Chigo CKF-34CV User manual

Air To Water Heat Pump

MODEL:CKF-34CV

9. Trouble shooting

2

+

X4

Expansion screws:

3

● Outer Structure

12

67

3

4

5

8

1.Handle

2.Maintenance Door

3.Water Outlet

4.

Water Inlet

6.Wire Controller And

Waterproof Box

7.Pressure Gauge

8.Fan and Motor

Power Supply

5.

990mm

1440mm

1470mm

494mm

735mm

4

Model CKF-34CV

Voltage/Phase/Frequency 380-400V/3PH/50HZ

Amps Per Phase 19.5Amps

Min. Circuit Size 25.4Amps

Heating Capacity 33.5KW

Heating Power Input 9.6KW

Sound Level 60dB(A)@3m

Type Scroll

Number Per Unit 2

FLA (Full Load Amp) 11*2Amps

Voltage/Phase 380~400V/3PH

Type External Rotor

Number Per Unit 2

Power Input 0.25*2KW

Voltage/Phase 220~240V/1PH

Fan Speed 850Rpm

Type Plate Type Heat Exchanger

Water Flow Rate (m3/h) 5.8

Max. Outlet Water Temp 55℃

Water Connections 1.5 Inch

Refrigerant R410a

Defrost Automatic Hot Gas Injection

Shipping Weight 296 kg

Dimensions L x W x H (cm) 147 x 73.5 x 99

※Heating: Outdoor Air Temp:15℃ DB ,11℃WB, Water Temp: 35℃

GENERAL INFORMATION

HEAT EXCHANGER (Water Side)

AIR TO WATER HEAT PUMP SPECIFICATIONS

Fan

Compressor

PERFORMANCE

ELECTRICAL INPUT

TECHNICAL DATA

7

9

Soft connection

Automatic

drain valve

19

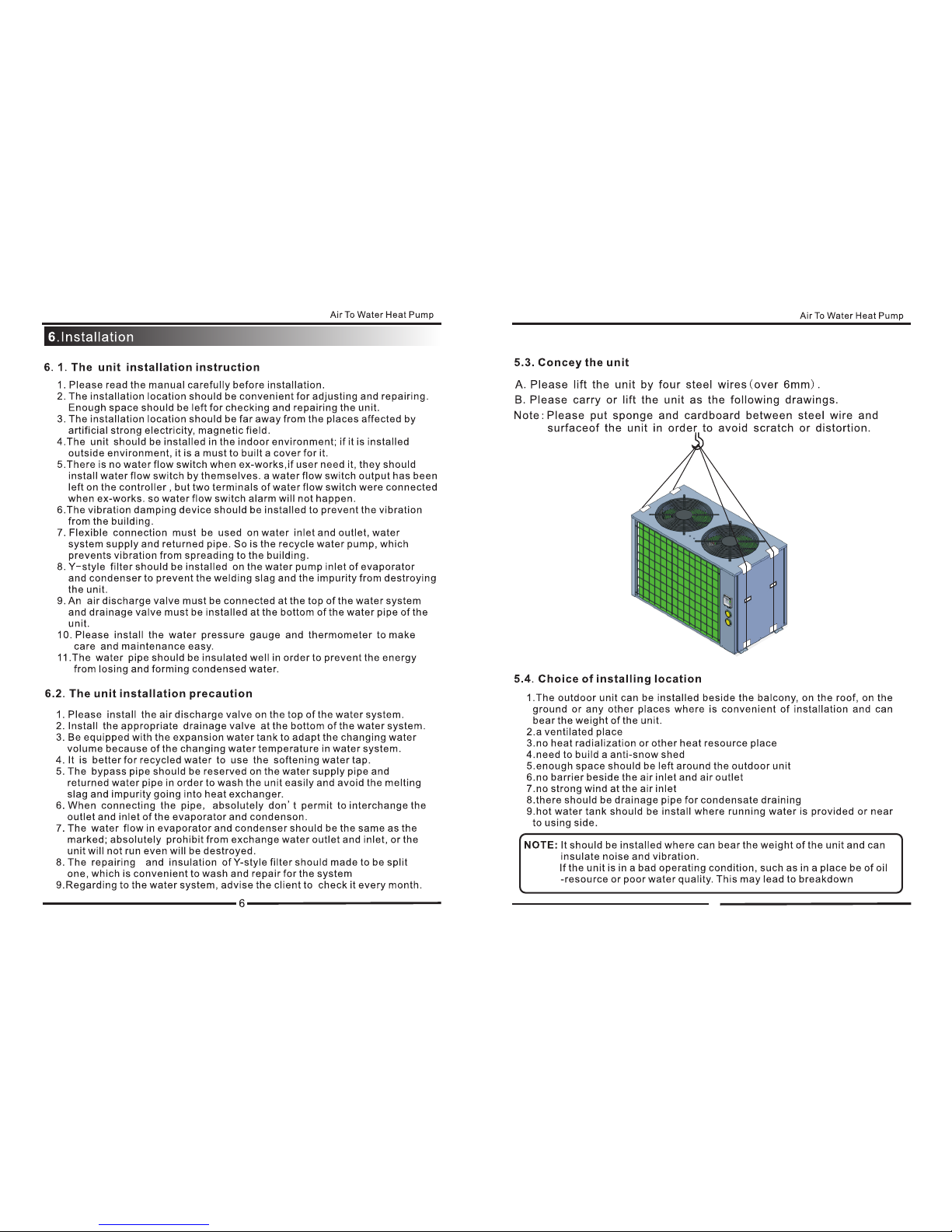

Failure Possible causes Solutions

1. Power source failure 1. turn off the switch and

check the power source

2. Loosened wiring 2. find the caused and repair

3. The power fuse has broke 3. change a new fuse

1. Water leakage of the water

system

1. check the water supply

device and inject water

2. There is air in the system 2. Discharge the air

3. the valves are not open

entirely 3. open the valves completely

4. Filter blockage 4. Wash the filter

1. refrigerant shortage 1. check leakage and supply

refrigerant

2. bad water thermal insulation 2. Improve the insulation

3. bad heat elimination of air

heat exchanger

3. wash the heat exchanger

and improve condensing

4. Water flow shortage 4. Wash the filter

1. Excessive refrigerant 1. discharge unwanted

refrigerant

2. Bad heat elimination of air

heat exchanger

2. Wash the heat exchanger

and improve condensing

1. refrigerant shortage 1. check leakage and supply

refrigerant

2. filter or capillary blockage 2. change new filter or capillary

3. water flow shortage 3. wash the filter or discharge

the air in the system

4. Capillary in the expansion

valve cracks 4. change the expansion valve

1. power source failure 1. examine the power source

and eliminate the failure

2. compressor contactor

failure 2. change the contactor

3. loosened wiring 3. check and repair it

4. Compressor over loading

protection

4. compressor over loading

protection

5. wrong setting for inlet water

temperature 5. Reset it

6. Water flow shortage 6. Wash the filter or discharge

the air in the system

No running of the unit

The pump is running

without water

recycling or with high

noise

Low refrigerant capacity

while

compressors are running

Over-high outlet

pressure of compressors

Over-low inlet pressure

of compressors

No running of

compressors

9.1

20

Failure Possible causes Solutions

1. Liquid refrigerant into the

compressor

1. Check the cause and

eliminate it

2. compressor crash 2. change the compressor

1.Relay failure 1. change the relay

2. fan motor destroyed 2. change the fan motor

1. completely leakage of

refrigerant

1. examine leakage and supply

refrigerant

2. Tube-in-tube heat exchanger

ruined

2. change the tube-in-tube heat

exchanger

3. Compressors fault 3. Change compressors

1. water flow shortage 1. Wash the filter or discharge

the air in the system

2. Low setting value on

temperature 2. Reset the temperature

1. water flow shortage 1. wash the filter or discharge

the air in the system

2. water switch damage 2. Change the switch

The compressors are

running, but the unit

is not cooling/heating

Low water temperature

protection

Low water flow

protection

High noise of

compressor

No running of fan

motors

9.2System Status

Code Description Range Remark

IN Water inlet tem p. -9℃~99℃Actual value

OUT Water Outlet tem p. -9℃~99℃Actual value

P1 System1 coil temp. -9℃~99℃Actual value

P2 System2 coil temp. -9℃~99℃Actual value

P3 Ambient tem p. -9℃~99℃Actual value

P4 System1 cooling coil tem p. -9℃~99℃Actual value

P5 System1 step of electronic

expansion valve 150P~470P Actual value

P6 System2 cooling coil tem p. -9℃~99℃Actual value

P7 Sys tem1 suction temp. -9℃~99℃Actual value

P8 Sys tem2 suction temp. -9℃~99℃Actual value

P9 System2 step of electronic

expansion valve 150P~470P Actual value

21

Parameter

Function Range Value

00 Water inlet temperature during

cooling mode 8-28℃12℃

01 Water inlet temperature during

heating mode 15-60℃50℃

02 Defrosting cycle 30-90Min 45Min

03 Initial defrosting temperature 0--30℃-9℃

04 Final defrosting temperature 2-30℃13℃

05 End time of defrosting 1-12Min 10Min

06 Electronic expansion valve control 0-1 1

07 Power down memory function 0-1 1

08 Model 0-3 1

9 Work Pattern of water pump 0(Ordinary)

/1(Special) 0

a Automatic water inlet temp.setting 8℃-60℃40℃

b System1 target superheat temp. -F(-15℃)~

F(15℃)5℃

cManual adjustment of electronic

expansion valve 15~47 35

b System2 target superheat temp. -F(-15℃)~

F(15℃)5℃

9.3 Parameter

Air To Water Heat Pump

22

Protection/Alarm Error Code Operation/Error indicator

light

Standby state off

Booting normally on

Water inlet temp. sensor fault PP 01

Water outlet temp. sensor fault PP 02

System1 coil temp. sensor fault PP 03

System1 suction temp. sensor fault PP 04

Ambient temp. sensor fault PP 05

Water outlet and inlet temp. differences

overlarge protection PP 06

Sub-cooling protection under cooling

mode PP 07

The First-degree antifreezing protection

in winter PP 07

The Second degree antifreezing

protection in winter PP 07

System1 cooling coil temp. sensor fault PP 08

System2 cooling coil temp. sensor fault PP 09

System2 coil temp. sensor fault PP 10

System2 suction temp. sensor fault PP 11

System1 high pressure protection EE 01

System1 low pressure protection EE 02

Water flow fault EE 03

Phase sequence protection EE 04

Water outlet and inlet temp. overlarge

fault EE 05

System2 high pressure protection EE 07

System2 low pressure protection EE 09

Defrosting

Communication fault EE 08

MODEL:CKF-34CV

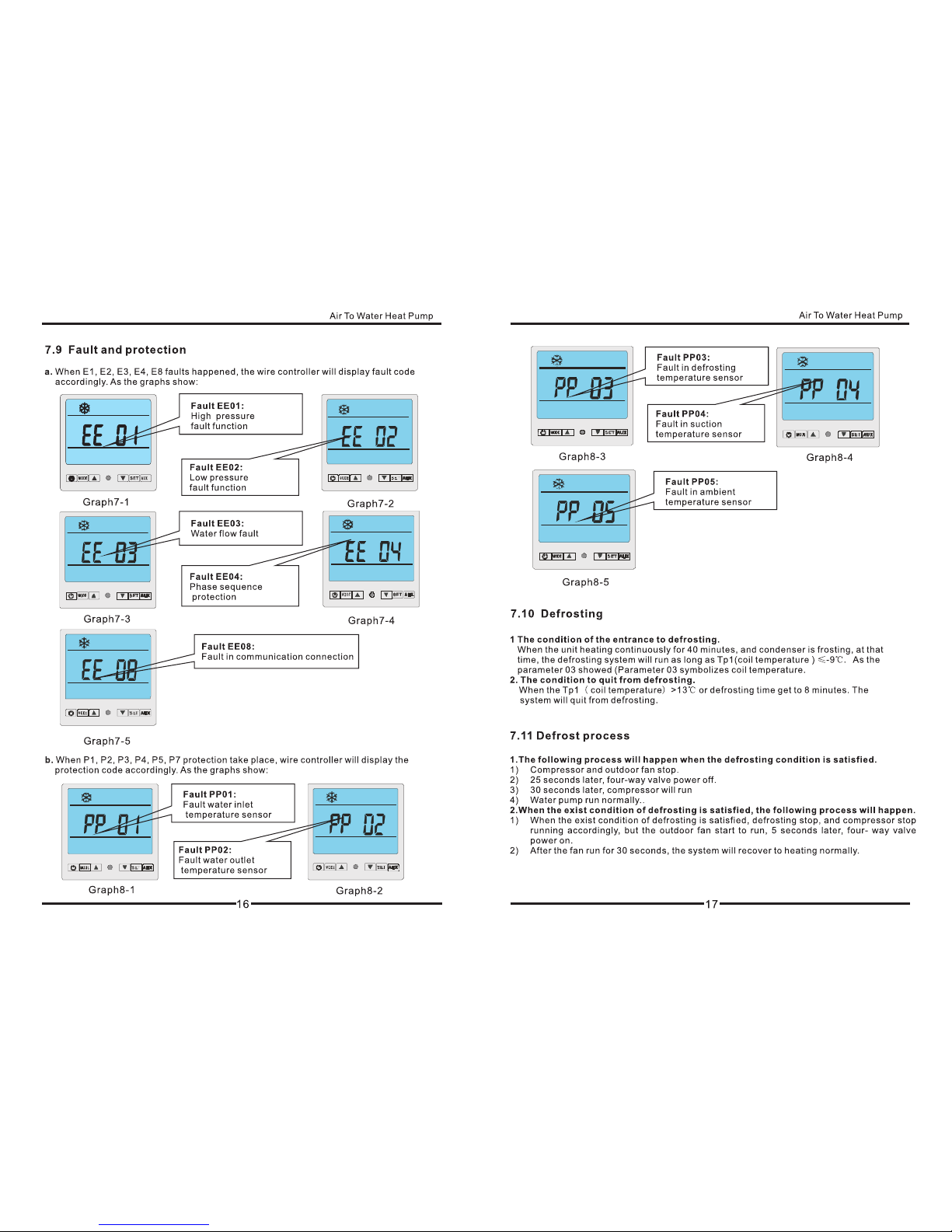

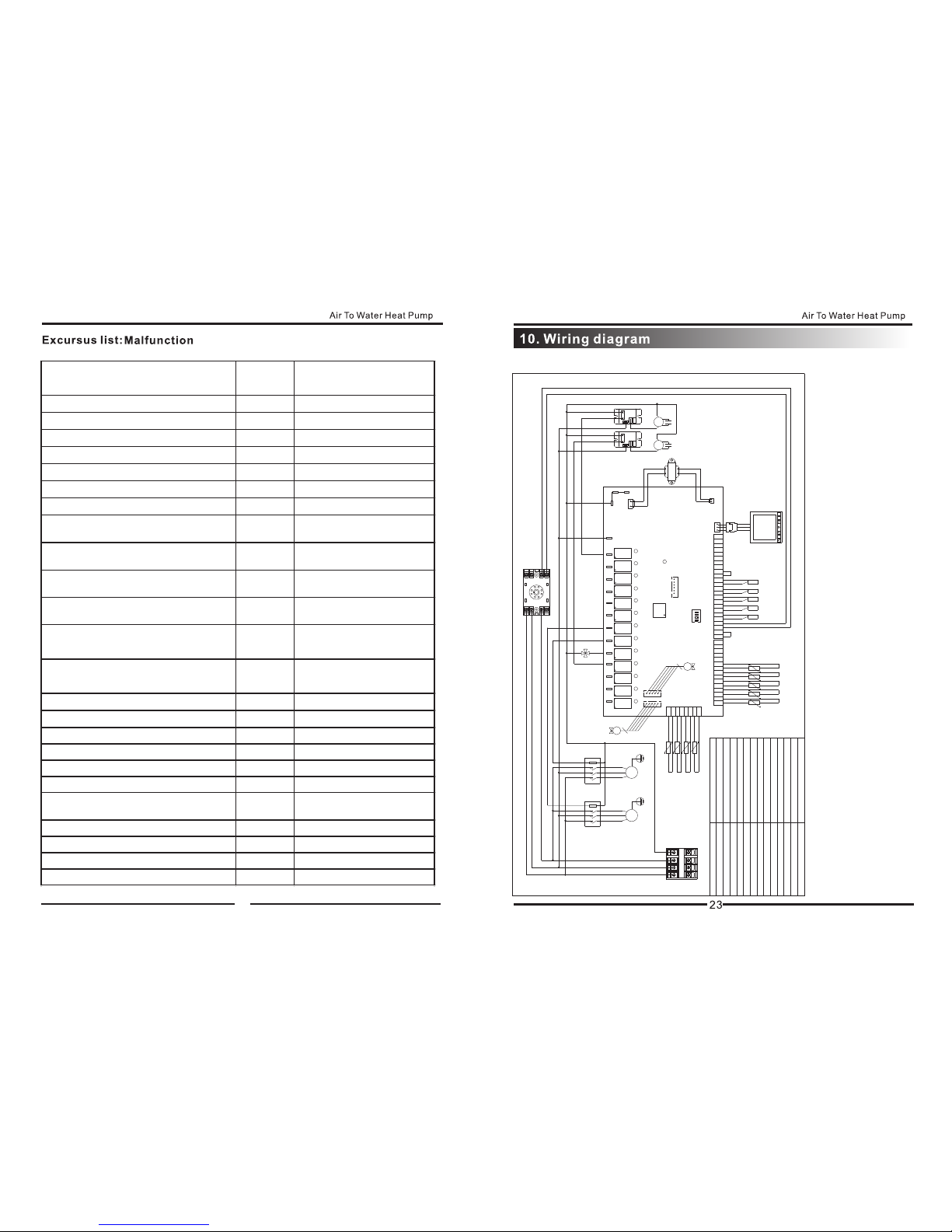

OUT13 OUT12 OUT11 OUT10 OUT9 OUT8 OUT7 OUT6 OUT5 OUT4 OUT3 OUT2 OUT1

01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

01 02 03 04 05 06 0708 09 10 11 12 1314 15

01 02 03 04 05 06 07 08

ON DIP

1 2 3 4

I;C

LED1

LED2

LED3

LED4

LED5

LED6

LED7

LED8

LED9

LED10

LED11

LED12

LED13

N3

N2

AC-N

AC-L

PP05

PP01

PP02

PP03

PP10 PP04 PP11 PP08 PP09 EE03

EE04 EE09

EE07EE02EE01

water inlet sensor

water outlet sensor

F5

low pressure switch1

F4

cooling coil sensor1

electrical expansion valve1

V2

V1

KM1/KM2 Comp AC contactor

fan

M3

R6

4-way valve

E1 transformer

ambient sensor

R5

F3

high pressure switch1 coil sensor1

R4

suction gas sensor1

R1

M1/M2 compressor

F2

F1 water flow switch

T1 power supply

V1

R2

R3

E1

F2F1

MSET AUX

A2

F3 F4 F5

R5 R6 R7 R8 R9

R1

R2

R3

R4

E

V3

E

V2

A1

main control board

wire controller

A2

A1

low pressure switch2

high pressure switch2

electrical expansion valve2

V3

R9

R8

cooling coil sensor2

R7

coil sensor2

suction gas sensor2

M2

(AC380V)

R S T N

T1

KM1

M1

KM2

phase sequence protection board

A3

K2K1

M3

COM

NO NO

COM

A3

5

6

7

8

4

321

relay

K1/K2

M4

water pump

M4

Other Chigo Heat Pump manuals