Chemitec 50 SERIES User manual

50 SERIES

MULTIPARAMETER PLUG & PLAY

ANALYZER

TECHNICAL MANUAL

P/N: ………………….

Rev. 0 Ver. 1.2

EDITION June 2012

50 Series

MULTIPARAMETER PLUG & PLAY ANALYZER

TECHNICAL MANUAL P/N XXX-0000 Rev.0 Ver.1.0

II

GENERAL CLAUSES

Despite the fact that the utmost attention has been given taken in the

preparation of this document, CHEMITEC s.r.l. cannot guarantee the

accuracy of all information contained and cannot be held responsible for any

consequent mistakes or damages that may arise from its use or application.

The products, materials, software and services presented in this document

are subject to development and with regards to presentation and

performance characteristics, CHEMITEC s.r.l. reserves the right to carry out

any modifications without prior notice.

COPYRIGHT

The reproduction or copy of this manual, even partial, and using any

procedure is strictly prohibited.

AUTHORISED TECHNICAL SUPPORT CENTRES

CHEMITEC s.r.l.

Via Isaac Newton, 28 – 50018 Scandicci - FIRENZE

50 Series

MULTIPARAMETER PLUG & PLAY ANALYZER

TECHNICAL MANUAL P/N XXX-0000 Rev.0 Ver.1.0

III

INDEX

1 GENERAL ............................................................................................................................................................... 1

1.1 INFORMATION ON THE MANUAL.............................................................................................................. 1

1.1.1 CONVENTIONS ........................................................................................................................................ 1

1.2 DECLARATION OF RESPONSIBILITY BY THE MANUFACTURER........................................................ 2

1.3 LIMITS OF USE AND PRECAUTIONS FOR SAFETY.................................................................................. 2

1.3.1 ELECTRICAL SAFETY ............................................................................................................................. 2

1.3.2 SAFETY OF THE OPERATIVE ENVIRONMENT .................................................................................... 3

1.4 GRAPHIC SYMBOLS ...................................................................................................................................... 4

1.5 CAUTION SYMBOL........................................................................................................................................ 4

1.6 PLATE DETAILS ............................................................................................................................................. 5

1.7 INFORMATION ON RECYCLING AND USE OF MATERIALS .................................................................. 5

1.7.1 SPECIAL ATTENTION TO CRITICAL COMPONENTS .......................................................................... 5

2 GENERAL DESCRIPTION................................................................................................................................... 6

2.1 PARAMETERS DETECTED BY THE INSTRUMENT ................................................................................. 6

2.2 MAIN CHARACTHERISTICS......................................................................................................................... 6

2.2.1 TECHNICAL CHARACTERISTICS FOR DISSOLVED OXYGEN ........................................................... 7

2.2.2 TECHNICAL CHARACTERISTICS FOR PH MEASURING .................................................................... 7

2.2.3 TECHNICAL CHARACTERISTICS FOR REDOX MEASURING ............................................................ 8

2.2.4 TECHNICAL CHARACTERISTICS FOR TURBIDITY AND SUSPENDED SOLIDS .............................. 8

2.2.5 TECHNICAL CHARACTERISTICS FOR nh4+ MEASURING ................................................................ 8

2.2.6 TECHNICAL CHARACTERISTICS FOR No3MEASURING.................................................................... 8

2.2.7 TECHNICAL CHARACTERISTICS FOR MEASURING OF SECONDARY TEMPERATURE................ 8

2.2.8 OPERATING FEATURES ......................................................................................................................... 8

2.3 CONTROLS, INDICATORS AND CONNECTIONS.................................................................................... 10

2.4 GRAPHIC DISPLAY ...................................................................................................................................... 11

2.4.1 LIST OF PRIMARY MENUS ................................................................................................................... 11

2.4.2 DIVISION OF THE GRAPHICAL DISPLAY INTO AREAS IN THE RUN METHOD ........................... 12

3 INSTALLATION................................................................................................................................................... 16

3.1 COMPOSITION OF THE SUPPLY................................................................................................................ 16

3.1.1 INSTALLATION OF WALL MOUNTED DEVICE.................................................................................. 16

3.1.2 CONNECTIONS TO THE POWER SUPPLY ..........................................................................................17

3.1.2.1 Electrical Connections to the dosage systems (Users) ........................................................................ 17

3.1.2.1.1 Connection terminal box for 50 Series .........................................................................................18

3.1.2.2 Connections to the Power Supply........................................................................................................ 19

3.1.3 OXYGEN PROBE CONNECTION .......................................................................................................... 19

3.1.4 PH / ORP, TURBIDITY / S.S. PROBE CONNECTION .......................................................................... 20

4 METHODS OF USE ............................................................................................................................................. 21

4.1 COMPOSITION OF THE MEASURING SYSTEM ...................................................................................... 21

4.1.1 MINIMUM CONFIGURATION .............................................................................................................. 21

4.1.2 MAXIMUM CONFIGURATION ............................................................................................................. 21

4.2 START UP OF THE SYSTEM ....................................................................................................................... 22

4.2.1 MENU FUNCTIONS AT START ............................................................................................................. 22

4.2.1.1 Contrast adjustment ............................................................................................................................. 22

4.3 INTRODUCTION OF OPERATIVE PARAMETERS –THE USE OF KEYS .............................................. 22

4.3.1 SETUP MENU (TEMPERATURE – SYSTEM SETUP) ..........................................................................23

4.3.2 SETUP MENU (DIGITAL INPUT) ......................................................................................................... 25

4.3.3 SETUP MENU (MEASURES SETUP - GENERAL)................................................................................ 25

4.3.4 SETUP MENU (MEASURES SETUP - OXYGEN).................................................................................. 26

4.3.5 SETUP MENU (MEASURES SETUP – TURBIDITY – PH – ORP – NH4+ – NO3).............................. 27

50 Series

MULTIPARAMETER PLUG & PLAY ANALYZER

TECHNICAL MANUAL P/N XXX-0000 Rev.0 Ver.1.0

IV

4.3.6 MENU SETUP OXYSMART .................................................................................................................... 28

4.3.6.1 Typical connection for Oxysmart functioning ....................................................................................28

4.3.7 MENU (RELAY OUTPUTS – SET POINT 1, 2, 3, 4).............................................................................. 29

4.3.8 OUTPUTS MENU (RELAY OUTPUTS – WASH, ALARM, LOGIC SET) ..............................................32

4.3.9 OUTPUTS MENU (CURRENT OUTPUT).............................................................................................. 34

4.3.10 OUTPUTS MENU (SETUP PID) ............................................................................................................ 35

4.3.11 CALIBRATIONS MENU.......................................................................................................................... 37

4.3.12 ARCHIVE MENU .................................................................................................................................... 44

4.3.13 MENU OF MEASURING GRAPHICS ....................................................................................................46

4.3.14 MENU MANUAL CONTROL .................................................................................................................. 47

4.3.15 FUNCTIONS IN RUN.............................................................................................................................. 48

5 USER MAINTENANCE ....................................................................................................................................... 50

5.1 SPECIAL CAUTIONS FOR CRITICAL COMPONENTS............................................................................. 50

6 APPENDIX: TABLES OF SOLUBILITY AND CONVERSION-CORRECTION FACTORS ................... 51

7 MODBUS PROTOCOL........................................................................................................................................ 52

8 WARRANTY ......................................................................................................................................................... 60

9 REQUEST FOR ASSISTANCE........................................................................................................................... 61

9.1 PROCEDURE OF REQUEST FOR TECHNICAL ASSISTANCE TECNICA .............................................. 61

9.2 MAIN CHEMITEC OFFICES......................................................................................................................... 61

50 Series

MULTIPARAMETER PLUG & PLAY ANALYZER

TECHNICAL MANUAL P/N XXX-0000 Rev.0 Ver.1.0

1

1 GENERAL

1.1 INFORMATION ON THE MANUAL

This document contains reserved information. It may be subject to modifications and updates

without any prior notice.

Printing chronology:

First edition: 50 Series – Ver. 0 Rev. 1.0

This manual is an integral part of the instrument. Upon initial installation of the equipment, the

operator must carry out a careful control of the contents of the manual in order to check its integrity

and completeness.

If for any reason it is ruined, incomplete or inadequate please contact CHEMITEC in order to

reintegrate or replace the non-compliant manual immediately.

The official versions of the machine, for which CHEMITEC is directly responsible, are the ones in

Italian and in English.

For countries of different languages from the ones indicated above, the official manual will remain

the one in Italian. CHEMITEC will not be held responsible for any possible translations in different

languages made by distributors or users themselves.

Compliance with the operative procedures and the precautions described in this manual is an

essential requirement for the correct operation of the instrument and to guarantee total operator

safety.

The manual must be ready in all parts, in front of the instrument, before use so that all methods of

operation are clear as well as the controls, connections to the peripheral equipment and precautions

for a correct and safe use.

The user manual must be stored, integral and legible in all parts, in a safe place and at the same time

it must be immediately accessible to the operator during installation, use and/or installation revision

operations.

1.1.1 CONVENTIONS

The present user manual uses the following conventions:

NOTE

The notes contain important information to be highlighted compared with the rest of the

text. They generally contain information that is useful to the operator to carry out and

optimise operative procedures of the equipment in a correct manner.

CAUTION

Caution messages appear in the manual before procedures or operations that must be

observed in order to avoid any possible losses of data or damages to the equipment.

CAUTION

Caution messages appear in the manual in correspondence to the description of procedures

or operations that, if carried out incorrectly, may cause damages to the operator or users.

50 Series

MULTIPARAMETER PLUG & PLAY ANALYZER

TECHNICAL MANUAL P/N XXX-0000 Rev.0 Ver.1.0

2

1.2 DECLARATION OF RESPONSIBILITY BY THE MANUFACTURER

CHEMITEC will be held responsible for the safety, reliability and performance of the equipment

only if used in compliance with the following conditions:

•Calibration, modifications or repairs must be carried out by qualified personnel, specifically

authorised by CHEMITEC.

•Opening of the equipment and access to its internal parts may only be carried out by personnel

qualified for maintenance and specifically authorised by CHEMITEC.

•The environment in which the equipment is used must comply with safety regulations.

•The electrical connections of the environment must be carried out according to regulations and

must be perfectly efficient.

•Replacements that can be carried out on parts of the equipment and accessories must be done so

with others of the same kind and of the same characteristics.

•The use and maintenance of the equipment and of relative accessories must be carried out in

compliance with the instructions indicated in this manual.

•This manual must always be kept integral and legible in all parts.

1.3 LIMITS OF USE AND PRECAUTIONS FOR SAFETY

In order to guarantee safety of the operator together with the correct functioning of the equipment, it

is important to work within the limits permitted and to adopt all of the precautions listed below:

CAUTION

Check before use to make sure that all safety requirements are fully satisfied. The

equipment must not be powered or connected to other equipment until safety conditions are

satisfied.

1.3.1 ELECTRICAL SAFETY

CAUTION

All of the connections on the are isolated from the environment ground (mass is not

isolated).

DO NOT connect any of these connections to earth.

In order to guarantee conditions of utmost safety for the operator, we recommend that all of the

indications listed in this manual are respected.

•Power the equipment exclusively using network tension according to specifications (100 ÷

240 Vac/dc 50-60 Hz)

•Replace damaged parts immediately. Cables, connectors, accessories or other parts of the

equipment that may be damaged or not working correctly must be replaced immediately. In this

case contact your nearest authorised technical assistance centre.

•Only use accessories and peripheries specified by CHEMITEC. In order to guarantee all of

the safety requirements, it is important to make exclusive use of the accessories specified in this

manual which have been tested in combination with the equipment. The use of accessories and

consumption materials of other manufacturers or not specifically recommended by CHEMITEC

will not guarantee the safety and correct operation of the equipment. Only use peripherals that

comply with the regulations of their specific categories.

•According to UL, not connect to relay outputs a voltage exceeding 115V

50 Series

MULTIPARAMETER PLUG & PLAY ANALYZER

TECHNICAL MANUAL P/N XXX-0000 Rev.0 Ver.1.0

3

1.3.2 SAFETY OF THE OPERATIVE ENVIRONMENT

•The panel of the 50 Series device is protected against the introduction of liquids. Avoid

subject the equipment to the risk of dripping water, sprays of water or immersion in water and

the use in environments in which such risks may be present. Equipment in which liquids may

have accidentally penetrated must be immediately switched off, cleaned and controlled by

authorised and qualified personnel.

•Once programming has been carried out, we recommend that the transparent panel is closed.

•Protection.

50 Series Wall mounting

−IP65 EN60529

−EMI /RFI CEI EN55011 - 05/99

•Use the equipment within the environmental limits of temperature, humidity and pressure

specified. The instrument has been developed to operate in the following environmental

conditions:

−Temperature of the working environment 0°C ÷ +50°C

−Temperature of storage and transportation -25°C ÷ +65°C

−Relative humidity 10% ÷ 95%RH – not condensing

CAUTION

The water treatment plant in which the instrument is introduced must be developed in

accordance with the functional requirements imposed by current legislation.

The apparatus must be inserted perfectly into the plant.

The plant must be kept operative in full compliance with the safety regulations provided.

The parameters indicated on the analyser must comply with current regulations.

Any signals of faults to the device must be positioned in an environment that is constantly

controlled by operative personnel or plant assistants.

Non compliance with even just one of these conditions may lead the “logics” of the device

to operate in a potentially dangerous manner for users of the service.

Therefore, we recommend that service personnel and/or maintenance personnel operate

with the utmost care, pointing out any changes to the safety parameters immediately, in

order to avoid the creation of any potentially dangerous situations.

As the considerations indicated above cannot be controlled by the product in question, the

manufacturer will not be held responsible for any damages that these malfunctions may

cause to people or things.

50 Series

MULTIPARAMETER PLUG & PLAY ANALYZER

TECHNICAL MANUAL P/N XXX-0000 Rev.0 Ver.1.0

4

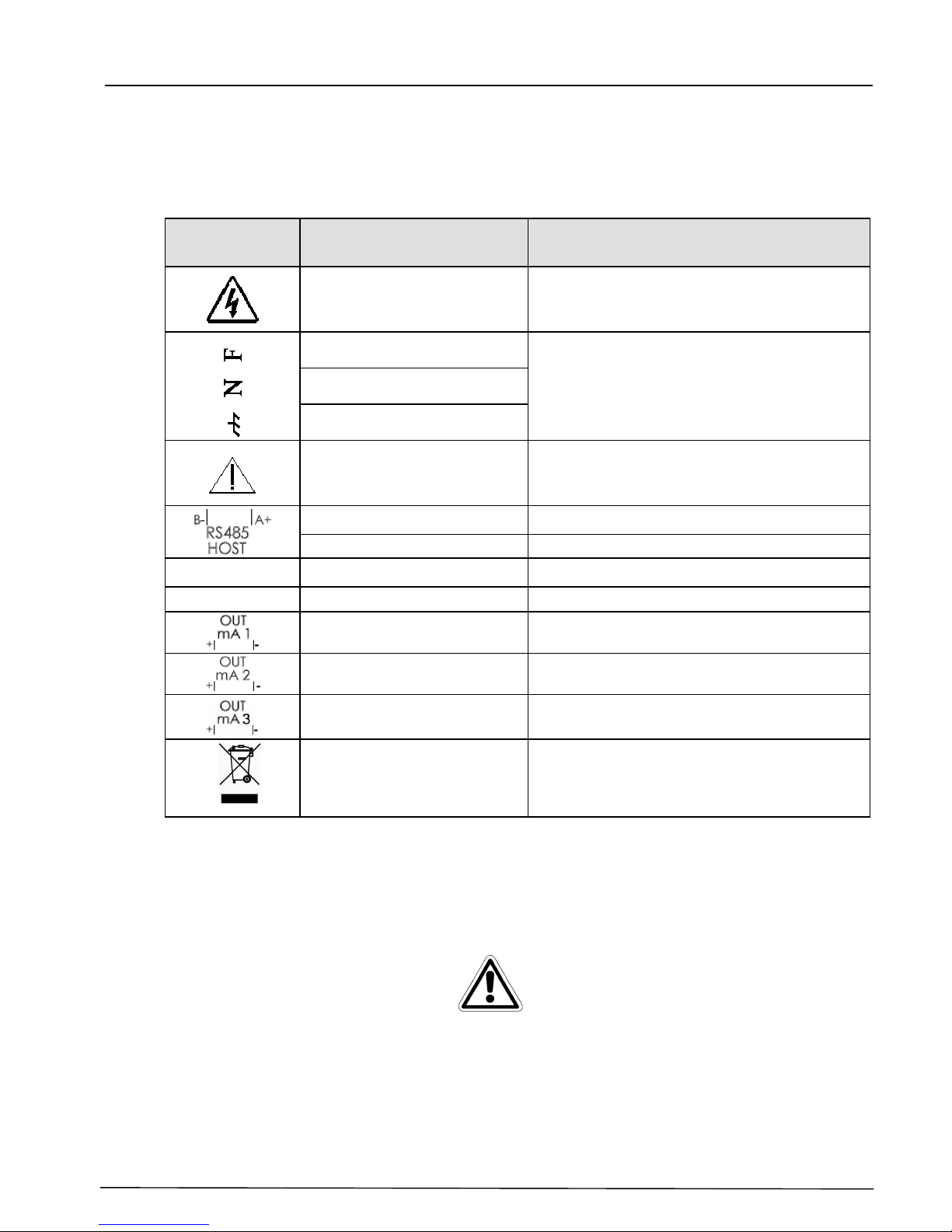

1.4 GRAPHIC SYMBOLS

The following table illustrates the drawings, the relative description and the position of all graphic

symbols present on the equipment panels and on any other equipment or external devices to which

they may be connected.

SIMBOLO DESCRIZIONE POSIZIONE

Danger symbol A symbol located close to the clamps for

connection to power.

Phase

Symbols located close to the connections of the

equipment to the electricity network

Neutral

Earth protection

Caution! Refer to the

documentation attached

A symbol located close to the points in which the

user manual should be consulted for important

information. (see paragraph CAUTION).

Positive POSITIVE pole of the connector RS485 (A+)

Negative NEGATIVE pole of the connector RS485 (B-)

PROBE 1 Probe 1 Connections of the first sensor

PROBE 2 Probe 2 Connections of the second sensor

Analogical output n.1 0/4 ÷20mA separated galvanically

Analogical output n. 2 0/4 ÷20mA separated galvanically

Analogical output n. 3 0/4 ÷20mA separated galvanically

Symbol of separate collection

of electrical and electronic

equipment.

Symbol placed on the top of the electronic box

1.5 CAUTION SYMBOL

The symbol illustrated below represents the CAUTION symbol and reminds the operator that he

should read the user manual for important information, advice and suggestions for the correct and

safe use of the equipment.

In particular, when it is positioned close to connection points to cables and peripheries, the symbol

in question refers to careful reading of the user manual for instructions related to the nature of such

cables and peripheries and the methods for correct and safe connections.

For the position of the CAUTION symbols on the equipment, refer to Chapter 2 “Commands and

Indicators, Connections” and Chapter 3 “Installation” of this user manual. The reproductions of

50 Series

MULTIPARAMETER PLUG & PLAY ANALYZER

TECHNICAL MANUAL P/N XXX-0000 Rev.0 Ver.1.0

5

equipment panels, with relative commands, connections, symbols and labels are provided in this

chapter. Each caution symbol is accompanied by a detailed explanation of its meaning.

1.6 PLATE DETAILS

1.7 INFORMATION ON RECYCLING AND USE OF MATERIALS

CHEMITEC, in accordance with specific European regulations, aims at constant improvement of

development and of production procedures of its equipment with the objective of drastically

reducing the negative impact on the environment caused by parts, components, consumption

materials, packaging and the equipment itself at the end of its life cycle.

Packaging is conceived and produced to allow for its re-use or recovery, including recycling of the

majority of the materials and to reduce the amount of waste or residues to be disposed of, to a very

minimum. In order to assure a correct environmental impact the equipment has been designed with

the smallest circuit possible, with the lowest differentiation possible of materials and components,

with a selection of substances that guarantee utmost recycling and maximum reuse of the parts and

waste disposal free from ecological risks.

The equipment is made in such a way as to guarantee the easy separation or dismantling of the

materials containing contaminants compared with others, in particular during maintenance

operations and the replacement of parts.

CAUTION

The disposal/recycling of packaging, of consumption materials and of the equipment itself

at the end of its life cycle must be carried out in accordance with the norms and regulations

that are currently valid in the country in which the equipment is used.

1.7.1 SPECIAL ATTENTION TO CRITICAL COMPONENTS

The instrument is fitted with an LCD liquid crystal display, which contains small amounts of toxic

materials.

Mod. 50 Series Plug & Play

Max 115V on relay outputs

50 Series

MULTIPARAMETER PLUG & PLAY ANALYZER

TECHNICAL MANUAL P/N XXX-0000 Rev.0 Ver.1.0

6

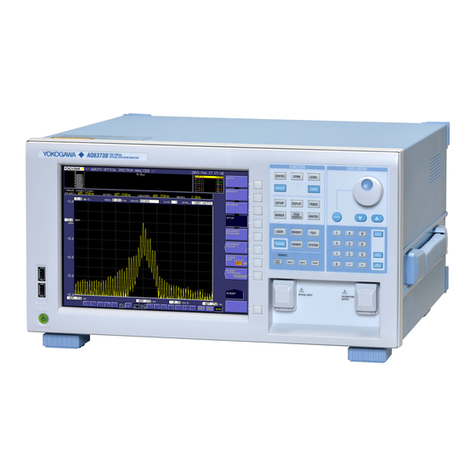

2 GENERAL DESCRIPTION

The analyser of this manual is made up of an electronic device plus a technical manual.

The device may be installed on a wall at a maximum distance of 15 metres from the measuring

Probe.

It is powered by the network (85÷265Vac/dc-50/60Hz), 7W power consumption by a Switching

feeder.

This equipment has been designed to analyse ON-LINE and pilot the dosage pumps for the

treatment of water in different applications:

•Waste water treatment plant

•Treatment and Discharge of Industrial Water

•Fish farm

•Primary Water, Drinking Water

Figure 1 – Wall mounting Multiparameter analyzer (50 Series)

2.1 P ARAMETERS DETECTED BY THE INSTRUMENT

•MEASURING OF PH

•MEASURING OF ORP

•MEASURING OF TURBIDITY

•MEASURING OF SUSPENDED SOLIDS

•MEASURING OF DISSOLVED OXYGEN

•MEASURING OF AMMONIA

•MEASURING OF NITRATES

2.2 MAIN CHARACTHERISTICS

•Up to two simultaneous digital measurements. Turbidity \ Suspended Solids \ pH \ diff. pH \

ORP \ diff. ORP \ Oxygen \ Ammonia \ Nitrates.

•Measuring of Temperature using the PT100/PT1000 probe

•Programming key pad with 5 keys

50 Series

MULTIPARAMETER PLUG & PLAY ANALYZER

TECHNICAL MANUAL P/N XXX-0000 Rev.0 Ver.1.0

7

•"CAL" Function Key to direct access to the calibration menu

•"GRAPH" Function Key to direct access to the graphs of measure

•“USB” Function Key for data download on USB support

•“MODE” Function Key for self-recognition probes

•LCD Graphic display 128x128 with background illumination

•Internal Data Logger (flash 4 Mbit) with the possibility of graphic and table visualisation of

measurement trends

•PID adjustment

•Serial outlet RS485 MOD BUS RTU

•Data download on USB support

•3 Programmable Analogical Outlets (with two equal measures the 3rd output can be set as

average)

•4 Relay Outlets for intervention thresholds (2 for each measurement)

•1 Relay Outlet for Instrument Anomaly Alarm

•1 Relay Outlet for Probe Washing or Temperature Set Point

•1 Digital Entrance for disabling of doses

Main hardware characteristics of the electronic device

The hardware structure of this periphery is based on the adoption of extremely new CPU CMOS

with 8 bits developed specifically for the execution of the so-called “embedded” applications.

The card uses an EEPROM to store the Set-up data and flash memories for storage of the archives

of historical data and LOG files of events.

The Card has 1 RS485 gate (opto-isolated) for local networks used for connections with local

communication devices (configuration computer, terminals and remote controls etc).

The card integrates a Real Time Clock (clock with date) that allows the software to storage figures

in a chronological order.

The device has been designed to be fitted onto a panel, and is built with an IP66 protection

panel.

2.2.1 TECHNICAL CHARACTERISTICS FOR DISSOLVED OXYGEN

The technical characteristics of the Analyser are listed in the following Table:

Measurement range 0.00 ÷ 20.0 ppm O2

0.00 ÷ 20.0 mg/L

000 ÷ 200 % SAT O2

Resolution ± 0.1 ppm O2

± 0.1 mg/L

± 001 % SAT O2

Accuracy ± 0.5% F.S.

2.2.2 TECHNICAL CHARACTERISTICS FOR PH MEASURING

Measurement range 00.00 ÷ 14.00pH

Resolution ± 0.01pH

Precision ± 0.2% f.s.

50 Series

MULTIPARAMETER PLUG & PLAY ANALYZER

TECHNICAL MANUAL P/N XXX-0000 Rev.0 Ver.1.0

8

2.2.3 TECHNICAL CHARACTERISTICS FOR REDOX MEASURING

Measurement range ± 1500mV

Resolution ± 1mV

Precision ± 0.2% f.s.

2.2.4 TECHNICAL CHARACTERISTICS FOR TURBIDITY AND SUSPENDED SOLIDS

Due to the connected probe:

Digital Probe Measuring Range / Measuring Unit

S461T 0 ÷ 4 NTU

0 ÷ 40 NTU

0 ÷ 400 NTU

0 ÷ 4000 NTU

S461S 0.00÷ 30.00 g/L

S461T Accuracy ± 2% F.S.

S461S Accuracy ± 3% F.S.

2.2.5 TECHNICAL CHARACTERISTICS FOR NH4+ MEASURING

Measurement range 0÷ 100ppm

Resolution ± 2ppm

Precision ± 2% f.s.

2.2.6 TECHNICAL CHARACTERISTICS FOR NO3MEASURING

Measurement range 0÷ 100ppm

Resolution ± 2ppm

Precision ± 2% f.s.

2.2.7 TECHNICAL CHARACTERISTICS FOR MEASURING OF SECONDARY

TEMPERATURE

Sensor PT100/PT1000

Measurement range 0 ÷ +130°C

Resolution ± 0.1°C

Accuracy ± 1% F.S:

2.2.8 OPERATING FEATURES

Power supply 100 ÷ 240 Vac/dc 50-60 Hz (optional 24 Vac/dc)

Power consumption < 7W

Relay outputs:

Set Point ON – OFF 0.0 ÷ 20.0 ppm O2 (for example )

0.0 ÷ 20.0 mg/L

000 ÷ 200 % SAT O2

ON – OFF Time 000 ÷ 999 Seconds

For every digital output a relay with contacts opened

normally is used. The maximum current commutable is

50 Series

MULTIPARAMETER PLUG & PLAY ANALYZER

TECHNICAL MANUAL P/N XXX-0000 Rev.0 Ver.1.0

9

1 Ampere, the maximum tension commutable is

230Vac, maximum power 230VA on a resistive load

Alarm:

Function Delay, Faults and Min./Max.

Delay time 00:00 ÷ 99:99 min

Threshold disabling Enable / Disable

Relay function Closed / Open

Holding range 0.0 ÷ 20.0 ppm ∆O2

0.0 ÷ 20.0 mg/L ∆O2

000 ÷ 200 % SAT ∆O2

Holding time 00:00÷ 99:99 min

For alarm end wash digital output, a relay with

contacts opened normally is used. The maximum

current commutable is 1 Ampere, the maximum tension

commutable is 230Vac, maximum power 230VA on a

resistive load

Digital input:

Input voltage 24 Vcc /ac

Absorption 10mA max

Analogic outputs:

Outputs n.3 programmable outputs 0/4-20mA

Max. load 500 Ohm

NAMUR alarm output 2.4 mA (with range 4/20mA)

PID dosing function P – PI – PID

Proportional band 0 – 500%

Integration 0:00 – 5:00 min

Derivative 0:00 – 5:00 min

50 Series

MULTIPARAMETER PLUG & PLAY ANALYZER

TECHNICAL MANUAL P/N XXX-0000 Rev.0 Ver.1.0

10

2.3 CONTROLS, INDICATORS AND CONNECTIONS

Figure 2 – Wall instrument, front panel

1. Visualizer with LCD Display

2. UP key

3. ESC key

4. ENTER key

5. DOWN key

6. GRAPH key

Figure 3 – Access to the terminal box

1

2

4

5

3

6

50 Series

MULTIPARAMETER PLUG & PLAY ANALYZER

TECHNICAL MANUAL P/N XXX-0000 Rev.0 Ver.1.0

11

2.4 GRAPHIC DISPLAY

The graphic display allows for visualization of the various programming menus and, in the

measuring method (RUN), visualization of the measurements and of the state of operation.

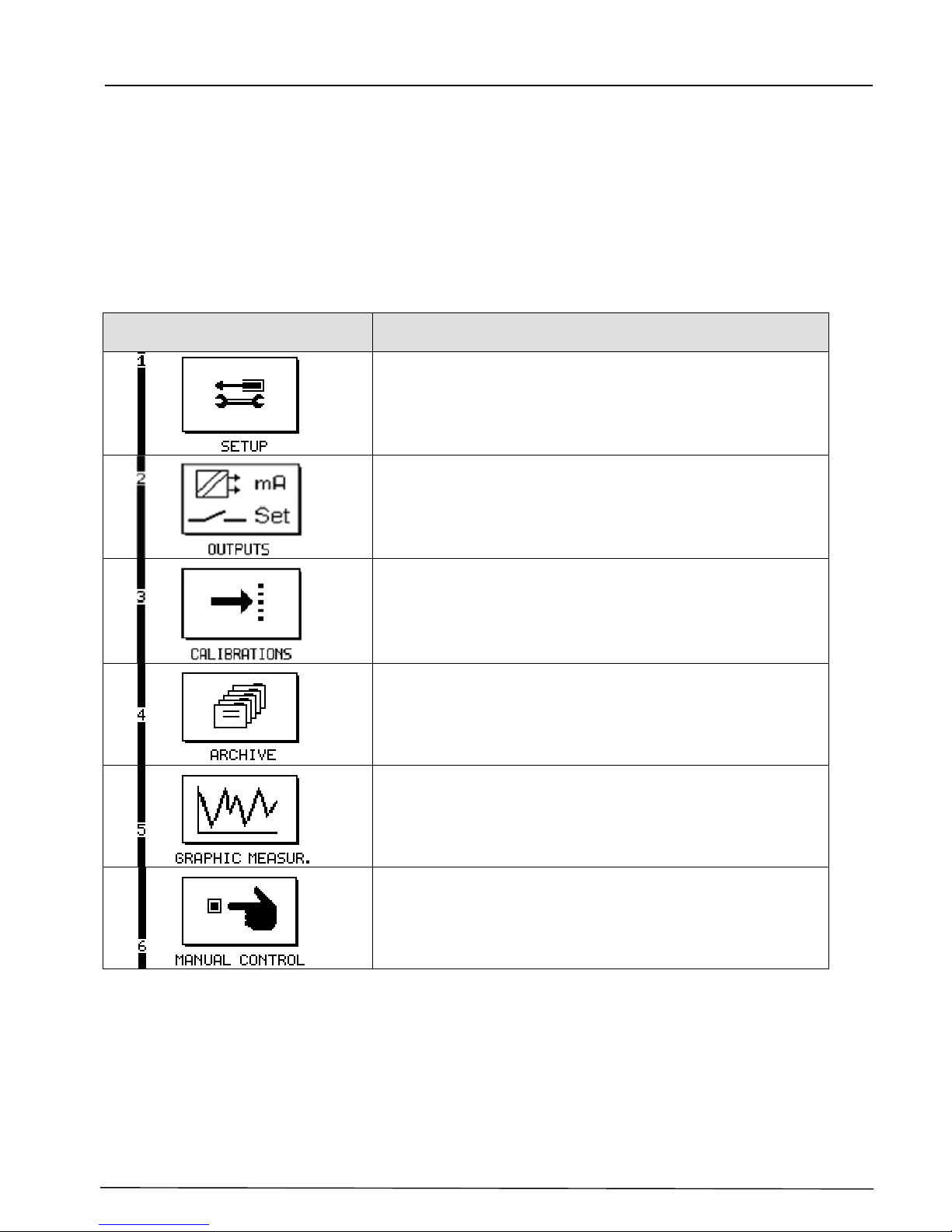

2.4.1 LIST OF PRIMARY MENUS

The following table illustrates the symbols visualized on the display which represent the various

programming menus.

VISUALIZATION

ON THE GRAPHIC DISPLAY

DESCRIPTION

SETTINGS MENU

All basic parameters for operation logics are set

OUTPUT MENU

Setting of analogical and digital outputs

CALIBRATIONS MENU

Calibration Procedure of the electrode

ARCHIVE MENU

Setting of the data archive and visualization mode

GRAPHICAL MEASUREMENT MENU

Visualization of archives in a graphical form

MANUAL CONTROL MENU

Manual control and activation of Inputs and Outputs

50 Series

MULTIPARAMETER PLUG & PLAY ANALYZER

TECHNICAL MANUAL P/N XXX-0000 Rev.0 Ver.1.0

12

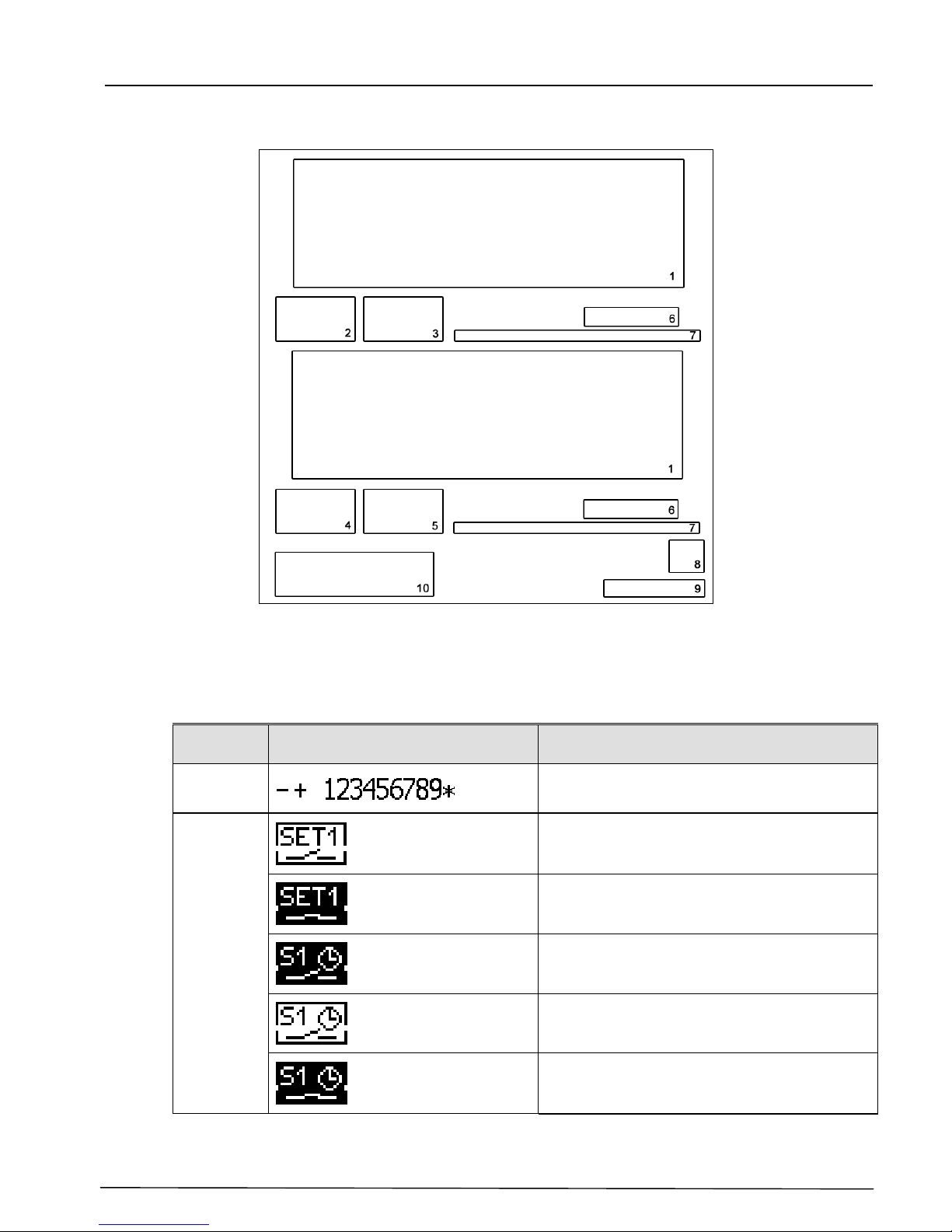

2.4.2 DIVISION OF THE GRAPHICAL DISPLAY INTO AREAS IN THE RUN METHOD

Figure 4 – Graphic display - divided up into areas

In the following table, for every area of the display indicated in figure 3, the symbols that may

appear during functioning of the device in a measurement method (RUN) are represented and

briefly described.

GRAPHIC

ZONE

VISUAL REPRESENTATION DESCRIPTION

1

Numerical

2

Set1 - Open Relay

Set1 - Closed Relay

Set1 – Timed

Active Threshold Relay Open

Set1 – Timed

Deactivated Threshold Relay Open

Set1 - Timed

Active Threshold Relay Closet

50 Series

MULTIPARAMETER PLUG & PLAY ANALYZER

TECHNICAL MANUAL P/N XXX-0000 Rev.0 Ver.1.0

13

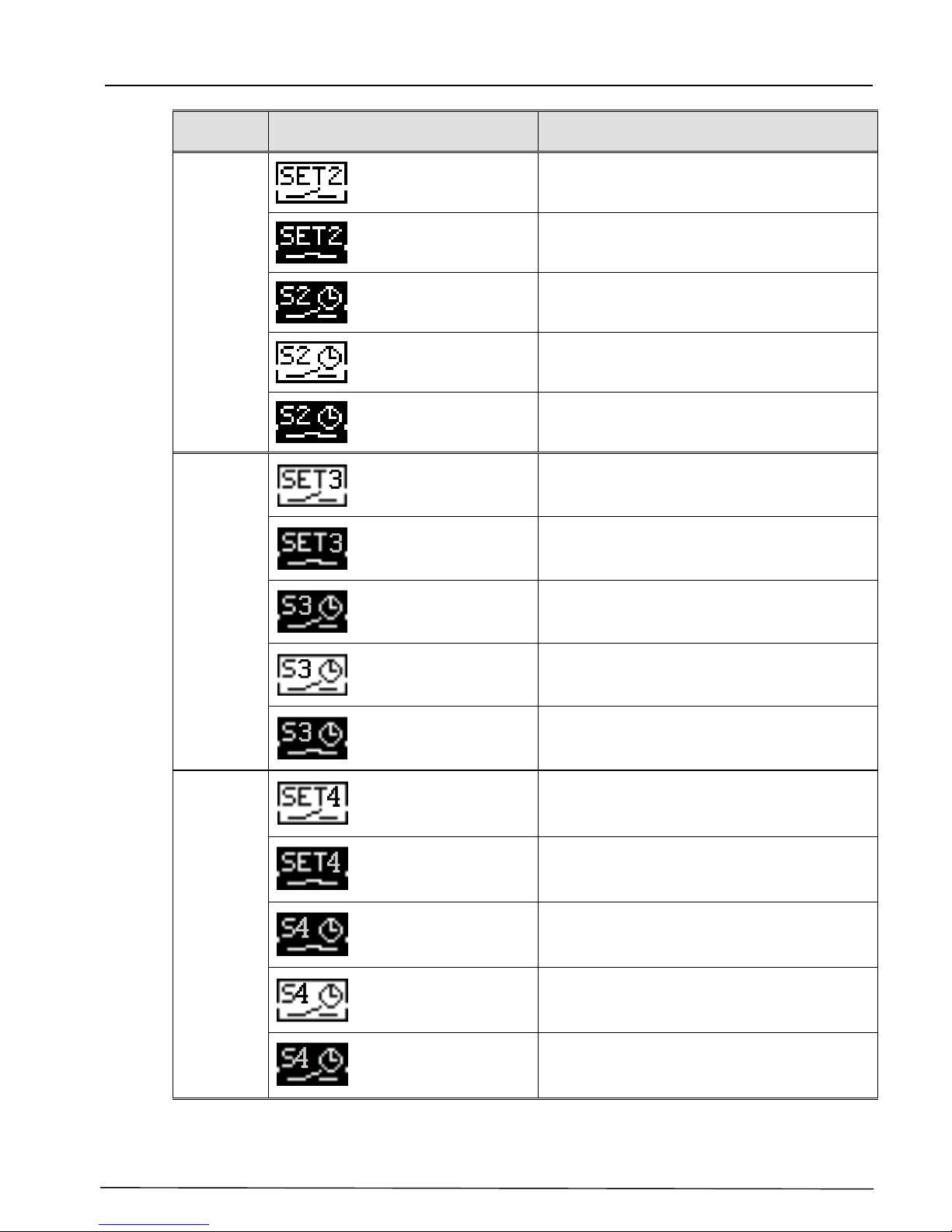

GRAPHIC

ZONE

VISUAL REPRESENTATION DESCRIPTION

3

Set2 - Open Relay

Set2 - Closed Relay

Set2 - Timed

Active Threshold Relay Open

Set2 - Timed

Deactivated Threshold Relay Open

Set2 – Timed

Active Threshold Relay Closed

4

Set3 - Open Relay

Set3 - Closed Relay

Set3 – Timed

Active Threshold Relay Open

Set3 – Timed

Deactivated Threshold Relay Open

Set3 - Timed

Active Threshold Relay Closet

5

Set4 - Open Relay

Set4 - Closed Relay

Set4 – Timed

Active Threshold Relay Open

Set4 – Timed

Deactivated Threshold Relay Open

Set4 - Timed

Active Threshold Relay Closet

50 Series

MULTIPARAMETER PLUG & PLAY ANALYZER

TECHNICAL MANUAL P/N XXX-0000 Rev.0 Ver.1.0

14

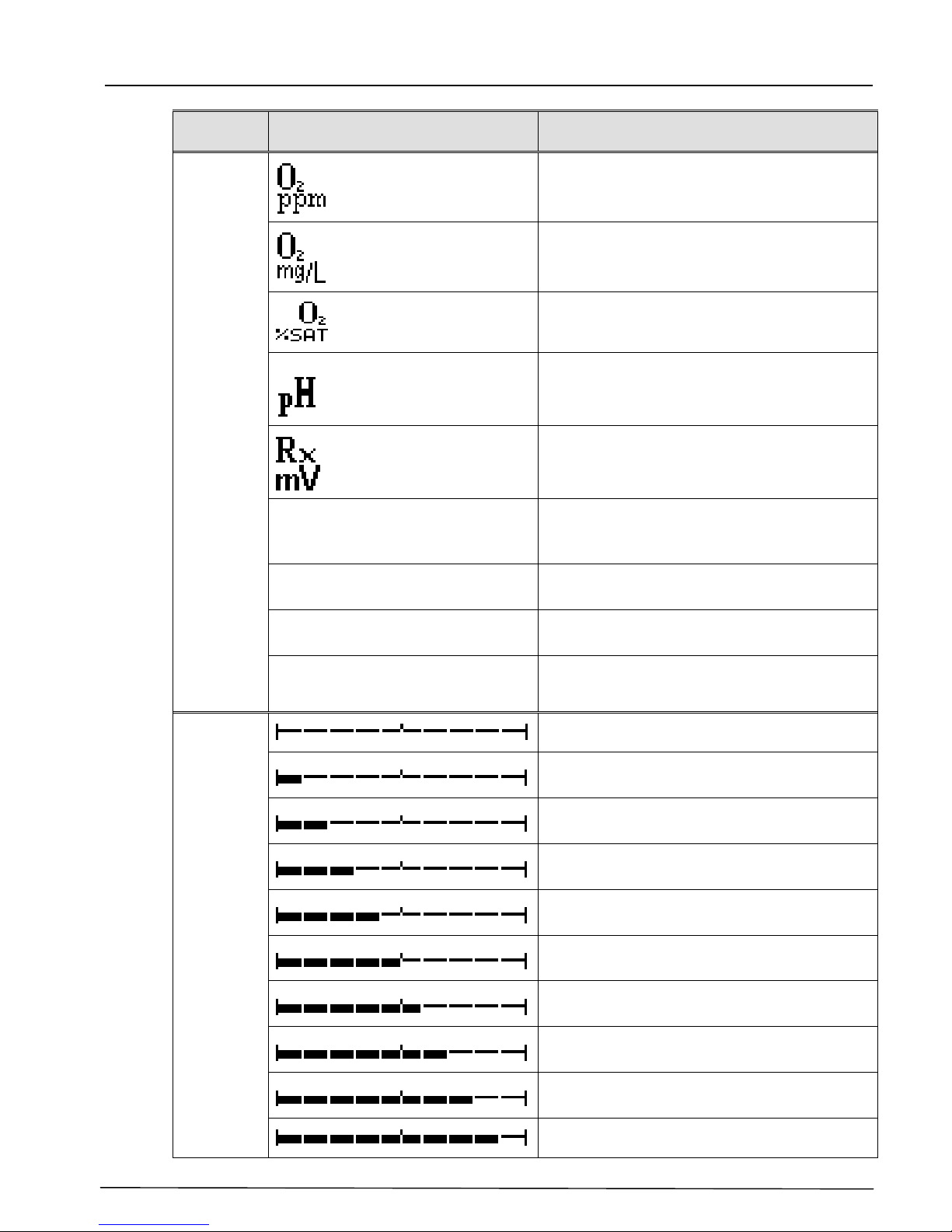

GRAPHIC

ZONE

VISUAL REPRESENTATION DESCRIPTION

6

Oxygen measurement unit

Oxygen measurement unit

Oxygen measurement unit

pH measurement unit

ORP measurement unit

NTU Turbidity and Suspended Solids

measurement unit

mg/L Turbidity and Suspended Solids

measurement unit

g/L Turbidity and Suspended Solids

measurement unit

ppm NO3/ NH4+

Unità di misura

7

0% of the scale

10% of the scale

20% of the scale

30% of the scale

40% of the scale

50% of the scale

60% of the scale

70% of the scale

80% of the scale

90% of the scale

50 Series

MULTIPARAMETER PLUG & PLAY ANALYZER

TECHNICAL MANUAL P/N XXX-0000 Rev.0 Ver.1.0

15

GRAPHIC

ZONE

VISUAL REPRESENTATION DESCRIPTION

100% of the scale

8

Value outlet n.1 (in mA)

Value outlet n.2 (in mA)

Value outlet n.1 with PID function PID (in

mA)

Value outlet n.2 with PID function PID (in

mA)

9

Real temperature value (in Fahrenheit)

Real temperature value (in Centigrades)

Manual temperature value (in Centigrades)

10

Disabling Set

Indicates digital entrance ON

Maximum Logical Set Exceeded

Minimum Logical Set Exceeded

Maximum dosage time exceeded

Washing stage active

Seconds during stabilization

Storage of Data

Archive full

50 Series

MULTIPARAMETER PLUG & PLAY ANALYZER

TECHNICAL MANUAL P/N XXX-0000 Rev.0 Ver.1.0

16

3 INSTALLATION

Although the unit is suitable for installation in outdoor environments, it is recommended to avoid

direct exposure to sun and weather. Before installing the 50 Series carefully read the instructions

provided below.

3.1 COMPOSITION OF THE SUPPLY

The supply consists of just one package which contains the following parts:

•1 electrical control and command panel PN ............?????

•1 Technical Manual PN ............?????

3.1.1 INSTALLATION OF WALL MOUNTED DEVICE

The wall must be completely smooth in order to allow for perfect adhesion of the device.

Figure 5 – Dimensions and encumbrance of the wall mounted device

Mechanical Dimensions 50 Series

Dimensions (L x H x P) 144x144x122,5mm

Fixing depth 122,5mm

Material ABS Grey RAL 7045

Mounting Wall

Weigth 1 Kg

Frontal Panel Policarbonate UV Resistant

Open the instrument, open the pre-shaped holes and fix the instrument itself to the wall. Use the

provided plastic caps to close the holes.

The terminal box for connections is located on the bottom of the gear case and it is necessary to

keep it separated from other equipment by at least 15 cm. in order to make it easier to use. Keep

away from water drips and/or sprays of water from adjacent areas in order to safeguard the

instrument during programming or calibration stages.

Other manuals for 50 SERIES

1

Table of contents

Other Chemitec Measuring Instrument manuals