CHSP-9039 | 2021-09-10 2

Table of Contents

Introduction ........................................................................................................................................................ 3

User Guide Conventions.................................................................................................................................. 3

Special Messages ......................................................................................................................................... 3

Product Description ......................................................................................................................................... 4

Hazard Sticker.............................................................................................................................................. 4

Technical Specifications................................................................................................................................ 4

Qualified Staff.............................................................................................................................................. 4

General Considerations................................................................................................................................ 4

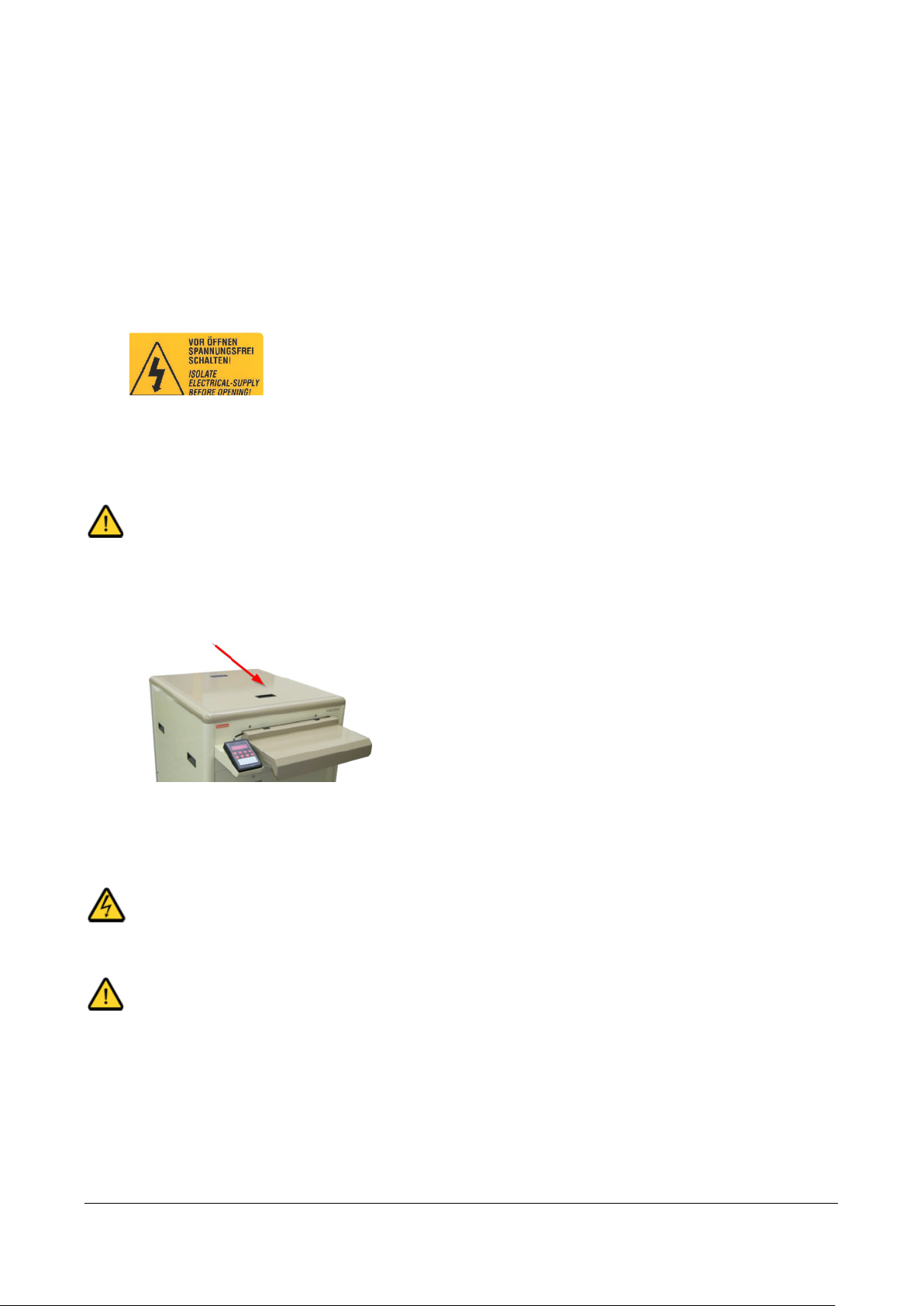

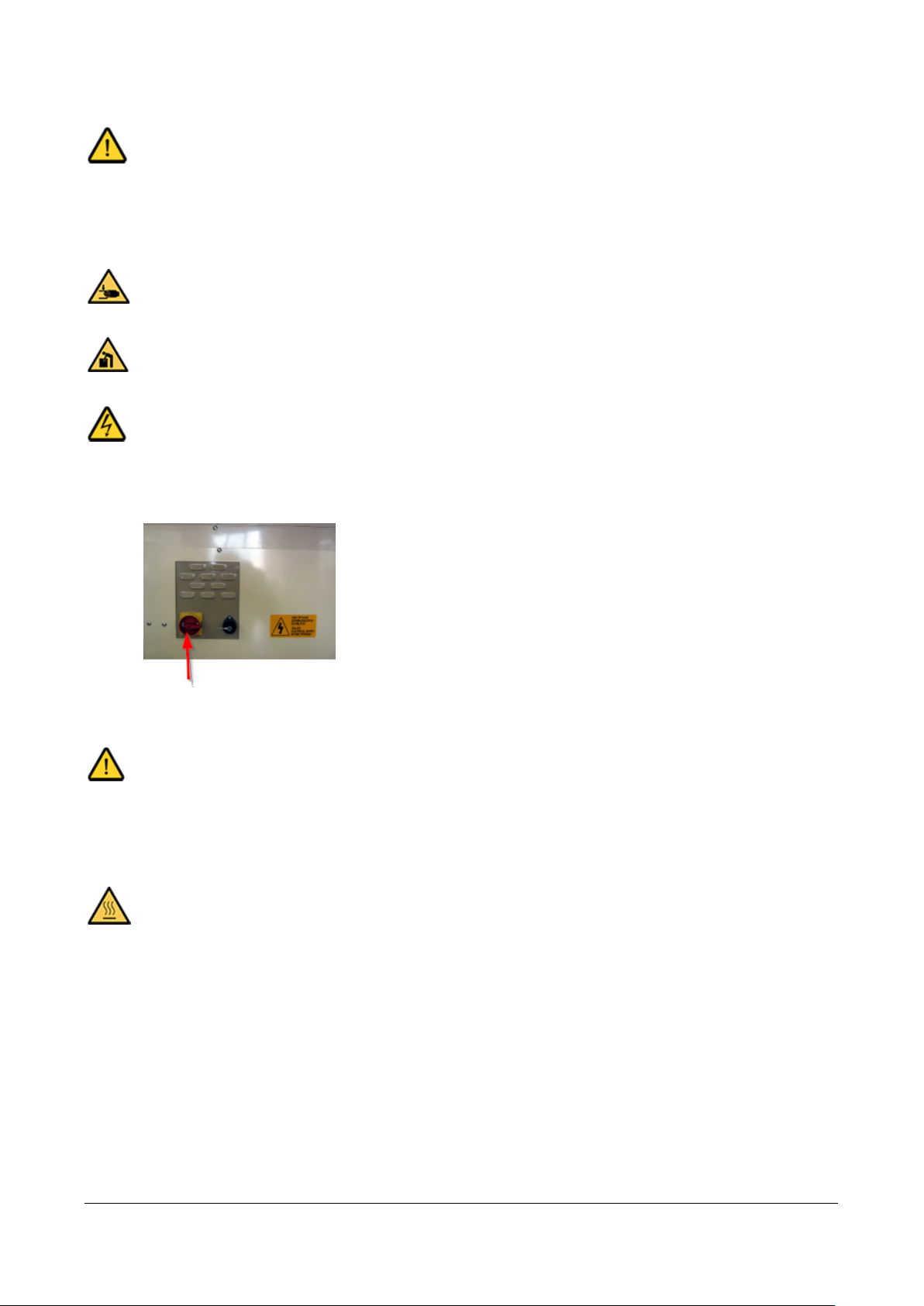

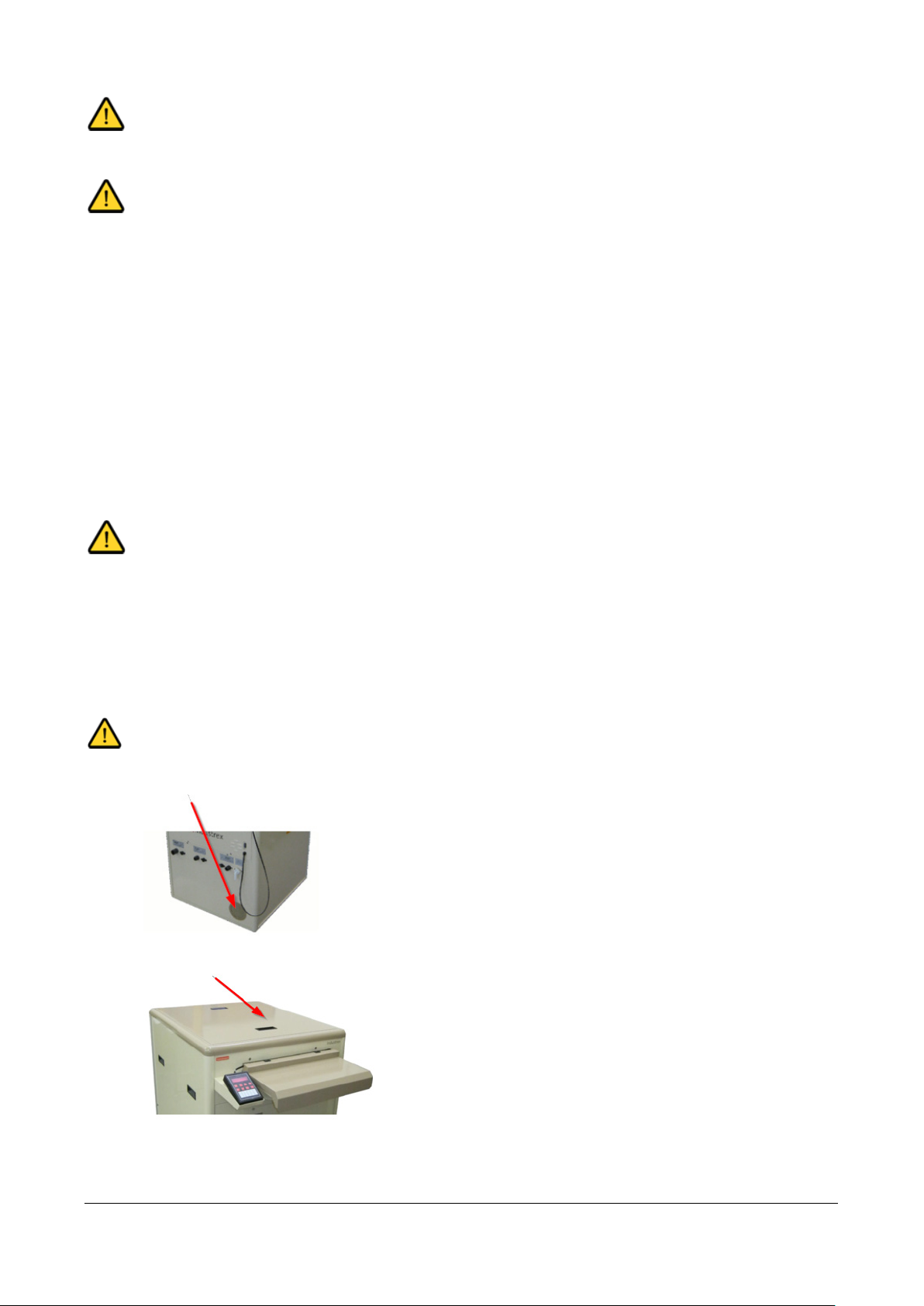

Mechanical Hazards..................................................................................................................................... 5

WEEE and RoHS Compliance Statement ....................................................................................................... 7

Tanks and Chemicals.......................................................................................................................................... 8

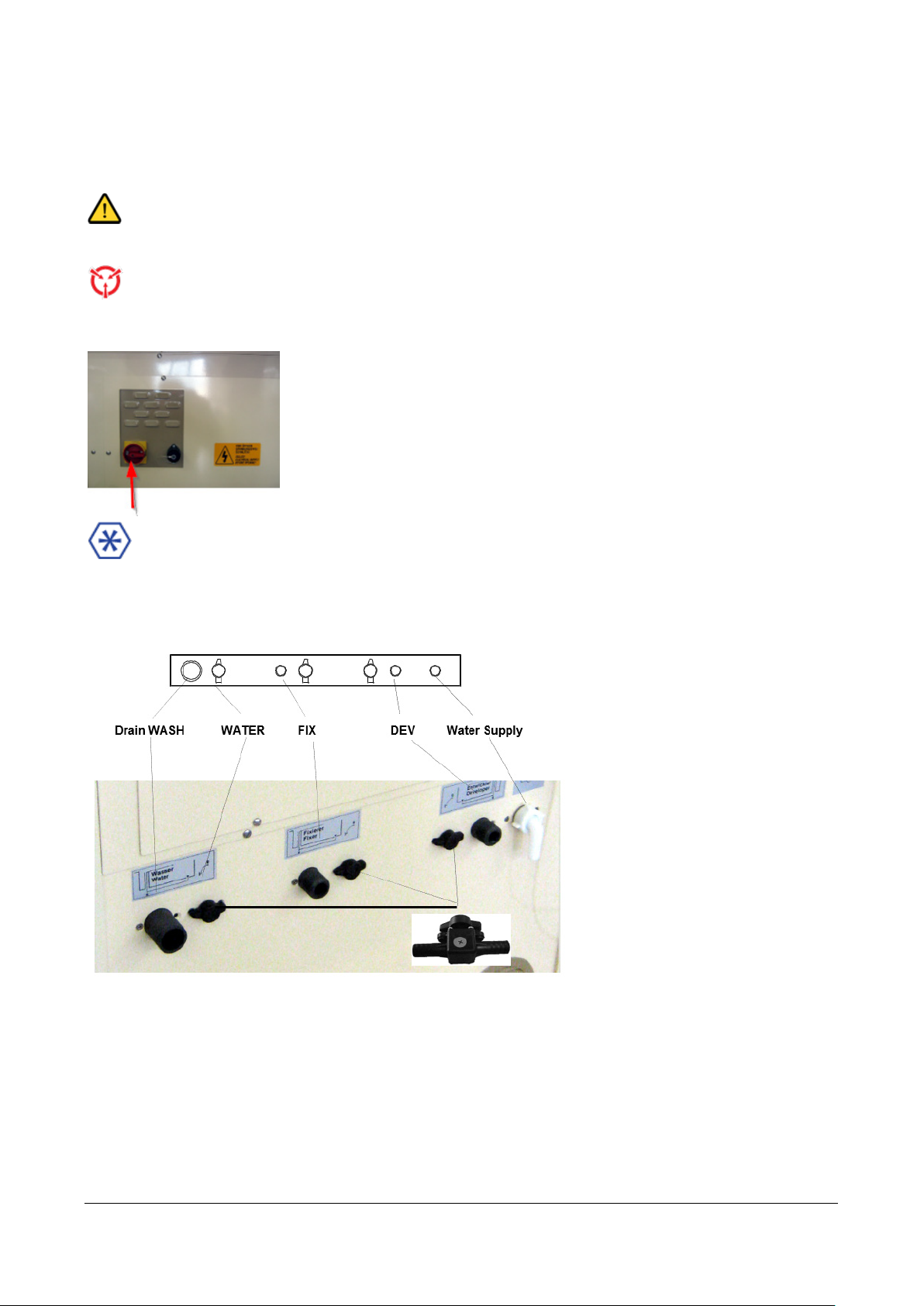

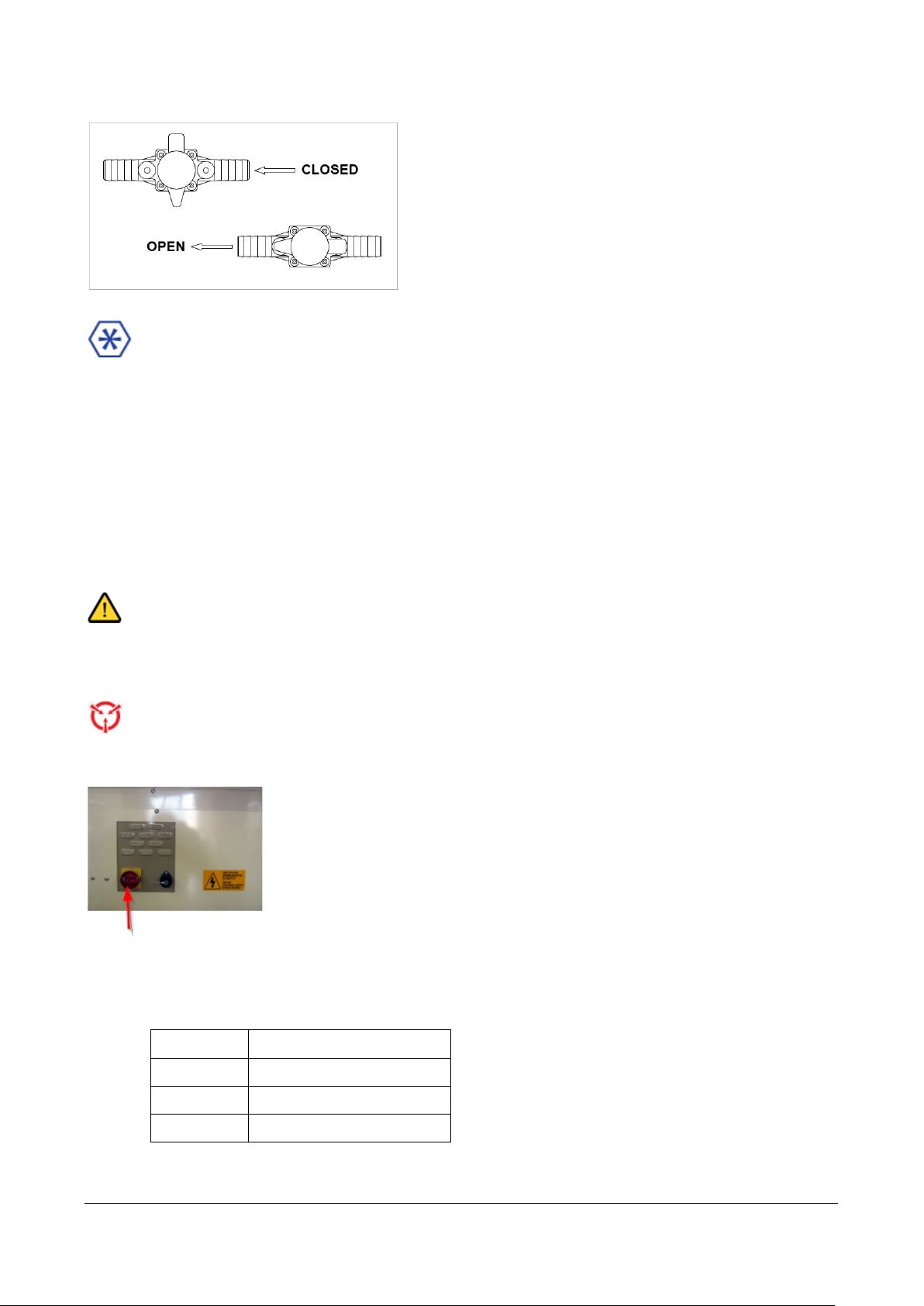

Draining the Tanks .......................................................................................................................................... 8

Installing the Transport Racks .......................................................................................................................... 9

Additional Connection for the Fix Rack ...................................................................................................... 11

Fix Rack ..................................................................................................................................................... 11

Filling the Tanks ................................................................................................................................................ 12

Fill the Fixer Tank........................................................................................................................................... 12

Fill the Developer Tank .................................................................................................................................. 12

Operating the Film Processor............................................................................................................................. 13

Daily Startup.................................................................................................................................................. 13

Starting Work................................................................................................................................................ 13

Daily Shutdown ............................................................................................................................................. 13

Functions....................................................................................................................................................... 14

Using the Display ............................................................................................................................................. 15

Overview ....................................................................................................................................................... 15

Programming the Values............................................................................................................................... 16

Changing the Program .............................................................................................................................. 16

Setting the Date and Time ......................................................................................................................... 17

Check the Parameters and the Work in Progress in Automatic Mode ............................................................ 17

Use the Options in Standby Mode ................................................................................................................. 18

Use the Manual Replenishment Cycle ............................................................................................................ 19

Check the Errors............................................................................................................................................ 19

Start and Stop the Film Processor Manually ................................................................................................... 19

Turn the Back Light On and Off..................................................................................................................... 19

Loading the Film............................................................................................................................................ 19

Using the Monitor Mode ............................................................................................................................... 20

Using the Filter Control.................................................................................................................................. 21

Additional Features – Auto-fill Water / Auto-fill Chemicals (Dev & Fix) ........................................................... 21

Automatic Wash Tank Fill / Automatic Wash Tank Drain ............................................................................ 21

Automatic Developer and Fixer Tank Fill..................................................................................................... 22

Systems............................................................................................................................................................. 23

Tempering..................................................................................................................................................... 23

Temperature Sensing..................................................................................................................................... 23

I2C Bus.......................................................................................................................................................... 23

Ventilation..................................................................................................................................................... 24

Chemical Replenishment ............................................................................................................................... 25

Infrared Sensor Bar........................................................................................................................................ 26

Maintenance, Troubleshooting, and Error Messages ......................................................................................... 27

Daily Maintenance......................................................................................................................................... 27

Weekly Maintenance..................................................................................................................................... 28

Three-to-Six Months Maintenance................................................................................................................. 28

Troubleshooting ............................................................................................................................................ 30

Error Messages .............................................................................................................................................. 34

Publication History ..................................................................................................................................... 35