

from

nozzle

(106)

and

quickly

insert

the

free

end

of

the

pipe

(M)

into

the

nozzle

in

order

to

prevent

loss

of

oil

(fig.

29).

10.

Connect

the

cable

)

of

the

servo-mechanism

to

the

socket

(108)

located

at

the

upper

end

of

the

oil-level

indicator

tube

(107)

(fig.

30).

*

American

gallon

=

1.2

Bri

sh

gallon

Fig

24

Fig

26

Fig

25

Fig

27

.-

Fig

30

fig

28

Fig

29

Table of contents