Chen Hsong Ai-02 User manual

Ai-02 Operation Manual

Chen Hsong Ai-02 Injection Multi-function Computer

Operation Manual

CHENHSONG HO DINGS TD.

TE : +852-26653888,26653222 (Headquaters, Hong Kong)

+86-755-84139999 (Industrial park, Shenzhen)

Web : www.chenhsong.com.hk

Version: 2013_04

1

Ai-02 Operation Manual

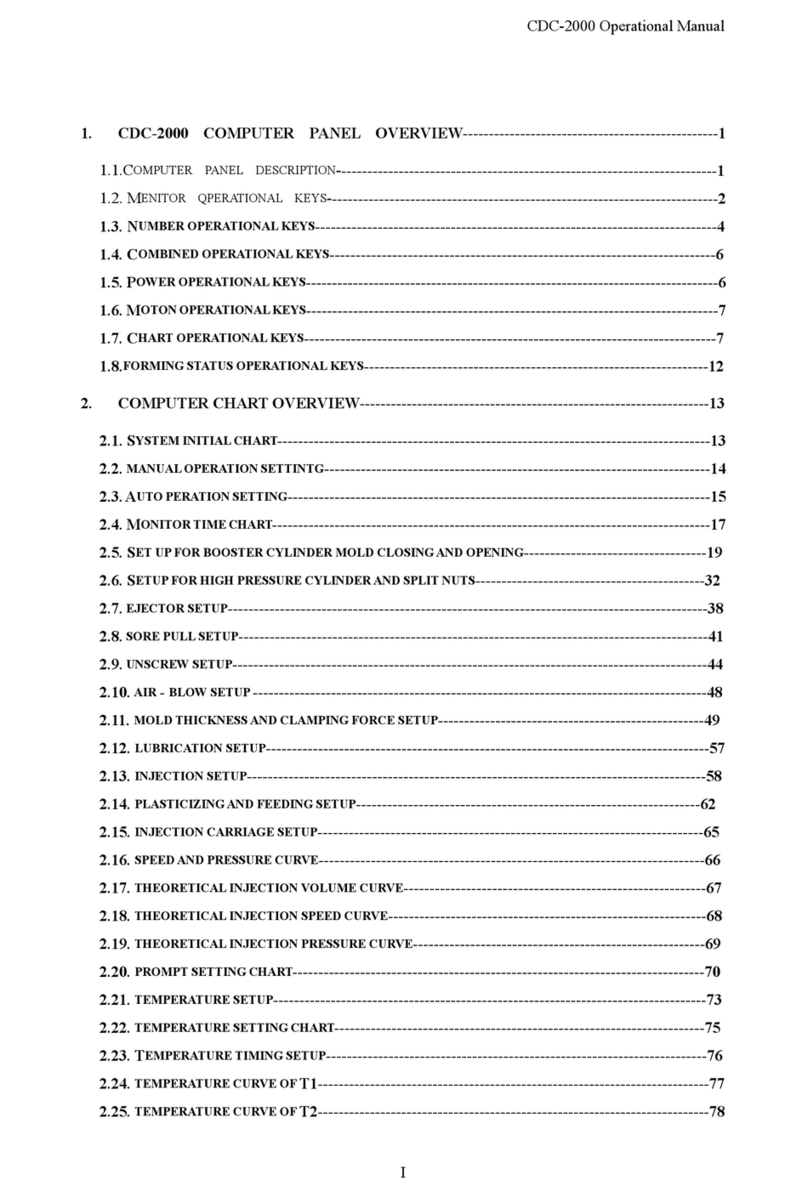

Contents

1.Characteristics:.......................................................................................................................5

2.Basic features.........................................................................................................................5

3.Function Comparison ............................................................................................................6

4. Introduction on each Part of Computer’s Panel....................................................................

4.1 Computer’s Panel ..............................................................................................................

4.2 Keys for Operation Mode control.................................................................8

8

4.3 Keys for function of for ing conditions........................................................8

4.4 Digital data key, cursor key and auxiliary operational .................................9

4.5Power Switch:...........................................................................................10

5. Operational instructions for computer interface...............................................................10

5.1Starting the co puter .................................................................................10

5.2 Setting nor al operation..............................................................................12

5.3 Monitor the cycle..........................................................................................13

5.4 Setting of Mould opening.............................................................................14

5.5 Setting of Mould closing...............................................................................15

5.6 Interface of Mould Cla ping and Injection Pressure Setting......................17

5.7 Injection Setting............................................................................................17

5.8 Setting of pressure holding..........................................................................20

5.9 Setting of plasticizing/back pressure............................................................22

5.10 Setting of auto atic purge.........................................................................24

5.11 Setting of Ejector........................................................................................25

5.12 Setting of Carriage.....................................................................................27

5.13 Setting of air blowing..................................................................................28

5.14 Setting of Core pulling A.............................................................................29

5.15 Setting of Core pulling B............................................................................31

5.16 Setting of Core pulling C............................................................................33

5.17 Setting of Ti er..........................................................................................35

5.18 Setting of Counter 1...................................................................................37

5.19 Setting of Te perature Deviation Alar ....................................................39

5.20 Te perature setting of hot runner..............................................................40

5.21 Setting of Function.....................................................................................42

5.22 The Selection of Mould Data......................................................................44

5.23 Statistical value..........................................................................................46

5.24 Ti e onitor...............................................................................................48

5.25 Counter onitor.........................................................................................51

5.26 Input onitor.............................................................................................52

5.27 Output onitor...........................................................................................53

5.29 Progra onitor......................................................................................55

5.30 Injection ter ination position.....................................................................56

5.31 Injection speed curve...............................................................................57

2

Ai-02 Operation Manual

5.32 Injection pressure curve.............................................................................58

5.33 Help 59

5.34 Language and Syste ti e setting ...........................................................61

5.35 Action stroke stage nu bers selection......................................................62

5.36 Ra p setting..............................................................................................63

5.37 Speed 1 output setting..............................................................................64

5.38 Pressure output ........................................................................................65

5.39 Back pressure output setting....................................................................67

5.40 Speed 2 output setting.............................................................................68

5.41 Initial setting (Origin setting for decoder)..................................................69

5.42 Auxiliary velocity and pressure setting......................................................71

5.43 Ti er setting...........................................................................................72

5.44 Counter setting 2......................................................................................74

5.45 Factory setting..........................................................................................75

5.46 Warning record display.............................................................................77

5.47 Network 78

5.48 Password odification.............................................................................80

5.49 Manual lubrication setting..........................................................................81

5.50 Mould Adjust ent setting...........................................................................82

5.51 Machinery Adjust ent..........................................................................84

5.52 Maintenance setting..................................................................................85

5.53 Reset ethod of initial point.......................................................................86

5.54 Initial position setting of decoder..............................................................87

6. Alarm and Treatment........................................................................................................91

6.1 Title Explanation of Co puter Alar ............................................................91

6.2 Explanation of For ing Operation...............................................................95

6.2.1 Temperature Control Setting............................................................................95

6.2.2 Temperature Deviation (Alarm) Setting:......................................................96

6.2.3 Heat Preservation Setting:.............................................................................9

6.2.4 Automatic/Semi/Automatic/Manual mode choosing......................................9

6.2.5 Position, Speed and Pressure Material Setting................................................9

6.2.6 Figure Material Setting of the Forming Condition..........................................98

6.2. Adjustment of Proportional Control.................................................................98

6.2.8 Instruction of the Counter inside the Computer.............................................100

6.2.9 Instructions for usage of timer inside the computer.......................................101

6.2.10 Description for input & output point of computer.......................................105

6.3 Ai-02 Special Interface Operation..............................................................109

6.4 Ai-02 circuit diagra ...................................................................................110

6.4.1 Ai-02 Input Connection (Encoder Version)..............................................110

6.4.2 Ai-02 I/O Board Layout (potentiometer version)...........................................111

6.4.3 Ai-02 Motor & Power Control Circuit Diagram(piston pump)....................112

112

6.4.4 Ai-02 Motor & Power Control Circuit (SVP)...............................................113

.................................................................................................................................114

6.4.5 Ai-02 Input Point Connection Diagram of Computer I/O Board

(potentiometer).........................................................................................................114

3

Ai-02 Operation Manual

6.4.6 Ai-02 Input Point Connection Diagram of Computer I/O Board ..................115

6.4. Ai-02 Output Point Connection Diagram of Computer I/O Board................116

6.4.8 Ai-02 extension I/O board Connection Diagram...........................................11

6.4.9 Ai-02 Robot Interface (Euromap 6 ).............................................................118

118

4

Ai-02 Operation Manual

1.Characteristics:

It is designed, researched and developed by using the technology of Japan and

co plying with JIS standards, equipped with TFT 320×240 color liquid crystal

display. Power range applies to AC110V ~AC280V 50/60HZ. It features LED

backlight, high brightness and long life of usage. The electronic co ponents and

production technique adopt the ost advanced technology of SMT with highest

stability and reliability. The processing data can be stored for over 5 years reliably

and safely under power failure. It can freely choose Chinese and English for the

convenience of study and operation, have the function of intelligent fault detection

and auxiliary operation instructions and fully support the network syste – iChen.

2.Basic features

1.Storage of 150 groups of olding data, like ti e, ti es, pressure,

speed, stroke, etering, ould thickness, ould data, function selection,

te perature of raw aterials, etc.

2.Detailed tips on online operation.

3.Lock the software data by stage encryption.

4.Mistake-proof tips when inputting aterials in case of unsuitable odification. The

aterials odification can be stored on the central server online through iChen

Syste .

5.Most advanced SMT electron plate asse bling technology with a high reliability.

6.32 bit high speed CPU.

7.Auto atically setting the position value of high pressure cla ping.

8. Scale and te perature control of nozzle (standard), supporting additional furnace

nozzle ther o eter (optional).

9. 8 groups of PID te perature control, adjust ent between 30℃ and 500℃ with a

high degree of accuracy of control.

10. Prevent the startup of cold aterials, auto atic te perature-keeping setting,

detection of nozzle Reserved and aterials overflowing.

11.During the operation, setting the deviation of high and low te perature and

detecting the breakage of te perature-sensing line.

12. Setting injection 5 stage speed, 5 stage pressure and 5 stage pressure holding.

13. Setting plasticizing 3 stage speed, 3 stage pressure and 3-stage back press.

14. Support the function of 3 groups of blowing and 3 groups of core pulling.

15. Cla ping, injection and ejector all adopt high precision optics encoder (standard)

or linear potentio eter (optional).

16. The storage of historic records of alar s is convenient for the technique

debugging and aintenance.

17. Setting production quantity and batch. Can set auto stop as per production

quantity. Can coordinate with order arrange ent syste of iChen Syste .

18. Setting auto lubrication of toggle. Alar in case of oil starvation.

5

Ai-02 Operation Manual

19. The operation actions are showed in figures, convenient for the supervision of

the operation of plastic jetting-for ing achine.

20. Monitor the operate ti e of circulation for the convenience of adjust ent to

shorten the circulation ti e.

21. Statistics of the injection speed, pressure and the co parison between pressure

standard graph and current graph, injection ending position.

22. Online onitor the progra run status and all the status of in-out point, ti er and

counter, convenient for debugging and aintenance.

23. Support the onitor on the status of 32 output points, 32 input points, 100 ti ers

and 20 counters, and extend another 48 output points and 48 input points.

24. Offer free options for copying or clearing old data, reservedly, use preset old

data in the co pute to save ti e.

25. Intelligent fault detection and auxiliary operation instructions.

26. Support the te perature control of at ost 40 channels of hot runner for the

old.

27. Perfect support for iChen Syste of workshop network anage ent.

28. Perfect support for iChen Wireless Network.

3.Function Comparison

Ai-02 Multi-function co puter is the upgraded version of Ai-01 co puter.

The detailed co parison in function are as follows:

FUNCTION AI-02 AI-01

Potentiometer input 4 channel 3 channel

LCD isplay TFT true color STN

Air blow Support 4 sets of

multi-sequence

air blow

Fix sequence of

other 3 sets of air

blow

Keylock function by passwor No

FRAM for backup of

parameters

Backup of machine

parameters an 10

sets of mol ata

No

PID temperature control 10 channel 8 channel

6

Ai-02 Operation Manual

4. Introduction on each Part of Computer’s

Panel

4.1 Computer’s Panel

Ai-02 Operation Manual

4.2 Keys for Operation Mode control

4.3 Keys for function of forming conditions

The keyboard is responsible for the switch of forming operation

status.

The keyboard has the following functions:

(1)Can set the for ing conditions like position, speed, pressure, ti e, counter and

te perature, etc.

(2)Can change the ould data and rewrite the aterials of ould data.

(3)According to the require ents of finished products and ould design, choose the

function or action required by for ing.

(4)Under any operational interface, the cursor can be oved to the expected

position for changing data.

8

Ai-02 Operation Manual

4.4 Digital data key, cursor key and auxiliary operational

This keyboard has the following functions:

If press + + at the sa e ti e, then turn on the

power of the co puter, the ould data and syste setting inside the

co puter can be initialized. After hearing the alar of a long “beep”, the

initialization is co pleted. Release the three keys, and the operation on

co puter can be continued.

When operating the co puter, press and si ultaneously, the

function of pageup can be realized; press and

si ultaneously, the function of pagedown can be realized.

(1) Input the digital data required by for ing conditions:

Speed setting ranges 00%~99%; 00% eans no speed.

Pressure setting ranges 00%~99%; 00% eans no pressure.

Position setting ranges 0000~999.9 .

Ti e setting ranges 0~999.9 sec.

Counter setting ranges 0~65535.

Mould thickness setting ranges 0~9999.9 .

(2) To check if the function keyboard is all right.

(3) To onitor the operation states of all outputs, inputs, ti er and counter.

(4) To display the injection curve.

(5) To review help infor ation.

9

Ai-02 Operation Manual

4.5Power Switch:

(1)E ergency Stop Button

The E ergency Stop Button locates in the botto -right of the co puter

operation panel. If press it, the power can be cut off. If restart is required, the

button ust be released by turning rightward.

(2)Start Button

The Start Button locates on the right under the co puter operation

panel. If the E ergency Stop Button has been released, the power of the

achine can be switched on by pressing the Start Button. This function can

effectively protect the control syste .

(3)Equipped with voltage stabilizer of high perfor ance, this controller is

enabled to applicable to power input of AC90-AC265V, 50/60HZ with vast

variation.

5. Operational instructions for computer

interface

5.1Starting the computer

The interface of starting the co puter (01)

The interface of starting screen (02)

10

Ai-02 Operation Manual

(1)After the co puter is powered on and when the syste is perfor ing

auto atic test, at which o ent the startup screen (00) is displayed, just input the

account no. and password you will be authorized to log into the control syste if the

syste is online,then, press the key and hold it, the co puter shall pause

at (02), this screen indicates the odel, achine no. and the running progra , in the

event the achine wants aintaining or technical answer to the inquiry, please fill

the custo er service of this factory with these data so as to enjoy expeditious

service.

(2)If no action is conducted, the syste will auto atically switch to the interface (03)

after about 3 seconds, which re inds you to input the password of 6 digits or press

the interface key for o itting. If you input a password, you will gain the power of

controlling corresponding level of interface without the need of inputting the

password again. The password can be divided into 3 levels of powers like Operator,

Ad inistrator or Manufacturer. After 3 seconds, it will be switched into operation

interface (03) auto atically.

11

Ai-02 Operation Manual

5.2 Setting normal operation

Interface of nor al operation (03) is as follows under nor al operation:

Interface of nor al operation (03)

(1)Press one ti e to display this interface (After the nor al start of the

syste , the default is anual operation. After the start is co pleted, this interface

will appear auto atically).

(2)To odify the set value of te perature (Nozzle, T1~T8 、Oil), use to

select the te perature stage to be set, input the nu erical value and press ,

then the setting is co plete.

This interface is used to onitor the relevant para eters of operation and each

stage te perature settings of the barrel.

(3) Input the nu erical value and press the then the set is co pleted.

"Nozzle para eter":Nozzle te perature setting

"T1":Stage 1 te perature setting

12

Ai-02 Operation Manual

"T2":Stage 2 te perature setting

"T3":Stage 3 te perature setting

"T4":Stage 4 te perature setting (depend on achine odel)

"T5":Stage 5 te perature setting (depend on achine odel)

"T6":Stage 6 te perature setting (depend on achine odel)

"T7":Stage 7 te perature setting (depend on achine odel)

Note : T7 can be selected as oil te perature control or barrel

heating control。

5.3Monitor the cycle

Interface of onitoring the cycle (04)

Press twice to call the cycle monitor screen , which shows the entire

action cycle:

Clamping ―→Carriage Forward ―→Injection ―→Pressure Holding

―→Delay…...―→Ejector―→ Recycle

The numerical value of each step is the time consumption of this step. The

frame in the middle of the interface shows the cycle time, product number,

cycle number and rejected part number.

13

Ai-02 Operation Manual

5.4 Setting of Mould opening

Interface of Setting of Mould opening (05)

(1)Press to call ould open close setting screen .

(2)Use to select the para eters to be set, input the nu erical value and

press , then the setting is co pleted.

CLP pos:58222p ean the current position of opening.

“AA”: Setting for speed of slow mold opening

“BB”: Setting for pressure of slow mold opening

“CC”: Setting for the end-point of mold opening

“DD”: Setting for speed of 2nd stage of mold opening

“EE”: Setting for pressure of 2nd stage of mold opening

“FF”: Setting for ending position of 2nd stage of mold opening

“GG”: Setting for speed of 3rd stage of mold opening

“II”: Setting for ending position of 3rd stage of mold opening

14

Ai-02 Operation Manual

“JJ”: Setting for speed of fast mold opening

“KK”: Setting for pressure of fast mold opening

“LL”: Setting for ending position of fast mold opening

“MM”: Setting for speed of slowed mold opening

“NN”: Setting for pressure of slowed mold opening

“OO”: Setting for ending position of slowed mold opening

“PP”: Setting for reserved of mold opening (Optional)

“QQ”: Display maximum stroke

←─── ←──── ←──── ←──── ←───

MM% NN% JJ% KK% GG% HH% DD% EE% AA% BB%

Slowed mold Fast mold 3rd Stage of 2nd stage of slow mold

opening ↑ opening ↑ mold opening ↑ mold opening ↑ opening

OO mm LL mm II mm FF mm CC p

5.5 Setting of Mould closing

Interface of setting of cla ping (06)

(1)press key twice to display clampin screen(06)。

15

Ai-02 Operation Manual

(2)press key to select the cla ping para eters。

Input proper value,and then press key,to co plete the

setting。

cla ping force” is use to display the cla ping force and correspond pulse

position for auto atic force adjust ent.

CLP POS:“25999p”mean the current position of clampin 。

LOW PRESS CLAMP Ti er is used to count the ti e for building up low

pressure for cla ping. If this ti er is count over, old protection alar s occur. The

old will be opened and stop auto atic operation.

“AA”: Setting for speed of fast mold clamping

“BB”: Setting for pressure of fast mold clamping

“CC”: Setting for ending position of fast mold clamping

“DD”: Setting for speed of 2nd stage of mold clamping

“EE”: Setting for pressure of 2nd stage of mold clamping

“FF”: Setting for ending position of 2nd stage of mold clamping

“GG”: Setting for speed of 3rd stage of mold clamping

“HH”: Setting for pressure of 3rd stage of mold clamping.

“II”: Setting for ending position of 3rd stage of mold clamping

“JJ”: Setting for speed of mold clamping of low pressure

“KK”: Setting for pressure of mold clamping of low pressure

“LL”: Setting for ending position for mold clamping of low pressure

“MM”: Setting for speed of mold clamping of high pressure

“NN”: Setting for pressure of mold clamping of high pressure

“OO”: Setting for ending position of mold clamping of high pressure

“PP”: Setting for ending position of reserved of mold clamping (Optional)

“QQ”: Display the tonnage of mold clamping force, this value is

automatically computed according to the FF p position.

←─── ←──── ←──── ←──── ←───

MM% NN% JJ% KK% GG% HH% DD% EE% AA% BB%

Mold clamping Mold clamping 3rd stage 2nd stage Fast mold

of high pressure↑of low pressure↑ mold clamping ↑ of mold clamping↑ clamping

OO p LL p II mm FF mm CC mm

16

Ai-02 Operation Manual

5.6 Interface of Mould Clamping and Injection Pressure

Setting

Interface of Mould Cla ping and Injection Pressure Setting (07)

(1) Press for three ti es or for five ti es and you can enter into interface of

ould cla ping and injection pressure setting (07).

(2)Use to select the para eters of ould cla ping to be set,

Input the nu erical value and press the, then the set is co pleted.

Of which,

Cla p pressure is used to set the cla ping force for direct hydraulic cla ping

achine

Injection pressure is used to set the pressure for switching to the holding

stage(filling to holding)

5.7 Injection Setting

Interface of Injection Setting (08)

1

Ai-02 Operation Manual

(1) Press and you can enter into interface of injection setting (08).

(2) Use to select the para eters of injection to be set,

Input the nu erical value and press the, then the set is

co pleted.

Of which,

"AA":Set the filling ti e fro stage 1 – 5 of injection

"BB":Set the ter ination position of injection

"CC":Set the injection ti e

"DD":Set the speed of stage 1 of injection

"EE":Set the pressure of stage 1 of injection

"FF":Set the ter ination of action of stage 1 of injection

"GG":Set the speed of stage 2 of injection

"HH":Set the pressure of stage 2 of injection

"II": Set the ter ination of action of stage 2 of injection

"JJ": Set the speed of stage 3 of injection

"KK":Set the pressure of stage 3 of injection

"LL":Set the ter ination of action of stage 3 of injection

"MM":Set the speed of stage 4 of injection

"NN":Set the pressure of stage 4 of injection

18

Ai-02 Operation Manual

"OO":Set the ter ination of action of stage 4 of injection

"PP":Set the speed of stage 5 of injection

"QQ":Set the pressure of stage 5 of injection

"RR":Set the ter ination of action of stage 5 of injection

19

Ai-02 Operation Manual

5.8 Setting of pressure holding

Interface of setting of pressure holding (09)

(1) Press for two ti es and you can enter into interface of

pressure holding (09).

(2) Use to select the para eters to be set,

Input the nu erical value and press the, then the set is

co pleted.

In which

“AA”: Setting for injection ti e ( to convert ti e into pressure holding)

“BB”: Setting for ending position of injection

“CC”: Setting for speed of 1st stage of pressure holding

“DD”: Setting for pressure of 1st stage of pressure holding

“EE”: Setting for ti e of 1st stage of pressure holding

“FF”: Setting for speed of 2nd stage of pressure holding

20

Table of contents

Other Chen Hsong Desktop manuals