2

Label

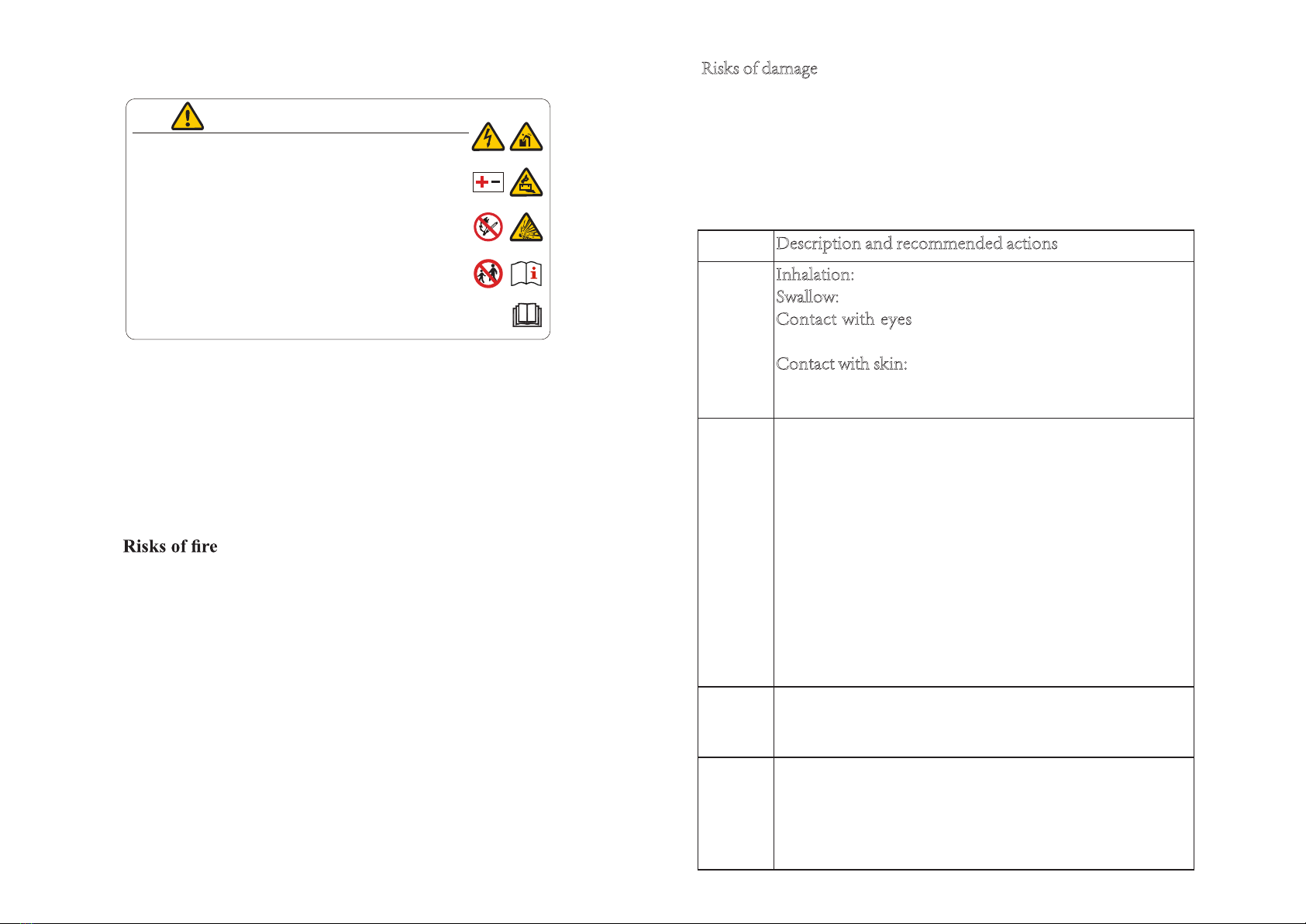

1.2 Precautions

Risks of electrolyte leakage

* Do not subject battery to strong impact.

* Do not crush or puncture battery.

* Prevent battery from falling. In case of fall, turn off the battery

immediately and stop using it.

* Do not open or mutilate batteries. Released electrolyte is

harmful to the skin and eyes.

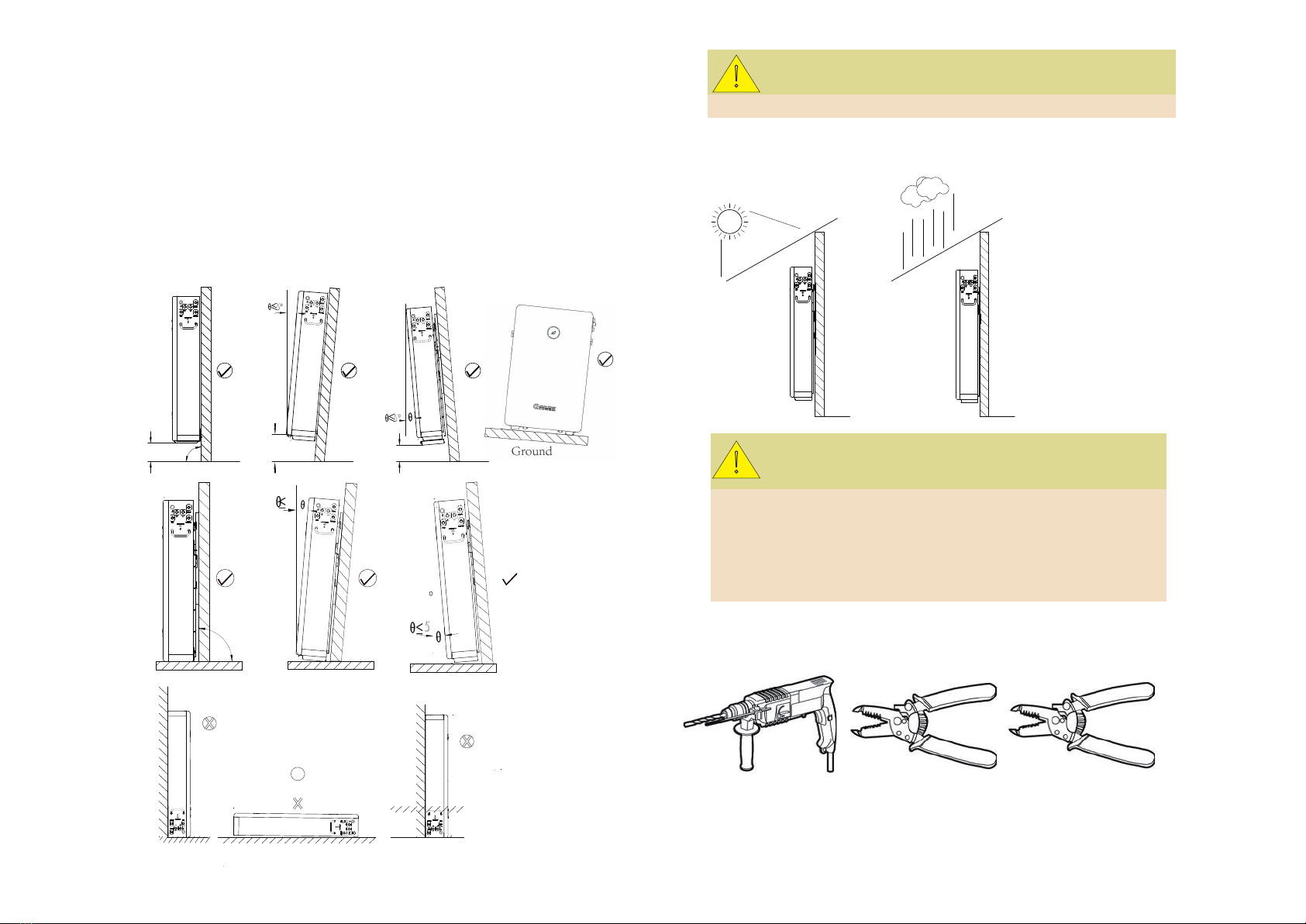

* Do not expose battery to direct sunlight.

* Avoid contact with conductive objects such as wires.

* Keep battery away from fire source, inflammable, explosive

and chemical materials.

* Do not dispose of batteries in a fire. The batteries may

explode.

Risks of electric shock

* Do not touch battery with wet hands.

* A battery can present a risk of electric shock and burns by

high short-circuited current.

* Battery installation and wire connection must be operated by

professionals.

1.3 Responses to Emergencies

Event Description and recommended actions

Leakage Inhalation: leave the contaminated area right now.

Swallow: induce vomiting.

Contact with eyes: flush eyes with flowing water for 15

minutes.

Contact with skin: wash thoroughly with soap and water.

Immediately seek for medical intervention after taking

emergency measures.

Fire Battery may catch fire when heated above 150℃ . Please

implement the following actions:

1. Extinguish fire before the battery catches fire. ABC

or carbon dioxide extinguisher is recommended.

2. If the fire is too strong to put out, move battery to

a safe place before it catches fire.

3. If battery is on fire, evacuate people first before

seeking help from professional fire protection

personnel.

4. If battery catches fire during charging, turn off

the breaker between battery and PCS when safety

can be guaranteed.

Wet

battery

If battery became wet or has been submerged in water,

do not access it. Immediately contact your distributor for

technical assistance.

Damage Damaged battery is dangerous and must be handled with

utmost care. They are not usable for use and could pose a

safety threat to people or property. If battery is suspected

to be damaged, stop any operation and return it to

distributor.

Risks of damage

* Keep a distance to water source.

* Do not subject battery to high voltage.

* Place battery on a flat surface. Do not place any foreign objec t

on top of battery nor step on battery.

* Battery-connected PCS should have reinforced insulation.

WARNING AVERTISSEMENT

1. Do not disassemble or alter the battery in any way.

Ne démontez ni modifiez la batterie en aucune façon.

2. Do not use the battery for purposes not described in its documentation.

N'utilisez pas la batterie à des fins non décrites dans sa documentation.

3. Do not drop, strike, puncture, or step on the battery.

Ne laissez pas tomber, ne heurtez pas, ne percez pas et ne marchez pas sur la batterie.

4. In case of electrolyte leakage, keep leaked electrolyte away from contact

with eyes or skin, immediately clean with water and seek help from a doctor.

En cas de fuite d'électrolyte, gardez l'électrolyte qui fuit loin du contact avec les yeux

ou la peau, nettoyez immédiatement avec de l'eau et demander de l'aide à un médecin.

5. Do not put the battery into a fire. Do not use it or leave it in a place near fire, heaters,

or high temperature sources.

Ne mettez pas la batterie au feu. Ne l'utilisez pas et ne le laissez pas dans un

endroit près de feu, de radiateurs ou de sources de températures élevées.

6. Do not submerge the battery in water, or expose it to moisture.

Ne plongez pas la batterie dans l'eau et ne l'exposez pas à l'humidité.

7. Do not allow the terminals to contact exposed wire or metal.

Ne laissez pas les bornes entrer en contact avec du fil ou du métal exposé.

8. The battery is heavy and can cause injury if not handled safely.

La batterie est lourde et peut provoquer des blessures si elle n'est pas manipulée en toute sécurité.

9. Keep out of reach of children or animals. Tenir hors de portée des enfants ou des animaux.