Chemglass CHEMcell CLS-1200-2CH User manual

F

F

Fi

i

iv

v

ve

e

e

P

P

Po

o

os

s

si

i

it

t

ti

i

io

o

on

n

n

M

M

Ma

a

ag

g

gn

n

ne

e

et

t

ti

i

ic

c

c

S

S

St

t

ti

i

ir

r

rr

r

re

e

er

r

r

C

C

CH

H

HE

E

EM

M

Mc

c

ce

e

el

l

ll

l

l™

™

™

T

T

Te

e

em

m

mp

p

pe

e

er

r

ra

a

at

t

tu

u

ur

r

re

e

e

C

C

Co

o

on

n

nt

t

tr

r

ro

o

ol

l

l

M

M

Mo

o

od

d

du

u

ul

l

le

e

e

3800 North Mill Road •Vineland, NJ 08360 •USA

Tel: 1-800-843-1794 •Fax: 1-800-922-4361

Web: www.cglifesciences.com

O

O

OP

P

PE

E

ER

R

RA

A

AT

T

TI

I

IO

O

ON

N

NS

S

S

M

M

MA

A

AN

N

NU

U

UA

A

AL

L

L

Rev. A

C

C

CL

L

LS

S

S-

-

-1

1

12

2

20

0

00

0

0-

-

-2

2

2C

C

CH

H

H

For Serial Number:

Page 2

General Description………………………………….………………… page 3

Specifications……………………………………………………page 3

Features………………………………………………..…….…...page 3

Additional Products………………………………….…..……..page 3

Unpacking Instructions…………………………….…………..……….page 3

Front and Rear Views………………..…………..……………..……… page 4

Set-Up Guide………….…………………………………………..….…..page 4

Figure 1 –Cell Culture Bag/Vent Heater ….………………..page 4

Figure 2 –Tray attached to Base..………….……….……… page 5

Figure 3 –Control Module Inputs/Outputs ….….………… page 5

Operating Instructions………….…………………………….…….…. page 5

Quick Reference Guide…………………..….……………….….……..page 6

Autotuning………………………………………………..…….….……. page 7

Autotuning Procedure……………………………………..…..page 7

Autotune Sequence……………………………………….……page 7

Autotuning the Controller for Very Fine Control.……..….page 8

Autotune Errors………………………………………….….….page 8

Overtemperature Protection Circuit……………………….…….…..page 9

Ramp and Soak Features……………..…………………….…….…...page 10

Important Points to Know………….……………………….……..…..page 11

Activating/Programming Ramp-to-Setpoint Feature.….……..…..page 12

Deactivating Ramp-to-Setpoint Feature …..……………….…..…..page 12

Troubleshooting……………………..………………………….…..…..page 12

Resetting Controller to Factory Default Settings……………..…..page 13

Service/Maintenance………………..…………………………..….…..page 14

CGLS Warranty and Limitations of Liability………………..…….. page 14

Table of Contents:

Page 3

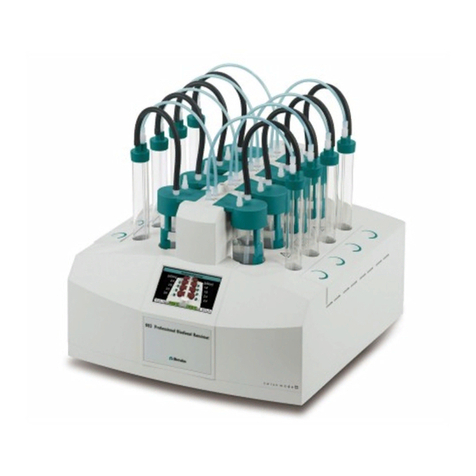

The CG Life Sciences CHEMcell Temperature Control Module has an easy to read digital display with a

ramp to set point feature. A 120VAC outlet for connection of the heater cord from either CLS-1200-250

or CLS-1200-300 Tray. Two 5vdc connections are provided for CLS-1200-FH, Filter Vent heaters.

Specifications:

•Digital PID Controller

•RTD connection (Mini-type plug)

•120VAC Power Outlet

•Two 5Vdc outlets

•Dimensions: (L x W x H; 7 ¾ x 5 ⅜x 3 ⅜)

•Operating Temperature: 0° –50°C

•Electrical Rating: 120VAC, 50/60Hz, 10 Amps, 1200 Watts

Features: ✓Brushed Stainless Steel Housing

✓Easily change set-point temperature

✓Over temperature Flashing Red LED indicator

✓Accommodates 20L or 50L Tray heaters

Additional Products (Purchased Separately):

➢CLS-1200-100, Chemcell Base unit

➢CLS-1200-250, 20-liter Tray

➢CLS-1200-300, 50-liter Tray

➢CLS-1200-GMM, Gas Mixing Module

➢CLS-1200-FH, Vent Filter Heater

➢CLS-1200-AP, Air Pump Kit complete

➢CLS-1200-RTD, Chemcell RTD Pt100 (One is included with each Tray)

Unpack the CHEMcell Temperature Control Module carefully. Read all Instructions before using. Be

certain to retain any warranty information, all packing material and operations manual(s). Record the

serial number, located on the bottom of the unit for future reference.

Any damage claims must be initiated with the delivering carrier within five (5) days of receipt of the

product.

This unit must only be connected to the correct voltage source (Grounded 120VAC @50/60Hz.)

General Description

Unpacking Instructions

Example: Serial Number

Page 4

CLS-1200-2CH, Temperature Control Module

1. Place Controller on a flat stable surface.

2. Ensure adequate space around controller.

3. Plug Controller into suitable electrical outlet.

4. Place Vent Heater (if applicable) over Vent Filter and connect end to ‘Filter Vent Heater’

outlet on Front of Controller. Note- Position of Vent Heater.

5. Insert RTD (Pt100 Sensor) plug into RTD receptacle.

6. Plug Tray Heater cord into Power Outlet rated at 1200 watts

DO NOT USE TRAY HEATER WITHOUT A CULTURE BAG IN PLACE

SET-UP Guide (refer to Fig. 1, 2 & 3)

FRONT VIEW

REAR VIEW

Vent Filter

Vent Heater

Figure 1 –Cell Culture Bag /Vent Heater

NOTE: Vent Heater must

be positioned to read

"THIS SIDE UP"

Page 5

NOTE: An offset temperature value has been added to this controller in a best effort to match the tray size and

RTD sensor used. The offset value compensates for the temperature difference between the tray surface and the

interior of a culture bag. See table below on next page.

1. Once all connections have been verified turn on the Controller via main power switch.

2. If a setpoint temperature value other than 37.0°C is required, then refer to the ‘Quick Reference Guide’

below to change setpoint temperature –the default value is 37.0°C.

3. The Controller will display the as measured temperature from the RTD sensor.

4. The unit will provide power to the Tray Heater which will heat the cell culture bag. Depending on the type

and size culture bags used and the tray size it may take an hour or more to reach the setpoint temperature.

Operating Instructions (refer to Fig. 3)

Figure 2 –Tray attached to Chemcell Base

Figure 3 –Temp. Control Module

Control Key

Down

Arrow

Up

Arrow

Filter Vent Heater,

5Vdc (CLS-1200-FH)

RTD Sensor Pt100

(CLS-1200-RTD)

Tray Heater

(CLS-1200-250 or

CLS-1200-300)

Main Power Switch

(RTD - Pt100 Sensor

adhered to Tray)

RTD

connector

Tray

Heater

Plug

Page 6

Quick Reference Guide –Entering Setpoint Temperature Value and

Adjusting the Displayed Temperature Value (see Fig. 3)

❖Entering Setpoint Temperature Value: [Default Setpoint is 37.0°C]

1) Press and hold the Control Key

2) While holding in the Control Key, press the Up Arrow to increase or the Down Arrow to

decrease the Setpoint Temperature value.

When the desired Setpoint value is displayed, release the Control Key to load the Setpoint

Temperature into memory. The display will now indicate the actual measured temperature. To

verify the loaded Setpoint temperature, press the Control Key to display value.

❖Changing the Displayed Temperature to correspond to an alternate measured or

anticipated temperature variation (i.e. adjusting the displayed temperature value by

offsetting or changing the “zero” value to match an offset or known temperature):

1) Press and hold both Up and Down Arrow keys at same time.

2) Once “tune” is shown in the display, the keys may be released.

3) Press the Down key once, “LEVL” is displayed.

4) While pressing and holding the Control Key, press the Up key until the display reads “3”, then

release the Control key.

5) Press the Up key until the display reads “zero”. The display will alternate between a numeric

value* and “zero”. *This is the zero offset value. Press and hold the Control key, then press

either the Up or Down key to enter a revised value. By changing this value, the displayed

temperature will change accordingly. Example: If the displayed temperature shows 40.5°C but

the actual temperature is 40.0°C, then a change of -0.5 should be added here.

6) The adjusted value will be saved by pressing both the Up and Down Arrow keys simultaneously

and then releasing once the measured temperature is displayed. Or, if no other keys are pressed

for about 60 seconds the changes will be saved and the new measured temperature will be

displayed.

The following table indicates an offset already added to this controller

Serial Number

Initial Zero

Value

Offset Added to Zero Value

(Tray compensation)

New Adjusted

Zero Value

Page 7

•Autotune is feature built into the temperature controller that automatically calculates the tuning

parameters (i.e. delay times, heating efficiency, heating load, etc.) for any type heater. After the

autotune procedure is complete and the tuning parameters are selected, the controller automatically

loads them into its memory for current and future use.

❖In most cases if the over temperature protection circuit is active, it must be inactivated

before starting this procedure.

1. Set the equipment up in the exact configuration it will be used. Ensure all connections to the

Temperature Control Module.

2. Turn controller on an enter the desired set point temperature. If the set point isn’t at least

30°C above ambient, then skip this procedure and go to the next procedure, ‘Autotuning the

Controller for Very Fine Control’.

Autotuning (refer to Fig. 3)

Page 8

❖In most cases if the over temperature protection circuit is active, it must be inactivated before

starting this procedure.

1. Set the equipment up in the exact configuration it will be used. Ensure all connections to the

Temperature Control Module.

2. Turn controller on an enter the desired set point temperature. If the set point isn’t at least 30°C above

ambient, then skip this procedure and go to the next procedure, ‘Autotuning the Controller for Very

Fine Control’.

To remove the “tunE”“FAiL”message, turn the controller off for 10 seconds. Try the procedure titled

“Autotuning the Controller for Very Fine Control”. If autotune continues to fail, call and discuss your

application with one of our engineers.

Page 9

❖The temperature controller is equipped with an over-temperature protection circuit that turns off

heating any time the temperature read-out goes 10°C above the entered setpoint. When the

temperature cools below the 10°C threshold, the circuit is reset and the controller returns to

operating normally. An over-temperature condition is indicated by the display blinking the

message ‘-AL-‘. The over-temperature feature acts to help prevent accidents in situations where

something has gone wrong, or the controller is having difficulty maintaining temperature control.

➢The Temperature Control Module, Heater (Tray), and RTD sensor form a closed loop

feedback system. When the controller is connected to a heater, the feedback loop should not be

broken at any point.

Over-Temperature Protection Circuit

Page 10

Ramp and Soak Features

Page 11

Important Points to Know

Page 12

Deactivating the Ramp-to-Setpoint Feature

Resetting the Controller to Original Factory Settings

Troubleshooting

Activating & Programming the Ramp-to-Setpoint Feature

See Autotune section

Page 13

Resetting Controller to Factory Default Settings

Page 14

In the event that a problem develops with your CGLS product, DO NOT attempt to perform any service on the

unit without first contacting the CGLS Customer Service Department at 1-800-843-1794. Unauthorized

servicing may void the warranty. CGLS will supply information on minor repairs upon request. In any

correspondence to CGLS concerning this unit, please include the catalog number (CLS-1200-2CH) and the serial

number, which may be found on the bottom of the unit.

WARNING: POTENTIAL SHOCK HAZARD EXISTS WHEN TOP COVER IS

REMOVED.

DISCONNECT POWER CORD BEFORE SERVICING.

1. Contact CGLS for troubleshooting assistance.

Preventive Maintenance Suggestions

1. Periodically check connection of Pt100 sensor for corrosion, clean if necessary.

2. Cleaning - keep the instrument dry and clean. The unit must be powered off and unplugged before

cleaning. Do not use abrasive cleaning agents. The exterior should be wiped with a damp cloth with

water and 70% alcohol if needed. Ensure unit is completely dry before plugging in and turning on.

3. Periodically check power cords for any tears or cracks, replace if necessary.

Service/Maintenance

CGLS WARRANTY AND LIMITATION OF LIABILITY

Chemglass, Chemglass Life Sciences, Warranty and

Limitation of Liability

Warranty:

Chemglass, Inc. guarantees this unit against defects in material and workmanship for a period of one year from the date of

purchase. If the unit should malfunction, it must be returned for evaluation. If the unit is determined to have a defect in

materials or workmanship, then it will be repaired or replaced at no charge. Tampering with the unit or damage resulting from

excessive current, heat, moisture, vibration, corrosive materials, or misuse will void this warranty. Programming changes or

reconfigurations are not covered under warranty. CGLS shall not be responsible to the original purchaser or any other party or

parties for bodily or property loss, damages, or injuries of any kind or nature through either direct or indirect use of the

product.

Return Authorization:

CGLS must authorize any return of product. Please contact a customer service representative via the correspondence listed

below to obtain a Return Merchandise Authorization (RMA) number. The purchaser is responsible for all packing and shipping

to CGLS. If the equipment or material came in contact or was proximate to any biological organism, toxic or corrosive material,

or any agent reasonably deemed to be potentially harmful, it must be cleaned and decontaminated prior to receipt by CGLS.

The purchaser is obligated to disclose fully in writing, the cleaning and decontamination method. We reserve the right not to

accept any unauthorized or potentially harmful shipment.

Correspondence:

Chemglass Life Sciences

3800 North Mill Rd.

Vineland, NJ 08360

USA

Phone: 800-843-1794

Email: customer-service@cglifesciences.com

Web: www.cglifesciences.com

Table of contents

Other Chemglass Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Diatron

Diatron Abacus 5 Operator's manual

MiCo BioMed

MiCo BioMed Veri-Q PCR 316 QD-P100 user manual

GYROZEN

GYROZEN 1730R user manual

Thermo Scientific

Thermo Scientific Orion Star Series quick guide

Thermo Scientific

Thermo Scientific iCAP RQ ICP-MS Pre-installation requirements guide

Metrohm

Metrohm 858 manual