Chilli Penguin short User manual

Contents

CPS 9768 06/2015

1

Welcome

p4

2

Dimensions & Technical

Specifications

p5

4

Instructions for Use

p20

a.

Diagram of outside including

a.

Short Penguin

top plate

b.

Woody

b.

Diagram inside including door

c.

Hungry Penguin

c.

Warnings & Pre-lighting

d.

Fat Penguin

checks

e.

High and Mighty

d.

YOUR FIRST FIRE - a

f.

Penguin 8

simple guide

g.

Penguin 8 with oven

e.

Principles of combustion

f.

The environment

g.

Instructions for use with wood

h.

Instructions for use with

smokeless fuels

i.

Cooking on a penguin

3

Installation Instructions

p12

5

Maintenance

p29

a.

Warning

a.

Routine checks and

b.

Smoke Control Areas and

cleaning

Exemption of Appliances

b.

Painting the stove and

c.

Fitting a Smoke Control Kit

flue pipe

d.

Ventilation

c.

Keeping the glass clear

e.

Floors

d.

Replacing Ceramic door

f.

Hearth

glass

g.

Plinth clamp

e.

Replacing a door seal

h.

Rear flue box

f.

Fire brick replacement

i.

Rear flue adaptor

g.

Removing the throat plate

j.

Base heat shield

h.

Removing the grate

k.

Distance to non combustible

i.

Trouble Shooting

walls

l.

Distances to combustible

6

Guarantee

p35

walls

m.

Distance to flue

Please be aware that our stoves are finished

with a high temperature stove paint so should

only be cleaned with a soft brush or dry lint

free cloth. Do not wipe with a damp cloth. If

you are plastering or painting please protect

the stove. The paint is in its most vulnerable

condition before curing in the first few fires.

n.

Chimney

A very warm welcome and croeso to your new chilli penguin stove

The charter of the penguin

We guarantee that your stove is good quality and well made

We guarantee that your stove will give you years of warm and efficient heating

We know this because we design and make them ourselves here in Wales

We are convinced that stoves make the autumn fabulous and the winter sublime

We hope that your stove will make the bad days bearable and the good days great

We think that human beings with stoves are happier than those without

We believe that your life has just got better

We put a lot of time and energy into developing and improving our stoves to enable

them to run as efficiently as possible and be simple to use. Please spend a few

minutes familiarising yourself with the stove so you can get the best possible

performance out of it. We love to hear how the penguins get on in their new homes, if

you have any comments or questions, please get in touch. www.chillipenguin.co.uk

The Chilli Penguin Team

Let your inner penguin smile

Your stove should arrive with

A pair of heat resistant gloves

A tool for operating the stove and removing the ash pan

Instruction manual

Ash pan drawer

Smoke control kit –must be fitted in smoke control areas

An aerosol of spray paint - coloured stoves only

Trivet - oven models only

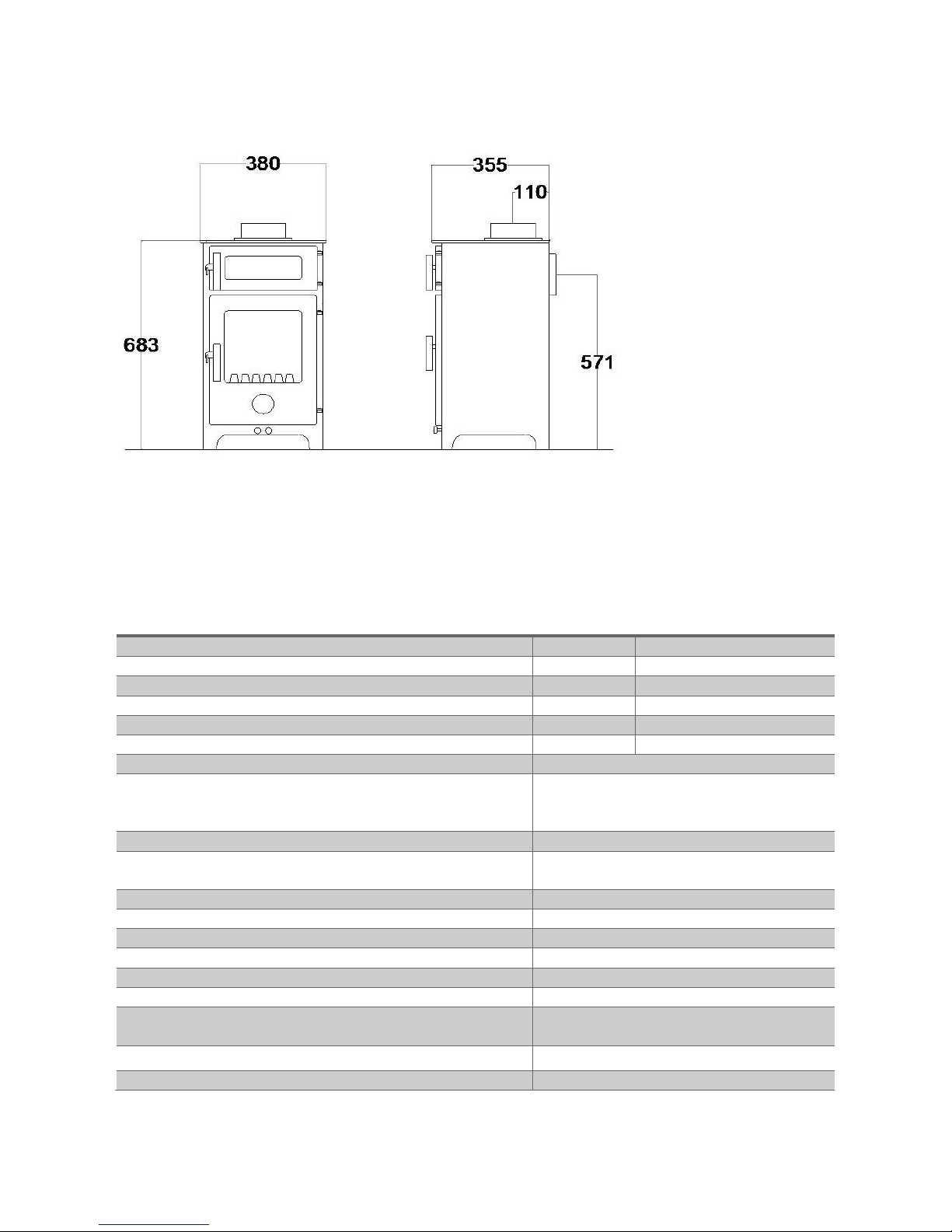

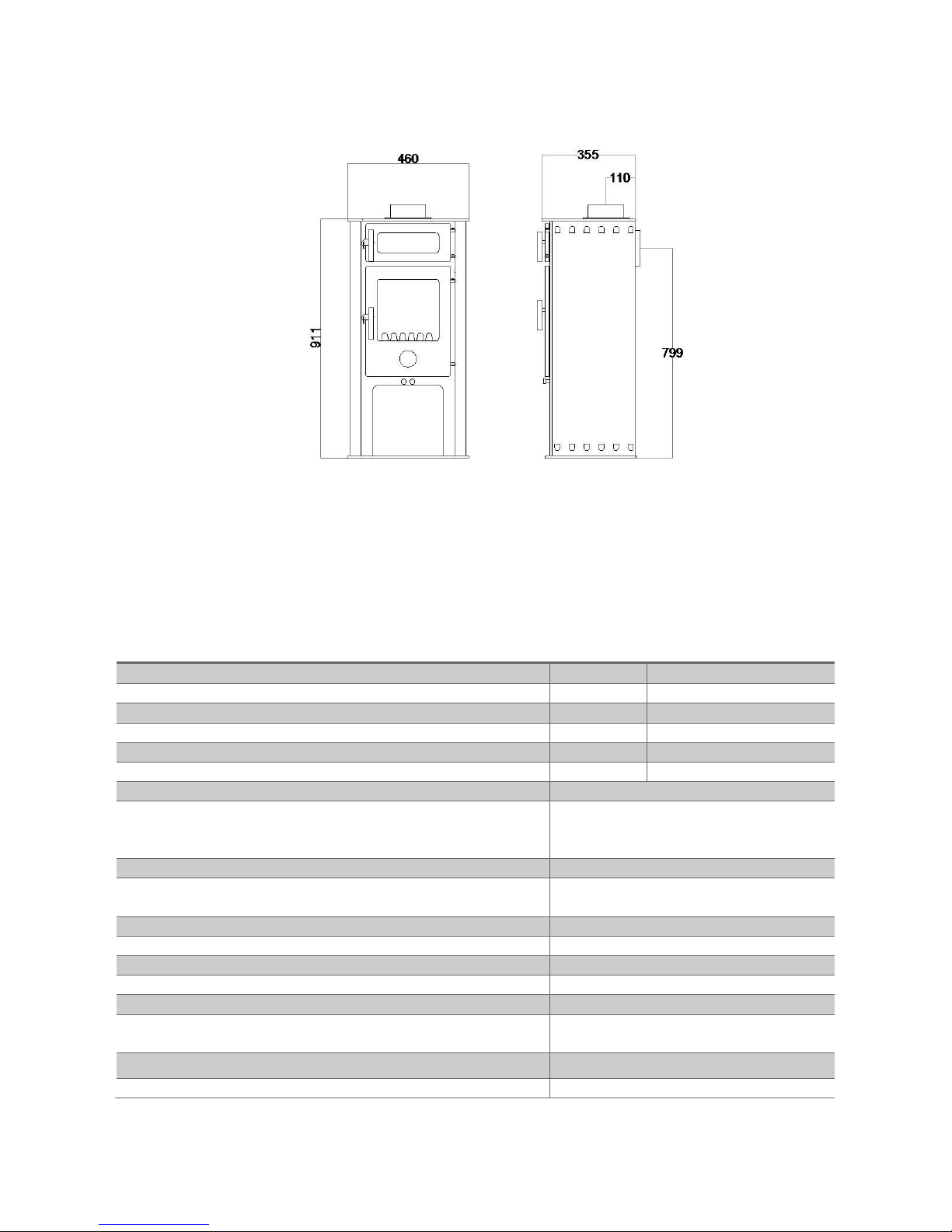

2 a.Technical Specifications - Short Penguin

Tested to EN 13240 and BS3841-2:1994 as intermittent burning

appliance

Item

Wood

Smokeless fuels

Fuel type

Yes

Yes

Nominal Output

5.0kW

4.8kW

Total Energy Efficiency %

81.9

72.7

Flue gas g/s

3.3

3.1

Co content @13% 02

0.21%

0.14%

Mean Flue gas temp. Deg.C

269

311

Exemption Testing complete

Yes

Max. Log length x average diameter*

*With split logs treat this as the greatest depth

/width measurement

270mm x 100mm

Flue collar diameter

127mm

Flue size required

150mm

(125mm if fitted with a smoke control kit)

Top Exit

Standard

Rear Exit

Optional flue box/adaptor required

Hearth type without base heat shield/plinth

constructional

Hearth type with base heat shield/plinth

12mm

Chimney draught required

12Pa

Optional boiler (non pressurised systems)

Not tested for use in smoke control areas

1.4kW

Construction

Welded steel

Nett weight

80kg

2 a. Stove Dimensions - Short Penguin sensational

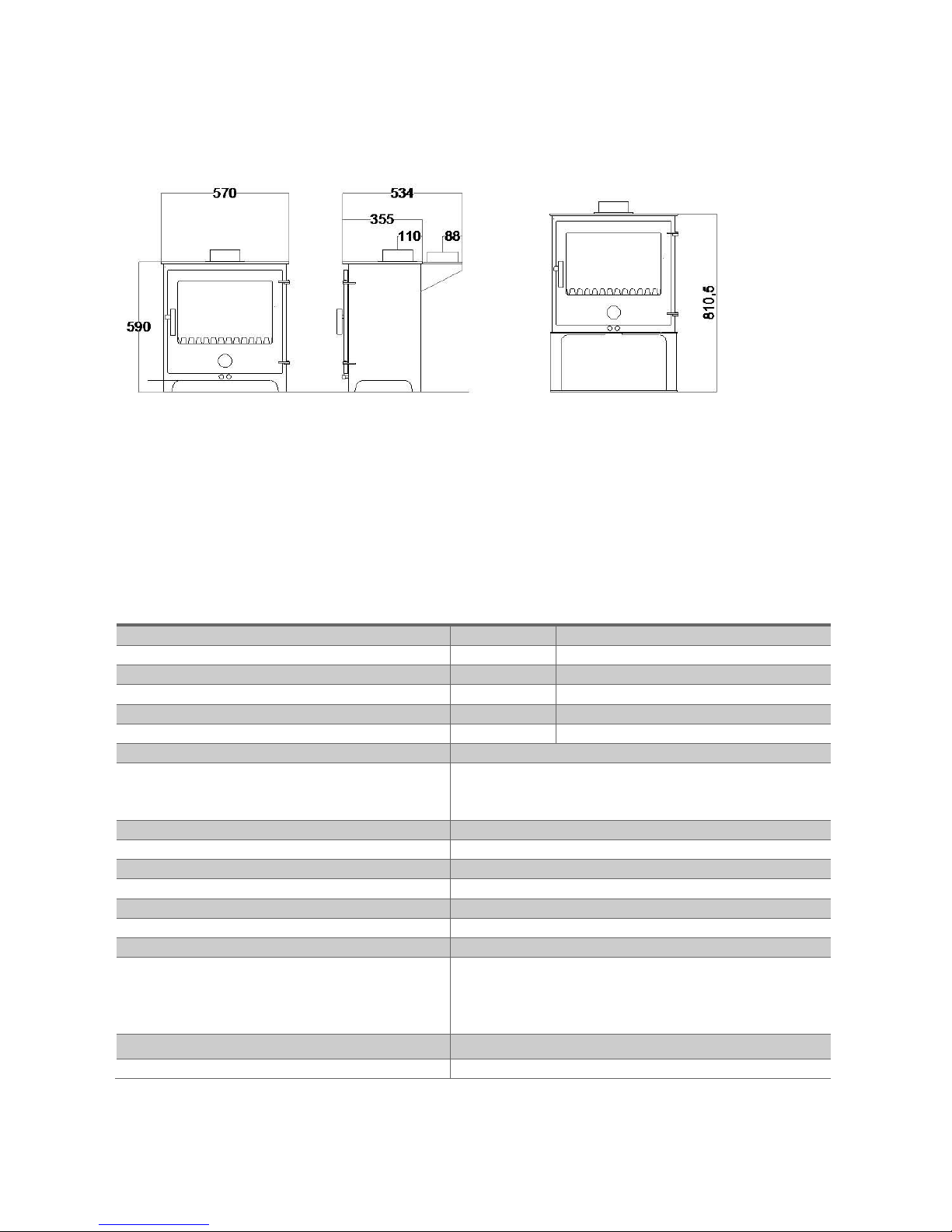

2.bTechnical Specifications - Woody

Tested to EN 13240 and BS3841-2:1994 as intermittent burning

appliance

Item

Wood

Smokeless fuels

Fuel type

Yes

Yes

Nominal Output

5.0kW

5.0kW

Total Energy Efficiency %

82

87

Flue gas g/s

4.0

3.2

Co content @13% 02

0.19%

0.21%

Mean Flue gas temp. Deg.C

200

223

Exemption Testing complete

Yes

Max. Log length x average diameter*

*With split logs treat this as the greatest depth

/width measurement

430mm x 100mm

Flue collar diameter

127mm

Flue size required

150mm

(125mm if fitted with smoke control kit)

Top Exit

Standard

Rear Exit

Optional flue box/adaptor required

Hearth type without base heat shield/plinth

constructional

Hearth type with base heat shield/plinth

12mm

Chimney draught required

12Pa

Optional boiler (non pressurised systems)

Not tested for use in smoke control areas

2.3kW

Construction

Welded steel

Nett weight

90kg

2.b Stove Dimensions - Woody efficient and fabulous

2.cTechnical Specifications - Hungry Penguin

Tested to EN 13240 and BS3841-2:1994 as intermittent burning

appliance

Item

Wood

Smokeless fuels

Fuel type

Yes

Yes

Nominal Output

5.0kW

5.0kW

Total Energy Efficiency %

82

87

Flue gas g/s

4.0

3.2

Co content @13% 02

0.19%

0.21%

Mean Flue gas temp. Deg.C

200

223

Exemption Testing complete

Yes

Max. Log length x average diameter*

*With split logs treat this as the greatest depth

/width measurement

270mm x 100mm

Flue collar diameter

127mm

Flue size required

150mm (125mm if fitted with smoke

control kit)

Top Exit

Standard

Rear Exit

Fit flue collar to rear

Internal cooker dimensions

h100 mm x w250mm x d220mm

Hearth type without base heat shield/plinth

constructional

Hearth type with base heat shield/plinth

12mm

Chimney draught required

12Pa

Optional boiler (non pressurised systems)

Not tested for use in smoke control areas

1.4kW

Construction

Welded steel

Nett weight

90kg

2.c Stove Dimensions - Hungry Penguin does it all

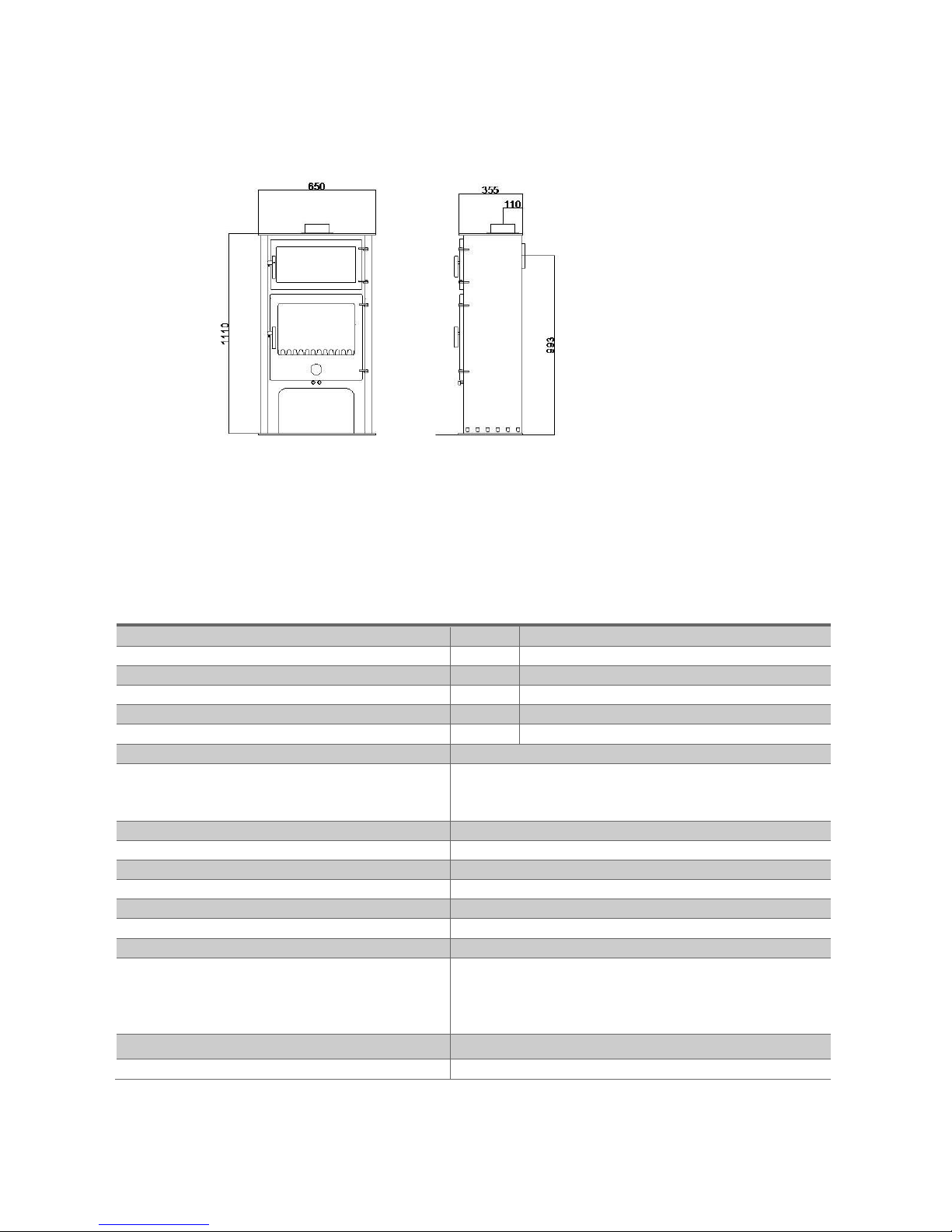

2.d Stove dimensions - Fat Penguin big, fat & beautiful

2.d Technical Specifications - Fat Penguin

Tested to EN 13240 and BS3841-2:1994 as intermittent burning

appliance

Item

Wood

Smokeless fuels

Fuel type

Yes

Yes

Nominal Output

5.0kW

5.0kW

Total Energy Efficiency %

82

87

Flue gas g/s

4.0

3.2

Co content @13% 02

0.19%

0.21%

Mean Flue gas temp. Deg.C

200

223

Exemption Testing complete

Yes

Max. Log length x average diameter*

*With split logs treat this as the greatest depth

/width measurement

270mm x 100mm

Flue collar diameter

127mm

Flue size required

150mm (125mm if fitted with smoke

control kit)

Top Exit

Standard

Rear Exit

Fit flue collar to rear

Internal cooker dimensions

h100 mm x w250mm x d220mm

Hearth type without base heat shield/plinth

constructional

Hearth type with base heat shield/plinth

12mm

Chimney draught required

12Pa

Optional boiler (non pressurised systems)

Not tested for use in smoke control areas

1.4kW

Construction

Welded steel

Nett weight

100kg

2.e Stove dimensions - High and Mighty smug as a sausage

2.e Technical Specifications - High and Mighty

Tested to EN 13240 and BS3841-2:1994 as intermittent burning

appliance

Item

Wood

Smokeless fuels

Fuel type

Yes

Yes

Nominal Output

5.0kW

5.0kW

Total Energy Efficiency %

82

87

Flue gas g/s

4.0

3.2

Co content @13% 02

0.19%

0.21%

Mean Flue gas temp. Deg.C

200

223

Exemption Testing complete

Yes

Max. Log length x average diameter*

*With split logs treat this as the greatest depth

/width measurement

270mm x 100mm

Flue collar diameter

127mm

Flue size required

150mm (125mm if smoke control kit

fitted)

Top Exit

Standard

Rear Exit

Fit flue collar to rear of stove

Internal cooker dimensions

h100 mm x w250mm x d220mm

Hearth type with integral plinth

12mm

Chimney draught required

12Pa

Optional boiler (non pressurised systems)

Not tested for use in smoke control areas

1.4kW

Construction

Welded steel

Nett weight

110kg

2.f Technical Specifications –Penguin 8

Tested to EN 13240 and BS3841-2:1994 as intermittent burning

appliance

Item

Wood

Smokeless fuels

Fuel type

Yes

Yes

Nominal Output

8.0kW

8.0kW

Total Energy Efficiency %

81

71

Flue gas g/s

5.1

9.8

Co content @13% 02

0.19%

0.21%

Mean Flue gas temp. Deg.C

200

223

Exemption Testing complete

Yes

Max. Log length x average diameter*

*With split logs treat this as the

greatest depth /width measurement

430mm x 100mm

Flue collar diameter

127mm

Flue size required

150mm (125mm if fitted with smoke control kit)

Top Exit

Standard

Rear Exit

Optional flue box/flue adaptor required

Hearth type without plinth

constructional

Hearth type with plinth

12mm

Chimney draught required

12Pa

Optional boiler (non pressurised

systems)

Not tested for use in smoke control

areas

3kW

Construction

Welded steel

Nett weight

95kg

2.f Stove Dimensions - Penguin 8 simply awesome

2.gStove Dimensions - Penguin 8 with Oven smoking hot

( plinth and side panels included )

2.g Technical Specifications

Tested to EN 13240 and BS3841-2:1994 as intermittent burning

appliance

Item

Wood

Smokeless fuels

Fuel type

Yes

Yes

Nominal Output

8.0kW

8.0kW

Total Energy Efficiency %

81

71

Flue gas g/s

5.1

9.8

Co content @13% 02

0.19%

0.21%

Mean Flue gas temp. Deg.C

200

223

Exemption Testing complete

Max. Log length x average diameter*

*With split logs treat this as the

greatest depth /width measurement

430mm x 100mm

Flue collar diameter

127mm

Flue size required

150mm (125mm if fitted with smoke control kit)

Top Exit

Standard

Rear Exit

Flue collar fitted to rear

Hearth type with integral plinth

12mm

Internal oven dimension (sloping roof)

h180 mm x w440 mm x d220 mm

Chimney draught required

12Pa

Optional boiler (non pressurised

systems)

Not tested for use in smoke control

areas

3kW

Construction

Welded steel

Nett weight

150kg

3. Installation Instructions

3.a Warning

All local and national regulations must be observed when installing the appliance. If

installed incorrectly serious accidents can be caused.

Building Regulation Document J must be referred to when installing this appliance.

It is the installer’s responsibility to ensure the manufacturer’s instructions are complied

with.

A HETAS qualified installation engineer should carry out the installation and issue a

compliance certificate or alternatively your local Building control department needs to

inspect the installation and register the work carried out.

3.b Smoke Control Areas and Exemption of Appliances

If you live in a smoke control area (introduced by The Clean Air Act,1993, see below) you are

permitted to burn approved smokeless fuel only, this does not include wood. However

if you use an Exempt stove then you can burn both seasoned wood and approved

smokeless fuels. NEVER BURN HOUSE COAL in a closed appliance like a stove.

The following stoves have been recommended as suitable for use in smoke control

areas when fitted with a smoke control kit when burning wood logs: the Short

Penguin, the Woody, the Hungry Penguin, the Fat Penguin, the High and Mighty and

Penguin 8. The appliances are not exempted when burning wood briquettes or paper

bricks or unauthorised fuels.

When a smoke control kit has been fitted this should be recorded in this manual.

The clip in boiler option on all our stoves is not approved for use in smoke

control areas.

The general principle to be observed in an Exempt chilli penguin stove is that the air

controls cannot be completely closed, allowing a permanent air supply to the fire

chamber.This means that fuel burns more efficiently, thereby emitting less harmful

emissions into the atmosphere.

“The Clean Air Act 1993 and Smoke Control Areas”

Under the Clean Air Act local authorities may declare the whole or part of the district of

the authority to be a smoke control area. It is an offence to emit smoke from a chimney

of a building, from a furnace or from any fixed boiler if located in a designated smoke

control area. It is also an offence to acquire an "unauthorised fuel" for use within a

smoke control area unless it is used in an "exempt" appliance ("exempted" from the

controls which generally apply in the smoke control area).

The Secretary of State for Environment, Food and Rural Affairs has powers under the

Act to authorise smokeless fuels or exempt appliances for use in smoke control areas

in England. In Scotland and Wales this power rests with Ministers in the devolved

administrations for those countries. Separate legislation, the Clean Air (Northern

Ireland) Order 1981, applies in Northern Ireland. Therefore it is a requirement that fuels

burnt or obtained for use in smoke control areas have been "authorised" in Regulations

and that appliances used to burn solid fuel in those areas (other than "authorised"

fuels) have been exempted by an Order made and signed by the Secretary of State or

Minister in the devolved administrations.

Further information on the requirements of the Clean Air Act can be found here:

http://www.gov.uk/smoke-control-area-rules

Your local authority is responsible for implementing the Clean Air Act 1993 including

designation and supervision of smoke control areas and you can contact them for

details of Clean Air Act requirements.

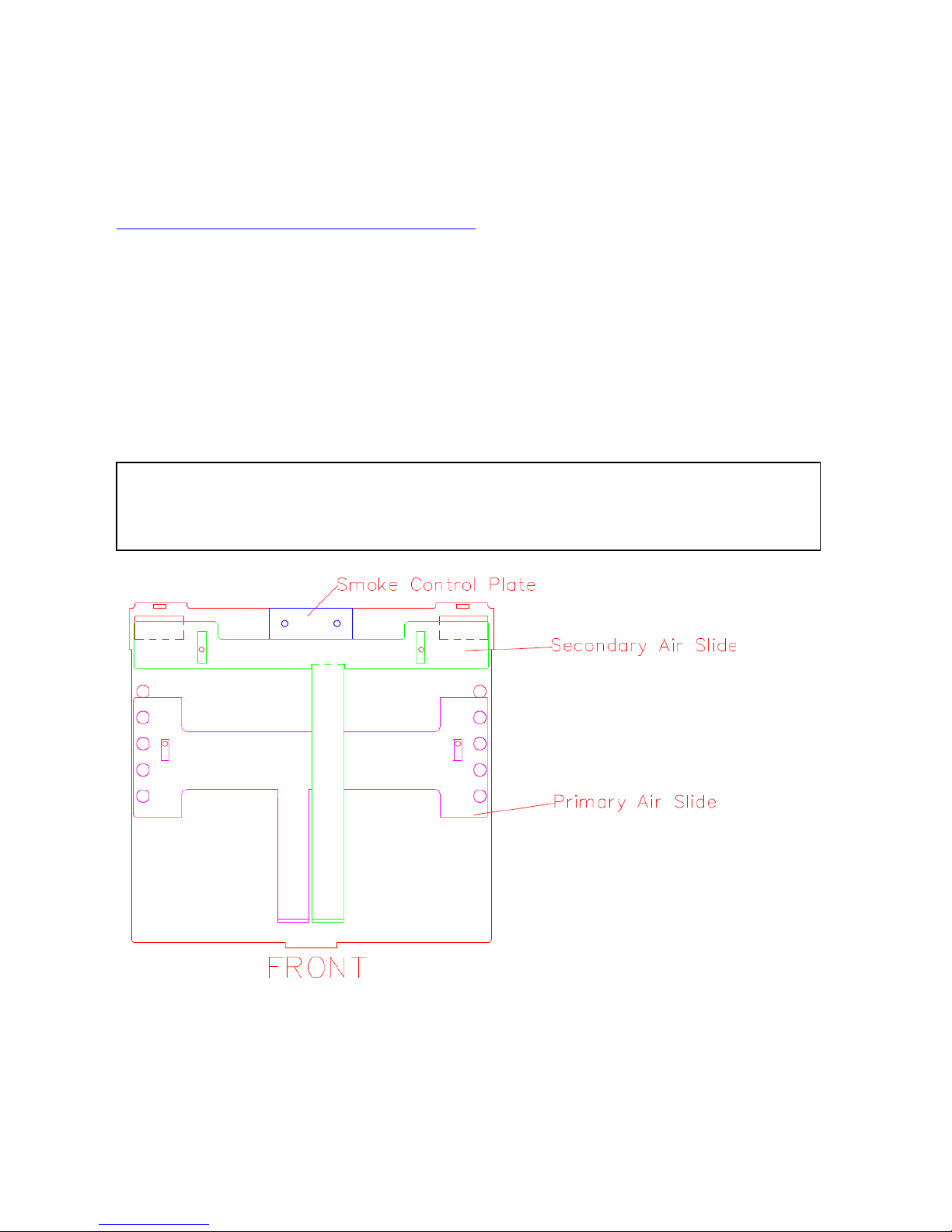

3.c Fitting the Smoke Control Kit

If you are installing a stove in a Smoke Control Area you must fit the Smoke Control kit

supplied. Record whether a smoke control kit has been fitted on the guarantee page of

this manual. The Smoke Control kit consists of a metal plate with 2 holes in, 2 screws

and 2 bolts.

Diagram of the underneath of the stove

3.d Ventilation: In order for the stove to operate correctly there needs to be sufficient

combustion air. For stoves of 5kw and over a permanantly open air vent is required.

For stoves of 5kW and under it may sometimes be required. In new build houses air

To fit: It is fitted to the underside of the stove prior to installation. See diagram

below for the position. When correctly fitted the secondary air knob will not push

in as far as the primary air knob.

vents are required for all sizes of stoves, this can apply to new extensions as well. This

will depend on the air leakage (air permeability) of your property.Your HETAS installer

should be able to guide you on your particular property. In addition a stove should not

be fitted in a room with an appliance such as extractor fan, ceiling fan or tumble drier, it

will affect the draw of the stove and could lead to fumes entering the room.

All air vents should be positioned so that thay are not liable to blockage.

3.e Floors: Make sure the floor can take the weight of the stove, the flue, the hearth

and any decorative surround.

3.f Hearth: A hearth is made up of 2 layers: a constructional hearth (base concrete

layer) and a superimposed hearth (top decorative layer). In some circumstances a

superimposed hearth is acceptable on its own. All of our stoves require a

constructional hearth unless the stoves are either on a plinth or have a base heat

shield fitted. (The Penguin 8 has not currently been tested for use with a base heat

shield but it can go on a plinth)

HEARTH REQUIREMENTS

All models

without base heat shield or plinth

Constructional

total depth (incl. superimposed) 125mm

All models on plinth

Superimposed 12mm (minimum)

All models (except Penguin 8) on

base heat shield

Superimposed 12mm (minimum)

In front of the stove

225mm (minimum)

Both sides of the stove

150mm (minimum)

NB. Do not place any soft furnishings within 1150mm of the stove.

3.g Plinth clamp

If you order a plinth it will come with a plinth clamp. This consists of two flat bars. The

Woody plinth clamp also has 4 bolts. It is designed to clamp the stove and the plinth

together securely.

photo of plinth clamp, taken inside the plinth, looking up

(the bar is painted red for illustration purposes only)

To fit: Place the bars inside the

plinth, one on the left side and one

on the right, running front to back.

Use the levelling bolts attached to

the legs of the stove to clamp the

bar to the underside of the plinth on

each side.

For Woody plinth, replace the

levelling bolts with the longer ones,

supplied.

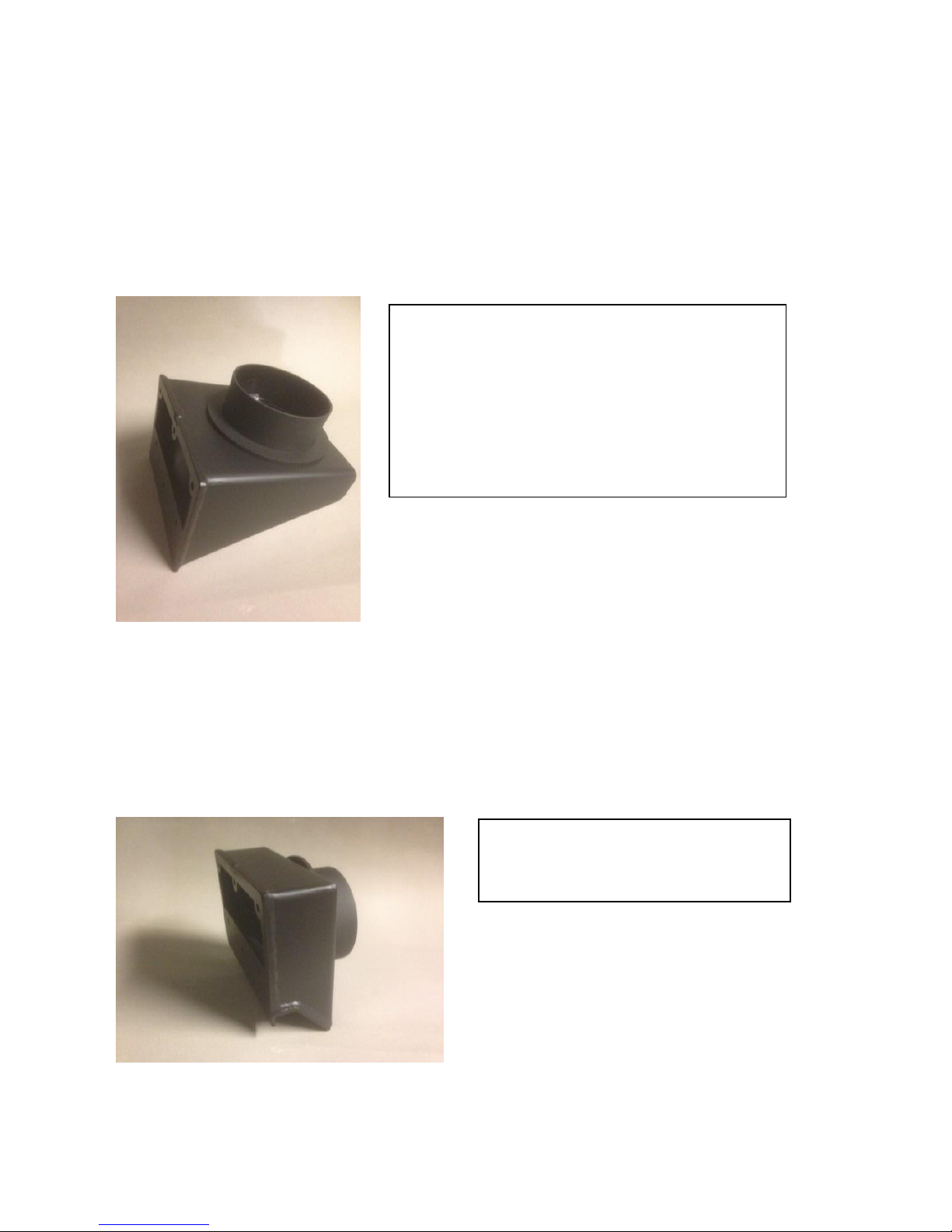

3.h Rear flue box

The usual route for a flue is out of the collar on top of the stove. However the way

some chimneys and fireplaces are set up, fluing out of the rear can be a better option.

Our stoves fall into two groups as far as rear fluing, as follows.

The oven models; the Hungry, the Fat and the High & Mighty have a removable plate,

so a rear flue box is not required, (a rear swept bend or T-junction with cap would be

required).

All other models; the Short, Woody and Penguin 8 would need the rear flue box.

The rear flue box allows you to flue out of the rear of the stove, the flue pipe then goes

vertically up the chimney.

photo of rear flue box

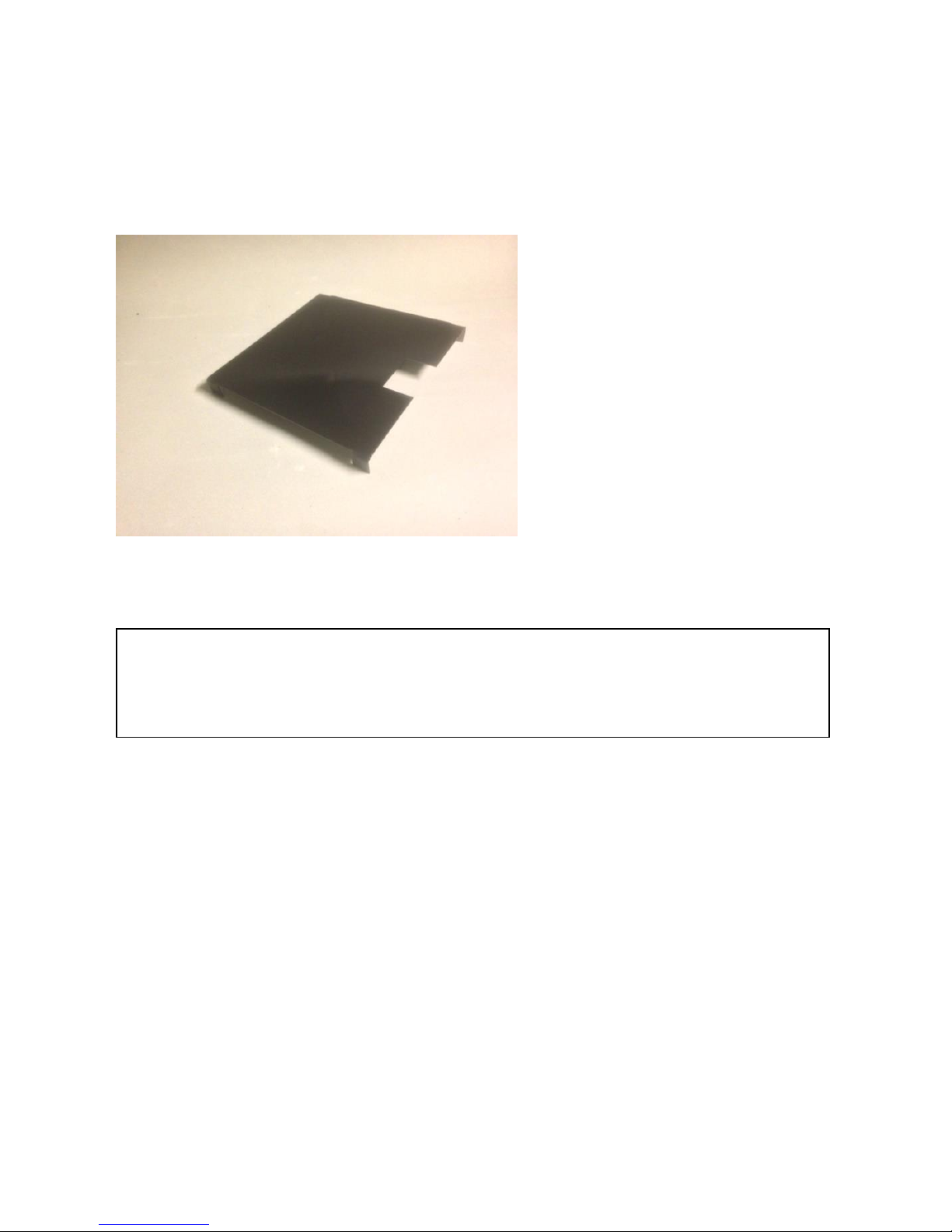

3 i. Rear flue adaptor

There are some circumstances where you may want to flue horizontally from the rear

of the stove. There is a very limited distance that you can rear flue horizontally, for

safety reasons, regulated by building regulations, your installer will be able to advise.

photo of rear flue adaptor

To fit: remove the rear heat shield and

blanking plate (10mm &13mm spanners

required), bolt the rear flue box to the area

where the blanking plate was removed from,

with the blanking plate bolts. Replace the

rear heat shield, having removed the cut out

with tin snips. Place the circular blanking

plate onto the top flue hole.

To fit: same instructions as for

rear flue box

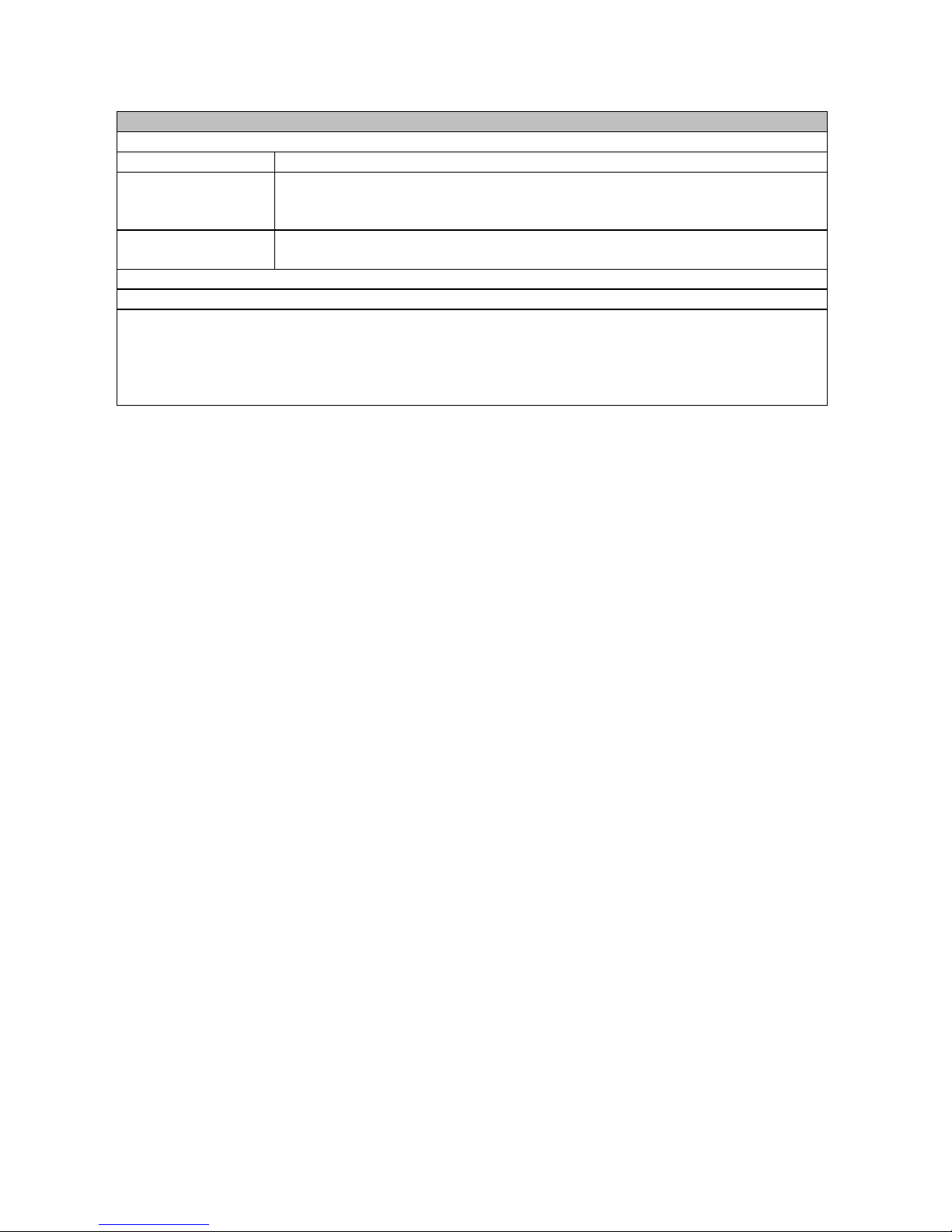

3.j Base Heat Shield

The temperature at the base of a stove will affect the type of hearth required, see

“hearth requirements”. If a constructional hearth is required but is not possible, then a

base heat shield can be fitted underneath the stove. This reduces the hearth

temperatures and allow the stoves to be installed onto a superimposed (12mm) hearth.

Record on the guarantee page whether a base heat shield has been fitted.

photo of base heat shield

To fit: Slide in at the base of the stove prior to installation. It needs to slide in from

the rear. The edge with the cut-out should slide in first, resting at the front of the

stove. The folded legs of the heat shield will sit on the tabs for the leveling screws,

(these are small square tabs with a hole in the centre).

The Woody is illustrated, but non combustible distances are the same for all models

3 k.MINIMUM DISTANCES TO NON COMBUSTIBLE WALLS (ie. stone/brick)

model

rear

sides

above

All models

50mm

100mm

150mm

Rear wall thickness needs to be at least 200mm thick.

These are minimum distances.

NB. Flue pipe safe distances can be greater than the appliance, depending on type

3.k Non Combustible Walls

Diagrams illustrating the minimum distances to combustible walls.

Diagram illustrating the minimum distances to combustible surfaces

3.lMINIMUM DISTANCES TO COMBUSTIBLE WALLS

model

rear

both sides

above

Short

400mm

500mm

450mm

Woody

350mm

400mm

550mm

Hungry

250mm

500mm

450mm

Fat

250mm

400mm

450mm

High & Mighty

250mm

250mm

450mm

Penguin 8

350mm

350mm

550mm

3.m The flue pipe (single wall)

Single walled flue pipe must be at least 3 times its diameter away from any

combustibles eg. a timber beam. This may be reduced if adequate protection is

provided to prevent heat transfer. Refer to Building Regulations Document J for heat

shielding guidance. N.B be aware that it is possible, particularly in older properties for

timber beams to enter the inside of the chimney cavity.

3.l Clearance to combustible walls

Short /Hungry 500mm

Fat /Woody 400mm

Pen 8 350mm

H&M 250mm

Short 400mm

Woody/Penguin 8 350mm

Fat/Hungry/H&M 250mm

Side

Rear

3.n Chimney and Access for sweeping

Existing chimney

Must comply with all current building regulations

height

4.5 metres

Non Exempt

(no smoke control

kit fitted)

Lined with 150mm diameter class 1 liner with 125mm stove pipe +

adaptor

Exempt models

Lined with 150mm diameter class 1 liner where possible, where not,

125mm flue is permitted

A flue way must not be shared with other appliances

A flue way must be gas tight and free of tar deposits

Provision must be made for sweeping access and for the removal of soot and debris. Chilli

penguin stoves can be swept through the stove on a lined chimney if the correct super flexible

rods are used. The debris will fall into the fire box from where it can be removed. However if

the chimney is unlined the cooker models cannot be swept through the stoves (due to size of

brushes) so additional provision will need to be made.

New chimney: A new chimney of factory made insulated flue system must comply

with Building Regulations. Consult a chimney specialist for advice on suitable flue

systems for solid fuel.

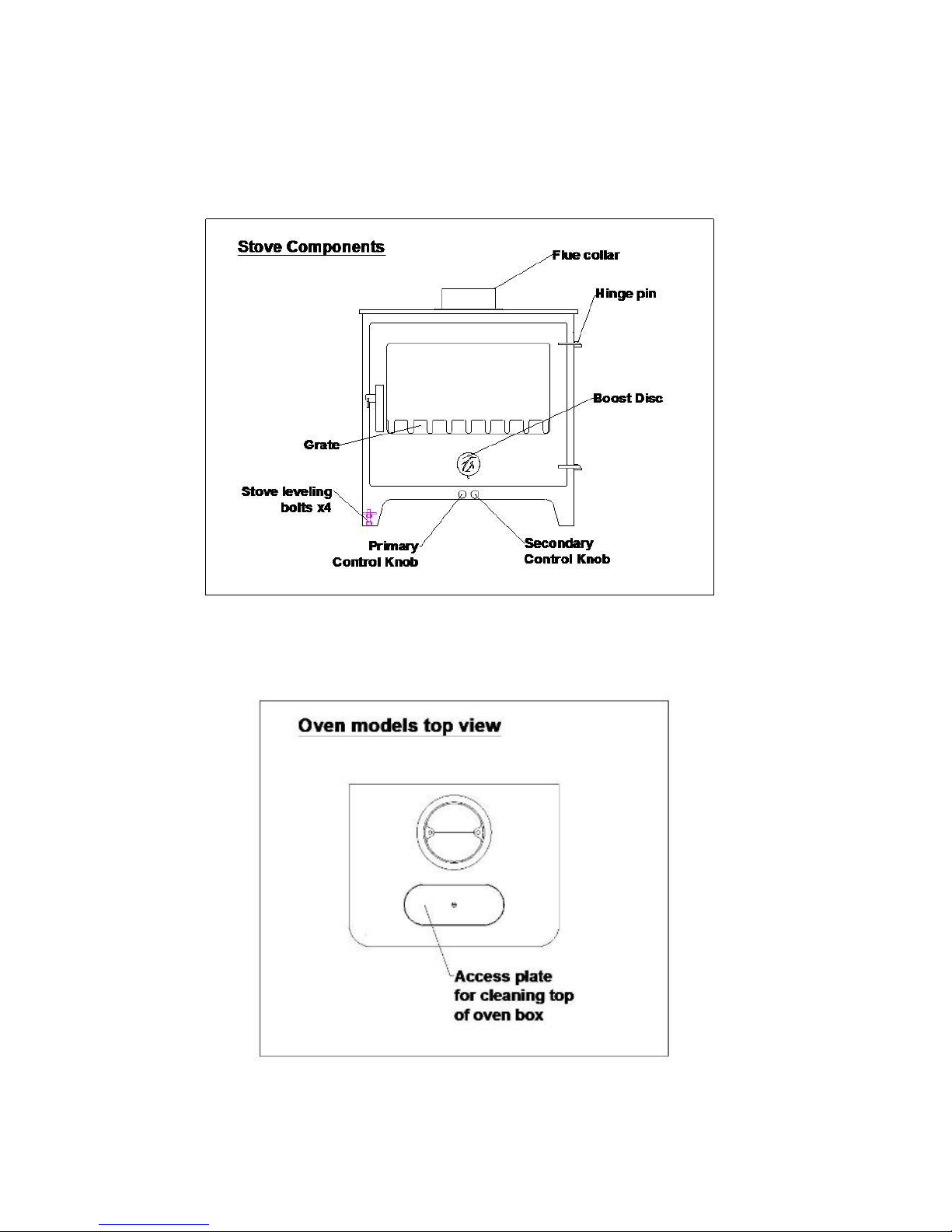

4.aInstructions for use

Diagram of the outside of the stove

When you look at your penguin, smile, because it’s looking back at you

Grate:the cast iron grill that sits on the base of the fire chamber, the castellated edge can be seen

through the glass fire door

Stove levelling bolts: bolts on each leg used to level the stove during installation

Primary air control knob: stainless steel knob on the LH side of the stove as you face it. It

controls the flow of air underneath the fire

Secondary air control knob: stainless steel knob on the RH side of the stove as you face it (fully

out it will protrude 10mm further than the other knob). It controls the flow of air over the top of the

fire and the door glass

Boost disc: brushed stainless steel disc with penguin logo on it. In the balanced open position

this will allow the maximum air flow in to the fire. It should swing easily into the closed position

once the fire is established.

Hinge pin: pins to hold the door to the stove body

Flue collar: the 5”/125mm collar on the top of the stove, (the stove is designed to burn on a 6”

flue, a 5-6” adaptor is required unless the smoke control kit is fitted)

Access plate (cooker models only): this removable access plate is designed to enable the

removal of soot from the top of the oven box. Soot can be brushed back into the fire box and

swept out.

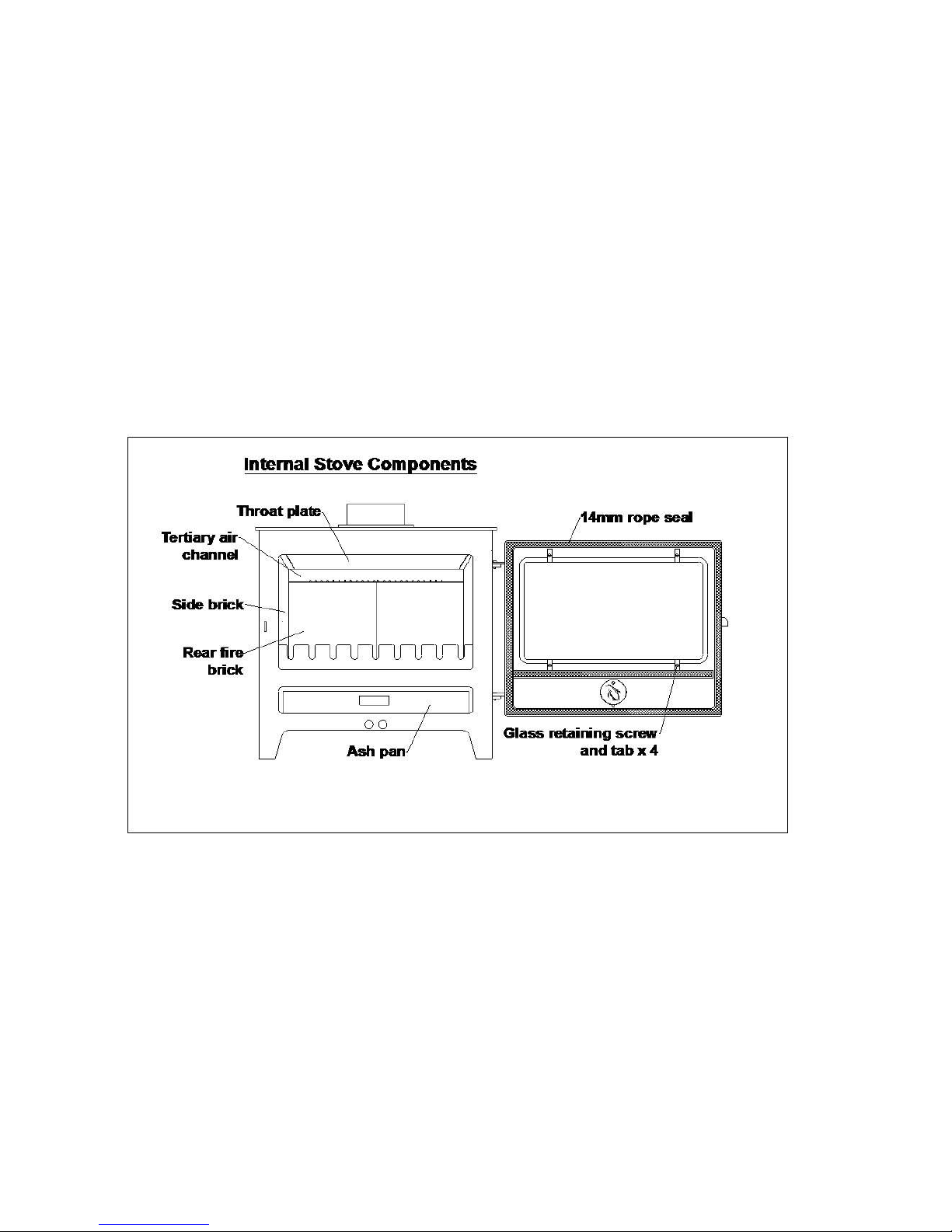

4.b Diagram of the inside of the stove looking into a penguin’s soul

throat plate: this forms the “roof” of the fire box. It has 2 components, a steel plate and a

vermiculite brick, the brick should be underneath the steel plate. It is designed to be easily

removable for the removal of soot

tertiary air channel: this is the perforated metal channel running across the back of the stove, it

is one of the passage ways for air into the fire box. The back of the throat plate rests on this

side brick: one of the two vermiculite side fire bricks

rear fire brick: vermiculite brick at the rear, some models have 1 brick/some 2

ash pan: rectangular metal drawer used for the collection of ash

glass retaining screws and tabs: screw and plates to hold the door glass in situ

rope seal: seal used to form a gas tight seal around all door edge

4 c. Warnings and Pre-lighting checks

Chilli penguin stoves will not be responsible for any damage caused to the stove due to

either the incorrect installation of the stove or the incorrect use of the stove, including the

use of the wrong fuels. We strongly recommend the use of a qualified and experienced

installer. Please read through these warnings and information carefully prior to use.

Protecting the stove surface

Your stove has been painted using a high temperature paint, this will give a long lasting

and durable finish after the paint has cured. The process of curing occurs during the

first few times you light the stove,(see section 5). Care must be taken when handling

the stove prior to the first firings. It is at its most vulnerable at this stage. With the lighter

colours, particularly the almond, we recommend you wear clean gloves from unpacking

onwards. It is dry surface clean only, do not use damp cloths. If you are plastering

/decorating in the same room keep the stove covered.

Painting flue or stove

IF you wish to touch up your stove or paint your flue pipe to match the stove, please read

the 5.b before you begin. All coloured stoves will come with an aerosol of the matching

colour.

Fumes

While the stove paint is curing, it will give off fumes. Please ensure you ventilate the

room, opening doors and windows as necessary.

Smoke emissions

Properly installed and operated the stove will not emit smoke into your home with the

exception of the occcasional smoke from de-ashing and re-fuelling. Occasionally adverse

weather conditions can cause a down-draught, this should be very occasional. Persistent

smoke emission is dangerous and must not be tolerated. If smoke emission does persist:

Open all doors and windows

Let the fire go out

Check flue or chimney for blockage.

Do not re-light fire until cause of problem has been rectified. Seek professional help.

Hot surfaces

The surfaces of the appliance are designed to get hot during operation. It is

recommended to use a fireguard in the presence of children or vulnerable adults.

CO Alarm:It is a legal requirement to install a Carbon Monoxide and smoke alarm when

you install a solid fuel appliance such as a stove.

Wrong fuel

Only burn seasoned wood or smokeless fuels suitable for closed appliances. DO NOT

burn house coal or treat your stove as an incinerator for gereral rubbish. DO NOT use

any liquid fuels.

Chimney fire

In the event of a chimney fire close all stove doors and air vents. Evacuate the house and

phone the fire brigade.

Pre-Lighting checks

The door closes correctly and the rope seals and glass are intact.

The throat plate is installed correctly (see section 5)

All labels and packaging have been removed (including from the flue system)

Any access points in the flue are closed off.

You’ve bought an amazing stove. Let it be amazing

This manual suits for next models

5

Table of contents

Other Chilli Penguin Stove manuals

Popular Stove manuals by other brands

Dometic

Dometic ORIGO E100 operating manual

Sergio Leoni

Sergio Leoni MARLENE P/I installation guide

Monogram

Monogram 30 inch owner's manual

Harman

Harman Allure50 installation manual

Hunter Stoves

Hunter Stoves Herald 6 CE VII Installation and operating instructions

Palazzetti

Palazzetti INSERT A78 instruction manual

RIKA

RIKA TOPOII operating manual

Campingaz

Campingaz CAMP'BISTRO DLX Instructions for use

Jøtul

Jøtul GF 100 DV II Nordic QT Installation and operation instructions

Vogelzang International

Vogelzang International VG130 Owner’s Instruction and Operation Manual

Regency

Regency F39-NG Owners & installation manual

FDI

FDI Rocket instruction manual