5

V.M.S01-R1 Low Noise Silent Box

INSTALLATION INSTRUCTION

3 Installation Instruction

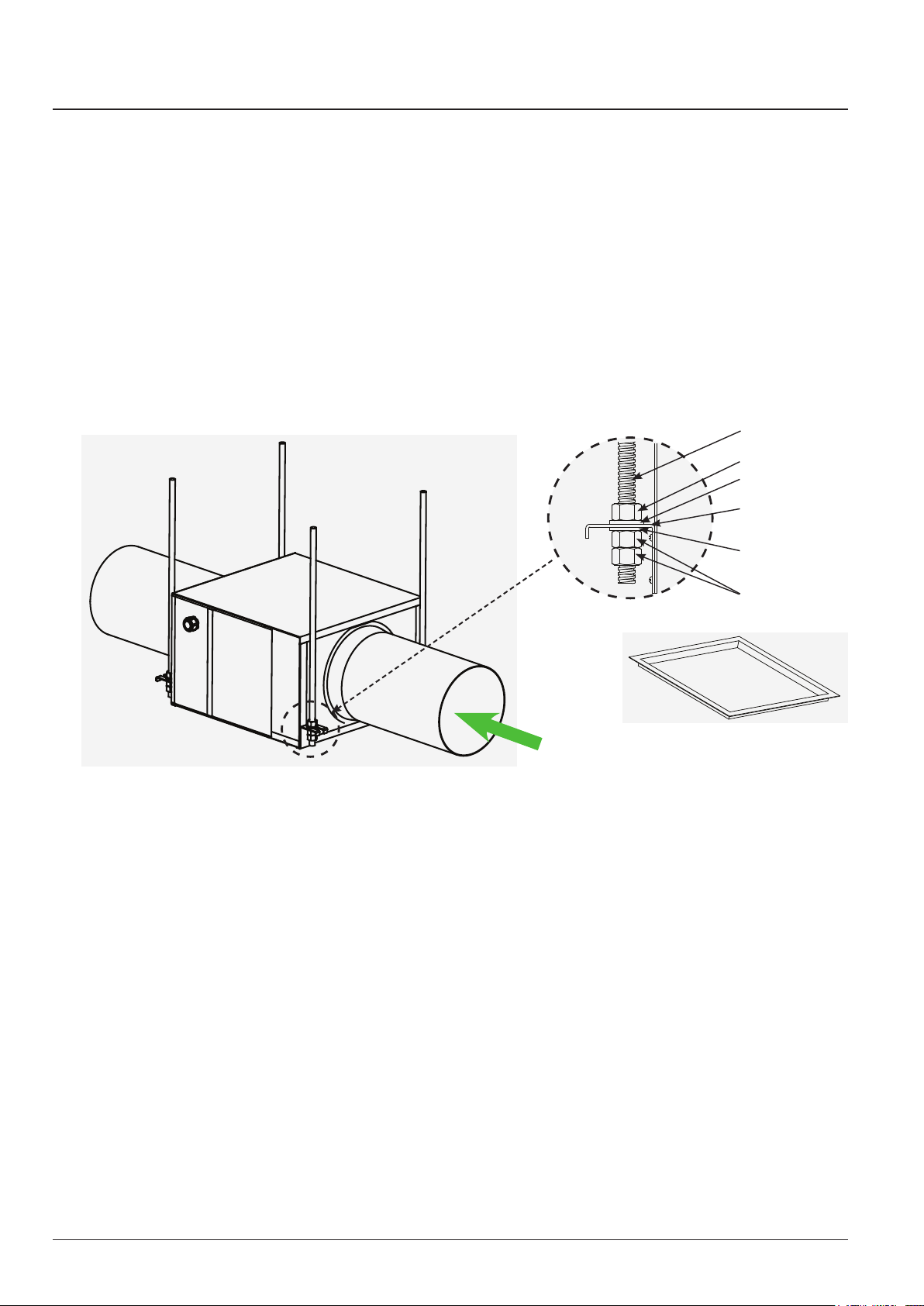

>Secured upon the strengthened foundations for

installation.

Be sure to take reinforcement measures if required for

sufcient instalIation strength.

Improper installation may cause accident

because of the falling of the product.

> Specied number and size of the bolts should be used

for hanging the unit and they must be tightened.

May cause injury due to insufcient strength.

>Beware of C.G. and weight when moving.

Hang only as the unit is normally assembled,

or else it may drop and cause injury.

>Electrical installations should be doneaccording to the

wiring diagram and localelectrical wiring rules of xed

wiring.

Unqualied wiring may cause electric shock or

re.

>Weight of duct should not load on the unit.

May cause injury due to malfunctions or

dropping.

>Grounding should be connected.

May cause electric shocks.

2

> Precautions must be taken to avoid the back-ow of

gases into the room from the open ue of gas or other

fuel-burning appliances.

May cause back-ow gases.

>Avoid a location with high temperatures.

TroubIe may be caused and the motor life may

be shortened.

>Do not instal l the fan where the humidity is high (85%

or higher) such as near a swimming pool, public hot

spring bathing area or outdoors.

>Avoid a location with too much oil fume.

>Install a fan protection device like a motor overload

breaker in the wiring.

>There should be an all poles switch with min.3mm

contact gap in the xed wiring.

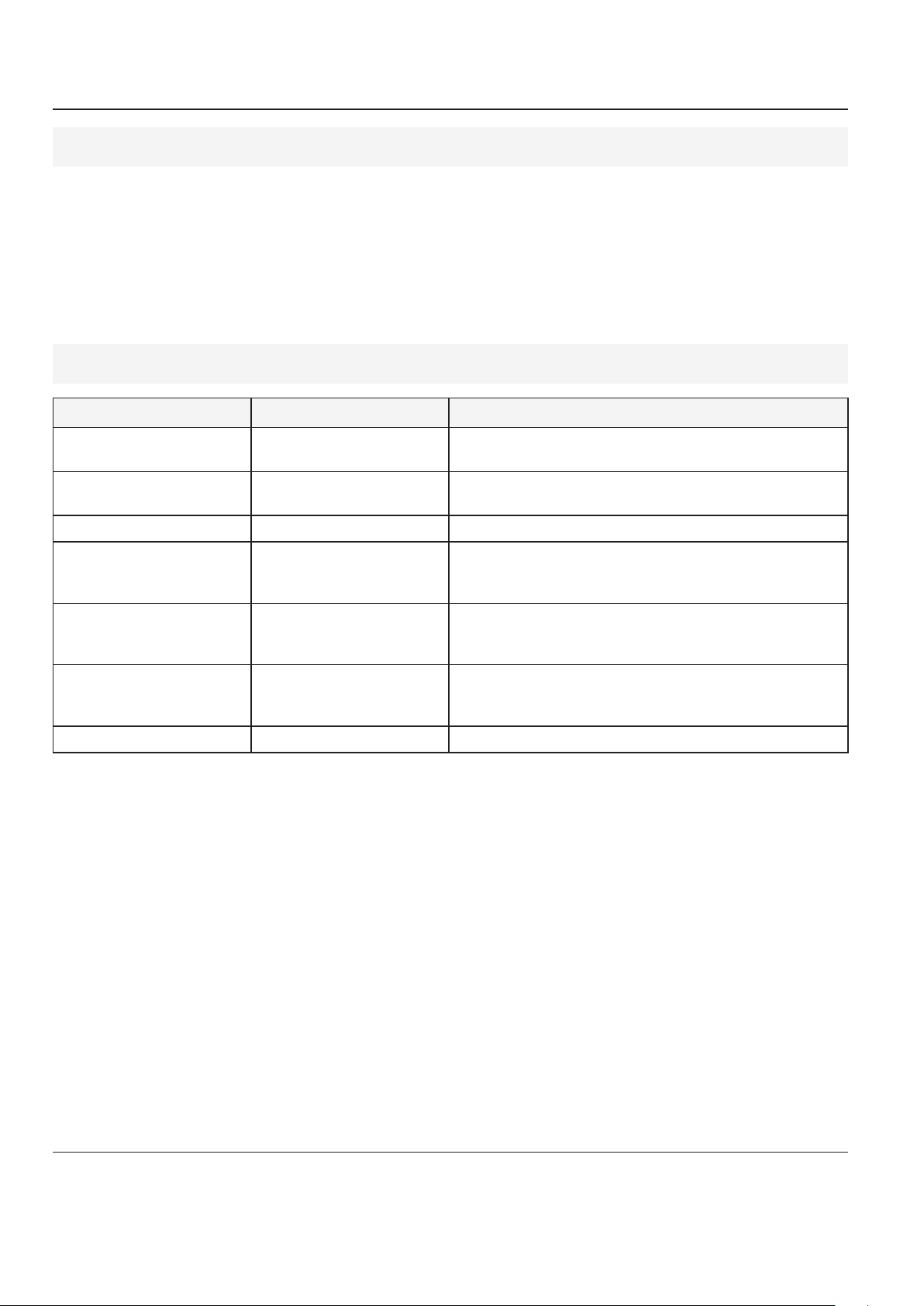

>Connect the duct avoiding the following cases.

1) Sharp bending angle;

2) Bended more than once;

3) Reduced diameter at the connection;

4) Bending near the discharge port and suction

port.

>During installation or maintenance, the power cord

should be lower than the outlet of terminal box.

May cause water ow along the power cord

into wiring box or scrape the power cord.

>The installation height of Cabinet Fan shall be more

than 2.3m above the oor.

Prevent accident

>The motor and frame should not touch any object.

May cause vibration and noise.

Caution:

1. When ventilating a room that use combustion equipment with a chimney, provide a suction port large enough.

The size of the suction port should be decided by the instruction of the combustion equipment. (Exhaust gas may

reverse into the room, which may cause carbon monoxide poisoning.)

2. For an exhaust duct to outdoor, attach a pipe hood to the end and keep at least a 1/100 slant downward. (To

prevent rain or frozen water entering.)

3. Heat insulation should be taken if there is dewfall outside of the adapter and frame when indoor heating in winter.