Form No. 264587 8/03

2

Fluid Cleanliness – Control particle contamination

by changing or cleaning all filter elements

periodically BEFORE they become clogged and start

to by-pass.

Electrical Inspection – Periodically check to assure

proper voltage, and that all electrical connections are

making good contact.

After Extended Shutdowns – Some types of

hydraulic fluids become tacky after long periods of

non-use. Manually actuate valves several times

after extended shutdowns to assure that all

components move freely before powering up.

CAUTION – Before manually actuating any

Directional Control Valve, be sure that any

resulting machine function will not endanger

persons or equipment.

VSD08M VALVE REPAIR PROCEDURES

DISASSEMBLY and REASSEMBLY

GENERAL

Disassembly and reassembly of Directional Control

Valves is a delicate operation. Anyone attempting it

must assume responsibility for the operation of the

valve. Continental valves may be returned to the

factory or to an Authorized Repair Center for repair.

Contact your local Distributor or Continental

Hydraulics for details.

If interchanging spool types or making other

conversions, remark the escutcheon plate to show

the correct code. Include stops, spool, spring, and

detent orientation. See Figure 2 to serve as a guide

to correct numbering.

Disassembly in the field by other than an Authorized

Repair Center technician, whether for repair or

modification may void warranty.

Before disassembly, study the exploded view on

Page 3 and note the orientation and location of all

parts. Special care should be taken to avoid

damage to the spool and/or body bore. Even a

microscopic nick in a land on the spool or body may

ruin the valve.

All valves can be disassembled and reassembled in

a horizontal-mounted position, provided there is

adequate space and the work area is clean.

Place the spool in a bath of clean oil to coat it with a

protective film, and ease assembly. Inspect o-rings

for nicks, and make sure they are well oiled. It’s a

good idea to replace all seals whenever the valve is

disassembled.

Continental valves are precisely machined to

exacting tolerances. Do not force any parts, or

overtighten threaded fasteners.

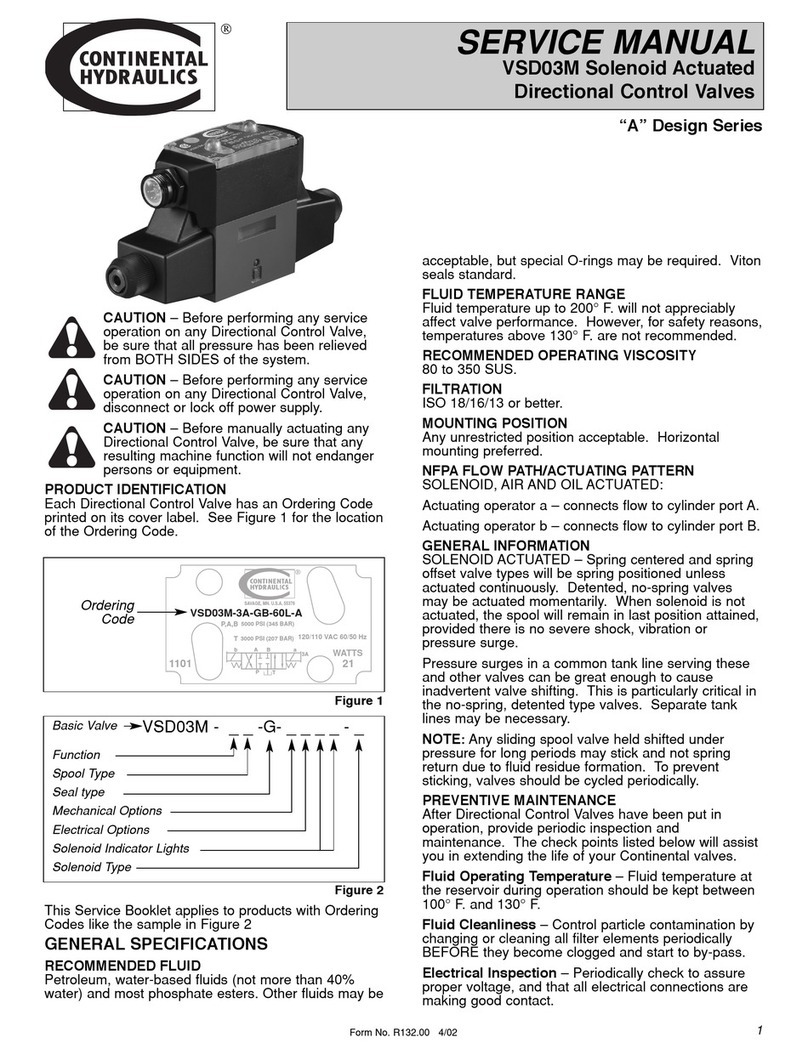

PART AND ASSEMBLY IDENTIFICATION

The parts drawing and parts list on Page 3 may be

used to identify individual parts and assemblies in

directional control valves.

VSD08M PILOT AND DRAIN

Continental pilot operated valves are ordered from

the factory with either internal or external drains.

Converting the pilot or drain to either internal or

external mode may be done as follows:

When internal pilot and/or drain is used, the

corresponding “X” and “Y” ports in the subplate must

be plugged. The pilot pressure, whether internal or

external, must be at least 70 psi (5 bar) greater than

the pressure at the tank (“T”) line. It may be

desirable to use external pilot when system pressure

is subject to wide fluctuations. External drain must

be used when either an “open” center or “tandem’

center spool is used. External drain is also

recommended when using pilot chokes. Pilot

chokes do cause some pressure variations in the

tank line that will affect spool movement if internal

drain is used.

MAXIMUM A, B, P Ports 5000 psi 345 bar

OPERATING T, & Y Ports 3000 psi 207 bar

PRESSURES

MINIMUM OIL PILOT PRESSURE 70 psi 4.8 bar

MAXIMUM CYCLE RATE up to 300 cpm

NFPA MOUNTING SURFACE ANSI/B93.7-1986 - D08

ISO 4401 - SIZE 08

WEIGHT Single Actuator 33 lbs. 15 kg

Double Actuator 34 lbs. 15.4 kg

PERFORMANCE SPECIFICATIONS

SECTION A-A

SECTION B-B

CODE LOCATION PILOT DRAIN

ABC

1INTERNAL PILOT RBB

EXTERNAL DRAIN

2EXTERNAL PILOT BRB

EXTERNAL DRAIN

3INTERNAL PILOT RBO

INTERNAL DRAIN

4EXTERNAL PILOT BRO

INTERNAL DRAIN

B = Blocked 1/16 NPT Pipe Plug (Item #30)

R = Restricted 1/16 NPT Pipe Plug with 0.070 Orifice (Item #33)

O = Open No Plug