ChemBall | CSB

Safety Instructions

To ensure that the valve functions correctly, it is

important to follow these installation and opera-

ting instructions. Only qualied personnel who have

been instructed in the installation, tting, commissi-

oning, operating and maintenance of the device are

permitted to install the valve. ChemValve-Schmid AG

assumes no liability for faults resulting from impro-

per installation.

Warnings and Precautions

• During installation and maintenance work, suita-

ble protective clothing, including gloves and

protective goggles, must be worn.

• Prior to installation and maintenance work, the

pipe must be depressurised and emptied. If the

valve operates with dangerous ow media, the

pipe has to be emptied completely and ushed

with an appropriate cleaning uid. Inappropriate

cleaning products can harm the valve!

• If ange connections or locking screws are deta-

ched, hot water, steam, caustic uids or toxic

gases can be emitted. Severe scalding, burns and

poisoning are possible!

• During operation the valve may become very hot

or very cold. Installation and maintenance work

should only be carried out if the valve‘s tempera-

ture is the same as the ambient temperature.

• Prior to dismounting the valve, preventative

measures against the possible leakage of dange-

rous media should be made.

• When removing the valve from the pipeline, it is

important to ensure that the PFA lining, ball and

seals are not damaged. Damaged parts may only

be replaced by genuine ChemValve-Schmid AG

parts.

• Only suitable cleaning products may be used.

Personnel Requirements

The improper handling of shut-off valves can lead to

injury and material damage! Only trained specialists

with the requisite qualications and experience may

dismantle, assemble and test the valves.

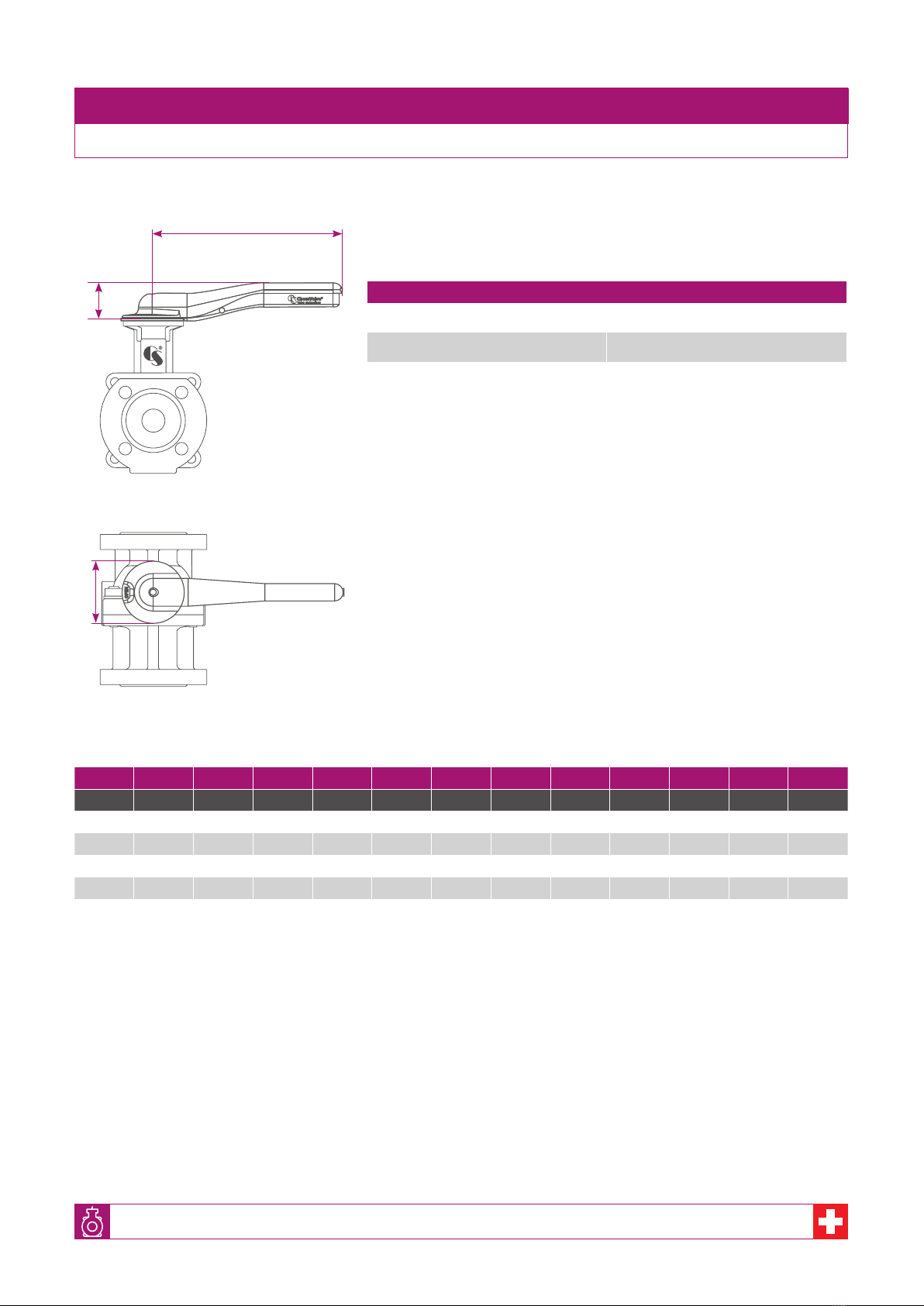

Protective Equipment

To minimise the likelihood of injury, the wearing of

personal protective equipment is required. Com-

pany guidelines must be strictly followed. Each

worker is responsible for their own safety.

All workers must wear the following:

Protective work clothing is tight-t-

ting clothing with good tear resistance,

tight arms and no protruding parts. Such

clothing protects against abrasion, punc-

ture wounds, corrosive substances and

burns from hot surfaces, liquids and gases

Helmets protect against falling and ying

objects, as well as liquids and gases

Safety shoes to protect against heavy

objects, hot surfaces, corrosive liquids and

gases and to minmise slips and falls on

unstable surfaces

Safety Gloves to protect hands from abra-

sion, puncture wounds, corrosive substan-

ces and burns from hot surfaces, liquids

and gases

Safety Glasses to protect the eyes from

corrosive or liquids and gases

Further protective equipment, such as ear

protection, should be worn, depending on the

environment or company guidelines.

4

ChemValve-Schmid AG |Duennernstrasse 540 |CH-4716 Welschenrohr |+41 32 639 50 10 |sales@chemvalveschmid.com

ChemBall |CSB Installation & Operating Instructions V2.1 EN |Copyright©by ChemValve-Schmid AG |Subject to change