Checkmate TR3 User manual

TR3 Tripod

User Manual

ANSI Z359.18-2017

TR3 Tripod

Issue 0

TR3 Tripod

User Manual

Page

INDEX

1.0 Introduction to TR3 &

Scope of Use

2.0 Assembly

3.0 Confined Space Recommendations

4.0 Storage, Issue & Inspection

5.0 Quality, legislation & Exclusions

6.0 Installation, Use, Opening/Clearance

Requirements & Fall Clearance

7.0 Warning! & Compatibility

8.0 Labeling

9.0 Record Card

3

4 - 6

7 - 8

9

10

11 - 12

13

14

15

WARNING!

Working at height is dangerous. This product is designed to reduce

the risk of working at height, by providing protection in the event of a

fall to reduce the risk of injury. The product must be used as intended,

and the user must be trained, competent, and aware of the correct

usage and limitations of the product. The user MUST be supplied

with the manufacturers user instructions and MUST read and fully

understand and follow the instructions within. The user must also

comply with OSHA and local safety regulations.

Failure to follow these guidelines could result in injury or death.

The Checkmate TR3 meets the requirement of ANSI Z359.18-2017, A10.32.12,

OSHA 1910 and OSHA 1926 Subpart M

Issue 0

TR3 Tripod

User Manual

Introduction to TR3 & Scope of Use

PAGE 3 Section 1.0

TR3 Tripod

The TR3 Tripod has been designed for your safety. The TR3 is supplied as a passive fall arrest device. The

device is designed to be used above structures and confined entry areas where other attachment is not

possible. The TR3 is totally portable and is therefore a temporary anchorage. In the event of a fall the

Tripod will provide a tested anchorage and a secondary anchorage for rescue if required. If in any doubt

please clarify application with Checkmate Technical Support.

Head Pulley x 2

Locking tabs x 3

WG-01

Mounting Bracket

Leg Pins x 3

FABX2R or

FABXLR

Swivel Feet x 3

Anti-splay

Webbing

Eyebolt Attachment x 2

Position A = Max extension with bracket fitted

Position B = Min extension with bracket fitted

Position C = Min extension - no bracket (connect to eyebolt only)

Position HTHED

A 94 87 56

B 71 63 39

C 71 63 39

All measurements in inches

HT = Height to top of TR3 crown

HE = Height to bearing point of eyebolt

D = Diameter to inside of feet

For opening and clearance requirements please

see p.g. 11

Principal Materials:

Aluminum, stainless steel, galvanized steel,

powder coated steel, polyester, nylon

PART NO. DESCRIPTION

32200 Height adjustable tripod (TR3) & carry bag

32208 Tripod carry bag only

32205 Tripod (TR3), tripod bag, 65ft work winch (WG-01), winch adaptor bracket (WG-02), 60ft galvanized SRLR (FABX2R) &

SRLR adaptor bracket (FABXR-DB)

32206 Tripod (TR3), bag, 65ft work winch (WG-01), winch adaptor bracket (WG-02), 100ft galvanized SRLR (FABXLR) & SRLR

adaptor bracket (FABXLR-DB)

32207 Tripod (TR3), bag, 65ft winch (WG-01) & winch adaptor bracket (WG-02)

Model Designation

Issue 0

TR3 Tripod

User Manual

Assembly

Page 4 Section 2.0

NOTE:

The Checkmate TR3 and FABX2R/FABXLR are designed for rescue use only. If the device is to be used as

a primary man riding winch Checkmate recommend the use of a secondary rescue device. The device is

designed to be used in free running mode and in the event of a fall the user can be rescued via the winching

facility. For advice or further information contact Checkmate.

Fig. 1

Unpack tripod and stand upright.

Fig. 2

Release leg pins and slip up to

desired height.

Fig. 3

Lock individual legs with pins.

Fig. 4

Open legs out and ensure sprung

loaded tabs lock out in position.

Fig. 5

Check anti splay webbing is

secure.

Fig. 6

Ensure feet are sitting flat on the

ground as shown when used on

hard ground, or fully folded back

for use on soft ground.

Spiked Feet

Flat Feet

Issue 0

TR3 Tripod

User Manual

Assembly

Page 5 Section 2.0

Fig. 7

Fix FABXR-DB or FABXLR-DB with

two supplied pins.

Fig. 8

Insert FABX2R or FABXLR into

the bracket as shown seating the

cable end in the bracket

Fig. 9

Secure with M12 bolt.

Fig. 10

Pull cable up to tripod head and

insert hook through central hole.

Fig. 11

Slide sprung loaded pulley to right,

insert cable in pulley groove, and

release pulley.

Fig. 12

The device is now ready for use.

Follow the instructions for safe

use of other equipment.

Folding:

Reverse the above procedure, ensuring that the sprung loaded leg locking pins are released by hand before

folding each leg. It is acceptable to leave the FABX2R fitting in the FABXR-DB Bracket when removing from

the TR3.

Issue 0

TR3 Tripod

User Manual

Assembly

Page 6 Section 2.0

Fig. 1

Slide the bracket (WG-02)

which is fixed to the winch

onto the tripod leg.

Fig. 2

Align the holes in the bracket

with the holes in the tripod leg

and insert a detent pin.

Fig. 3

Insert the second detent pin.

Fig. 4

Pull cable up to tripod head

and insert hook through

central hole.

Fig. 5

Slide sprung loaded pulley to

right, insert cable in pulley

groove, and release pulley.

Issue 0

TR3 Tripod

User Manual

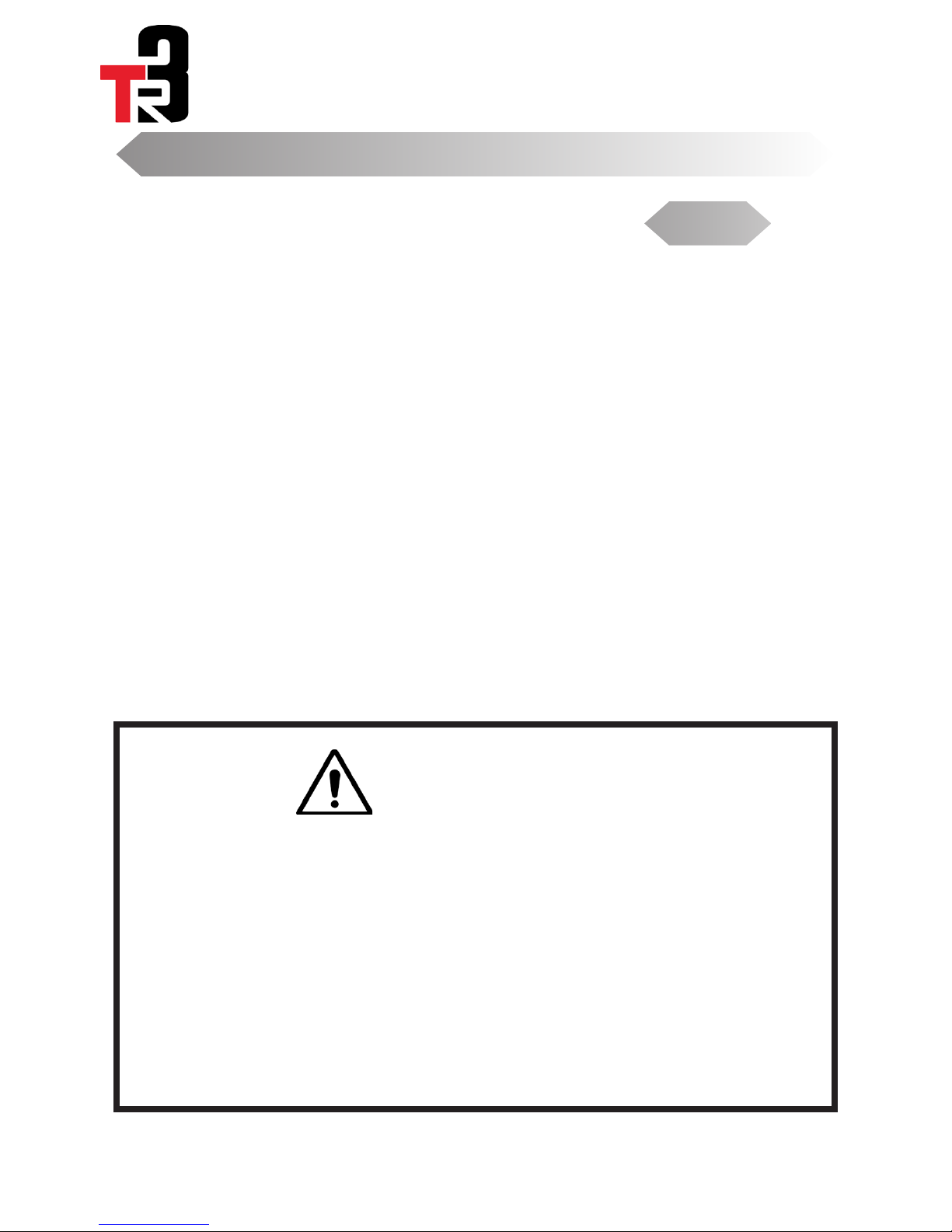

Page 7 Section 3.0

Confined Space

Recommendation Option 1

Primary Fall Arrest Device with Secondary Backup

When entering a confined space when a fixed access system is installed the user should use:

1 x Tripod (TR3)

1 x SRLR (FABX2R or FABXLR)

1 x SRLR adaptor bracket (FABXR-DB or FABXLR-DB)

The FABX2R/FABXLR should be in free run mode and in the event of a fall the device will automatically lock

on and then the winch can be engaged.

PLEASE NOTE THAT THE FABX2R/FABXLR IS NOT INTENDED TO BE USED AS A CONTINUOUS

WINCH, ONLY AS A RETRIEVAL DEVICE IN EMERGENCY SITUATIONS.

FABX2R or

FABXLR

Issue 0

TR3 Tripod

User Manual

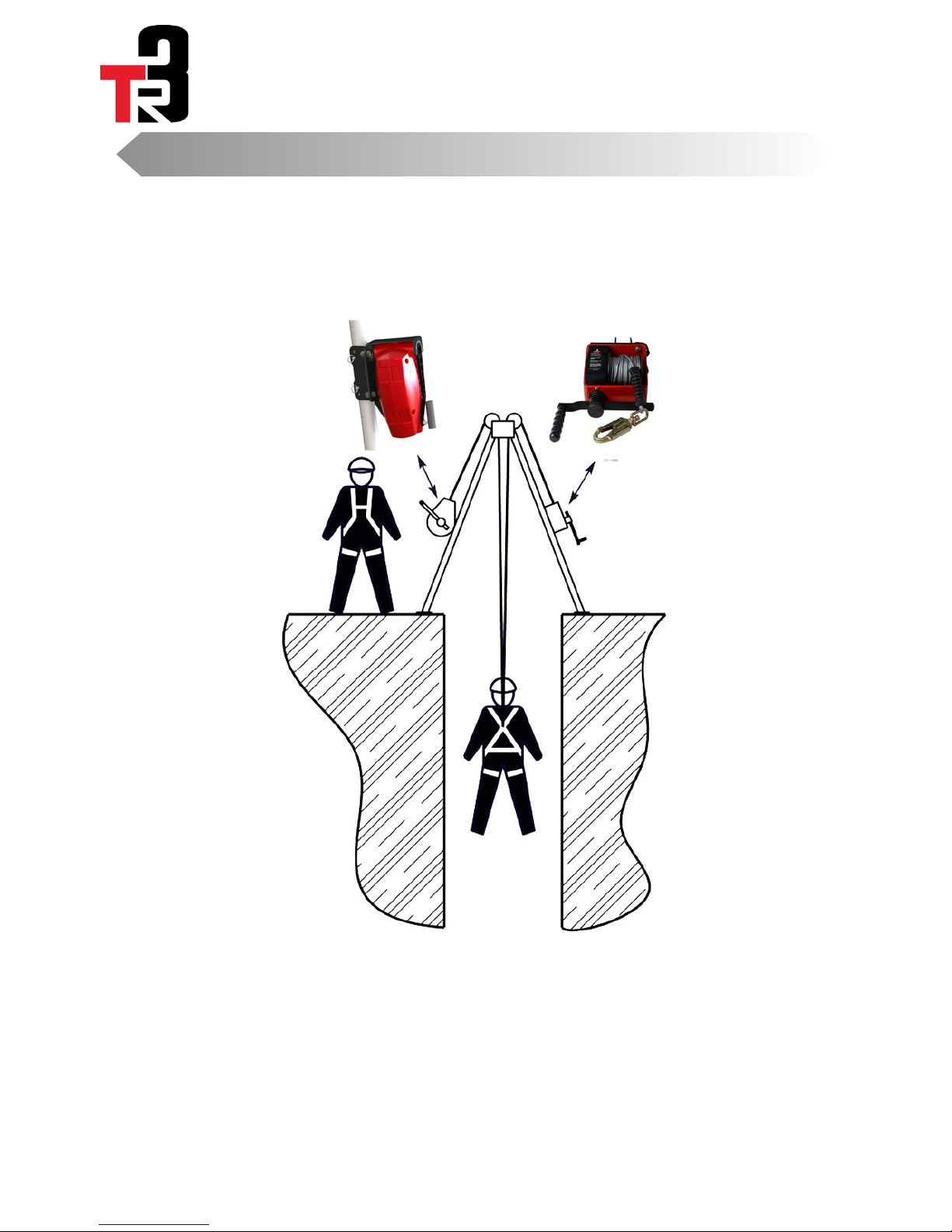

Page 8 Section 3.0

Primary Raise and Lower Device with Secondary Backup

Confined Space

Recommendation Option 2

FABX2R or

FABXLR

WG-01

When entering a confined space when there is no fixed access system and there is a need to lower the

user down under control, you should use:

1 x Tripod (TR3)

1 x SRLR (FABX2R or FABXLR)

1 x SRLR adaptor bracket (FABXR-DB or FABXLR-DB)

1 x Work winch (WG-01)

1 x winch adaptor bracket (WG-02)

The WG-01 is your primary lowering device and in the event of a fall the FABX2R/FABXLR will

automatically lock on and the winch can be engaged.

Issue 0

TR3 Tripod

User Manual

Storage, Issue & Inspection

Page 9 Section 4.0

Storage

Storage in a central protected location allows assurance of inspection on issue and return

This tripod should be stored in a clean dry place where it can be protected from damage by chemical attack and sharp

objects . It should be stored with its instructions and record card at all times.

After use return to the store, Never leave the device lying around site.

Cleaning

To clean the tripod a mild detergent can be used with warm or cold water and then dry with a clean soft cloth.

Issue

This and associated equipment must be visually inspected by a competent person when initially delivered to site, there

after the product must be inspected before and after use. A record card is printed on the reverse of this manual and

should be updated after each routine inspection. Follow the points laid down in the section headed “Inspection” without

deviation.

The supervisor must ensure that the equipment is being used correctly and that the user is aware of its safe use and

inspection. Additionally the supervisor must ensure that the site to which the device is to be used has been approved fit

for use and is in a good condition.

Inspection & Maintenace

Inspect the device for corrosion or damage.

Check the head and leg pins for signs of wear or damage and replace wear necessary.

Pay attention to condition of leg tubes for damage, bends and hole wear.

Check the sprung loaded locking tabs self-engage when the legs are opened.

Check the sprung loaded pulleys return to central position when slid to the side and released.

Check the condition of the pulley and eyebolt attachment. Pulleys should run free, but the eyebolt must be fixed.

Check rubber pads are fitted and not missing on feet.

Check the condition of the entire length and buckle of the anti-splay tape for damage.

Check the device opens and closes fully.

Tripods which fail inspection must be removed from the field of service immediately and marked out of service. If

irreparable the Tripod must be destroyed and discarded to prevent further use.

Ensure that device certification is current before use, the device must have been serviced within the last 12 months and

3 months if used in corrosive or off-shore environments.

If for any reason the inspection of this device shows signs for concern or doubt then the device must be

quarantined and removed from service immediately. Qualification should be sought from the supervisor and if

still concerned the device must be sent to the supplier, an approved service agent or the manufacturer for

service and re-calibration.

This device must only be serviced by the manufacturer or a trained and competent individuals

approved by the manufacturer.

Never attempt to service this device or tamper with its function in any way.

Issue 0

TR3 Tripod

User Manual

Quality, Legislation & Exclusions

Page 10 Section 5.0

5.1 Quality

All Checkmate products are

manufactured under ISO 9001 and

to the highest standards. The scope of

use within the certification held allows

Checkmate to design, manufacture and

test Personal Protection Equipment.

Horizontal tensile test machine,

abrasion testers and dynamic drop test

rig are just part of the full range of test

facilities used to ensure ultimate safety

of our product range.

All Checkmate systems must only be

installed by Checkmate personnel or an

approved installer. Strict training is given

and written exam are completed before

full certification can be given to installers.

5.2 Legislation and Standards

The TR3 Tripod has been designed

to meet the requirements of ANSI

Z359.18:2017, A10.32.12,

OSHA 1910 and OSHA 1926 Subpart M

For clarification on any certification

issues contact Checkmate.

5.3 Exclusions

Checkmate holds global product

liability cover for your safety.

Checkmate will NOT however be

responsible for:

Users who are out of the scope of any

written manuals of training given.

Any systems that have NOT been

inspected under the current legislation.

Operators who do not use load limiting

PPE.

Devices that have been damaged.

The Max weight has been exceeded.

Devices that have NO serial number

markings, and the manufacturers name.

Checkmate Lifting & Safety Ltd present.

Rescue and Risk Assessment

Suitable planning and risk assessment

should be carried out by the user and or

supervisor. A suitable rescue plan and

equipment shall be in place to minimise

post fall suspension time. Checkmate

can offer a complete range of rescue

equipment to suit your requirements.

Issue 0

TR3 Tripod

User Manual

Installation & Use

Page 11 Section 6.0

Installation

As a minimum, when in use the tripod must always be

installed with either load lifting equipment i.e hand winch

and/or load limiting device i.e. SRLR.

The device must not be used where the following

hazards may endanger the user or prevent the efficient

operation of the system.

The area below the device must be free of obstruction

which may obstruct the movement of the user.

The environment must be free of heavy solvents or acids

that will degrade the device, lanyard or the hook.

The structure to which the device stands must be in good

condition and suitable for use

The webbing anti splay strap must be fitted and tensioned

prior to use, check all pins are inserted and secured.

Only install on flat level ground on a stable surface. Ensure

footing is stable and can support the intended load. (see

below)

The mounting surface onto which the tripod will be installed

must meet the requirements of ANSI Z359.18:2017 and

the criteria stated below:

Fall arrest:

The mounting surface on which the tripod will stand,

selected for personal fall arrest systems (PFAS) must be

capable of withstanding a static load of at least 3,600lbs

(16kN) (1) in all directions permissable by the PFAS

when certification exists ( see ANSI Z359.18-2017 for

more certification details). In the absence of certification

the mounting surface must be capable of withstanding

5,000lbs (22.2kN) (2) of static force. If more than one

tripod is to be installed on the mounting surface for

simultaneous fall arrest use, the static strengths (1) & (2)

must be multiplied by the number of systems attached to

the mounting structure.

Work Positioning:

The mounting surface must be capable of withstanding

a static force of 5,000lbs (22.2kN) in all directions

permitted by the work positioning surfaces.

Material Handling:

The mounting surface must be capable of withstanding a

static load of 2,500lbs (11.1kN) in all directions permitted

by the handling equipment.

Rescue:

The mounting surface must be capable of withstanding a

static load of 2,500lbs (11.1kN) in all directions permitted

by the rescue equipment.

The minimum strength of the TR3 is 5,000lbs (22.2kN)

Use

Fall Protection

Check the anchorage to ensure it has not been damaged,

follow the inspection routine laid down in this manual.

The device will arrest a fall normally within the specification

of the device attached in normal use the anchorage can

only be used with devices or systems where a shock

absorber or device with shock absorption is used limiting

arrest forces to below 1,800lbs (8 kN).

Connection is either in the leg plane from the mounting

bracket or vertically downward from the anchorage

points. For details please ask your local Checkmate

representative.

The unit is designed to used within systems that limit the

force in a fall to less than 1,800lbs (8kN) on the user.

Rated for one worker, or two workers during assisted

rescue. Each worker must attach to a separate connection

point.

Worker capacity range (including all equipment): 130-

310 lbs. If used in assisted rescue, maximum combined

worker capacity is 620 lbs. If used for equipment hoisting,

maximum

equipment weight is 551 lbs./250 kg.

Materials Handling

The TR3 may be used for materials handling with a

maximum load of 550lbs (250kg) and a suitable winch.

Ensure that the TR3 is not subjected to any shock loads,

and that the stability of the TR3 is not compromised. Do

not use the TR3 for materials handling and PPE at the

same time.

Do not attach more than one personal fall arrest system

to the tripod unless certified for such purpose.

Opening & clearance requirements

Maximum hole diameter (tripod max extension): 36”

(3.75ft)

Maximum hole diameter (tripod min extension): 21”

(1.75ft)

Minimum foot to opening distance: 9”

Minimum head clearance: 48”/4ft (ground to obstruction

distance)

Maximum tripod footprint diameter: 56” (4.7ft)

It is imperative that proper maintenance of adequate

clearance around and within the tripod is upheld to

provide unrestricted movements in, through, and

around the tripod and minimizing tripping or other

events which may result in dislodging the tripod.

For fall clearance requirements see page 12.

Issue 0

TR3 Tripod

User Manual

Fall Clearance

Page 12 Section 6.0

Issue 0

TR3 Tripod

User Manual

Warnings! & Compatability

Page 13 Section 7.0

Warnings!

Read and understand manufacturers instructions before

inspection, installation or use of this product. Do Not use if

you weigh more than 310lbs (141kg). Only use approved

equipment with Tripod. If there are any points in this manual

that you are unsure of seek a competent, trained person to

advise you before using.Seek medical advice from a doctor

before using this product if, you have sustained a spinal

injury, suffer from a neck or back complaint, or you are taking

prescription medication. Never use if you are under the

influence of alcohol or recreational drugs. Extra care should

be taken if welding whilst using this product, protect the device

from splatter and heat at all times. The TR3 tripod must only

be installed on flat level ground with a stable surface using

the installation procedure provided within this document. If

subjected to the forces of arresting a fall, the tripod must

be removed from service immediately and inspected by an

authorised person.

Never attempt to:

• Alter the device;

• Misuse the equipment;

• Combine components or subsystems, or both, which

may interfere with the safe function of each other;

• Expose the equipment to chemicals which may

produce a harmful effect, consult the manufacturer if

in doubt;

• Use the equipment around moving machinery and

electrical hazards;

• Use the equipment around sharp or abrasive surfaces

• Use the equipment without the minimum protection

equipment installed to the tripod i.e hand winch and/

or SRLR.

Service temperature Range: (-30°F / -34.4°C) - (130°F /

54°C)

NOTE: The Checkmate TR3 and FABX2R/FABXLR are

designed for rescue use only. If the device is to be used as

a primary man riding winch Checkmate recommend the use

of a secondary rescue device. The device is designed to be

used in free running mode and in the event of a fall the user

can be rescued via the winching facility. For advice or further

information contact Checkmate.

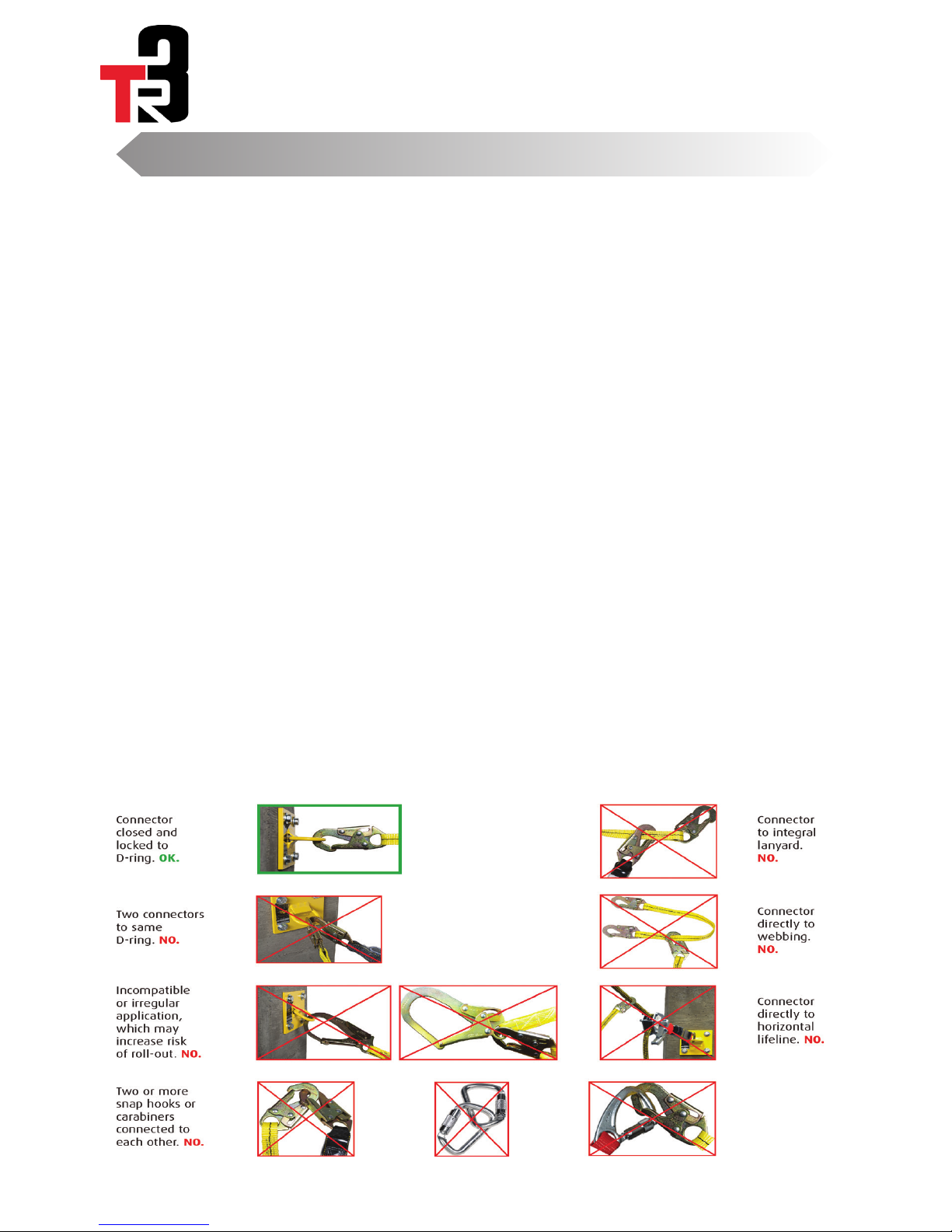

Compatibility

The tripod is suitable for fall arrest when used with a Full

Body Harness (approved to ANSI Z359.11-2014), suitable

shock absorbing lanyards (approved to ANSI Z359.3-2013),

suitable non-shock absorbing lanyards (approved to ANSI

Z359.3-2017)

Compatible SRLs and SRLRs for recovery (approved to ANSI

Z359.14-2014). Hand winch (approved to ANSI Z359.4)

hand winch must be used with secondary back up. This unit is

not suitable for use in explosive atmospheres. When making

connections with TR3, eliminate all possibility of roll-out. Roll-

out occurs

when interference between a hook and the attachment point

causes the hook gate to unintentionally open

and release. All connections must be selected and deemed

compatible with TR3 by a Competent

Person. All connector gates must be self-closing and self-

locking, and withstand minimum loads of 3,600 lbs.

See the diagram below for examples of compatible/

incompatible connections.

Issue 0

TR3 Tripod

User Manual

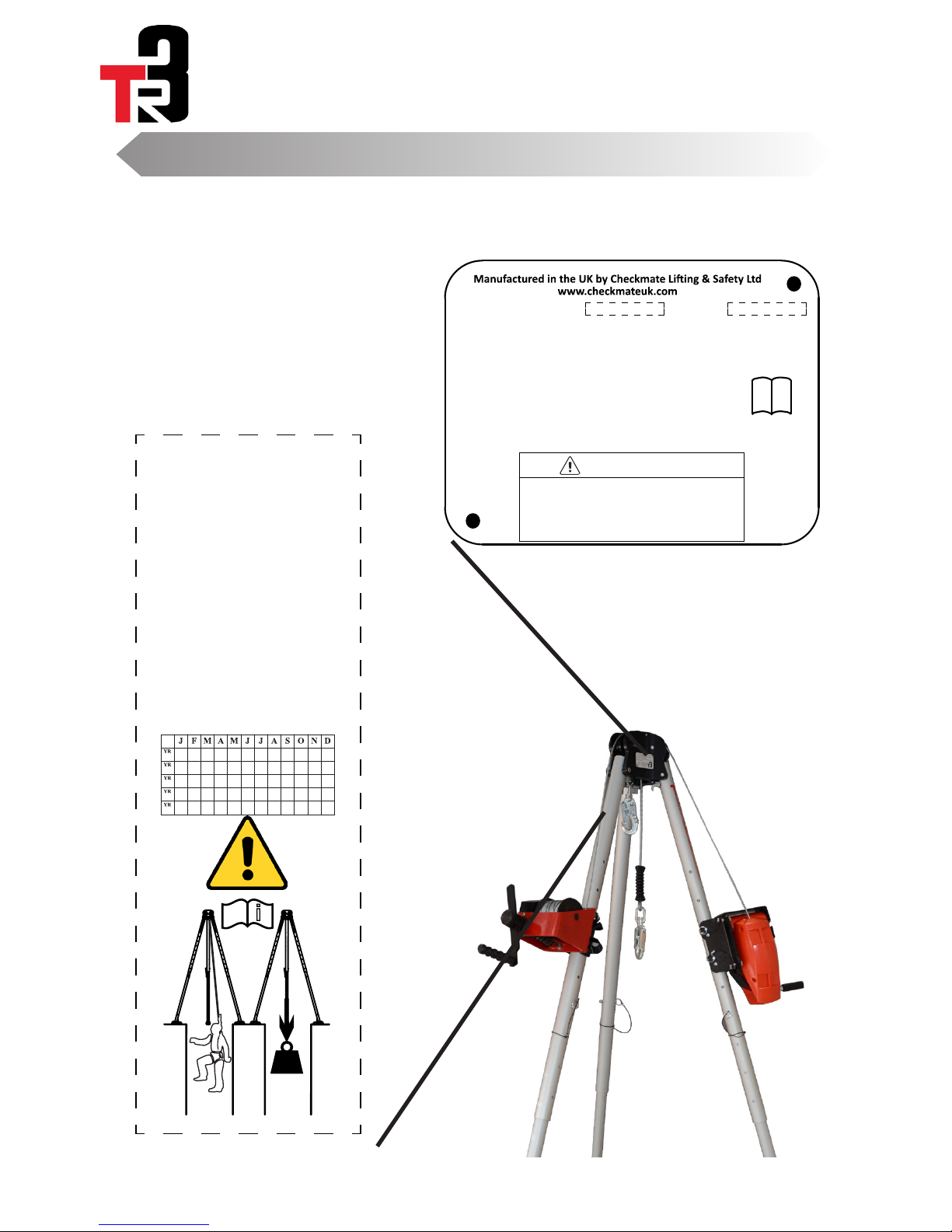

Labeling

Page 14 Section 8.0

i

Manufacturer’s instructions supplied with product must

be followed at all times. Alteration or misuse of this

product, or failure to follow instructions, may result in

serious injury or death. Avoid contact with hazards,

including, but not limited to, heat, chemicals, electricity,

and sharp or abrasive edges and surfaces.

WARNING

46MM

60MM

DOM: Serial #:Model #: 32200

= cut-out for screw

= cut line for laser engraving

Notes:

ANSI Z359.18-2017 & A10.32-12 / OSHA 1926 Sub M & 1910

Type A Anchorage connector

Only make compa�ble connec�ons

5,000 lb. MBS (min. breaking strength).

Min. service temperature: -30�F

Inspect prior to each use. Competent person must

inspect and record at least every 12 months

PPELAB-333 IS4

CHECKMATE

All Intellectual Property, including drawings, branding, logo's and patents are owned by Checkmate Limited.

1:1

+44(0) 1795 668 280

+44(0) 1795 580 333

New Road, Sheerness, Kent, England ME12 1PZ, UK

www.checkmateuk.com

LET'S INNOVATE

CHECKMATE LIFTING & SAFETY

LTD

LIFTING & SAFETY

1

MAX

551lbs/

250kg

MAX

310lbs/

141kg

MAX USER WEIGHT - 310lbs/141kg

WLL - GOODS - 551lbs/250kg

PPELAB-405 ISS 4

INSPECTION GRID

Prior to use, read and understand all manufacturer's

instruc�ons provided with equipment at �me of

shipment from manufacturer.

Compliant with OSHA 1910, OSHA 1926 Subpart M, ANSI

Z359.18-2017 and ANSI A10.32-12.

Worker capacity range (including

all equipment): 130-310 lbs.

If used in assisted rescue, maximum

combined worker capacity is 620 lbs.

equipment weight is 551 lbs./250 kg.

limited to, heat, electricity, chemicals, and sharp or

abrasive edges and surfaces.

inspect at least every 12 months.

point.

White Background

55mm(W) x 171mm(L)

PPELAB-405

ANSI TR3 Leg label 4

PPELAB-405

Cut Line

Issue 0

TR3 Tripod

User Manual

Record Card

Page 15 Section 9.0

SERIAL NO:

PRODUCT CODE:

DATE OF FIRST USE:

USER:

DATE CONDITION OF SYSTEM INSPECTED BY

UM-131_PSGTR3_IS0

Checkmate Lifting & Safety Ltd, Sheerness, Kent. England. ME12 1PZ, UK

Approved service company:

Table of contents