Chemitech IT Perdana pH/ORP-3500 Series User manual

pH/ORP-3500

pH/ORPTransmitting controller

Operation manual

V1.1

Chemitech IT Perdana | Solution For Your Trouble | Service Laboratorium Instrument

https://chemitech.id

order via whatsapp: +6282366660856

Introduction

Thanks for choosing pH/ORP-3500 series pH/ORP meter. Please read the operation manual

carefully before installation. Proper sensor installation and parameter setting would give maximum

performance and advantage of this instrument for your good usage. So please carefully read this

manual before installation.

This instrument is a precise electrochemical analysis Dosing &Control Integration System,

which should be operated by technicians with relevant professional knowledge.

Please contact technical backup when you meet any problems during installation and usage.

Check the actual product with complete set after you receive the package, and contact us if

any missing or damage.

Our serious promise:

1. The meter’s quality guarantee is one year from the date of purchasing. During this period,

if the meter has quality problems, manufacturer is responsible for maintenance for free or

replacement.

2. We provide lifelong maintenance service for the product whatever you purchase from us or

distributors.

3. If the damage of the meter is caused by the following reasons, it is out of the maintenance

service:

A).The meter is burned caused by misconnection with high voltage power supply or soggy.

B).The meter is refitted or misused without permission.

C).The meter is damaged under the condition out of use environment.

D).The relevant damage caused by choosing the wrong type.

E).The physical damage caused by ultimate load

F).The meter is out of operation caused by improper storage and transportation (refer to

SJ/T10463-93 standard)

G).Consumable material is out of maintenance service.

Please take care of the items which with this sign.!

*Without the influence on the operation, any small change or improvement on the products by the

manufacturer will not be notified separately. Please make the object as the standard

Chemitech IT Perdana | Solution For Your Trouble | Service Laboratorium Instrument

https://chemitech.id

order via whatsapp: +6282366660856

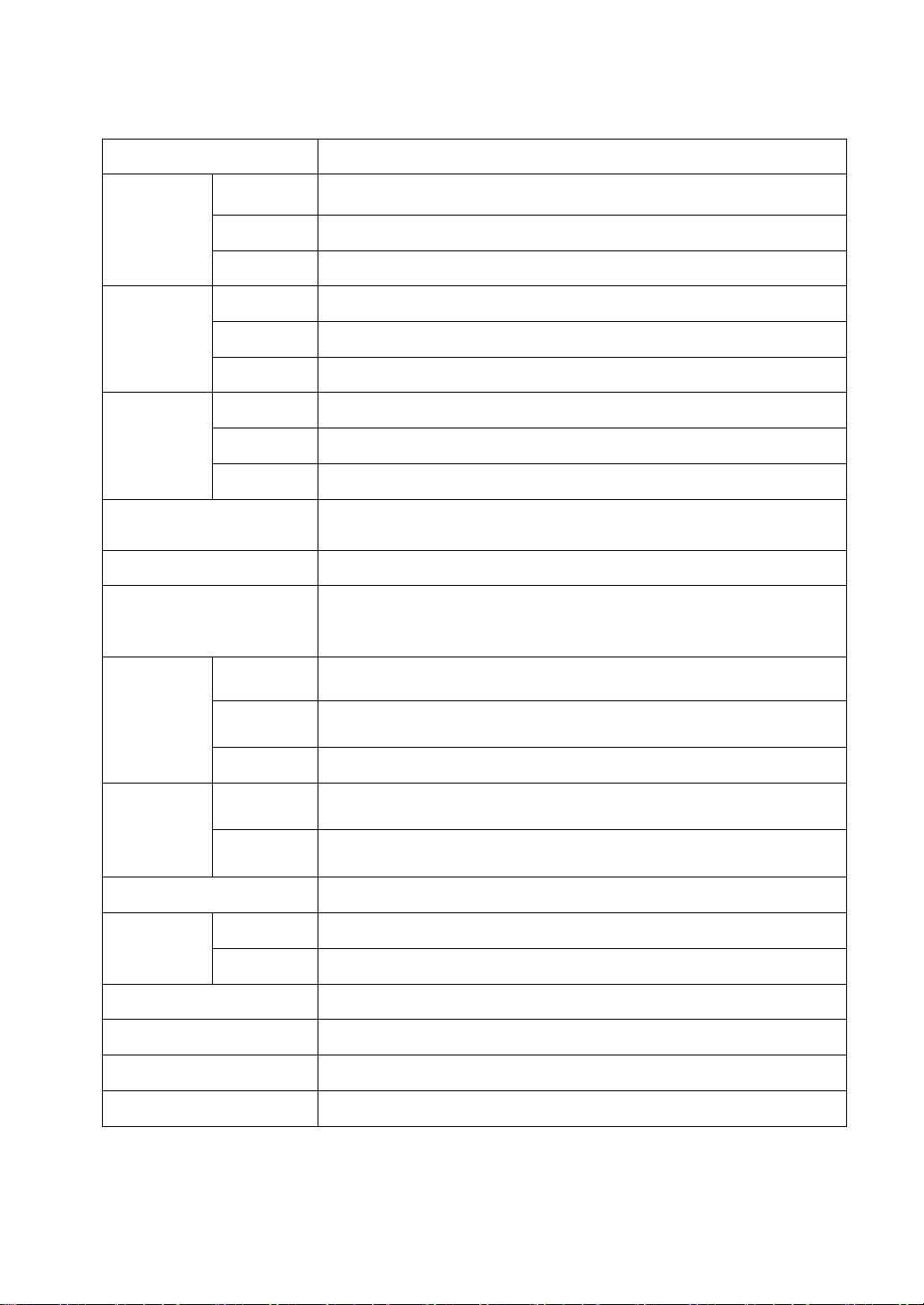

Content

Ⅰ、GENERAL..............................................................................................................1

1.1 WORKING PRINCIPLE................................................................................................................. 1

1.2APPLICATION................................................................................................................................ 1

1.3 CLASSIFICATION......................................................................................................................... 2

1.4TECHNIQUE INDEX...................................................................................................................... 3

Ⅱ、INSTALLATION....................................................................................................4

2.1 INSTALLATION OF INSTRUMENT............................................................................................ 4

2.2ELECTRICAL CONNECTION....................................................................................................... 5

2.3DIAGRAM OF 4-20MA OUTPUT.................................................................................................. 6

2.4 RELAY CONTROL CONNECTION.............................................................................................. 7

2.5 CONTROL MODE.......................................................................................................................... 7

2.6INSTALLATION OF SENSOR....................................................................................................... 8

2.6.1ASSEMBLING AND REPLACEMENT.................................................................................. 8

2.6.2INSTALLATION METHOD.................................................................................................... 9

2.6.3 INSTALLATION REQUIREMENT...................................................................................... 10

Ⅲ、SETTINGS............................................................................................................10

3.1MEASUREMENT MODE............................................................................................................. 12

3.1.1NORMAL DISPLAY..............................................................................................................12

3.1.2 TRANSIENT DISPLAY........................................................................................................ 12

3.2 SETTING MODE.......................................................................................................................... 12

3.2.1 FUNCTION SELECTION..................................................................................................... 13

3.2.2 4MA SETTING...................................................................................................................... 13

3.2.3 20MA SETTING.................................................................................................................... 13

3.2.4HIGH-LIMIT ALARM SETTING.......................................................................................... 13

3.2.5 LOW-LIMIT ALARM SETTING.......................................................................................... 13

3.2.6 ALARM HYSTERSIS SETTING.......................................................................................... 14

3.2.7 TEMPERATURE SETTING.................................................................................................. 14

3.3 SENSOR CALIBRATION............................................................................................................14

3.3.1 SYSTEM CALIBRATION..................................................................................................... 14

3.3.2 BUFFER SOLUTION CALIBRATION................................................................................ 14

3.3.3 OFF-LINE CALIBRATION.................................................................................................. 15

Ⅳ、MAINTENANCE................................................................................................. 16

4.1 SENSOR MAINTENANCE......................................................................................................... 16

4.2 USAGE OF SENSORS................................................................................................................. 16

Ⅴ、TROUBLE SHOOTING.......................................................................................17

Ⅵ、COMPLETE SET................................................................................................. 17

Ⅶ、ORDER DIRECTORY......................................................................................... 18

7.1SENSOR SELECTION.................................................................................................................. 18

7.2FLOW DEVICE SELECTION....................................................................................................... 18

Chemitech IT Perdana | Solution For Your Trouble | Service Laboratorium Instrument

https://chemitech.id

order via whatsapp: +6282366660856

1

Ⅰ.GENERAL

pH/ORP-3500 series is a kind of popular and cost-effective online pH and ORP

controller , with plug-in pH/ORP-1220 sensor, which have good measurement

accuracy, anti-interference,easy to install and operation features.

¾White backlight LCD screen,several operations, easy for operation

¾Be compatible for six kinds of buffer solution(10.00,9.18,7.00,6.86,4.00,4.01)

which suitable for international standard.

¾Selectable temperature sensor which reduce the replacement cost.

¾Manual calibration is easy for on-site calibration.

¾EMC enhancement type could run smoothly under kinds of industry

environment.

¾(4~20)mA output support instrument/transmitter modes and satisfy all

(4~20)mA receiving unit.

¾Double relay high/low and delay control function could fulfill pH or ORP

interval control and adjustment.

¾Several power supply to be selection according to the different models.Input

AC/DC power, no polarity connection.

1.1 Working Principle

The weak voltage change is generated when H+affected the inserted sensor, the

changeable value will transmit to the instrument. After converting and calculating the

generated pH/ORP signal, the instrument will show the values on the screen.

1.2Application

This series instruments are widely used for online pH/ORP monitoring in

environment protection water treatment, pure water treatment, industrial process and

so on.

Chemitech IT Perdana | Solution For Your Trouble | Service Laboratorium Instrument

https://chemitech.id

order via whatsapp: +6282366660856

2

1.3 Classification

model Power

supply

frequency

(Hz)Current mode Sensor selection

pH/ORP-3500 DC 24V ------- Instrument/transmitter pH-1220B plug-in

sensor;

ORP-1220B plug-in

sensor or other

sensors;

TE-1230-14

temperature sensor

pH/ORP-3510 AC

110V 50/60 Instrument/transmitter

pH/ORP-3520 AC

220V 50/60 Instrument/transmitter

【NOTE】

1. Put the instrument in dry environment and the water-drop or moisture will

cause the damage or measurement error;

2. Pay more attention on the power supply before wiring connection.

Chemitech IT Perdana | Solution For Your Trouble | Service Laboratorium Instrument

https://chemitech.id

order via whatsapp: +6282366660856

3

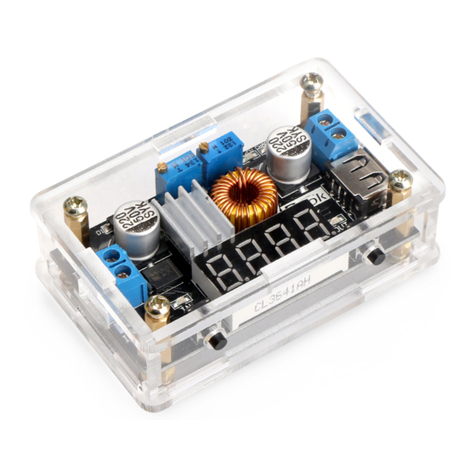

1.4Technique index

model pH/ORP-3500series pH/ORP online transmitting controller

Measureme

nt range

pH 0.00~14.00

ORP -2000mV~2000mV

Temp. (0.0~50.0)℃(temperature compensation component: NTC10K

Resolution

pH 0.01

ORP 1mV

Temp 0.1℃

accuracy

pH 0.1 level

ORP ±5mV(electronic unit)

Temp ±0.5℃

Approximate input

impedance 3×1011Ω

Buffer solution 10.00;9.18;7.00;6.86;4.01; 4.00

Temp. compensation

range

(0~50)℃(with 25℃ as standard)

Manual and automatic temperature compensation

(4~20)mA

characteristic

s

Isolated,fully adjustable,reversible,instrument/transmitter for

selection

Loop

resistance 500Ω(Max),DC24V

accuracy ±0.1mA

Control

contact

Electrical

contacts Double relay SPST-NO, hystersis model

Loop

capacity AC220V/AC110V 2A(Max);DC24V 2A(Max)

Power consumption <3W

Working

environment

temperature (0~50)℃

humidity ≤85%RH(none condensation)

Storage environment Temp.(-20-60) ℃;relative humidity:≤85%RH(none condensation

Outline dimension 48mm×96mm×80mm(H×W×D)

Hole dimension 44(H)mm×92(W)mm

installation Panel mounted,fast installation

Chemitech IT Perdana | Solution For Your Trouble | Service Laboratorium Instrument

https://chemitech.id

order via whatsapp: +6282366660856

4

Ⅱ、INSTALLATION

Top view Side view

2.1 Installation of instrument

pH/ORP-3500 series is adopted panel mounted type, which could be installed easily.

Please follow the steps:

1. Put the instrument into the fixed hole 44mmX92mm(HxW)

2. Then push the quick clamp along with the trench and fasten the instrument.

3. Do not let the instrument drop on the floor when dismounting the

meter.Withdraw the quick clamp and take the instrument down.

Do not put the instrument unde

r

the sun since the UV will dama

g

ethe

LED screen.

Chemitech IT Perdana | Solution For Your Trouble | Service Laboratorium Instrument

https://chemitech.id

order via whatsapp: +6282366660856

5

2.2Electrical Connection

The measurement cable can not be mixed with high-pressure and high frequency

cable. To avoid any interference, the cables should be 30cm distance and connect

with the ground.

Connect the power line and signal line according to the below diagrams:

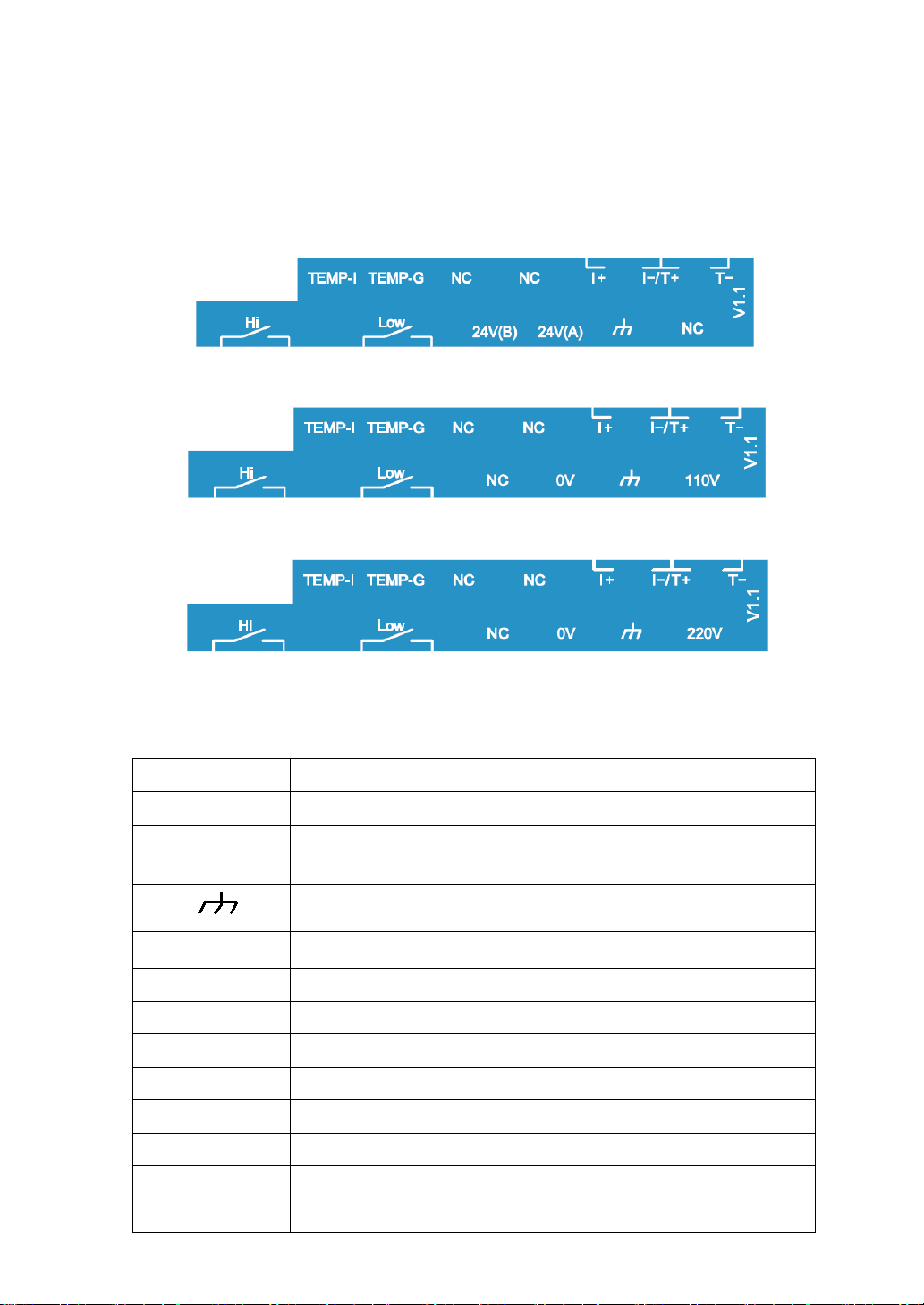

pH/ORP-3500 rear terminal

pH/ORP-3510 rear terminal

pH/ORP-3520 rear terminals

Wiring connection:

0V/220V AC 220V input interface (pH/ORP-3520)

0V/110V AC 110V input interface (pH/ORP-3510)

24VA/B DC 24V input interface (pH/ORP-3500)

(Internal automatic recognition of polarity )

Electromagnetic compatibility group protection terminal

Hi High limit alarm control terminal blocks

Low Low limit alarm control terminal blocks

T- (T+、T-) transmitting mode external feed

T+/I- Transmitting /Instrument Mode public terminal

I+ (I+、I-)Instrument mode mA output terminal

TEMP-I Connect the receiving terminal of the temp.sensor(red)

TEMP-G Connect grounding terminal of the temp. sensor (black)

NC Empty terminal

BNC connector Connect pH or ORP sensor

Chemitech IT Perdana | Solution For Your Trouble | Service Laboratorium Instrument

https://chemitech.id

order via whatsapp: +6282366660856

6

2.3Diagram of 4-20mA output

Instrument mode

Transmitting mode

Chemitech IT Perdana | Solution For Your Trouble | Service Laboratorium Instrument

https://chemitech.id

order via whatsapp: +6282366660856

7

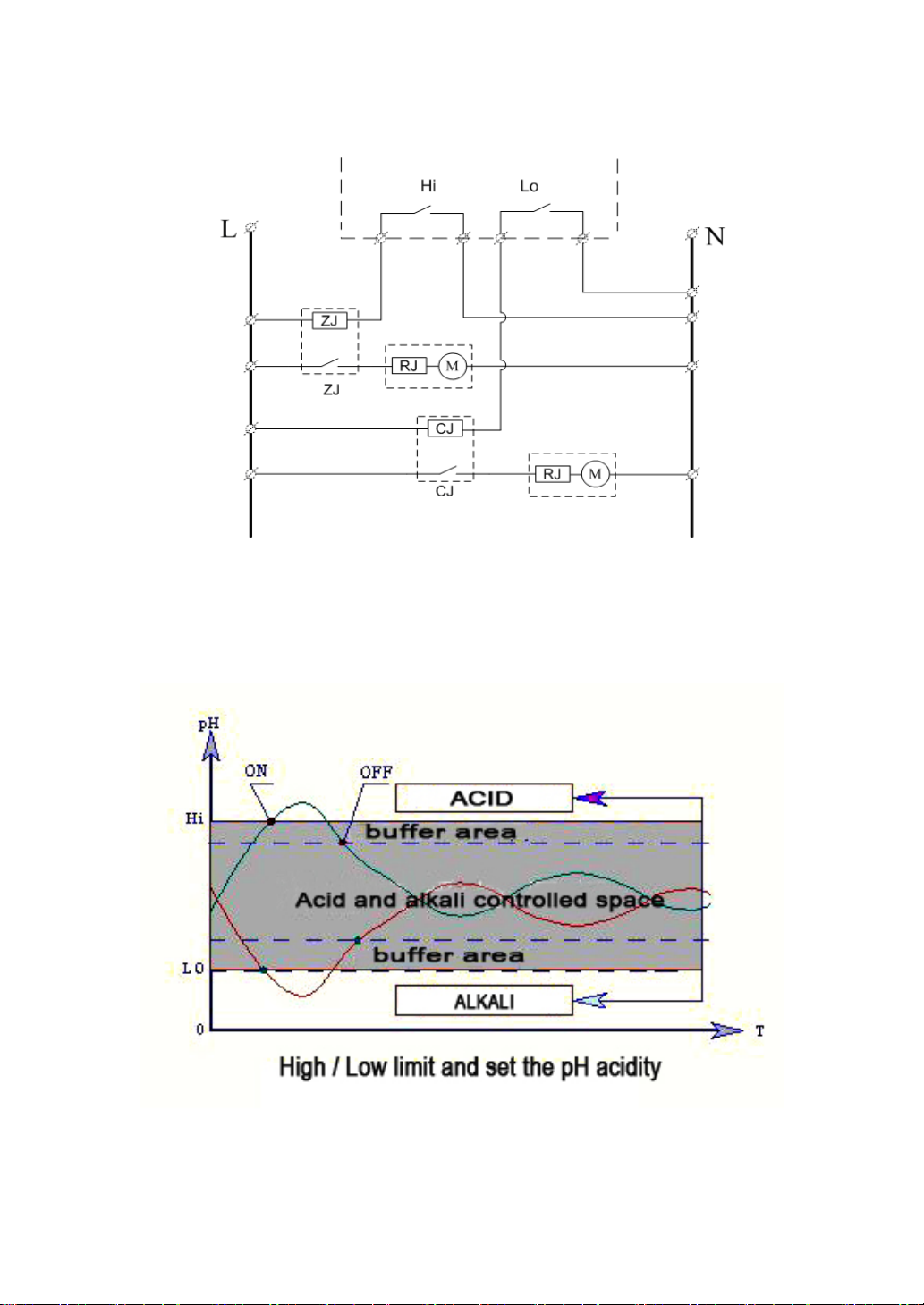

2.4 Relay control connection

Relay ON/OFF contact component control wiring diagram

2.5 Control mode

Chemitech IT Perdana | Solution For Your Trouble | Service Laboratorium Instrument

https://chemitech.id

order via whatsapp: +6282366660856

8

2.6Installation of sensor

Adapter

Connection cap

Chemical

p

robe

Themiddlefixedcap

(

f

o

r

se

l

ect

i

o

n

)

Sensitive glass

membrane

(glass bulb)

2.6.1Assembling and replacement

Location key

Location slot

(3)

(2)

(1)

Screw

Chemitech IT Perdana | Solution For Your Trouble | Service Laboratorium Instrument

https://chemitech.id

order via whatsapp: +6282366660856

9

The location key and location slot must be occlusive exactly. No rough

installation.

2.6.2Installation method

Flow device P34A Flow device P34B

[Note] :Recommend using the flow device with needle valve (P34)

1. Needle valve flow device (model P34A/B) is recommended when pipeline installation,

which can change probe under pressure-bearing、continue condition;

2. Round sensitive glass steep pH probe direct install in the pipeline, it will threaten the

probe when the pipeline pressure change, water hammer or siphon effect,after using

flow device, the probe and atmosphere will communicate, operational states safe and

measure stability

3. When direct install pipeline,pure water measurement value will instability because the

water is weak electrolyte,sensitive glass film(glass bubble)and salt bridge present

discontinuity open circuit,result the measure value instability

4. When direct install the pipeline to measure pure water,high concentration KCL of pH

probe and pure water form huge concentration difference,trough liquid abutment spread

into the water largely. Cause the probe lose effectiveness,pollute the pure water

meantime.,make the conductivity under probe downstream of pH probe rise hugely.

Chemitech IT Perdana | Solution For Your Trouble | Service Laboratorium Instrument

https://chemitech.id

order via whatsapp: +6282366660856

10

2.6.3 Installation requirement

Horizontal installation does not work Backward installation does not work

Ⅲ、SETTINGS

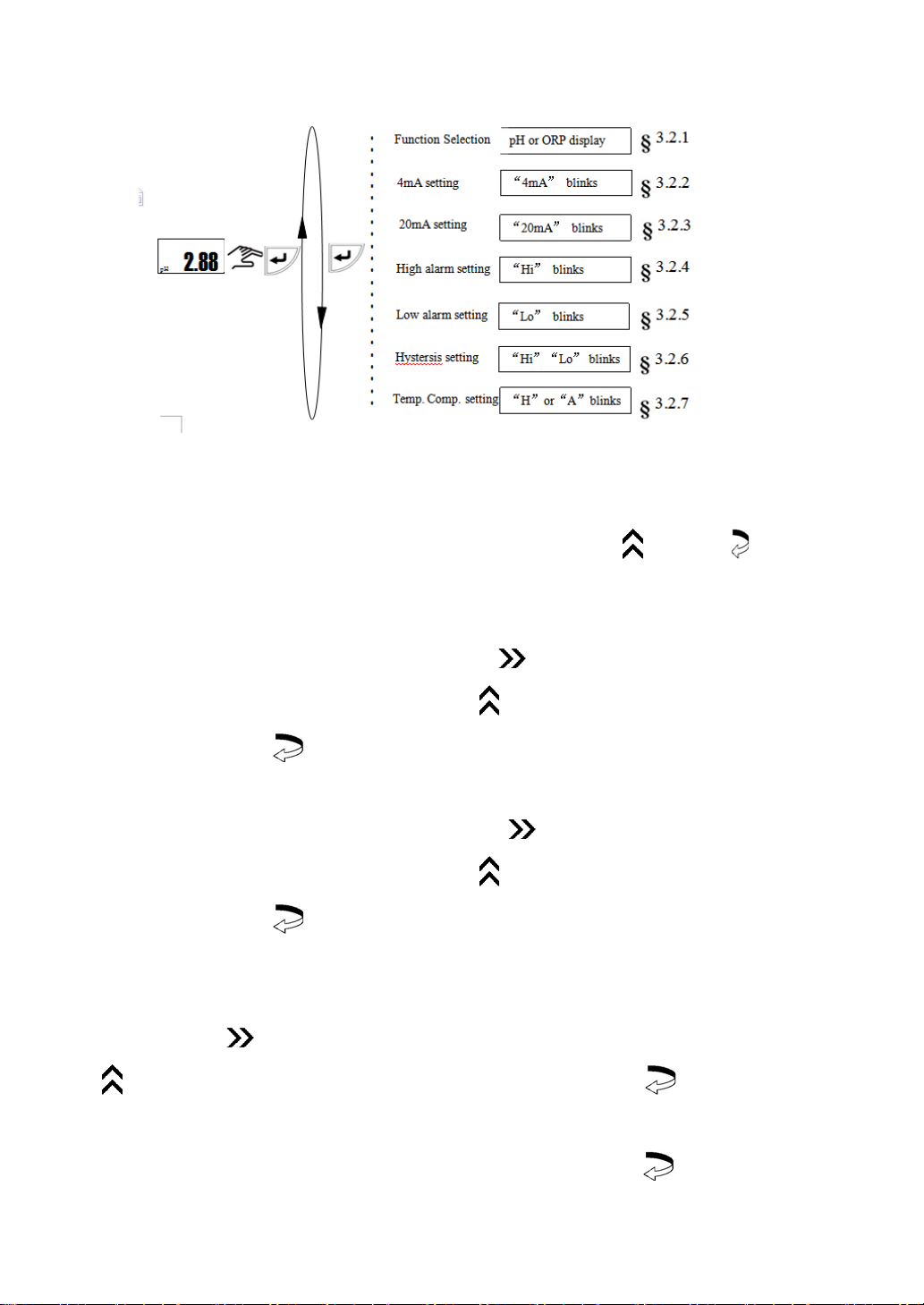

You could set the relative parameter after connect the instrument and sensor. Please enter into the

setting mode to check and set the relative parameters for your first use. These parameters are in

different menus.

Middle 1 1/4"NPSC straight pipe thread

fitting Upright install or slant install no more

than 30 º

bottom 3/4"NPT taper thread fitting;Upright install or

slant install no more than30 º

Chemitech IT Perdana | Solution For Your Trouble | Service Laboratorium Instrument

https://chemitech.id

order via whatsapp: +6282366660856

11

Main Menu

Please operate the meter with the keys. Under the different mode, the function will be

different.

Sign Name Function

SELECT

1. check the temp. compensation value under pH measurement

status

2. exit o

r

skip the setting paramete

r

3. select thousand, hundred ,ten and unit circularl

y

unde

r

parameter setting interface

4. long-time press the key unde

r

pH measurement status, it will

enter into pH mV calibration interface

Add key

1. set the 0-9 figure under parameter setting status

2. long-press the key unde

r

pH measurement status, it will ente

r

into the buffer calibration interface.

3. check mV value under pH measurement status.

Enter key 1. ente

r

into the main menu

2. save the paramete

r

settin

g

s

Three functions shows on the main interface: the upper icon is menu bar which guide the

operation; the left area displays the measurement unit of the current time; the value means the

measurement data or menu items.

pH/ORP-3500 working mode:

◆Measurement mode:Normal display、transient display

◆Setting mode:Parameter setting

Chemitech IT Perdana | Solution For Your Trouble | Service Laboratorium Instrument

https://chemitech.id

order via whatsapp: +6282366660856

12

Switch the mode as following:

3.1Measurement mode

3.1.1Normal display

The instrument will display the current pH/ORP value after powered on.

3.1.2 Transient display

Under pH measurement status, check the current temperature by pressing ,

and check the mV value by pressing It will return to normal display without

operation for five seconds

3.2 Setting mode

Some parameters have been set before ex-factory. If the test environment changes (such as

replacement of electrode, reset the alarm setting), please check the parameter which is in different

menus. The specific content and operations as following:

Chemitech IT Perdana | Solution For Your Trouble | Service Laboratorium Instrument

https://chemitech.id

order via whatsapp: +6282366660856

13

3.2.1 Function selection

Choose “pH” or “ORP” function selection by pressing and press for saving

the setting and enter into the next parameter setting.

3.2.2 4mA setting

When the screen displays “4mA”, press to select the digital position and

input the actual pH/ORP value by pressing , and save and enter into the next menu

setting by pressing .

3.2.3 20mA setting

When the screen displays “20mA”, press to select the digital position and

input the actual pH/ORP value by pressing , and save and enter into the next menu

setting by pressing .

3.2.4High-limit alarm setting

The screen will displays “Hi” after entering the interface of high-limit alarm

setting, press to select the digital position and input the actual value by pressing

, and save and enter into the next menu setting by pressing .

3.2.5 Low-limit alarm setting

Same operation as the high-limit alarm setting, and press after setting.

Chemitech IT Perdana | Solution For Your Trouble | Service Laboratorium Instrument

https://chemitech.id

order via whatsapp: +6282366660856

14

3.2.6Alarm Hysteresis setting

When “Hi”and“Lo”appear at the same time, set the pH/ORP hysteresis value

by pressing“ ” and“ ”. Save and enter into the next menu.

回差 The MIN value: pH≥0.1;ORP≥10mV!

3.2.7 Temperature setting

When“H”or“A”blinks,press “ ” to do the manual temperature compensation

(H25.0℃)or automatic temperature compensation (A25.0℃) (automatic

temperature compensation need to connect a temp. sensor NTC10K.). Then save and

return to measurement status.

NO THIS OPERATION FOR ORP MEASUREMENT!

3.3 Sensor calibration

3.3.1 System Calibration

pH/ORP sensors are electrochemical and their sensitivity decreases with

influence of time and medium. In order to get an accurate measurement, it is

suggested to often calibrate sensor’s slope. The calibration period relays on the

influence from the measured medium

1) Normal buffer solution ,10.00\9.18\7.00\6.86\4.00\4.01

2) If the medium are acid or alkali, please choose two point slope calibration, use two kind

buffer solution.

3) Before the calibration, please read the instruction carefully , and prepare the standard buffer

solution

4) The meter with directly input calibration method, please reference the calibration steps.

5) If the sensor with long time storage, please put it in the water or KCL solution for 12

hours , and then calibrate it.

3.3.2 Buffer solution calibration

1. Choose the correct buffer solution to calibrate.;

2.Press the for 3 seconds and enter into buffer solution calibration interface

under pH measurement interface, input the current temperature , save and enter

into buffer solution calibration by pressing .

3. When the “C10.0” and pH blinks,it means to enter into the buffer solution

selection; press “ ”and enter into the next calibration menu.

4. Put the clean sensor into the buffer solution for 3-5 minutes.

Chemitech IT Perdana | Solution For Your Trouble | Service Laboratorium Instrument

https://chemitech.id

order via whatsapp: +6282366660856

15

5.Press“ ”to save the settings and enter into the next calibration,fetch the

sensor out and clean, then put it into the suggestive buffer solution and finish the

calibration in turn.

6. Check the buffer solution and recalibrate when“ ” comes out and then

recalibrate.

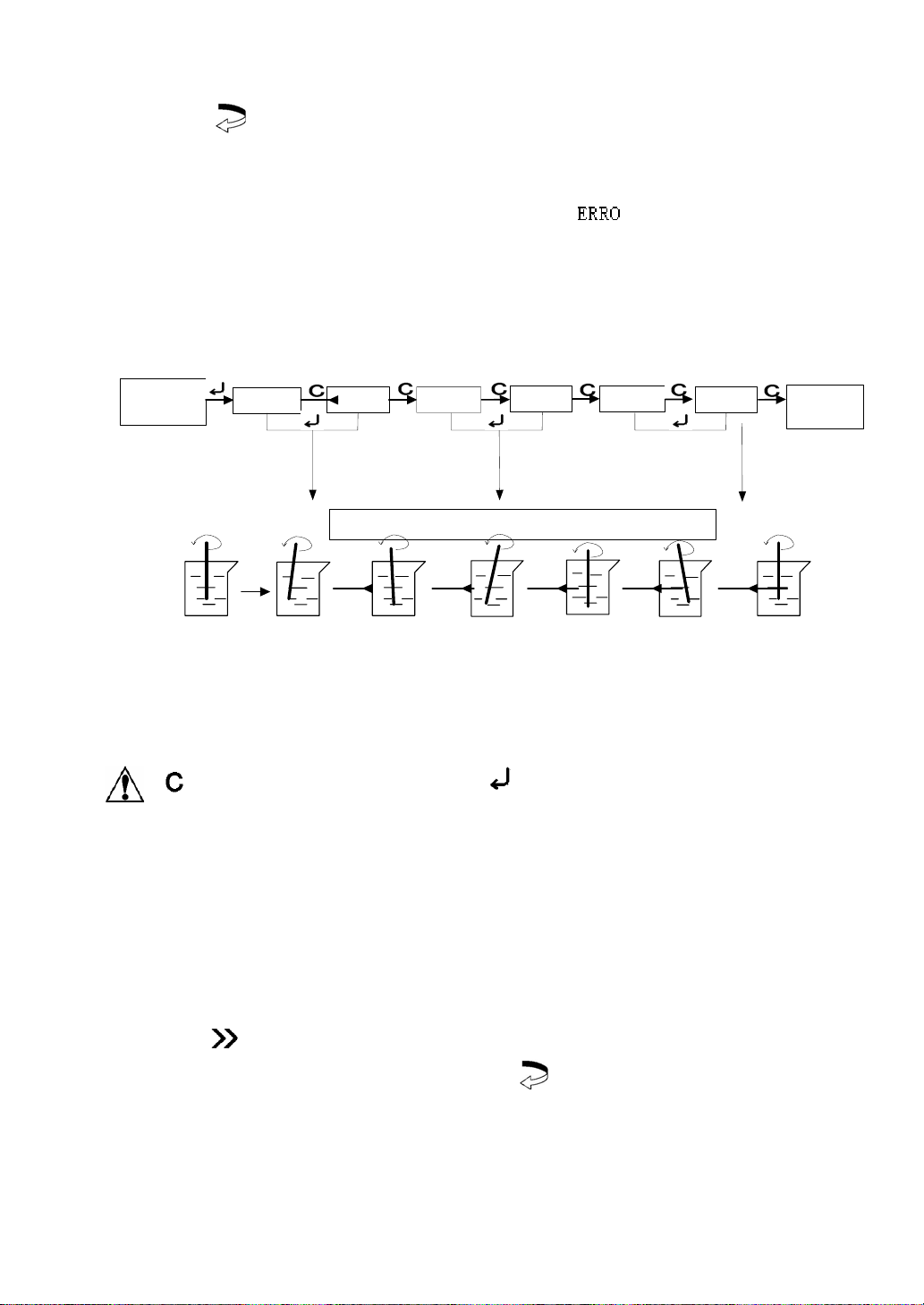

Please follow the below detailed calibration process:

“ ”means skip this operation;and “ ”means enter the operation.

3.3.3 OFF-LINE CALIBRATION

When field calibration is not good to carry on ,the calibration to sensor’s slope by

using lab devices and buffer solution is recommended .Take notes of corresponding

mV value of buffer solution in room temperature.Input of this record value to off-line

calibration is called as manual input calibration.

Press “ ”for 3 seconds under pH measurement status,input the corresponding

mV value in different buffer solution, press “ ”to save and enter into the main

menu.

Clean

water

clean the

sensor

10.00

Calibration

solution

Temp. imput

10.00/9.18

solution

7.00/6.86

solution

Clean

water

clean the

sensor

4.01/4.00

solution

7.00 4.01

9.18 6.86 4.00 Measurement

main

enterface

Clean

water

clean the

sensor

Clean

water

clean the

sensor

Put sensor into selected buffer solution to

calibrate

Calib

rate

calib

rate

calib

rate cleanclean

clean

Chemitech IT Perdana | Solution For Your Trouble | Service Laboratorium Instrument

https://chemitech.id

order via whatsapp: +6282366660856

16

Incorrect mV value input during calibration process, the screen will display “ ”.

Press “ ” to continue the calibration, and press “ ”to enter into the next

calibration.

Ⅳ、MAINTENANCE

4.1 Sensor Maintenance.

1. To avoid long time dry store, the sensor should be kept in the protection cap

with KCl solution in 3.0mol/L.;

2. Clean the sensor and calibrate the same on the indicator regularly.;

3. In case of suspende

d

stuff attached, wash it with HCl o

r

NaOH solution in

0.01mol/L and rinse with clean water;

4. If the above methods are invali

d

to reset slope, it means that the senso

r

should be replaced.;

5. The platinum surface of ORP senso

r

should

b

e shining. In case of smudginess,

wash it with HCl or NaOH solution in 0.01mol/L and rinse with distilled

water. If the surface of platinum is polluted and formed oxidation film, the

platinum could be polished with sand paper and toothpaste, then clean it with

distilled water;

6. Place the senor into 3.5 mol/L KCl solution for 6 hours before usage;

7. Buffer solution gets different value at different temperature so please confirm

the temperature of buffer solution at calibration。

4.2 Usage of sensors

1. pH/ORP sensors are consumables .Lon

g

time stora

g

e is not su

gg

ested;

2. Sensitive

g

lass fil

m

(

g

lass

b

ubble) is forbidden to use when the medium with

hydrofluoric acid, fluorion and high-concentration sulfion.

3. pH/ORP sensors are not allowe

d

to measure an

y

or

g

anic solution which will

Chemitech IT Perdana | Solution For Your Trouble | Service Laboratorium Instrument

https://chemitech.id

order via whatsapp: +6282366660856

17

damage or dissolve PC or ABS(such as carbon tetrachloride, trichloro

ethylene or tetrahydrofuran etc….);

4. The chemical part of the senso

r

is

g

lass, please protect carefull

y

durin

g

transportation and storage.

5. Please clean the senso

r

at a re

g

ula

r

time

by

usin

g

swab an

d

neutral cleanser;

do not use the acid and corrosive solution to clean the sensor。

6. High-temp. pH glass senso

r

is recommende

d

fo

r

b

iopharmacy an

d

high-pressure autoclaved sterilization. The protection part is optional;

7. pH signal is wea

k

signal, the collecting cable shoul

d

run separately. Do not

mix the cable together.

8. Measurement cable is fo

r

special use, it’s not allowe

d

to cut o

r

len

g

thene

d

privately or replaced by other cables.;

9. Install a filte

r

b

efore senso

r

when there is molecule in the medium to protect

the pH glass bubble.

Ⅴ、TROUBLE SHOOTING

Problem Possible causes Trouble shooting

No display

when

powered on

A.Badconnectionof

power supply

B.Instrument fault

Acheck to see if there is 24Vvoltage between power

terminals 24VA and 24VB.

B.Check by professional technicians.

Unstable

display

A.Improper wire

connection of sensor

B.Air bubbles in the

pipeline

C.Unstable water

quality

D.badness connection

A.refer to the instruction manuals

B.select the proper measurement point or change the

pipeline

C.stabilizing the water quality

D.Check the connector to be connected

Big deviation

A. Senso

r

fault

B. The cable is

damaged

C. incorrect

installation

D. setting proble

m

A.Take out the sensor from the pipeline and calibrate

B.replace the senor which can not be calibrated

C.find the correct measurement point and use the flow

device

D.reset the parameter of the instrument

Difference at

transmitting

data

A. loop resistance is

too large

B. incorrect

connection mode

C. unusual powe

r

supply

D. wrong transfer

volume

A. replace the cable to reduce the loop resistance

B. check the connection ri

g

ht o

r

not

C.

p

owered

by

the standard

D. reset the transferred volume

Ⅵ、COMPLETE SET

Chemitech IT Perdana | Solution For Your Trouble | Service Laboratorium Instrument

https://chemitech.id

order via whatsapp: +6282366660856

This manual suits for next models

3

Table of contents

Popular Controllers manuals by other brands

Advantech

Advantech ADAM-5510 Series Startup manual

Johnson Controls

Johnson Controls M9203-B Series installation guide

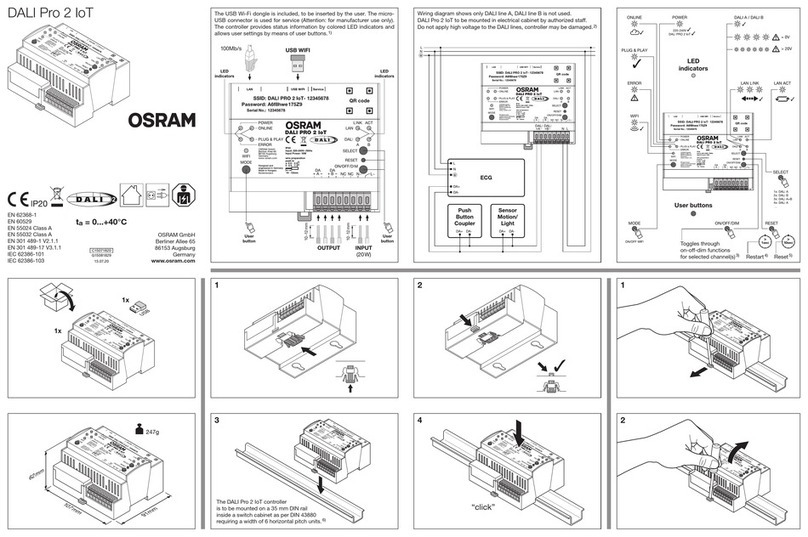

Osram

Osram DALI PRO 2 IoT manual

Allen-Bradley

Allen-Bradley Mini-PLC-2/15 Assembly and installation manual

Ascon tecnologic

Ascon tecnologic K48 Engineering manual

Huawei

Huawei ECC800 user manual