CONTENT

1. WARNINGS AND SAFETY PRECAUTIONS........... 4

2. INTRODUCTIONS ................................................ 6

3. TECHNICAL DATA ................................................ 7

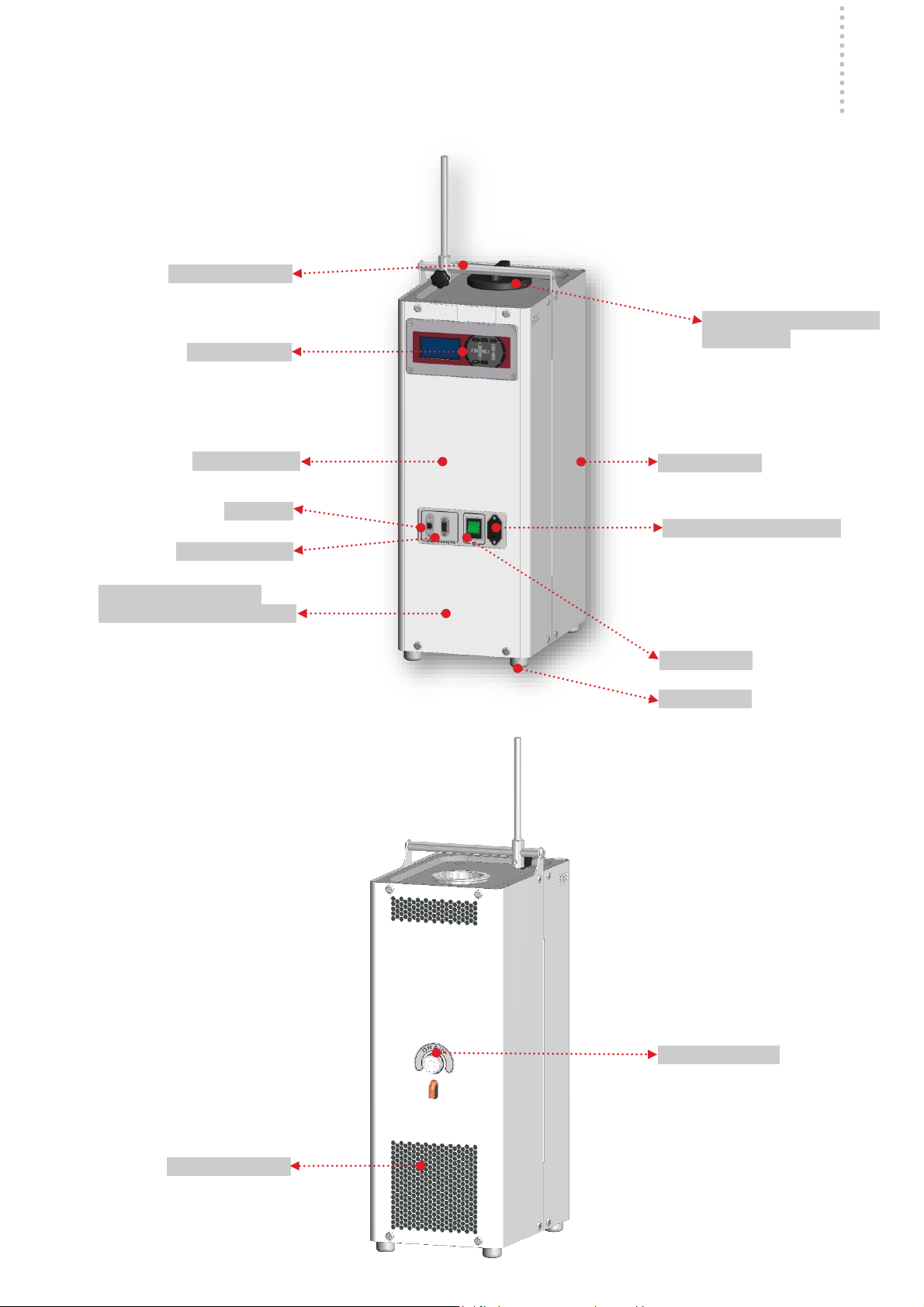

3.1 Front view............................................................. 8

3.2 Rear view ............................................................. 8

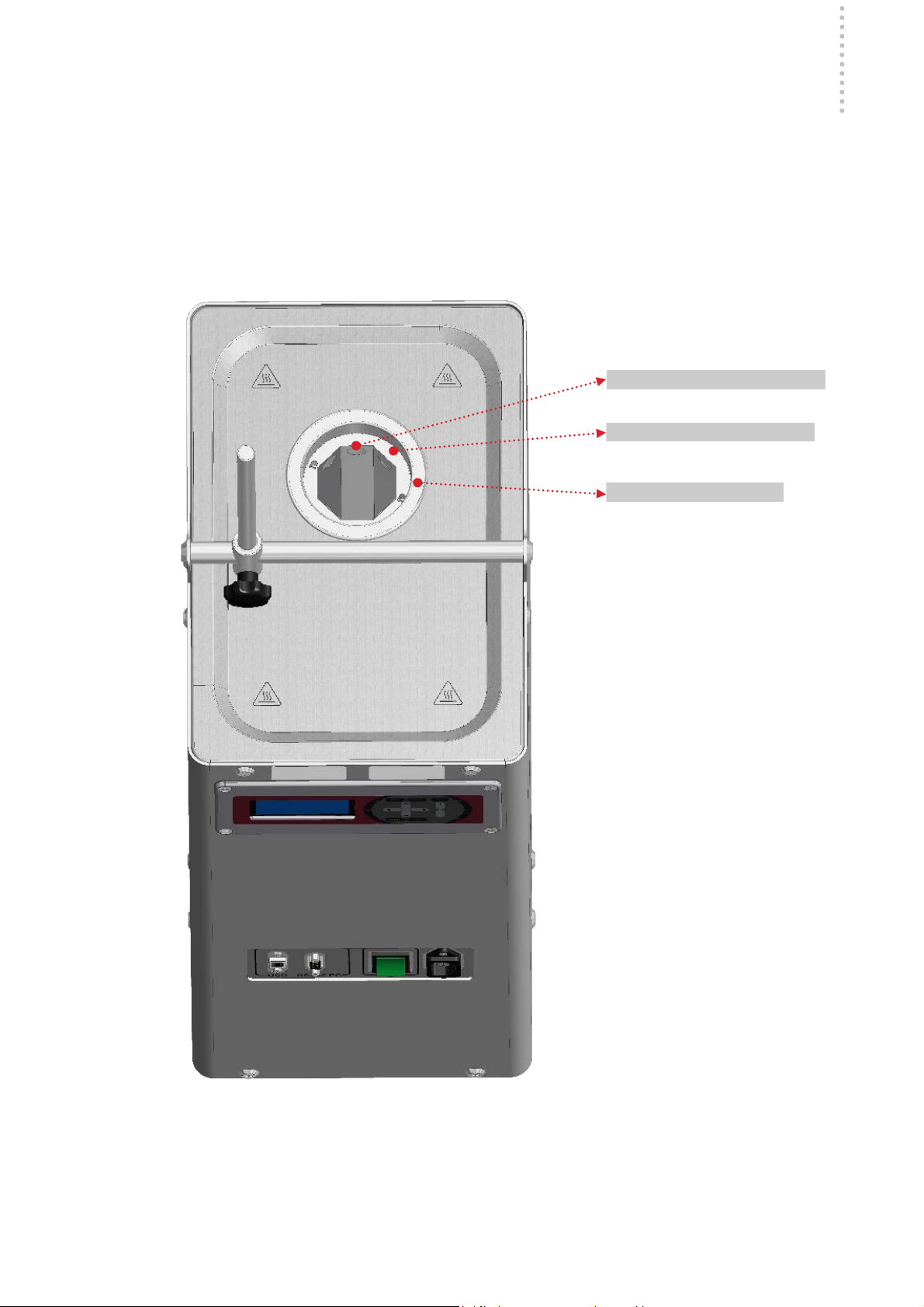

3.3 Top view............................................................... 9

4. INSTRUCTIONS FOR USE.................................. 10

4.1 Basic Setup ......................................................... 10

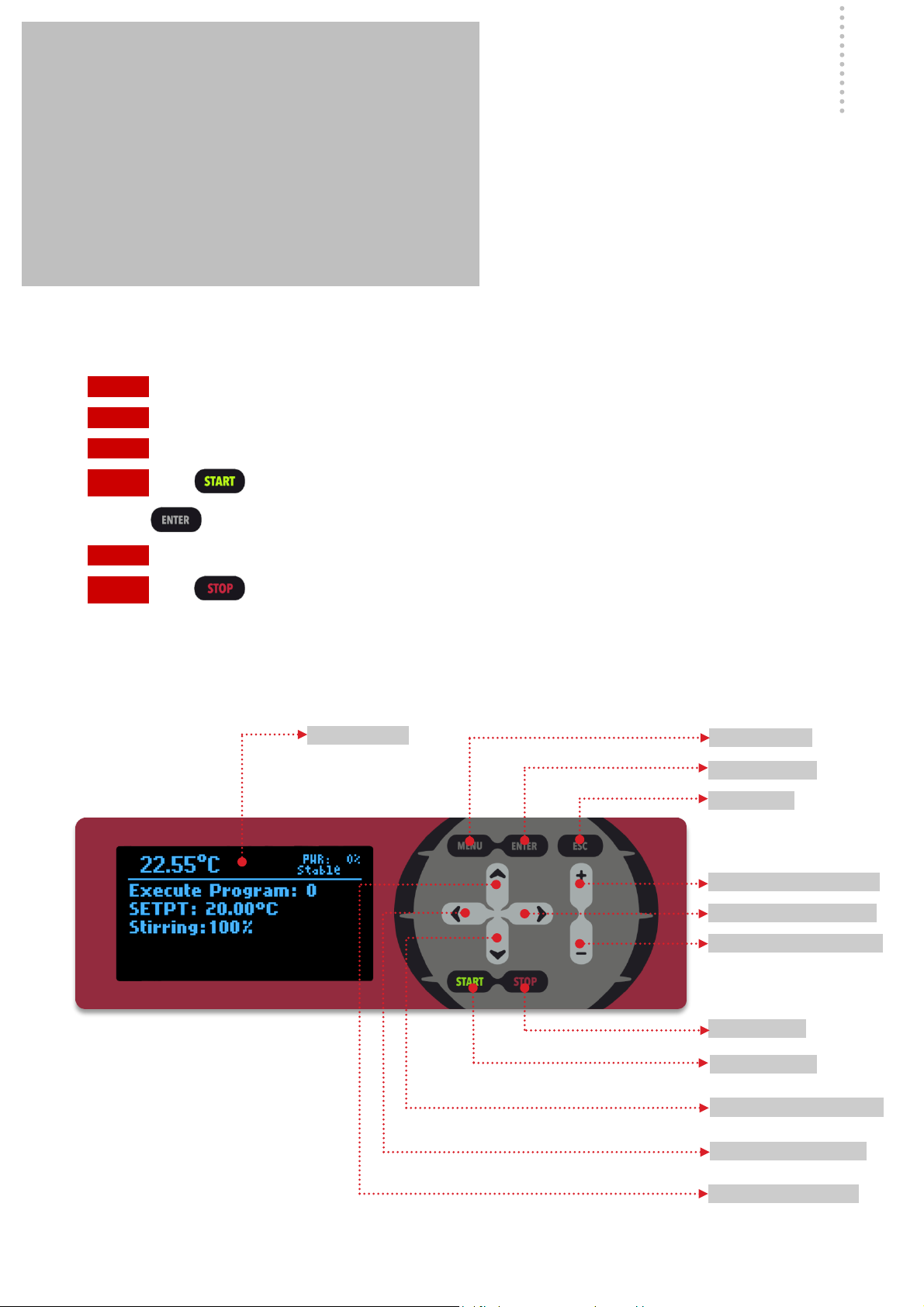

4.2 Control Panel with OLED display and keyboard...... 10

4.2.1 Main Screen (running) ...................................... 11

4.2.2 Main Screen (not running)................................. 11

4.2.3 Program selection and start............................... 12

4.2.4 Menu and navigation ........................................ 15

4.3 Program Setup ................................................... 16

4.4 Instrument Setup ............................................... 18

4.4.1 Display Parameters ........................................... 18

4.4.2 Time and Date ................................................. 19

4.4.3 System Parameters........................................... 19

4.4.4 Bath Calibration ............................................... 20

4.4.5 PID parameters ............................................... 20

4.4.6 Change Password ............................................. 21

4.5 Service .............................................................. 22

5. SERVICE AND MAINTENANCE .......................... 23

5.1 Draining the Bath ................................................ 24

6. REQUIRES SPACE AND CONECTIONS .............. 25

7. SAFE USE AND SAFETY ELEMENTS ................... 26

8. DISMANTLING AND DISPOSAL ........................ 27

9. ABBRIVATIONS ................................................. 28

10. TROUBLESHOOTING ....................................... 29

11. ATTACHMENTS ................................................ 30

11.1 Wiring diagram

11.2 Declarations

11.3 RS232 Communication protocol