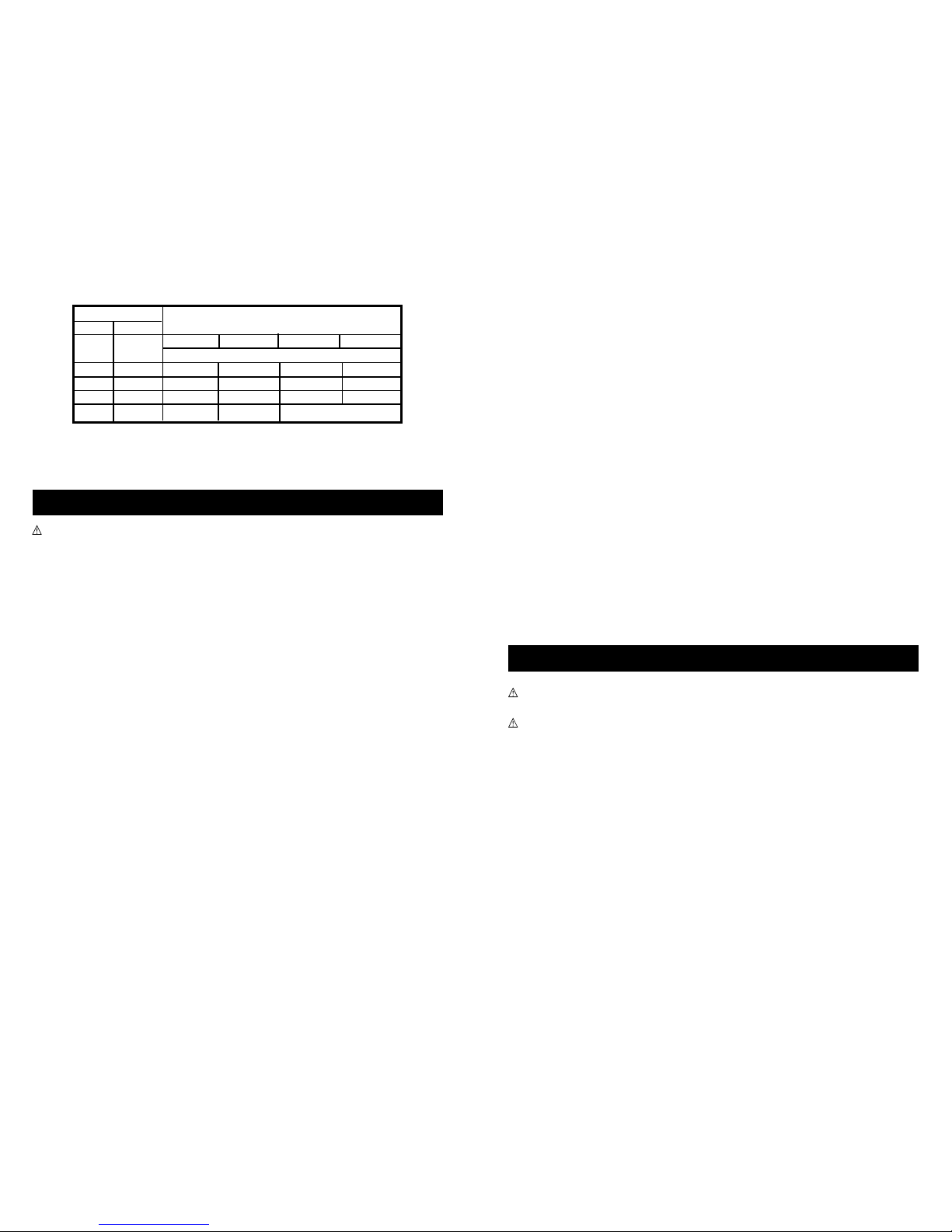

38

MAINTENANCE

Amp Volts

25 ft. 50ft 100ft 150 ft

1-5 120V 18 16 16 14

6-10 120V 16 16 14 12

11-12 120V 14 14 14 12

12-16 120V 14 12 Not Recommended

Table 1.

Minimum Gage For Power Cord

Total Length of cord in feet

Rating

AWG

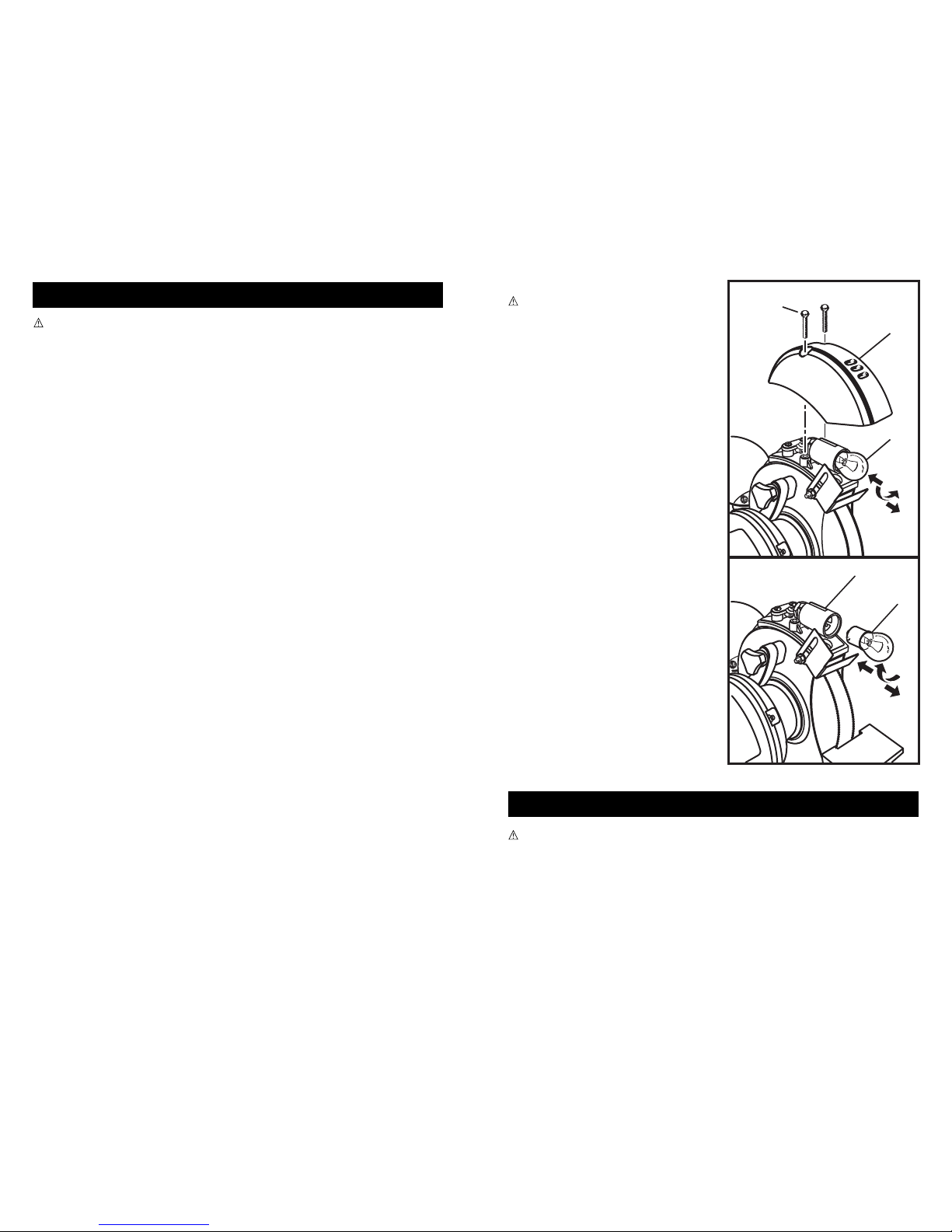

WARNING! ForYour Own Safety Read Instruction Manual before Operating Grinder

1.Always use guards and eye shields.

2.Do not over tighten wheel nut.

3.Adjust distance between wheel and work rest to maintain 1/16 inch or less separation as the

diameter of the wheel decreases with use.

4.Frequently clean grinding dust from beneath grinder.

5.Always keep hands and body away from grinding wheel at all times during operation.

6.Do not operate the tool in explosive atmospheres or in presence of flammable liquids or gases.

7.Donotoperate grinder untilit has been assembled and installed according to the"Assembly"

instructions of this manual.

8. Grinding wheels or other accessory must have a minimum speed (RPM) rating greater

than or equal to the "No Load" speed on the tool nameplate.

9. Inspect grinding wheel carefully for damage prior to use. Never use a damaged wheel.

Replace cracked wheel immediately.

10.Never use a grinding wheel larger or smaller than 6" in diameter for Model 2201994(60701240)

and 8" in diameter for Model 2201952 (60701250). Read and follow wheel manufacturer's

instructions for wheel mounting and use.

11.Grinding wheels can produce flying parks and other debris.Always wear eye protection,

protective clothing and make sure sparks are directed away from operator, others present or

flammable materials.

12.Never use the side of grinding wheel,use only the cutting edge.

13.Use only flanges furnished with the grinder.

14.Disconnect the power cord and wait for the wheel to come to a complete stop before making

any adjustments.

15.Always tighten adjustments knobs before use.

16.Keep arms,hands and fingers away from the grinding wheel to prevent severe cuts.

17.Always hold workpiece firmly when grinding. Use a clamp when practical.

18.Avoid kickback,always grind on the downward portion of the wheel.

SPECIFIC SAFETY RULES FOR GRINDERS

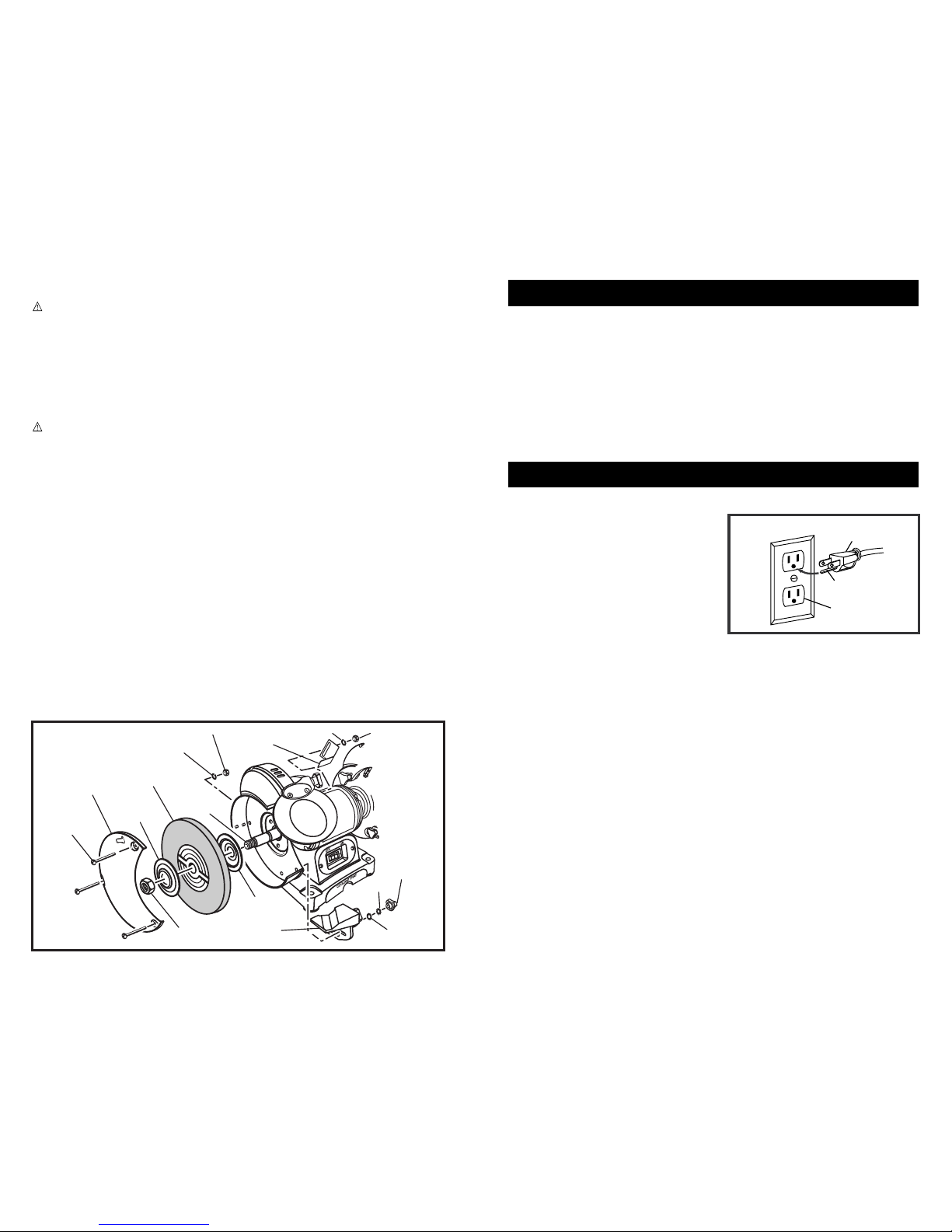

WARNING: RISK OF PERSONAL INJURY. Always disconnect tool from power source

before making any adjustments, installing or changing accessories.

CAUTION:Tool service must be preformed only by qualified repair personnel. Service or

maintenance performed by unqualified personnel could result in a risk of injury. When servicing

a tool,use only identical replacement parts. Follow instructions in the Maintenance section of

this service manual. Use of unauthorized parts or failure to follow Maintenance Instructions

may create a risk of electrical shock or injury.

1. Clean the tool housing,grinding wheel and grinding wheel guards after each use.

2. Keep the tool dry, clean and free from oil and grease.

3. Store the tool on a safe and dry place, out of reach of children.

4. Do not use cleaning agents or solvents that could attach the plastic parts of the tool

5. Turn the tool off immediately and do not operate,until repaired,if tool begins to make abnormal

noise, vibrations,produces smoke or burning odor.

6. During normal use, grinding wheels can become grooved,rough,rounded at the edges or

loaded with grinding debris. Use a dressing tool (available at most hardware stores) to restore

the smooth flat surface of the wheel.

Grinding

• Allow grinder to reach full speed before contacting the work piece to the grinding wheel or

other accessory

• Adjust the tool rest to accommodate large or unusually shaped workpieces.

• Always keep the workpiece moving across the face of the grinding wheel. Grinding

continuously on the same spot on the wheel will cause grooves to be worn into the wheel.

The wheel may crack or become damaged more easily, and grinding of other objects will

be difficult.

• If the workpiece becomes hot,dip it into water or oil to cool it.

• Always grind on the face of the wheel (around the diameter),NEVER on the sides. Side

pressure on grinding wheels can cause cracking and damage.

• If the face of the grinding wheel is worn unevenly,becomes grooved,or is no longer smooth

and flat,the wheel should be reshaped with a dressing tool (not supplied).

• If the diameter of the grinding wheel is no longer round,the wheel should be reshaped with a

dressing tool or replaced.

• If the surface of the wheel becomes loaded and dull with workpiece material,the wheel

should be cleaned with a dressing tool.

• After reshaping, always readjust the tool rests and spark arrestors.