3

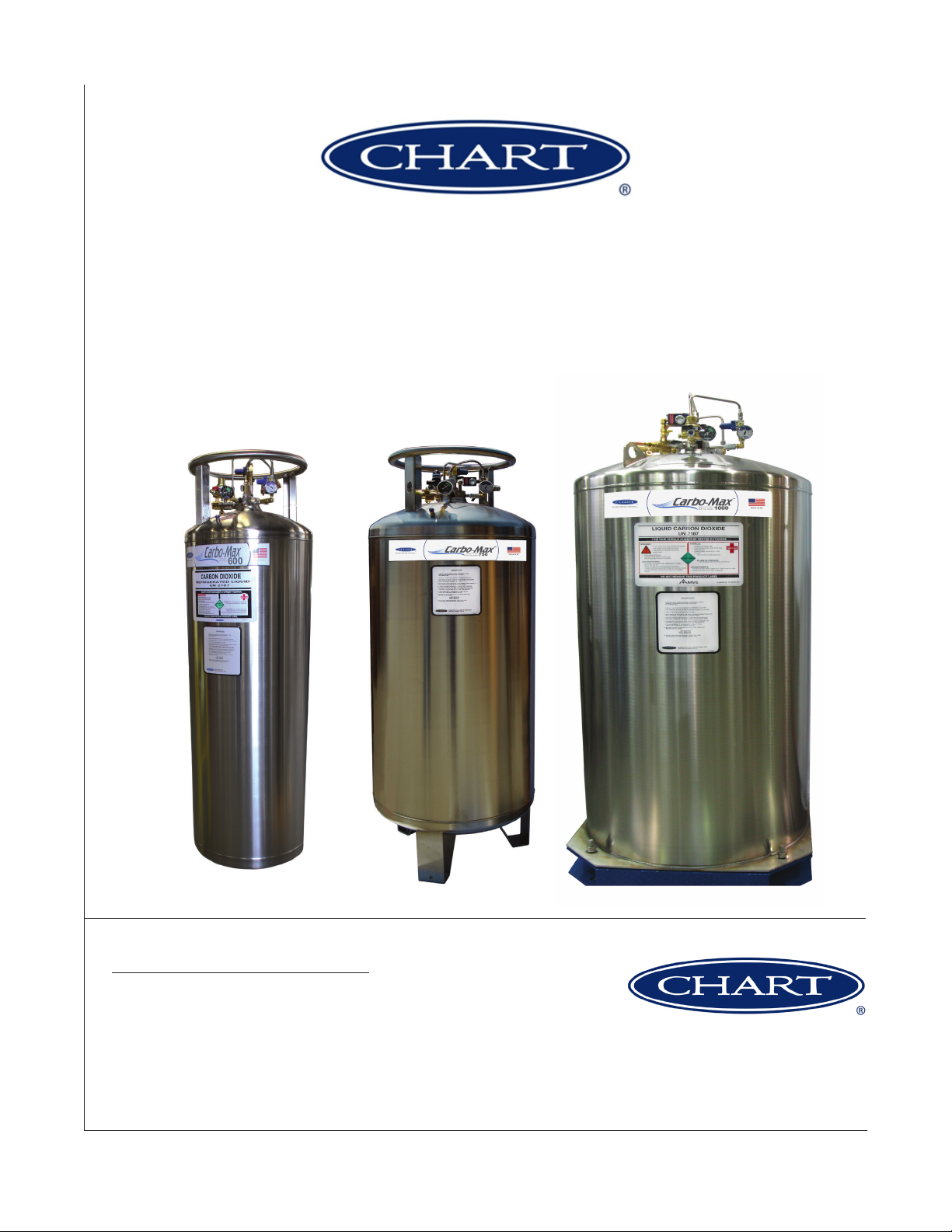

Product Manual - Carbo-Max®Bulk CO2Systems

General

The system described in this manual holds and dispenses

carbon dioxide (CO2) gas under pressure. All persons using

this equipment must read and understand the operation and

safety information contained in this manual and must be

adequately trained to operate this equipment.

Warning! Asphyxiation hazard. Carbon

dioxide gas can cause serious

injury or death. Do not breathe

CO2gas. Avoid entering tank

area if a leak is suspected and

thoroughly ventilate area.

Warning! Frostbite hazard. Contents are

extremely cold and can cause

frostbite. Do not touch liquid,

ice, or ice crystals on or near

tank. Stay away from escaping

gas.

Warning! CO2vapors in air may dilute

the concentration of oxygen

necessary to support or sustain

life. Exposure to such an oxygen

decient atmosphere can lead

to unconsciousness and serious

injury, including death.

CO2gas is a colorless, odorless, tasteless gas that displaces

oxygen and does not support life. The gas is dicult to

detect without the assistance of special equipment. Avoid

breathing or contacting CO2in gas, liquid or solid form.

Exposure to concentrations of less than 5% can cause

physical symptoms including unconsciousness, injuries or

death. Even low concentrations of CO2can cause:

• Dizziness, headaches, nausea or disorientation

• Increased respiration or heart rate

• Shortness of breath or rapid suocation

CO2is heavier than air and can collect in low areas such

as basements, stairwells, and conned spaces. Avoid entry

into areas where CO2leaks or high concentrations of CO2

are suspected. Enter those areas with caution only after they

have been thoroughly ventilated.

Whenever the tank is inside a building its safety relief circuit

must be connected to an outdoor vent typically in the ll box.

The ll box and/or vent must never be located in or above

any below-ground spaces or stairwells. The tank must not

block emergency exits, aisles, re suppression equipment

or utility boxes or accesses. CO2lines or hoses must be

located away from trac areas and heat sources and must be

protected from potential causes of damage. All connections,

lines, and components must be leak-free.

This equipment should be installed and serviced only by

professional agents who are qualied to work with CO2

and the mini-bulk liquid CO2storage tanks. They should be

familiar with all pertinent safety procedures.

Handle liquid so that it will not splash or spill. Protect your

eyes and cover skin where the possibility of contact with

liquid CO2, cold pipes and equipment, or cold gas exists.

Safety goggles or a face shield should be worn at all times

when connecting to ll connections, while lling the tank

and during disconnection from the ll connection. Clean,

insulated gloves that can be easily removed and long sleeves

are recommended for arm and hand protection. Cuess

trousers should be worn over the shoes to shed spilled liquid.

Equipment Safety and Handling

Note: A bulk CO2storage tank is an ASME coded

tank designed for permanent installation.

It is not designed to meet DOT regulations

and must not be transported when

containing liquid CO2. It must be shipped,

stored and used in a vertical position to

avoid structural damage. When loading a

tank onto or o of a truck, use a power lift

gate, crane, or an inclined ramp. Never

attempt to manually lift or slide a tank on

or o a truck bed.

CO2Monitoring Systems

The Analox 50™and Ax 50™Carbon Dioxide Analyzers

are precision instruments that provide continuous, accurate

monitoring of CO2levels to ensure a safe working

environment for your employees, suppliers and yourself.

Safety