China Hangyu EHS350C Application guide

PORTABLE CUT-OFF SAW

EHS350C

Operation/Parts Manual

Version No. 061003

Introduction

Thank you for

purchasing our cutoff saw

Model: EHS350C

WARNING: For safety and efficient operation, always follow the instructions in this manual

This Manual contains operating and safety instructions for your Model EHS350C

cut-off saw.

r cut-off saw model EHS350C,

is important that you read and understand the maintenance and safety manual before

ny of the instructions in this Manual.

, special safety precautions must be

bserved before operating the saw. Careless or improper use could cause serious or even

atal injury.

To receive maximum performance and satisfaction from you

it

operating the saw. Contact your dealer or the distributor in your area if you do not

understand a

Because the EHS350C operates at high speed

1

o

f

Table of Contents

Main parts of EHS350C and their functions………………………………………5- 9

Safety precautions………………………………………………………..…………..10- 20

Specifications……………………………………………………..……………………21- 22

Operation guide to EHS350C cut-off w…………………………………….……23- 32

1. Before starting…………………………………………………………………….23 - 26

2. Starting……………………………………………………………………………..27- 29

2

sa

3. Operation…………………………………………………………………………..30

4. Emergency St

1

41

opping……………………………………………………………..31

5. Notes on operation……………………………………………………………..…31- 32

Adjustment of EHS350C cut-off saw………………………………………………..32- 34

1. Adjusting V-belt tension………………………………………………………..…32

2. Adjusting carburetor…………………………………………………..…………..32- 34

3. Adjusting blade guard………………………………………………….…………34

Maintenance & repair of EHS350C cut-off saw…………………….………….…..35- 4

1. Cleaning and maintenance of air filter………………………………………….35 - 36

2. Maintenance of spark plug……………………………………………………….36- 37

3

3. Replacing starter rope……………………………………………………………37 - 38

4. Replacing pawl…………………………………………………………………….39

5. Maintenance chart…………………………………………………………………40-

Storing EHS350C cut-off saw…………………………………..…………………….42

Exploded parts views and parts lists……………………………………………….43- 59

nd a

ven by

y for

utting work.

1. Crankshaft Housing Assembly…………………………………………………..43-44

2. Crankshaft & Piston Assembly…………………………………………………..45-46

3. Cylinder & Muffler Assembly……………………………………………………..47-48

4. Oil Tank & Carburetor…………………………………………………………….49-50

5. Handle & Main Cover Assembly…………………………………………………51-52

6. Air Filter Assembly………………………………………………………………..53-54

7. Transmission Box & Cutter Assembly…………………………………………..55-57

8. Front Handle & Support Assembly………………………………………………58-59

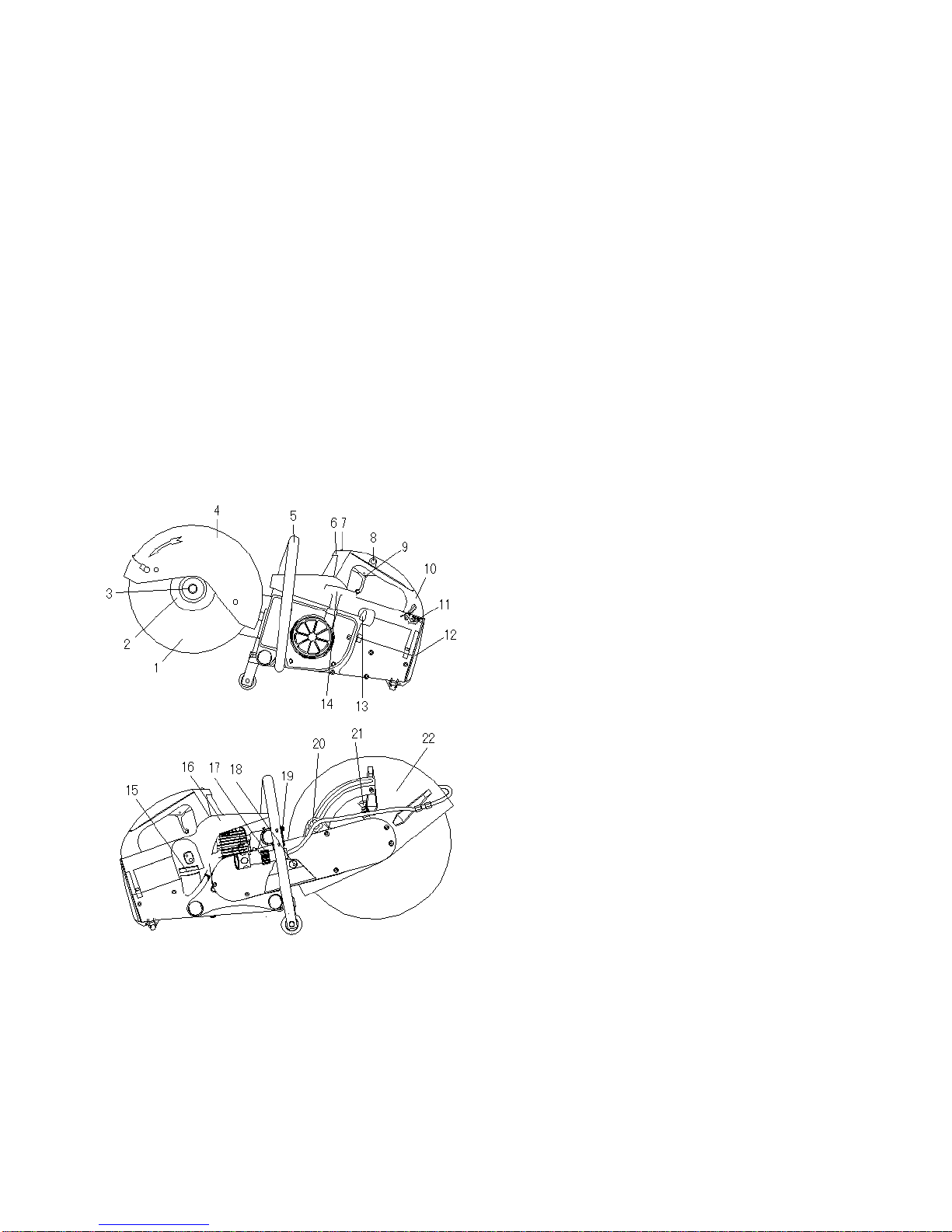

M ia n parts of EHS350C and their functions

4

This product is composed of two main sections: a gasoline powered 2-stroke engine a

dri ing/cutting system. When engine speed is up to 3800 RPM, the cutting blade, driv

the engine via belt transmission system, begins to rotate at high speed, and is read

c

Showed below are the main parts of the EHS350C cut-oflow are the main parts of the EHS350C cut-off saw and their corresponding

1. Blade

2. Flanges

3. Hexagon Bolt

4. Blade Guard

5. Front Handle

6. Spark Plug Cover

7. Kill Switch

f saw and their corresponding

1. Blade

2. Flanges

3. Hexagon Bolt

4. Blade Guard

5. Front Handle

6. Spark Plug Cover

7. Kill Switch

function descriptions (Ref. Fig 1):

function descriptions (Ref. Fig 1):

5

8. Full Throttle Lock Button

9. Throttle Trigger

10. Rear Handle

11. Filter Cover Lock Lever

12. Air Filter

13. Choke Lever

14. Starter Grip

15. Fuel Tank Cap

16. Decompression Valve

17. Water Attachment

18. Tensioning Nut

19.Muffler

20. Blade Guard Positioning Knob

21. Shaft lock

1. Blade:

Diamond or abrasive blades. Depending on t, these blades are

made of different materials. Be sure to being cut.

The maximum diameter of the blade for th ating speed of

the blade should be above or equal to 47

2. Flanges:

Clamp and support the diamond or abrasive blad

the material to be cu

6 choose right blade for the material

e saw is 14 inch. And the oper

00 RPM.

e.

3. Hexagon Bolt:

n.

switch is pressed and held.

ng this button while the trigger is fully

eturns the throttle to idle position.

lling the trigger backward opens

leasing the trigger slows down the engine.

Handle:

Tightens blade flange.

Blade Guard:

Safety guard, directs sparks and dust away from operator.

Front Handle:

urely hold the saw while under operatio

4.

5.

Used to sec

6. Spark Plug Cover:

r for access to the spark plugA removable cove

7. Kill Switch:

en thisEngine stops wh

8. Full throttle lock button:

ull open position by pressiLocks the throttle in f

depressed. Pressing and releasing the trigger r

er:

7

9. Throttle trigg

Controls engine speed by manipulating the throttle. Pu

the throttle and the engine accelerates. Re

10. Rear

Used to securely hold the s

11.

aw while under operation.

d

r. When air pressure in the engine

ue, it automatically closes.

17. W

eeds water to both sides of diamond blade. Connect to water supply for wet cutting.

Filter Cover Lock lever:

Locks the air filter cover. Pull back on the lever to open the filter cover.

12. Air Filter:

Filters dirt and debris from entering carburetor.

13. Choke Lever:

er counter clockwise closes the carburetor. Used to prime engine (colTurning this lev

starting). Turn clockwise for normal operation.

14. Starter Grip:

Pull to start engine.

:15. Fuel Tank Cap

Open this cap for filling the fuel. Close the tank for starting and operation.

Decompression Valve:

this valve to make starting easie

8

16.

Press down on

reaches a preset val

ater Attachment:

F

18. Tensioning Nut:

turn the nut

As the EHS350C cutoff saw is a high-speed power tool, improper use of this

saw might be hazardous. To avoid property damage or personal injury, it is

For V-belt tension adjustment. Turn this nut clockwise to loosen the V-belt,

ion the V-beltcounter clockwise to tens

19. Muffler:

Reduces both noise and emissions.

oning Knob :20. Blade Guard Positi

Loosen the knob to adjust blade guard position.

21. Shaft lock:

Lock the blade shaft to facilitate blade changing and installation.

Safety Precautions: 9

EXTREMELY IMPROTANT to read, fully understand, and observe the following safety

precautio f saw.

Requirements:

e

sufficient visibility, and be

d operator stands on should be non-skid. Take extreme care

zing weather (rain, snow, frost, ice).

hand d animals should never be allowed in the work area.

e objects may be thrown toward the operator by the cutting tool. So position the

ns before operating this cut-of

1. Wo

rksite

. The worksite should be free of any materials or objects that are flammable or

xplosive.

undings should be in order, with no clutters, having. Surro

well ventilated. The groun

when working in wet and free

. Bystanders should keep away from the saw when it is operating. Children, the

icapped an

. Loos

10

object to be cut securely to ensure it won’t be pushed around by the blade when

cutting.

Blade:2.

Befo e blade is above

r

or break and cause serious personal injury. Failure to follow these directions

may cause the blade to shatter or crack in use causing serious or fatal injury.

Never use

personal inj

iamond blades have a much better cutting performance than standard abrasive blades.

The blades are steel centered and diamond rticles are imbedded in their cutting edges.

re installing a blade make sure that the maximum operating speed of th

or equal to the spindle speed of your cut-off saw. Inspect the cutting blade frequently and

ace immediately if the cutting blade is cracked or warped. Cracked or warped blades

shatter

epl

may

carbide-tipped, woodcutting or circular machine blades. They can cause severe

ury from reactive forces, blade contact or thrown objects.

Use of the wrong cutting blade for which it was not designed may cause that blade to shatter

causing serious or fatal injury. 11

Only use the cutting blade approved for the type of material to be cut.

D

pa

Wet or dry cutting is possible. Cutting wet will extend the life of your diamond blades. A

ater attachment comes as standard equipment with the EHS350C. Before using the

is tightened.

Always install the blade so that the arrow on the blade points in direction of the rotation of

efore carrying or transporting your cut-off machine the engine must be off. Never leave

gonal

d correct if necessary.

art and operate this saw without

w

water attachment make sure that the screw that secures the outlet tube

the spindle.

B

the engine running whilst unattended, e.g. on the ground.

Proper tension of the V-belt is important. In order to avoid a false setting, the tensioning

rocedure must be followed as described in your manual. Always make sure the hexa

12

p

collar nuts for the cast arm are tightened securely. Check V-belt tension after one hour of

operation an

3. Operator:

. The cut-off saw is a one–person tool. So st

assistance.

. Make sure you are in good physical condition and are not under the influence of any

substance such as drugs or alcohol which may impair vision or dexterity. Take breaks

as needed to prevent you from getting fatigued.

.

Never let the EHS350C saw run unattended. NO untrained personal should ever be

use a cut-off machine. Bystanders, especially children and animals should

l

ear shorts.

allowed to

not be allowed in the area where a cut-off machine is in use.

Do not lend or rent your cut-off machine without the Operation Manual. Employers

should establish a training program for operators of this saw to ensure safe operation of

the EHS350C.

Avoid loose – fitting jackets, scarf, neckties, jewelry, flared or cuffed pants, unconfined

ong hair or anything that could become caught on any obstacles or moving parts of the

unit. Wear overalls or long pants to protect your legs. Do not w

13

Protect your hands with gloves when handing the cut-off saw. Heavy-duty, non-slip

gloves improve your grip and protect your hands.

with nonskid soles. Steel-toed safety

boots are recommended.

rly fitted safety glasses with adequate

otection is a must!

Use EHS350C cut-off saw only with both hands, keeping a firm grip on the front and

rear handles.

Maintain good balance and footing at all times.

Good footing is most important. Wear sturdy boots

To reduce the risk of injury to your eyes, never operate the cut-off saw

unless wearing goggles or prope

top and side protection. Proper eye pr

14

Wear an app d safety hard hat to protect your head. Cut-off machine noise could

Cutting masonry, concrete, metal and other materials can generate dust,

rove

damage your hearing. Earplugs or ear mufflers shall be worn at all times.

mists and fumes containing chemicals known to cause serious or fatal injury or illness,

such as respiratory disease, cancer, birth defects or other reproductive harm. Cutting

masonry, concrete and othe f dustr materials with silica in their composition may give of

espirator is

recommend d.

. Do not cut m

injury. Do not

4.

ed. Make sure all rubber hoses for oil flow are

tightly connected with no leaks.

, the Full Throttle Lock Button, the Choke

containing crystalline silica. Silica is a basic component of sand, quartz, brick clay,

granite and numerous other minerals and rocks. Use of an approved r

e

aterials containing asbestos as asbestos dust can cause severe physical

cut materials containing highly volatile or flammable substances.

Inspection of the cutoff saw before use:

. Make sure there are no loose objects on or near the saw.

. Except for the carburetor adjustment screws, all other bolts, nuts, screws and the fuel

tank cap should be securely tighten

15

. Make sure the blade rotates smoothly; the starter rope can be pulled through and

guided back without being tangled.

. Check to make sure the Throttle Trigger

Lever, the Decompression Valve and the kill Switch all function well without failure.

.

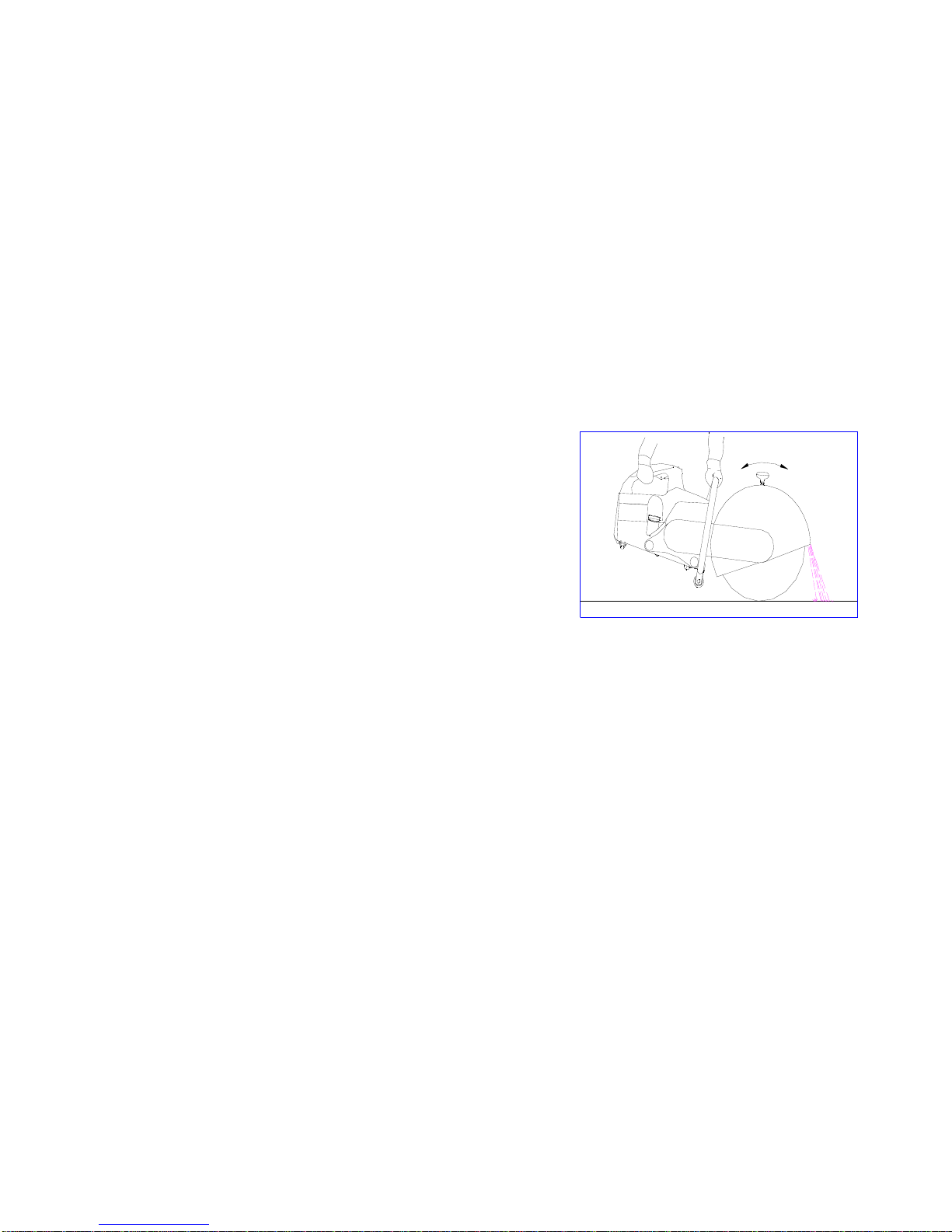

as necessary so

ef. Fig.2)

. Check to make sure the V-belt is properly

y and clean.

und or if it’s not completely and securely

assembled and properly adjusted.

5. Precautions on starting:

rope around your hand.

Fig 2

16

Check to make sure the blade guard has no

visual damage. Adjust the guard

the spark beam generated during cutting can be

directed away from the operator. (R

tensioned.

. Make sure the saw is free of oil spillage.

. Make sure the main cover and the handles are dr

. Do not attempt to start the saw if damage is fo

. Keep a good balance and secure footing.

. Take hold of the st earter grip firmly; do not wrap th

. To start, place the machine firmly against

the ground and make sure the blade is not in

contact with the ground or the object to be

cut.

. Pull sharply on the rope and guide it back

y

6. Pr

. Keep a good balance and secure footing while holding the saw firmly at all times.

. ake the engine accelerate gradually.

beginning to work.

de slowly toward the object to be cut, increase the pressure

ter the cutting edge comes in contact with the o Make sure the

.

slowly. Do not let go of the grip halfwa

through the pull to prevent it from snapping

back.

ecautions on operation:

Fig 3

17

(Ref. Fig.3)

Press the throttle trigger backward slowly to m

Wait until the blade builds up the rpm’s before

. Move the rotating bla

gradually af

cutting depth is appropriate

bject.

. Do not change direction of the cut or twist during the cut as this may produce a high

orsion load o

t n the blade and may cause it to break or shatter. Only move the machine

.

ake sure it won’t hit any part of your body or pinch the

t at this time. so

e or

n angle or push it into the cut as this may result in a

along a straight line, forward or “to and fro” in the cutting direction.

When cutting, position the saw at an appropriate distance so that your body is clear of

the blade attachment yet you don’t have to overreach.

. Release the pressure on the saw when the blade completes a cut. The cut-off portion

of the object may drop, so m

blade. .

. Whenever you hear an abnormal sound coming out of the cut-off saw, stop cutting

immediately for inspection (Note the muffler and the blade are very ho

take care not to get burned). Only resume work after the trouble is eliminated

. Do not make adjustments or any other maintenanc

troubleshooting with the cut-off saw while it is running.

. Take precaution when re-entering a cut and do not turn the

blade at a

pinching of the blade.

18

7. P

. ne cool off naturally. Do not take any other forceful

sure build-up in the tank to

y after fueling and clean off spillage if any.

have your body get

t

or repair work in clean and neat environment. Use proper tools

a

. Use only identical spare parts for

recautions on fueling:

. Fuel the machine only in a well-ventilated environment.

Before refueling, let the engi

measures to cool the engine down.

Remove the fuel tank cap carefully so as to allow any pres.

release slowly. (Ref. Fig.4)

. Tighten fuel cap securel

Fig. 4

8. Notes on transporting:

. Always stop the engine before relocating the saw.

19

.When carrying the machine with a hot engine, take care not to

burned by the muffler.

. Prevent the saw from touching the ground or any hard objects

s onNo e maintenance:

Perform any maintenance

nd operate with caution.

9. Do not attempt to modify your cut-off saw in any way

Table of contents