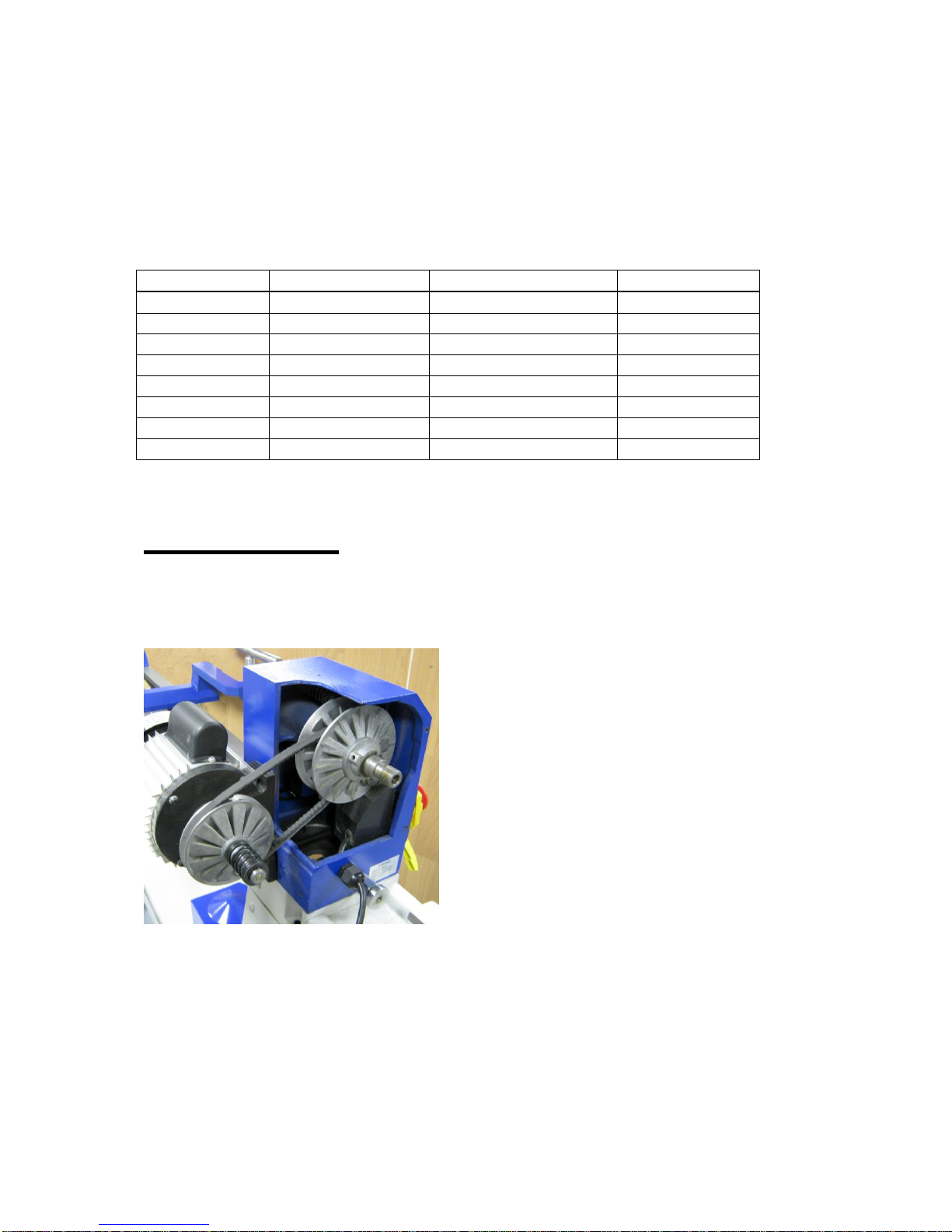

15. Disconnect the machine from power source before servicing and when

changing the drive belt.

16. To avoid accidental starting, make sure the switch is in the OFF position before

plugging in the mains cable.

17. Never leave the machine running unattended. Turn the power off. Do not leave the

machine until it comes to a complete stop.

18. Do not use any power tools while under the effects of drugs, alcohol or medication.

19. Always wear a face or dust mask if operation creates a lot of dust and/or chips.

Always operate the tool in a well ventilated area and provide for proper dust removal.

Use a suitable dust extractor.

ADDITIONAL RULES FOR LATHES

Never attempt to adjust any part of the workpiece whilst the lathe is still in motion. Wait until

the workpiece has come to a complete stop.

1. Ensure that chuck keys, tommy bars and similar items are removed before the lathe

is started.

2. Always stand to one side when you start the lathe so that if anything does fly off e.g.

a loose piece of bark, you will be out of the line-of-fire.

3. When mounting a new piece of timber, rotate the wood through 360oby hand to

ensure that it will not hit the tool rest or the bed of the lathe and then start the lathe at

its slowest speed. When you are certain that that the work is secure and not too out

of balance set the lathe to the normal turning speed.

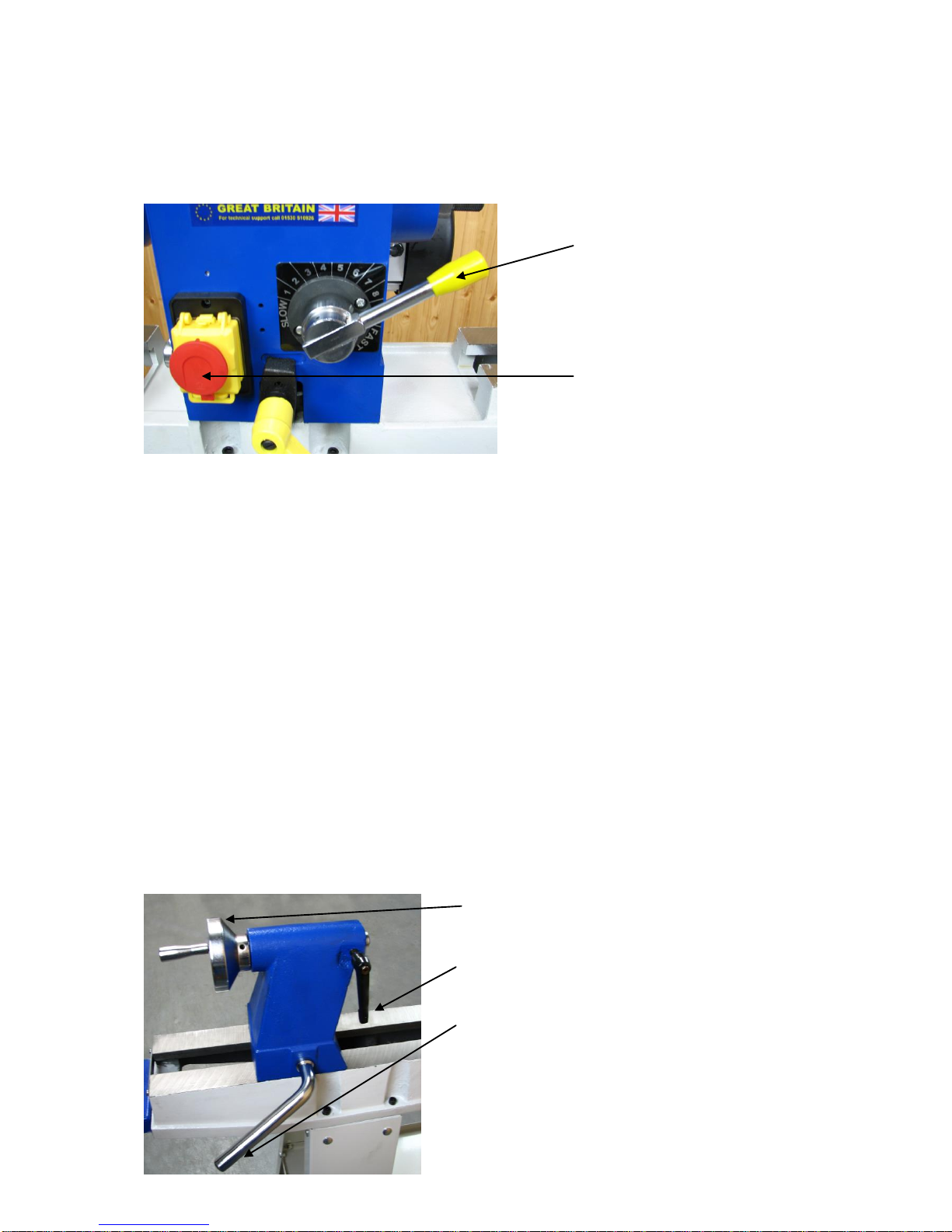

4. Always check the rotation speed before switching the lathe on to avoid the risk of

starting it whilst it is set to run at too high a speed.

5. The speed of the lathe must be adjusted to suit the size, balance, length and

condition of the timber being turned. The greater the diameter of the work, the slower

the rotation speed needs to be. If the piece you are turning is out of balance, then

you must start turning at a low speed, until it is balanced.

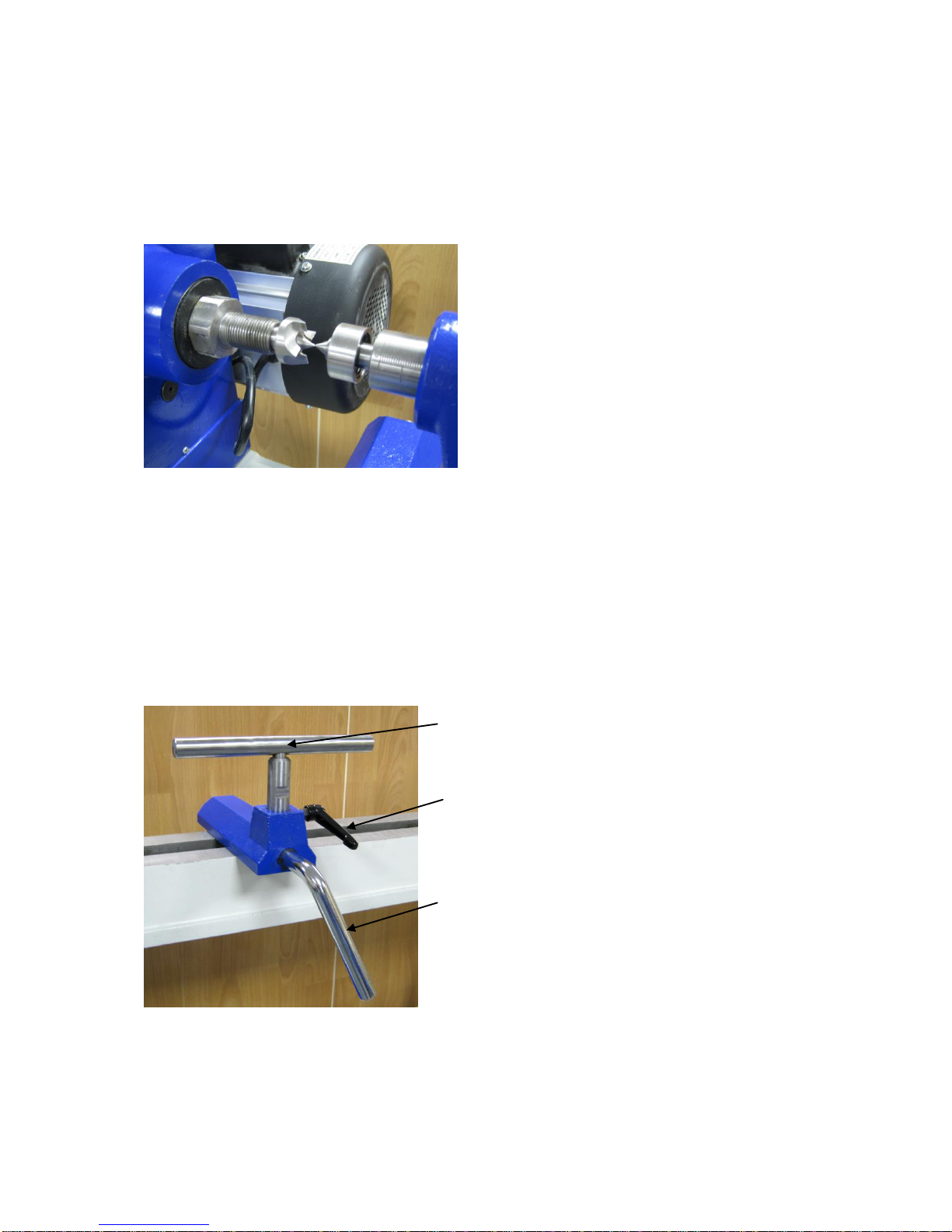

6. The tool must rest firmly on the tool rest before it is brought into contact with the

rotating wood and must never be lifted off the tool rest as long as it is in contact with

the timber.

7. Before sanding, polishing or doing anything else that brings your fingers close to the

work, remove the tool rest. Getting your fingers trapped between the tool rest and the

work will at least be very painful and may cause serious injury.

8. Never wrap the sandpaper of polishing cloth round the work. If it tightens up it will

pull your fingers into contact with the timber and may lead to serious injury.

Important:

Risk of Injury! Wear Eye Wear Ear

Never reach into Protection Protection

Moving parts