Chemitec 4204 User manual

4204

FLOW METER

With ULTRASOUND

measurement sensor

TECHNICAL MANUAL

P/N: ………………….

Rev. 5 Ver. 3.4

RELEASE December 2016

GENERAL CLAUSES

Although we have paid maximum attention and care in processing this document,

CHEMITEC s.r.l. cannot guarantee the exactness of all information herein contained

and thus cannot be held liable for errors that this may entail nor for the damages that

may result from the use or application thereof.

Material products, software and services shown in this document are subject to

evolution. In reference to characteristics of presentation and operation, CHEMITEC

s.r.l. shall reserve the right for any modifications without advance notice.

COPYRIGHT

It is prohibited to reproduce or copy this manual, even partially, and through any

process.

AUTHORISED SERVICE CENTRES

CHEMITEC s.r.l.

Via Isaac Newton, 28 – 50018 Scandicci – FLORENCE - ITALY

4204

FLOW METER

TECHNICAL MANUAL P/N XXX-0000 Rev. 5 Ver. 3.4

I

TABLE OF CONTENTS

1 GENERAL ............................................................................................................................................................... 1

1.1 MANUAL

INFORMATION ............................................................................................................................. 1

1.1.1 CONVENTIONS ........................................................................................................................................ 1

1.2 MANUFACTURER

DECLARATION

OF

LIABILITY................................................................................... 2

1.3 LIMITS

OF

USE

AND

SAFETY

PRECAUTIONS .......................................................................................... 2

1.3.1 ELECTRIC SAFETY .................................................................................................................................. 2

1.3.2 SAFETY OF OPERATING ENVIRONMENT ............................................................................................ 3

1.4 GRAPHIC

SIGNS ............................................................................................................................................. 4

1.4.1 DANGER SIGN.......................................................................................................................................... 4

1.5 PLATE

DATA................................................................................................................................................... 5

1.6 INFORMATION

ON

RECYCLING

AND

REUTILISATION

OF

MATERIALS............................................ 5

1.6.1 SPECIAL ATTENTION FOR CRITICAL COMPONENTS ....................................................................... 5

2 GENERAL DESCRIPTION................................................................................................................................... 6

2.1 MAIN

FEATURES............................................................................................................................................ 6

2.2 UNIT

HARDWARE

MAIN

FEATURES ......................................................................................................... 7

2.3 CONTROLS

AND

INDICATORS.................................................................................................................... 9

3 INSTALLATION................................................................................................................................................... 10

3.1 COMPOSITION

OF

THE

SUPPLY................................................................................................................ 10

3.1.1 INSTALLATION OF WALL MOUNTED DEVICE.................................................................................. 10

3.1.2 INSTALLATION OF 144x144 ELECTRICAL PANEL DEVICE .............................................................11

3.1.3 TERMINAL BOARD CONNECTIONS .................................................................................................... 12

3.2 CONNECTING

POWER

SUPPLY

LINE ....................................................................................................... 12

3.2.1 ELECTRICAL CONNECTIONS TO THE SYSTEMS .............................................................................. 13

3.2.2 INSTALLATION OF THE PROBE .......................................................................................................... 13

4 OPERATING MODE – GENERAL.................................................................................................................... 14

4.1 DISPLAYING

SYSTEM................................................................................................................................. 14

5 ENABLING THE SYSTEM ................................................................................................................................. 15

5.1 START ............................................................................................................................................................ 15

6 RUN MODE ........................................................................................................................................................... 16

7 PROGRAMMING MODE ................................................................................................................................... 19

7.1 ACTIVATION

OF

FUNCTIONS.................................................................................................................... 20

7.2 SETUP

[1] ....................................................................................................................................................... 23

7.2.1 RELAYS [1.1] (Fig. 7-2).......................................................................................................................... 24

7.2.1.1 Relays [1.1].......................................................................................................................................... 24

7.2.1.1.1 K1÷KL5 [1.111÷1.115] ................................................................................................................ 24

7.2.1.1.1.1 Disable....................................................................................................................................24

7.2.1.1.1.2 PULSES [follows 1.111÷1.115].............................................................................................24

7.2.1.1.1.3 Alarm [follows 1.111÷1.115] .................................................................................................24

7.2.1.2 Alarm [1.12] ........................................................................................................................................ 25

7.2.1.2.1 Loss of sensor connection ............................................................................................................. 25

7.2.1.2.2 Relay activation [follows 1.12]..................................................................................................... 25

7.2.1.2.3 Eco loss [follows 1.12].................................................................................................................. 25

7.2.2 SYSTEM SETUP[1.2].............................................................................................................................. 26

7.2.2.1 Date/Time [1.21] ................................................................................................................................. 27

7.2.2.2 Communications [1.22] ....................................................................................................................... 27

7.2.2.2.1 Address [segue 1.22] ..................................................................................................................... 27

4204

FLOW METER

TECHNICAL MANUAL P/N XXX-0000 Rev. 5 Ver. 3.4

II

7.2.2.2.2 Baud rate[1.22].............................................................................................................................. 27

7.2.2.3 Language [1.23]................................................................................................................................... 27

7.2.2.4 Password [1.24] ................................................................................................................................... 27

7.2.2.4.1 Status [1.241] ................................................................................................................................ 28

7.2.2.4.2 New [1.242]................................................................................................................................... 28

7.2.2.5 Display [1.25] ...................................................................................................................................... 28

7.2.2.5.1 Contrast ......................................................................................................................................... 28

7.2.2.5.2 Back light ...................................................................................................................................... 28

7.2.3 LEVEL [1.3] ............................................................................................................................................ 29

7.2.3.1 Level Param[1.31] ............................................................................................................................... 29

7.2.3.2 Parameters [1.32]................................................................................................................................. 29

7.2.3.2.1 h 0 Dist .......................................................................................................................................... 30

7.2.3.2.2 h max. ............................................................................................................................................ 30

7.2.4 FLOW [1.4] ............................................................................................................................................. 30

7.2.4.1 Generic Flow [1.41]............................................................................................................................. 30

7.2.4.1.1 Units .............................................................................................................................................. 30

7.2.4.1.2 Decimal ......................................................................................................................................... 30

7.2.4.1.3 PMD .............................................................................................................................................. 30

7.2.4.1.4 Exponent ....................................................................................................................................... 31

7.2.4.2 Flow Param [1.42] ............................................................................................................................... 31

7.2.4.2.1 Q Max............................................................................................................................................ 31

7.2.4.2.2 Cut off ........................................................................................................................................... 31

7.2.5 table [1.5] ................................................................................................................................................ 31

7.2.5.1 Set up for the “Bazin” type overflow .................................................................................................. 32

7.2.6 RESET SETUP [1.6] ............................................................................................................................... 33

7.3 MANUAL

CONTROL

[2.0] ........................................................................................................................... 34

7.3.1 TEST LEVEL [2.1] .................................................................................................................................. 34

7.3.2 RELAYS [2.2] ......................................................................................................................................... 34

7.3.3 ANALOG OUTS [2.3] ............................................................................................................................. 34

7.4

M

A

ANALOGUE

OUTPUT

[3.0] ...................................................................................................................... 35

7.4.1 OUT 1 ...................................................................................................................................................... 35

7.4.2 OUT 2 ...................................................................................................................................................... 35

7.5 ARCHIVE

[4.0] ............................................................................................................................................... 36

7.5.1 TOTALIZER............................................................................................................................................. 37

7.5.1.1 Display Data [4.11] ............................................................................................................................. 37

7.5.1.2 Totalizer File [4.12]............................................................................................................................. 37

7.5.2 FLOW [4. 2] ............................................................................................................................................ 37

7.5.2.1 Visualise Data [4.21] ........................................................................................................................... 37

7.5.2.2 Capacity Archive [4.22] ...................................................................................................................... 38

7.6 EXIT

MENU

[5.0] ........................................................................................................................................... 38

8 MAINTENANCE................................................................................................................................................... 39

8.1 SPECIAL

ATTENTION

FOR

CRITICAL

COMPONENTS .......................................................................... 39

9 MODBUS PROTOCOL........................................................................................................................................ 40

10 WARRANTY ......................................................................................................................................................... 44

11 REQUEST FOR SERVICE .................................................................................................................................. 45

11.1 PROCEDURE

FOR

SERVICE

REQUEST..................................................................................................... 45

11.2 MAIN

CHEMITEC

OFFICES......................................................................................................................... 45

4204

FLOW METER

TECHNICAL MANUAL P/N XXX-0000 Rev. 5 Ver. 3.4

1

1 GENERAL

1.1 MANUAL INFORMATION

This document contains copyrighted information. They may be subject to modifications and

updates without notice.

Printing sequence

First edition: µACP 4204 – Rev. 0 Ver 1.1

This manual is integral part of the instrument. At first installation of the instrument, the operator

must carry out an accurate verification of the content of the manual in order to verify its integrity

and completeness.

In case it shows to be damaged, incomplete or unsuitable, please contact CHEMITEC in order to

immediately integrate or replace the non-complying manual.

The official versions of the manual, for which CHEMITEC is directly responsible, are the Italian

and English versions. For Countries with languages different than those versions above mentioned,

the official manual in the one in Italian language. CHEMITEC shall not be held responsible for any

translations in different languages carried out by distributors or users.

Compliance with the operating procedures and warnings described in the present manual is an

essential requirement for the correct operation of the instrument and to guaranty safety for the

operator.

Before installing/operating the instrument, the manual must be read in its entirety while standing in

front of the same, in order to become very familiar with the operating procedures, controls,

connections to peripheral instruments and precautions for the safe and correct use of it.

The user manual must be saved, integral and legible in all of its parts in a safe place and, at the

same time, quickly accessible to the operator during installing operations, use and/or reviewing the

installation

1.1.1 CONVENTIONS

This manual utilises the following printing conventions:

NOTE

The notes contain important information to be emphasised with respect to rest of the text.

They generally contain information useful for the operator in order to execute correctly and

optimise the operating procedures.

WARNING

Warning messages appearing in the manual before procedures or operations which must be

respected in order to prevent possible loss of data or damages to the instrument.

CAUTION

Caution messages appear in the manual near descriptions of procedures or operations

which, if carried out incorrectly, may cause damages to operators or users.

4204

FLOW METER

TECHNICAL MANUAL P/N XXX-0000 Rev. 5 Ver. 3.4

2

1.2 MANUFACTURER DECLARATION OF LIABILITY

CHEMITEC shall be liable for the safety, reliability and performance of the instrument only if

utilised in compliance with the following conditions:

•Calibrations, modifications and repairs must be performed by personnel expressly qualified and

authorised by CHEMITEC.

•Opening of the instrument and access to its internal parts must be performed solely by personnel

qualified for the maintenance and appropriately authorised by CHEMITEC.

•The facility which the instrument operates, must conform to the safety requirements.

•The facility electrical system must be installed according to regulations and be perfectly

efficient.

•The feasible replacement of parts of the instrument and accessories, must be done with others

of the same type and specifications.

•Use and maintenance of the instrument and relative accessories must be carried out in

compliance with instructions described in the present manual.

•The present manual must be kept integral and legible in all of its parts

1.3 LIMITS OF USE AND SAFETY PRECAUTIONS

In order to guaranty safety for the operator together with the correct operation of the instrument, it is

necessary to operate within the admitted limits and implement all the precautions listed further:

CAUTION

Before operating the instrument, verify that all the safety requirements have been met. The

instrument must not be powered–up or connected to other instruments until all safety

conditions are met.

1.3.1 ELECTRIC SAFETY

CAUTION

All connections present on the instrument are insulated from the ground environment

(ground not insulated).

DO NOT connect any of these connections to the ground.

In order to guaranty the maximum safety conditions for the operator, we recommend following

faithfully all instructions listed in this manual.

•Supply the instrument with line voltage according to the specification (85÷265V ac

50/60Hz).

•Replace immediately damaged parts. Cables, connectors, accessories or other parts of the

instrument found to be damaged or not operating correctly, must be immediately replaced. In

such case, contact the nearest authorised technical service centre.

•Utilise only accessories and peripherals specified by CHEMITEC. To guaranty the meeting

of all safety requirements, is necessary to utilise exclusively accessories specified in this

manual, which have been tested together with the instrument. Use of other manufacturers’

accessories and consumable materials or not specifically indicated by CHEMITEC, does not

guaranty safety and correct operation of the instrument. Utilise exclusively peripherals that

comply with the regulations of the category to which they belong.

4204

FLOW METER

TECHNICAL MANUAL P/N XXX-0000 Rev. 5 Ver. 3.4

3

1.3.2 SAFETY OF OPERATING ENVIRONMENT

•The 4204 unit is watertight against any infiltration of liquids. Avoid subjecting the

equipment to risks of seepage, sprays or anything else and do not use in areas in which such

risks are possible. Any power units in which liquids may have accidentally fallen should be

immediately turned off, cleaned and checked by authorised and qualified personnel.

•Once programming has been completed, close the transparent panel.

•Protection.

4204 Wall mounting

−IP66 EN60529

−EMI /RFI CEI EN55011 - 05/99

4204 144x144 Panel mounting

−IP10 EN60529

−EMI /RFI CEI EN55011 - 05/99

•Utilise the instrument within the specified environmental limits of temperatures and

humidity. The instrument is constructed to withstand operation in the following environmental

conditions:

−environmental operating temperature 0°C ÷ +50°C

−storage and transporting temperature -25°C ÷ +65°C

−relative humidity 10% ÷ 95%RH - non-condensing

CAUTION

The plant, in which the instrument is introduced, must be constructed according the

operating requirements provided by the current legislation.

The instrument must be perfectly introduced in the plant.

The plant must be operated in full compliance with the provided safety regulations.

Any signals of faults to the power unit should be placed in an area constantly controlled by

operative personnel or plant assistants.

Failure to comply with one of these conditions may cause the unit “logic” to operate in a

potentially dangerous mode for the users of the service.

Therefore, we recommend to the servicing and/or maintenance personnel to operate with

the utmost thoroughness, promptly signalling any variations of the safety parameters, in

order to prevent the development of dangerous conditions or potentially dangerous

conditions.

Because the above explained considerations do not fall under the possibilities of control by

the instrument in the subject, the manufacturer shall not in any way or fashion be held

responsible for any damages that such malfunctions may cause to persons or things.

4204

FLOW METER

TECHNICAL MANUAL P/N XXX-0000 Rev. 5 Ver. 3.4

4

1.4 GRAPHIC SIGNS

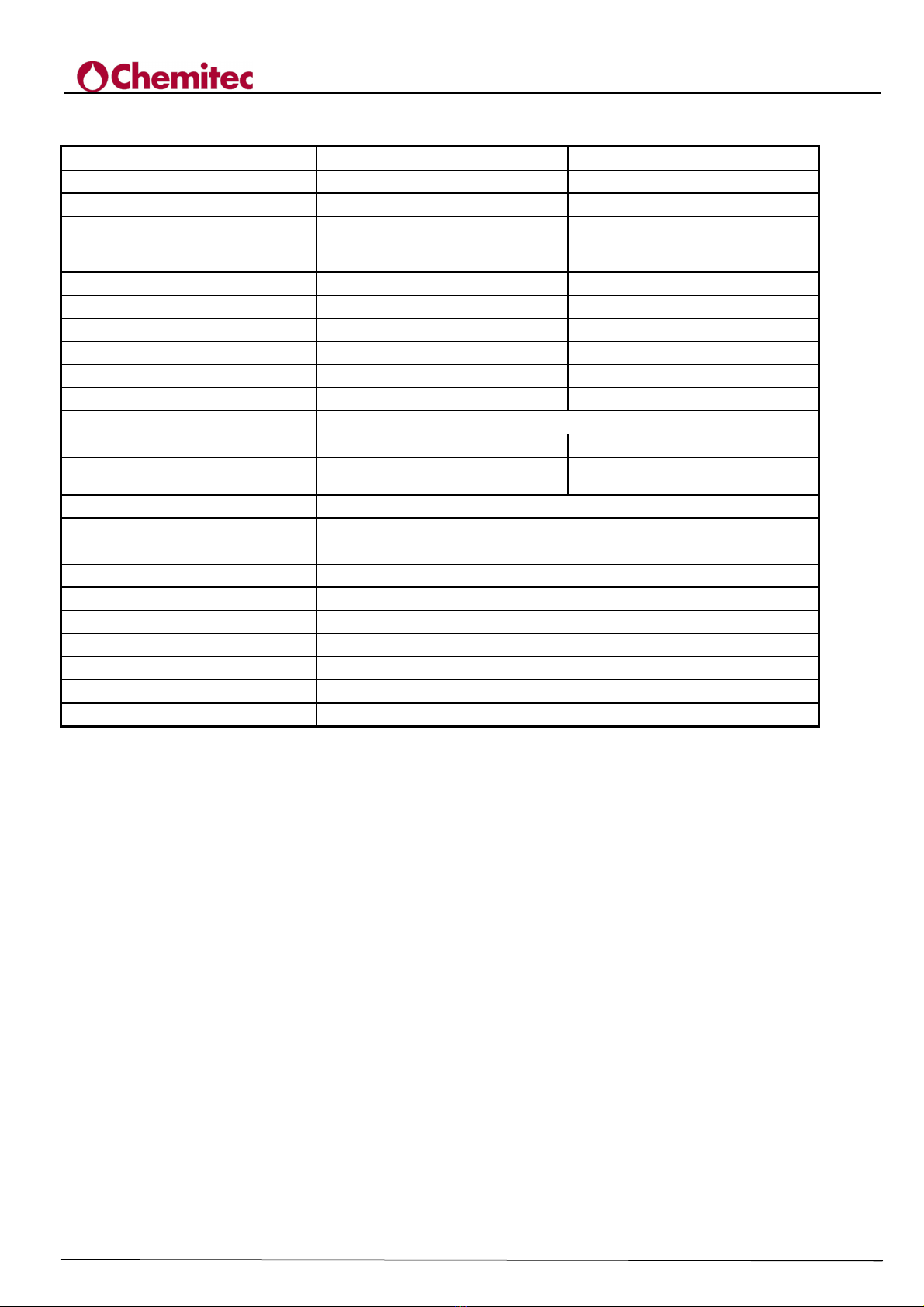

The following Table 1-1 indicates the drawings, relative descriptions and position of all the graphic

signs placed on the instrument panel and on any other external instruments or devices to which it

can be connected.

Table 1-1 Graphic signs

SIGN DESIGNATION POSITION

Danger sign Sign placed near the terminals for the connection

to line voltage (See Paragraph 1.4.1)

Phase

Signs placed near the connections of the

instrument to the power supply line (See Paragraph

3.1.1)

Neutral

Grounding protection

Caution! Consult the attached

documentation

Symbol positioned in correspondence with the

points in the manual that require special attention

Positive Positive pole of the connector RS485

Negative Negative pole of the connector RS485

Terminal Sign placed near the cable shielding for RS485

Analogue output no. 1 0/4 ÷20mA galvanic separation

Analogue output no. 2 0/4 ÷20mA galvanic separation

1.4.1 DANGER SIGN

The sign indicates DANGER for the operator. It is placed inside the instrument near the

points where the voltages present may be dangerous.

We recommend paying maximum attention.

Especially when the sign, placed near the cable connections to peripherals, refers to the attentive

reading of the user manual for a correct and safe connection.

4204

FLOW METER

TECHNICAL MANUAL P/N XXX-0000 Rev. 5 Ver. 3.4

5

1.5 PLATE DATA

The plate must be similar to the one reproduced in Figure 1-1.

Figure 1-1 Configuration of the Unit Number Plate

1.6 INFORMATION ON RECYCLING AND REUTILISATION OF MATERIALS

CHEMITEC objectives, in compliance with the specific European directives, including the directive

2002/95/CE, traditionally identified by RoHS, aims at continuously improving planning and

manufacturing of its own instruments, in order to reduce to the minimum the negative impact on

environment about handling the component parts, consumable materials, packing and instrument

itself, at the end of its useful life.

Packing are conceived and produced in order to allow their reutilisation or recuperation, including

recycling of most of the materials and to reduce to the minimum the amount of wastes and residuals

to dispose of. To guaranty a correct environmental impact, the instrument has been planned with

the utmost circuitry miniaturisation possible and with the least differentiation possible of materials

and components, through selection of substances that guarantee maximum recyclability and the

maximum reutilisation of the parts and a disposal of them devoid of ecological risks.

The instrument has been manufactured in a way to facilitate separation and disassembling of

materials containing polluting substances with respect to the others, especially during maintenance

and parts replacement operations, in accordance with the requirements of the Directive 2002/96/CE,

traditionally identified by RAEE.

WARNING

Disposal/recycling of packing, consumable materials or instrument itself at the end of its

useful life, must be carried out according to the provisions imposed by regulations and

directives currently in force in the country in which the instrument is utilised.

1.6.1 SPECIAL ATTENTION FOR CRITICAL COMPONENTS

The instrument is fitted with an LCD, liquid crystal display, which contains small quantities of toxic

materials.

Mod.

4204

SN.

XXXXXXX

Volt

100-240 Vac/dc

Hz

50/60

Fuse

3.15

SW Ver.

X.X

4204

FLOW METER

TECHNICAL MANUAL P/N XXX-0000 Rev. 5 Ver. 3.4

6

2 GENERAL DESCRIPTION

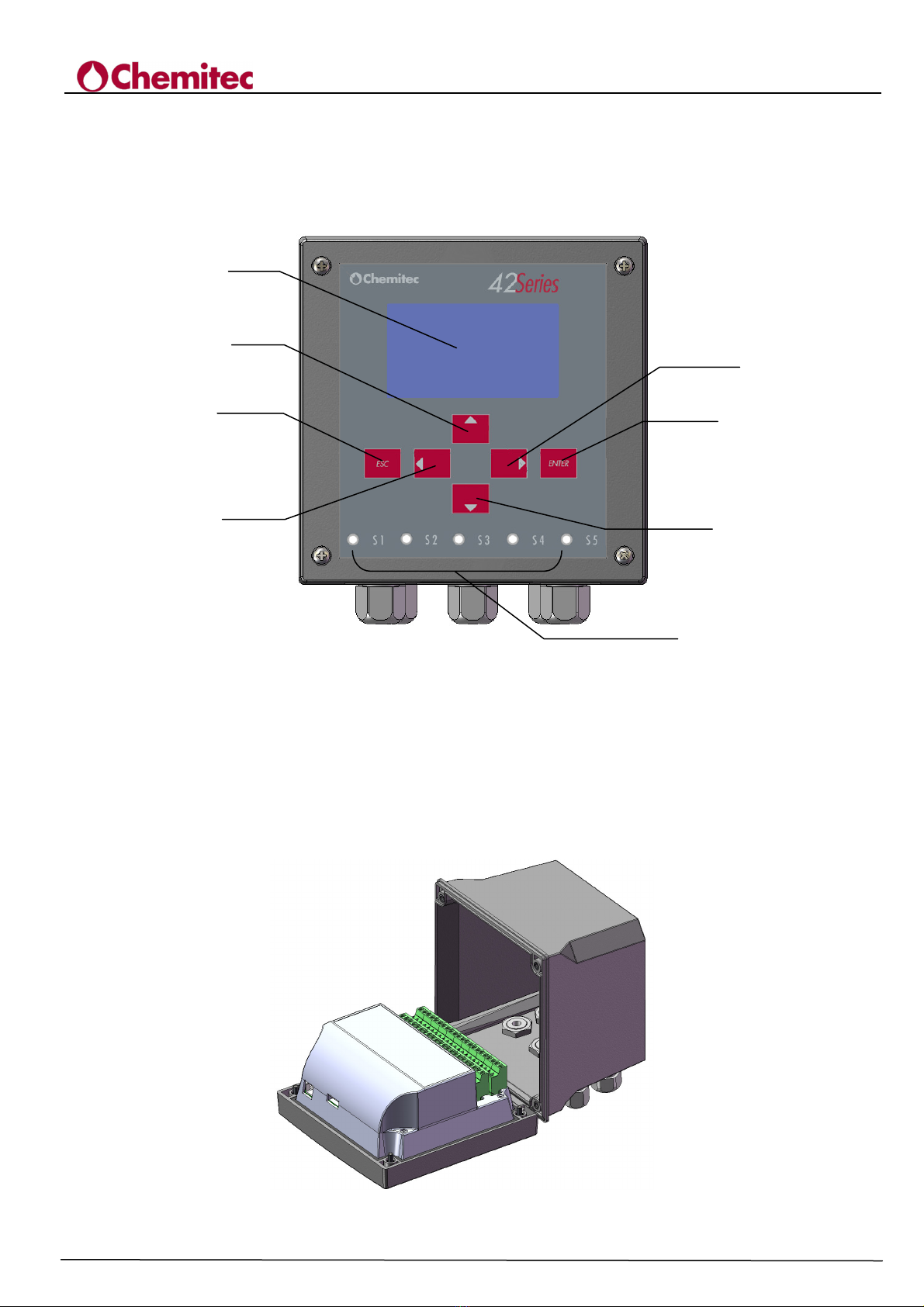

The unit shown in Figure 2-1 is provided for wall installation.

It is supplied by the line (85÷265Vac-50/60Hz) through power supplier Switching.

This instrument has been conceived as flow metre through an ultrasound probe with automatic

temperature compensation with display of the following at the same time:

•immediate flow (with a Bargraph percentage scale);

•total volume

•temperature

•status of the analogical outputs

•counters

Figure 2-1 – Ultrasounds level meter and regulator (4204)

2.1 MAIN FEATURES

•Ultrasound flow measurement

•Automatic temperature compensation

•Bubble 6 keys programming keyboard

•Graphic Display

•Serial Output RS485 MOD BUS RTU

•2 Programmable Analogue Outputs

•5 Relay output

•1 Relay output for Eco loss alarm

•Total counter that cannot be reset

•Partial counter accessible operatively

4204

FLOW METER

TECHNICAL MANUAL P/N XXX-0000 Rev. 5 Ver. 3.4

7

2.2 UNIT HARDWARE MAIN FEATURES

•Internal Data logger (flash 4 Mbit) with possibility of graphic and table display of

measurements trends.

•Five independent set points for threshold control, with programming of the work field

(hysteresis).

•Digital alarm output for eco loss.

•Primary output 0/4¸20mA with programmable limits for Flow/Temperature.

•Secondary output 0/4¸20mA with programmable limits for temperature/flow/level.

The technical specifications of the instrument are listed in Table 2-1, while the operating

specifications are listed in Table 2-2.

Table 2-1 Technical Specifications

Characteristics of dimensions

Measurement field Flow 0 ÷ 9999 mc/h

Level 0.30 ÷ 5.00 mt. - Temperatur : 0 ÷ 100 °C

Precision ± 0.2% F.S.

Unit of measurement Flow: mc/h, lt/sec – Level: m, cm, mm – Temperature: °C

Decimals Flow: 3 – Level: 3

Types of devices/exponents for each PMD

calculation (primary measuring device)

R TTANG (rectangular spout) / TRAP Z (Cipolletti spout) / V NTURI (Venturi

channel) /

PARSHALL (Parshall channel) / L OPOLD (Leopold Lagco channel) / STRAM. V (V

spout) /

OTH R (freely programmable exponent)

2 counters

Absolute at 9 figures - saved on Flash PROM not re-settable – Partial at 9 figures re-

settable

Characteristics of the

Hardware

DISPLAY screen

LCD STN Graphic 128x64 Backlit

Contemporary display of: Instant flow (absolute + bargraph for percentage of the

scale), Volume counted, Temperature, Status of the digital outputs, alarm events.

In scrolling: Level, Status of the analogical outputs, Re-settable counter

Controls 6 Bubble Keys

DATA LOGG R Internal with Flash 4 Mbit

Serial output n.1 RS485 Galvanic separated MODBUS RTU

Analogue outputs n.2 Programmable Galvanic Separated

1st Output: Flow / Temperature - 2nd output: Flow / Temperature / Level

Relay Outputs n.5 in xchange for Thresholds - n.1 in xchange for Alarm– (max load 1A ar 230V

ac resistive)

Digital Input n.5 Programmable

Power Supply 100÷240Vac/dc 50-60Hz – (Optional 24Vac/dc) – Transformer Insulation 4KV

Average power draw < 12W

4204

FLOW METER

TECHNICAL MANUAL P/N XXX-0000 Rev. 5 Ver. 3.4

8

Table 2-2 Operating Specifications

Measurement Recording

Instant flow Volume counted

Recordings Intervals 1/275/10/15/20/30/60 min 5/10/30 min. 1/2/6/12/24 h.

Type Circular /Filling Circular / Filling

Display

Graphic display of the minimum, maximum

and average values of the period and of

the Zoom function

Table

Analogue Outputs

Primary Secondary

Quantity/Size Flow / Temperature Flow / Level / Temperature

Type 0.00 ÷ 20.00 mA / 4.00 ÷ 20.00 mA 0.00 ÷ 20.00 mA / 4.00 ÷ 20.00 mA

Range Limit Programming: Lower / Upper Limit Programming: Lower /Upper

Maximum Load 500 Ohm 500 Ohm

Alarm Output according to NAMUR 2.4 mA (with Range 4/20mA) 2.4 mA (with Range 4/20mA)

5 relay outputs

Function– selectable Threshold Pulses

Programming ON-OFF with hysteresis De-multiplier: 1,10,100mc/h

Duration: 250,500,1000,2000 msec

Alarm

Function co loss alarm

Programming

Time Out ( eco loss time):

00:00 ÷ 24:00 h

Relay operation Closed/Open

Operating Conditions

Operating Temperature 0÷50°C

Transport and Storage -25÷65°C

Humidity 10-95% non condensed

Protection Closed IP66 N60529

MI / RFI C I- N55011 – 05/99

4204

FLOW METER

TECHNICAL MANUAL P/N XXX-0000 Rev. 5 Ver. 3.4

9

2.3 CONTROLS AND INDICATORS

Controls and indicators are grouped on the front of the Unit so that they can be easily available for

the operator.

Figure 2-2 identifies all the Unit controls and connecting devices.

1. LCD Display

2. S1÷S5

3. UP Key

4. RIGHT Key

5. ESC Key

6. ENTER Key

7. LEFT Key

8. DOWN Key

Figure 2-2 – Frontal Panel, Unit Wall model

Figure 2-3 – Access to the terminal box

6

4

8

3

5

7

1

2

4204

FLOW METER

TECHNICAL MANUAL P/N XXX-0000 Rev. 5 Ver. 3.4

10

3 INSTALLATION

Although the unit is suitable for installation in outdoor environments, it is recommended to avoid

direct exposure to sun and weather. Before installing the 4204 carefully read the instructions

provided below.

3.1 COMPOSITION OF THE SUPPLY

The supply consists of just one package which contains the following parts:

•1 electrical control and command panel PN ............?????

•1 Technical Manual PN ............?????

3.1.1 INSTALLATION OF WALL MOUNTED DEVICE

The wall must be completely smooth in order to allow for perfect adhesion of the device.

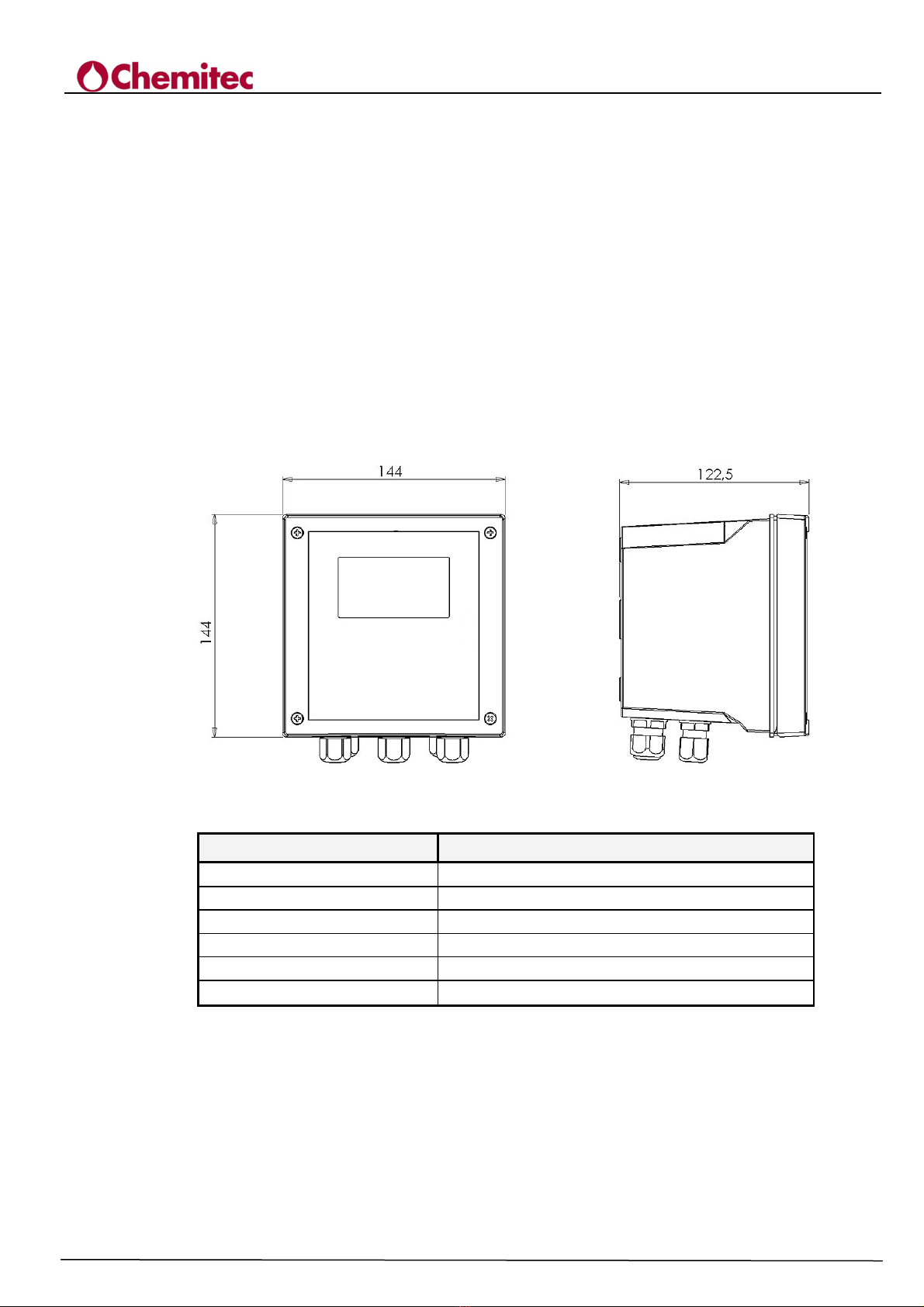

Figure 3-1 – Dimensions and encumbrance of the wall mounted device

Mechanical Dimensions 4204

Dimensions (L x H x P) 144x144x122,5mm

Fixing depth 122,5mm

Material ABS Grey RAL 7045

Mounting Wall

Weigth 1 Kg

Frontal Panel Policarbonate UV Resistant

Open the instrument, open the pre-shaped holes and fix the instrument itself to the wall. Use the

provided plastic caps to close the holes.

The terminal box for connections is located on the bottom of the gear case and it is necessary to

keep it separated from other equipment by at least 15 cm. in order to make it easier to use. Keep

away from water drips and/or sprays of water from adjacent areas in order to safeguard the

instrument during programming or calibration stages.

4204

FLOW METER

TECHNICAL MANUAL P/N XXX-0000 Rev. 5 Ver. 3.4

11

3.1.2 INSTALLATION OF 144X144 ELECTRICAL PANEL DEVICE

The wall must be perfectly smooth in order to allow for perfect adhesion of the electrical panel close

to the device.

The net depth of the panel must be at least 130 mm.

The thickness of the panel must not exceed 5 mm.

The perforation DIMA must comply with the following layout:

Figure 3 – Encumbrance and Dima for perforation of the panel

Mechanical Dimensions 4204 144x144 Panel Mounted

Dimensions (L x H x P) 144x144x86,5mm

Fixing depth 70mm

Material ABS Grey RAL 7045

Mounting Panel

Weight 0.7 Kg

Frontal Panel Policarbonate UV Resistant

The locking of the control unit to the panel is made through the mounting backplate, which is fixed

to the panel on the inner side, using the apposite screws.

4204

FLOW METER

TECHNICAL MANUAL P/N XXX-0000 Rev. 5 Ver. 3.4

12

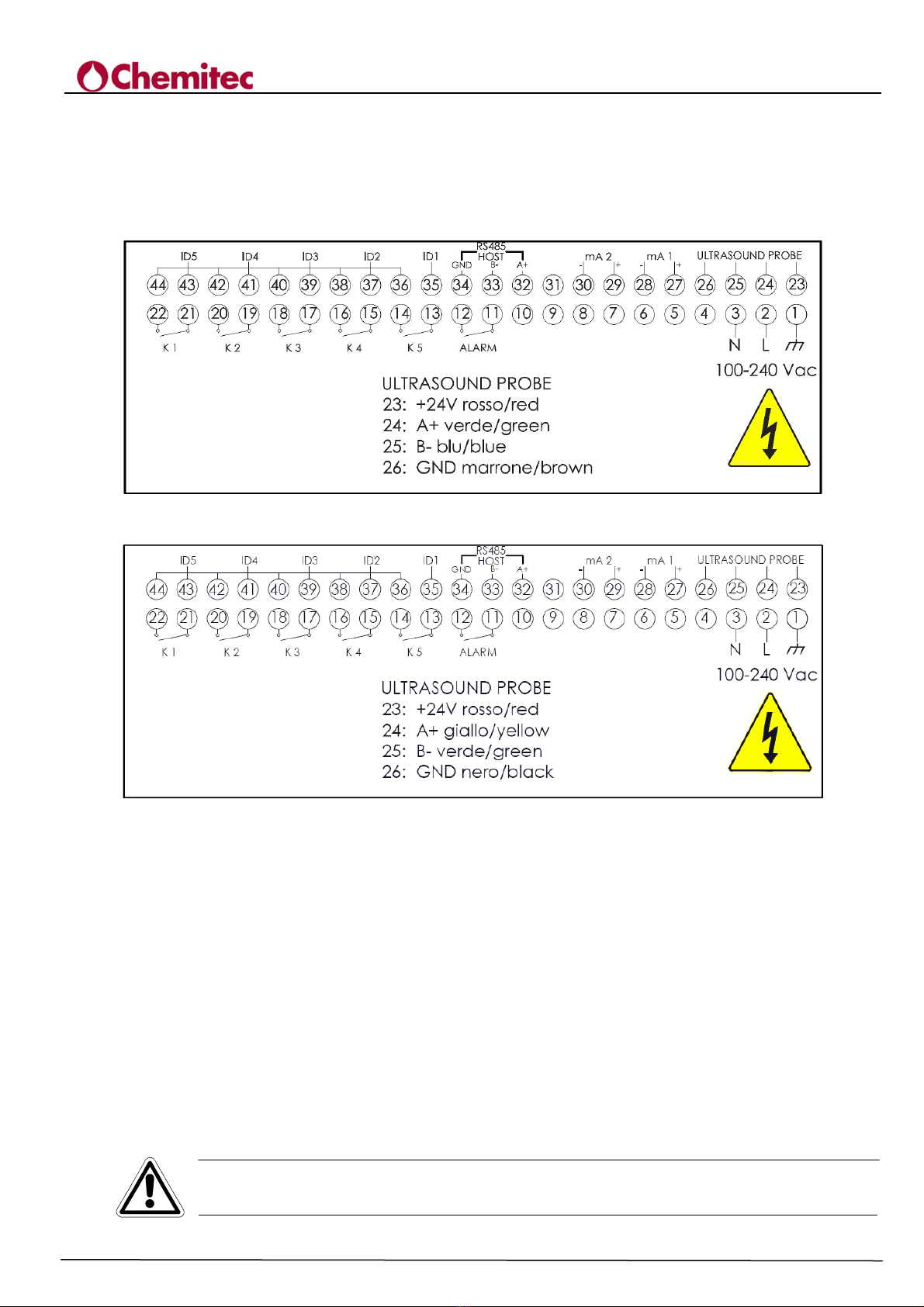

3.1.3 TERMINAL BOARD CONNECTIONS

The terminal board connections and the definitions of the Unit connections to the plant to be placed

under control are shown in Figure 3-2 and 3-3 (depending by the connected probe).

It shows the connections diagram viewable on the cover of the connections housing.

Figure 3-2 Electric connections for S425

Figure 3-3 Electric connections for S425/C

3.2 CONNECTING POWER SUPPLY LINE

If all possible make sure that there aren’t any cables assigned to the controls of other power drawing

equipments near the unit or on the same path of the connecting cable, which could create inductive

interferences for the instrument.

As much as possible, apply to the instrument stabilised power voltage according to the information

on the plate.

Absolutely avoid connecting the instrument to indirect/ reconstructed power supplies, for example,

through the use of transformers, where this reconstructed power goes to supply other systems

besides the unit (i.e.: inductive type), because this procedures generate high voltage spikes which

once they are radiated it’s difficult to block and/or eliminate them.

CAUTION

The electric line must be fitted with an appropriate circuit breaker and magnetothermic

switch, in compliance with good rules of installation

4204

FLOW METER

TECHNICAL MANUAL P/N XXX-0000 Rev. 5 Ver. 3.4

13

In any case, it is always advisable to verify the quality of Grounding. Often Ground connections,

found mostly within industrial environments, are themselves generators of interferences; where in

doubt about the quality, it is preferable to connect it to a pole dedicated only to the unit plant.

3.2.1 ELECTRICAL CONNECTIONS TO THE SYSTEMS

CAUTION

At the time pf starting the connections between the Unit and External Utilities, make sure

that electric board is turned-off and the cables coming from the Utility are not live.

•The Unit connections to the System must be carried out according the electric diagram of the

terminal board shown in Paragraph 3.1.1. The Unit is electronically protected, therefore, besides

the precautions on the power supply; it does not require special attentions.

•In reference to the sensor, it can be installed up to a distance of ~ 1000m from the Unit, without

causing any appreciable loss of signal.

•The position of the sensor should be between the limits the defined in the Chapter "Installation".

3.2.2 INSTALLATION OF THE PROBE

•Protect the probe from direct sunlight and reverb

•Wait at least 30 minutes after the first power on before calibrating the distance

•Keep the probe closer to the maximum water swing + 30 cm to prevent the air between the

projection and the water from assuming values that are too different from the probe

4204

FLOW METER

TECHNICAL MANUAL P/N XXX-0000 Rev. 5 Ver. 3.4

14

4 OPERATING MODE – GENERAL

This chapter describes the procedures that must be followed to enable all the functions of the

programme. The description is distributed between text and Figures:

•The Figures show all the menus and submenus as they appear on the display when enabled.

•The text analyses all items of the various menus and showing, for each of them, the enabling

procedures, functions they perform and range of values that can be set, whenever requested to

enter numeric values.

•All settings under the control of the Programme are described in a specific paragraph listed in

the index.

This editorial technique, even though makes numbering paragraphs complex, it offers a

noticeable advantage of transforming the index in a simple and powerful tool for the search

because it lists all the subjects and it indicates where they are discussed.

4.1 DISPLAYING SYSTEM

The displaying of the system is done through graphic displays, which allows viewing all the various

programming menus and, in operating mode, (“RUN”), the display of operating settings inputted

and their operating status.

•The operative methods related to activation of the System are described in Chapter 5.

•The operative methods related to the "RUN” menu are described in Chapter 6.

•The operative methods related to the “SETUP” menu are described in Chapter 7.

4204

FLOW METER

TECHNICAL MANUAL P/N XXX-0000 Rev. 5 Ver. 3.4

15

5 ENABLING THE SYSTEM

After installing the electronic central control unit, it is necessary to go on programming the

software, which will allows for “personalising” the settings for a correct use of the instrument.

TURN-ON the instrument by supplying power to it. The unit is not equipped with a switch for

power supply; it is activated automatically with connection to the network.

5.1 START

At the first System Start-up the system initialisations are carried out, which should occur during

installation or in case of power interruption which, if not modified, will depend from the settings

present on the flash disk.

During this phase a check of the flash disk is performed and, if errors are detected, the instrument is

blocked and the following message is displayed:

“FLASH DISK ERROR”

In the presence of this kind of error, request intervention from technical assistants. If, on the

contrary, everything runs smoothly, the programme will load the operative set-up parameters and

will start to operate with them as a base.

During a parameter recall operation, memorisation errors may occur. If this is the case, the

programme will cancel loading of these parameters and the intervention of technical assistants. If

everything runs smoothly, the set-up parameters set by the operator will be loaded; if errors are

encountered the following message will appear:

“DEFAULT SETUP LOADED”

indicating that the default parameters will be loaded (and used); to continue press the "ENTER" key.

This message will also appear if programming has never been carried out before (therefore the set-

up parameters in the flash disk have never been registered).

A bad quality of display may depend from an incorrect adjustment of the display contrast.

Contrast regulation may be set when the device is turned on by working with the "UP" or "DOWN"

key at the same time as feeding of the power unit (Fig. 5-1).

The contrast reader will appear indicating the percentage value which, in standard conditions,

should be between 65%÷70%. Once the best level of contrast has been achieved, press “ENTER”.

The programme will enter a "RUN" mode.

Contrast may be regulated operatively using the "CONTRAST" function as described in paragraph.

7.2.2.5.1.

Figure 5-1 – Contrast Mode Flow-Chart

69%

ENTER

DOWN220V

12/09/05 16:41

0 l

/s

0003496.54m

3

19

4204

FLOW METER

TECHNICAL MANUAL P/N XXX-0000 Rev. 5 Ver. 3.4

16

6 RUN MODE

This mode keeps operation of the plant under control in real time.

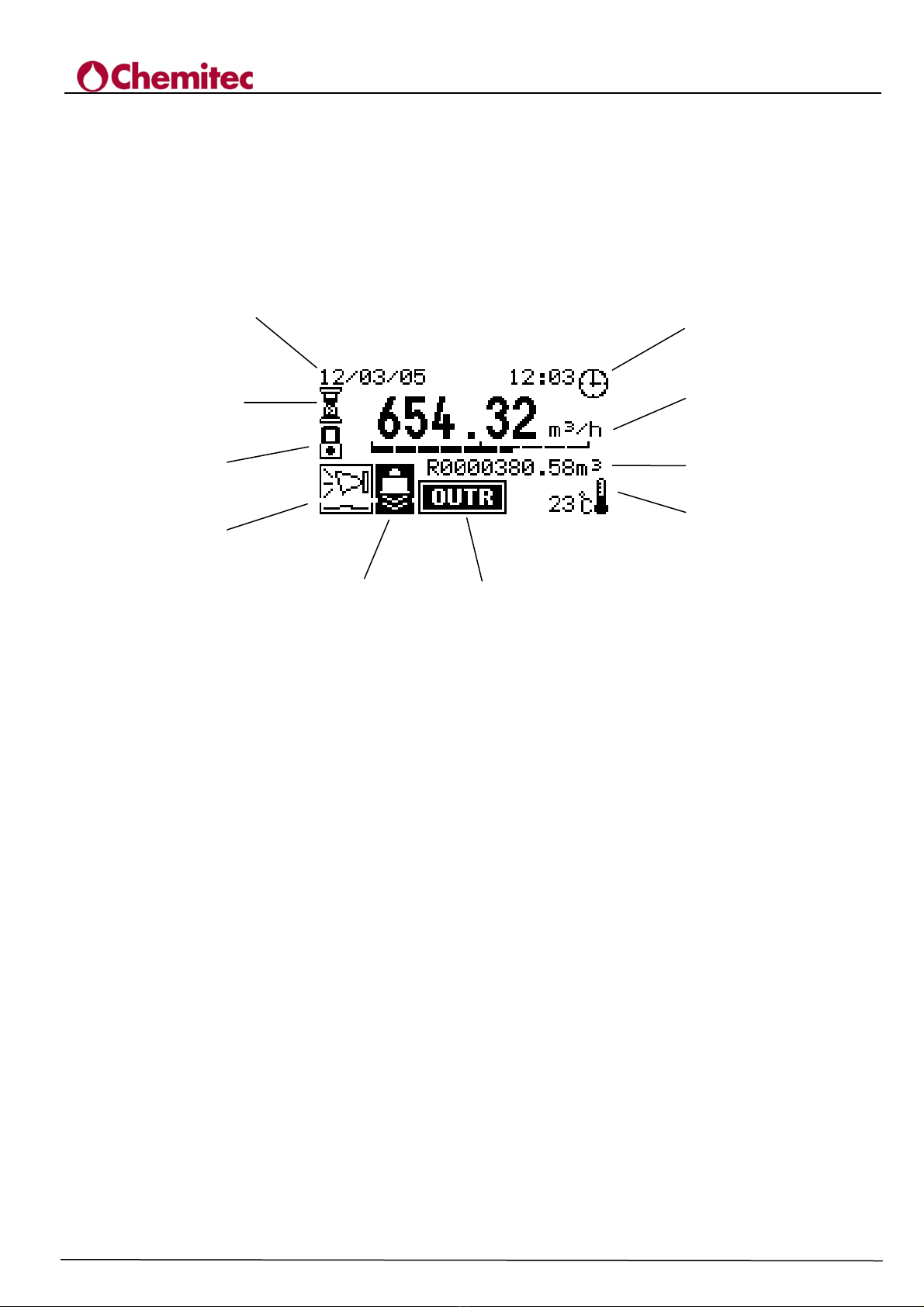

The operative parameters are represented on the screen by the power unit, according to the symbols

shown in Figure 6-1 and in Table 6-1.

Table 6-1 illustrates the operative symbols of the "RUN" mode, the meaning of which is as follows:

Figure 6-1 Typical Run Mode Displayed

2

1

3

4

5

6

7

9

11

12

Table of contents

Other Chemitec Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Arbiter Systems

Arbiter Systems 1092A Operation manual

Tektronix

Tektronix TLA 714 Service manual

Thermo Scientific

Thermo Scientific HAAKE RotoVisco 1 instruction manual

Automation Dr. Nix

Automation Dr. Nix QNix 5500 Operation manual

AquaLabo

AquaLabo PONSEL Supratec S200TUr owner's manual

DNT

DNT Video-Digitizer Grabstar PRO user manual