ChinaLight Solar CLS-230P User manual

Solar Power System

Installation Manual

Polycrystalline Solar module

ChinaLight Solar Co. ,Ltd.

No3, Xingguangsan Street,Opto-Mechatronics Industrial Park,Beijing,P.R.China

Postcode:101111

Tel:+86-10-8150 6588

Fax:+86-10-8150 6120

• Please read this manual carefully before installing the system and carry out the

installation procedures correctly.

• This manual does not list all precautions needed for safe work. Be sure to follow

OSHA guideline.

• This manual provides guidelines for installation, but it does not guarantee the

quality of installation work. Please complete all work in a responsible and

professional manner. Electrical work should be performed by a qualified electrician.

THE MOUNTING SYSTEM HAS BEEN LOAD TESTED AND VERIFIED BY A

PROFESSIONAL ENGINEER. THIS INFORMATION CAN BE PROVIDED UPON REQUEST.

ChinaLight Solar Co. ,Ltd.

No3, Xingguangsan Street,Opto-Mechatronics Industrial Park,Beijing,P.R.China

1. FOR SAFE INSTALLATION WORK............................................................................................4

1.1 CAUTIONS REGARDING INSTALLATION OF SOLAR POWER SYSTEMS .........................5

1.2 MOUNTING SYSTEM.................................................................................................6

1.3 PV MODULES...............................................................................................................7

2. POINTS TO CHECK WHEN SELECTING THE INSTALLATION LOCATION ................................10

2.1 CONDITION OF HOUSE WHERE SOLAR POWER SYSTEM IS TO BE INSTALLED ..........10

3. SPECIFICATIONS...................................................................................................................11

3.1 SOLAR MODULE AND ARRAY SPECIFICATIONS MODULES: CLS-230P .......................11

4. PARTS ..................................................................................................................................13

5. POINTS TO CHECK BEFORE INSTALLATION WORK ..............................................................14

5.1 UNPACKING AND CHECKING PARTS..........................................................................14

5.2 MATERIALS AND TOOLS YOU WILL NEED..................................................................14

6. INSTALLATION WORK..........................................................................................................16

6.1 PREPARING SHINGLE ROOF FOR INSTALLATION .......................................................16

6.2 CHECKING LAYOUT....................................................................................................16

6.3 INSTALLING THE FLASHINGS (OPTIONAL) .................................................................16

6.4 Mechanical Installation .............................................................................................17

6.5 SYSTEM GROUNDING................................................................................................22

6.6 INSTALLING MODULE SUPPORT RAILS......................................................................22

7. L IMI T ED WA R R ANT Y .....................................................................................................23

1 FOR SAFE INSTALLATION WORK

Warning

• Do not cut or modify Mounting System. Doing so is dangerous. Safety cannot be

guaranteed.

• Stop work during stormy weather. Solar modules can be caught in the wind,

causing you to fall.

Caution

• Never step or sit on the glass surface of a solar module. The glass may break,

resulting in shock or bodily injury. The module may also stop generating power.

• Always use the supplied parts to attach the solar modules and mounts. Use of

weaker parts, such as screws that are too short, is dangerous and may cause the

solar modules or mounts to fall.

• Always use the specified tools.

The solar modules or mounts may fall if the installation is not strong enough, for

example when parts are not tightened sufficiently.

• Regardless of whether you are working on a new or existing roof, never allow the

sheathing to become wet. Protect

the sheathing from rain during the installation. Failure to do so may cause leaks.

• Always use the specified materials.

Use of other materials is dangerous. Materials other than specified can reduce

performance and can cause leaks, shock, and so on.

• Do not modify or cut parts.

• Do not install system in a location within 0.3 miles from the ocean or any salt

water.

• Do not install in corrosive locations classified C5 by ISO.

• Protective earth grounding of the individual photovoltaic modules is achieved by

the secure of the modules to the mounting frames. The assembly instructions should

be closely followed, in order to ensure a reliable ground connection.

• The framing system has only been evaluated by TUV for use with the photovoltaic

modules listed in this manual.

1.1 CAUTIONS REGARDING INSTALLATION OF SOLAR POWER

SYSTEMS

This manual contains critical information regarding electrical and mechanical

installation and safety information which you should know before starting

installation.

The information in this manual is based on CHINALIGHT’s knowledge and experience,

however, the information and suggestions do not constitute a warranty.

CHINALIGHT reserves the right to make changes to the product, specifications, or

manual without prior notice.

Do not locate systems near coastal locations or other salt water locations or C5

locations as classified by ISO. Minimum distance is 0.3 miles from the body of water.

Do not locate in a corrosion prone area. The modules and system are TUV listed to

standard IEC61215. The TUV IEC61215 test is performed at 1.5 times the design load

of 30 lbs per square foot, or 45 lbs per square foot. The system has been load tested

by CHINALIGHT to 50 PSF. Building departments often require a design safety factor

of 1.5 or greater for structures. The maximum structural loading listed in this guide,

does not include an added safety factor. Check with your local building department

for code information.

Caution:

1Do not drill holes in frame. Do not cut or modify parts or rails.

2Work under dry conditions with dry tools.

3Do not stand or step on solar module.

4Do not install near flammable gases.

5Do not drop or allow objects to fall onto module.

6Completely cover solar module with opaque materials when wiring to halt

production of electricity.

7Keep the back side of solar module surfaces free of foreign objects.

8Do not use chemicals on solar modules when cleaning.

9Do not wear metallic jewelry, which may cause electrical shock.

10 Do not touch cable electrical contacts.

11 Do not expose solar modules to sunlight that is concentrated with mirrors, lenses

or similar means.

12 Consult local codes and other applicable laws and statutes concerning required

permits and regulations concerning installation and inspection requirements. Install

solar modules and systems according to applicable codes.

13 Product should be installed and maintained by qualified personnel. Keep

unauthorized personnel away from solar modules.

14 Avoid shadowing cells in order to prevent solar module hot spots and/or

reduction in power.

15 Avoid installing modules and mounting system in high corrosion areas.

1.2 MOUNTING SYSTEM

Solar modules are installed on rooftops where there is danger of personnel falling off

of the roof. Scaffolding, stepladders, and ladders may be dangerous and require

caution. The installation of solar modules involves work in high places, take extreme

precautions to avoid falling from roof. To prevent accidents, safety regulations must

be observed. Always take the following precautions to prevent accidents and injury.

1 Take the following precautions before starting work.

• Plan the job and visit the site before starting work.

• On site, do not work alone. Always work with at least one other person.

• Inspect power tools before using them.

2 When conditions make it necessary, tell workers to stop working.

• When it is raining, or there is a strong probability that it will start raining.

• Immediately after rain, and when work areas are slippery.

• When high wind conditions exist, or are expected, or when a high wind warning

has been issued.

• When it is snowing, or when there is snow underfoot.

• When the condition of the scaffolding and ladders are not satisfactory.

3 Wear appropriate work clothes and protective equipment.

• Work clothes for both the upper and lower body should fit well and allow you to

move freely.

• Always wear protective equipment such as harnesses and lifelines.

• Wear a helmet and secure it correctly.

• Wear non-slip shoes. Shoes get dirty when worn on a roof, so keep the soles clean.

4 Observe safety regulations for ascending and descending ladders and

stepladders.

• Before use, always inspect ladders and stepladders to makes sure they are in good

condition.

• Choose a safe spot to anchor ladders and stepladders.

• Always work with a partner. One person should hold the ladder steady.

• Ladders from a first-story roof to a second-story roof are very dangerous. Do not

set up a ladder on a roof. When there is no other choice, straddle the ridge and lay

down a rubber anchor mat, and secure the ladder to the mat. Always have one

person hold the ladder firmly.

• When you use a two-stage ladder, secure it with ropes or stays to prevent it from

sliding sideways, and have two persons hold the ladder steady.

• Use ladders with steps broad enough to permit safe work.

5 When working in high places, wear harnesses and use scaffolding.

• When working at heights of 6 ft or more, use scaffolds or other equipment to

ensure a stable work platform.

• Scaffolds should be designed and erected by a qualified person.

• When it is difficult to erect a stable work platform, install safety nets, wear

harnesses, and take other measures to prevent falls.

• Regulations mandate the use of harnesses. Fasten harnesses securely, and check

that the length of lifelines is 6 ft or less.

• Attach the primary support line securely to a metal fixture installed for that

purpose on a ridge or beam.

6 Install enclosures and covers.

• Install enclosures, guardrails, or covers at the end of work decks that are 10 ft or

more above ground, at openings, and at other dangerous locations.

• When it is extremely difficult to install enclosures, guardrails, or covers, or when

they must be removed to work in that location, install a safety net, wear harnesses,

and take other measures to prevent falls.

7 Protect against falling objects.

• When objects are thrown down from a height of 6 ft or more, appoint a

surveillance person on the ground and warn others about falling objects.

• Do not allow third parties to enter the work area during construction.

• Arrange tools and materials neatly and secure them with ropes, or use bags or

other measures to prevent falling objects.

8 Other

• When there are electric power lines near the roof or eaves, request the power

utility to take advance measures to prevent shock.

• Check the health of workers before starting work.

• Lift packaged modules by grasping both sides of the package. Do not lift by

grasping the band, as the band can break.

• Never step or sit on the glass surface of a solar module.

1.3 PV MODULES

Warning

Wiring work should be performed according to the provisions of the National

Electrical Code(NEC). Grounding work and wiring connections to the inverter should

be performed by a qualified electrician.

The solar array generates electricity whenever it is exposed to sunlight. Be careful

when handling it. There is a danger of shock if you touch the connectors or wires of

the electric cables.

1 Points to check before wiring.

• The solar modules generate electricity when exposed to light. You will need to

wear insulating gloves.

• You will need a multi-meter for volts, amps, resistance and continuity capable of

measuring DC and AC up to 600V and 40A.

• Make sure your tools are insulated.

2 Wiring the solar modules.

• Never step or sit on the glass surface of the solar modules. The glass may break.

• When you install the solar modules on the mount, never allow an output cable to

become caught between the mount and a module frame.

• The solar modules generate electricity when exposed to sunlight, take care not to

short circuit the output cables. The cables can become overheated and their cable

sheaths can melt.

• Ensure the module connectors are fully inserted. There is a risk of malfunction if

they are not pushed in all the way.

• Support output cables so that there is no slack. High winds can blow slack cable

against the mount, damaging the cables.

3 Wiring from solar arrays to the inverter (connector box).

• Follow the provisions of the National Electrical Code.

• For wiring through walls, protect the cables with metal conduits, flexible metal

conduits, or other protection. Failure to do so can result in shock and short circuits.

Always use conduit to protect sections of array output cables that are exposed to

sunlight. For wiring outdoors, protect cables with PVC conduits, metal conduits or

flexible conduits.

• Prevent water from entering or building up in conduit by using waterproof fittings

or duct seal.

• To prevent shock, tape and label the cut ends of array output extension cables (the

side opposite to the connector side) before connecting to solar module output

cables. Further, tape them again after measuring the voltage of each array.

• To prevent shock when you connect the array output cables to the inverter,

remove the tape one cable at a time as you connect the cables.

4 Measuring array output voltage

• See the description of how to measure the output voltage for each array.

• Make sure that all solar modules are exposed to sunlight. (Remove lightproof

sheets, if present.)

• Set the volt meter measurement range to a DC voltage, greater than the expected

measurement (for example 600 VDC).

• Keep the plus (+) solar array output cables away from the ends of the minus (-)

cables. Dangerous arcs can occur. (The array output voltage under normal conditions

(clear skies) can be very high.)

5 Grounding the mount

• To prevent shock, always connect a ground wire from the mounting hardware to

earth.

• Use a minimum #10 AWG ground wire. Run a continuous bond wire to each

module and rail in the array. Refer to section on grounding in this manual.

• Follow NEC 690 grounding provisions.

2 POINTS TO CHECK WHEN SELECTING THE INSTALLATION

LOCATION

Check the following items before starting installation work.

Refer to the inverter installation manual for more information about inverter

installation and electrical work.

2.1 CONDITION OF HOUSE WHERE SOLAR POWER SYSTEM IS

TO BE INSTALLED

INSPECTION OF ROOF STRUCTURE

It is important to inspect the structural integrity of the roof and the durability of the

roof materials. The mounting structure and solar modules require a strong base for

durable and reliable operation in local environments. Always wear a safety harness

when working on the roof. Inspect the roof surface in the area of the installation for

cracks, water leakage, and roofing material quality and uniformity. This is especially

important if the roof is older than 10 years. Inspect the roof for sags and other

abnormalities. A sag or deep depression in the roof may indicate a structural

weakness in the support system that may require correction. The following

illustrations detail typical roof construction as well as old roof problems.

INSPECTION OF THE ROOF SUPPORT SYSTEM

This may require access to the attic. Check that all rafters, trusses and other

materials are in good condition. Check for indication of previous water leaks.

Measure the spacing of the rafters or trusses to confirm the dimensions and prepare

for the system layout. Determine the location of the electrical roof penetration and

wire run, if wiring is planned for this area.

3 SPECIFICATIONS

3.1 SOLAR MODULE AND ARRAY SPECIFICATIONS MODULES:

CLS-230P

1 Array specifications (typical examples)

Array: Layout of series connected solar modules

Solar module CLS-230P

Solar modules 18 20 24 27

Solar power capacity

(kW) STC 4.1 4.6 5.5 6.2

Solar module area (㎡)29.4 32.7 39.2 44.1

2 Individual specifications and dimensions

Module model name CLS-230P

Maximum power 230W

Voltage at

(

)

29.28V

C

urrent at

(

)

7.86A

Open-circuit voltage( ) 37.38V

Short-circuit current( ) 8.31A

Weight 20KG

Dimension 1650mm*990mm*50mm

Rated electrical characteristics are within ±10 percent of the indicated values of Isc

and Voc and within +10/-5 percent of Pmax under standard test conditions

(irradiance of 100 mW/cm2, AM 1.5 spectrum, and a cell temperature of 25°C (77°F)).

Under normal conditions, a photovoltaic module may experience conditions that

produce more current and/or voltage than reported at Standard Test Conditions.

Accordingly, the values of Isc and Voc marked on TUV Listed modules should be

multiplied by a factor of 1.25 when determining component voltage ratings,

conductor capacities, fuse sizes and size of

controls connected to the module output.

4 PARTS

STANDARD PARTS

Part

No. 1 2 3 4 5 6

Name Dock

washer

M8

Bolt 20

Module

mounting

clip

Threaded

tab

M4

Sidecover

screw

Rail

OPTIONAL PARTS

Part

No. 1 2 3 4 5

Name

Cable

support

bar

Cable

clip

Silicone

caulking

Threaded

tab

M8 Bolt

30

5 POINTS TO CHECK BEFORE INSTALLATION WORK

WARNING

• The solar modules generate electricity when exposed to sunlight, so be careful not

to short circuit the output cables. The cables can become overheated and their cable

sheaths can melt.

• Stop working when the surface of the roof is wet. There is a danger of slipping,

falling, and shock.

CAUTION

• Never step or sit on the glass surface of the solar modules. The glass may break.

• Do not twist the solar modules when you mount them (twisting should not exceed

0.1" per 4"). Failures and damage can result.

• When you mount the solar modules on the rail, never allow an output cable to

become caught between the rail and a module frame. Short circuits and fire can

result.

5.1 UNPACKING AND CHECKING PARTS

When you unpack the system, check the model names of the components of each

system and check to be sure that you have the correct number of parts.

5.2 MATERIALS AND TOOLS YOU WILL NEED

Before starting installation work, make sure you have the following materials and

tools on hand (including materials and tools for electrical work).

Materials

tools

Ground

wire

Ground rod Electrical

tape

metal conduit

(to protect

electric cables)

Cable

ties

Pencil

Cordless

drill

Socket

drivers

8 mm & 13

mm

Phillips

driver bits

Drill Screw

driver

set

Needle

nose pliers

Line man’s

pliers

Wire

cutters

Hammer Chisel

Crimping

tool

Knife Tape

measure

Extension cord Chalk

line

Gloves &

safety

helmet

Rope Tool belt Ladders Safety

Harnes

s

Safety

glasses

Air mask Ratchet

Wrench

Measurement

Compass Calculator Solar

insolation

meter

Digital

multimeter

6.INSTALLATION WORK

6.1 PREPARING SHINGLE ROOF FOR INSTALLATION

1. Locate roof rafters or trusses.

Tip: here are 3 options to finding the locations.

A. Locate and measure the locations of the rafters in the attic or at the outside eave and transfer

measurements to the roof.

B. Use a rubber or leather mallet to tap the roof and locate the rafters. This will work with a cap sheet or

composition roof.

C. Scan the roof with a high sensitivity stud finder.

2. Once the rafters have been located, snap a chalk line on every rafter to identify the location.

3. Measure up from the eave 400 mm in at least 3 locations. Snap a chalk line. This marks the location of

the bottom edge of the slider feet.

Note: This line needs to be 5.5 mm away from the nearest front edge of shingles.

4. Measure up from chalk line 20 mm and snap a new chalk line. This marks the location of the bottom

edges of the modules.

5. Measure up from the module chalk line to the desired module length to form the array. Snap horizontal

lines at the measured locations.

6. Mark and layout solar module vertical lines.

Note: modules should not fall in shaded areas.

6.2 CHECKING LAYOUT

1. Before installing sliders, check layout of rails and splices.

2. Place all sliders in desired locations.

3. Pre-assemble rails and splices.

4. Place rails with splices into position. Ensure slider locations do not overlap splices.

5. If these overlap or seem too close, shift rails horizontally or move sliders to next rafter or remove splices

to switch the long and short rails to opposite sides. Reattach splices after rails are switched and recheck for

overlap.

6.3 INSTALLING THE FLASHINGS (OPTIONAL)

Flashings can improve water and ice management on the roof by directing the water around the rail slider

assembly. It is ideal for use in new construction, reroof,and in locations with significant precipitation. The

flashings are installed below the standard slider assembly. Each flashing is similar in size to the slider

assembly. The flashing has a large flange around it’s perimeter to allow for integration with the

surrounding shingles. There are 3 alignment marks on the flashing and identification for the orientation of

the part.

1. Confirm the locations of each standard slider assembly.Follow the same rules for installation as the

slider foot.The flashings located on the bottom rail (close to the eave), should be aligned with the chalk

lines created in the roof layout. Flashings used to support the center rails, should be centered on the rail

line. The flashings located at the top rail (close to the ridge), should have minimal exposure beyond the rail.

2. Dry fit the flashing in the location marked for installation. Use a utility knife to cut the surrounding

shingles to assure a flush and water resistant fit. Install flashing over a layer of shingles to insure water

resistance.

The arrow on the flashing should point to the eave side. Install flashing over a layer of shingles to insure

water resistance.

3. Invert the flashing, peel off the protective backing paper and apply a bead of roofing silicone along the

top and sides in the flange area. Leave the bottom flange clear for water drainage. Make sure that the

shingles are at room temperature, ~68°F. When shingles are cold, they become brittle and are difficult to

work with. Use a putty knife to lift the shingles and slide in the flashing.

4. Apply a bead of silicone on the top and sides of the flange that contact the surrounding shingles. Press

the area to create tight seal.

5. Peel off the backing paper from the standard slider.Place the standard slider assembly on the flashing

and secure with the supplied flashing screws 110 mm.

6.4 Mechanical Installation

ChinaLight Solar modules can be mounted using the following methods:

(Note: All installation methods herein are only for reference, and ChinaLight solar will not provide related

BOS components, the system installer or trained professional personnel must be responsible for the PV

system’s design, installation, and mechanical load calculation and security of the system.)

−Using corrosion-proof screws (M6) in the existing installing holes in the module frame.

−Using suitable module clamps on the long side of the module frame to mount the modules (“portrait

orientation”)

−Using suitable module clamps on the short side of the module frame to mount the modules (“landscape

orientation”)

module type Cell type Cell

quantity module dimension

A*B*C(mm)

Install hole dimension

E*F(mm)

Cable Length

(mm)

Profile cross-section size

H*C*I(mm)

CLS-170P Multi 6*8 1335*990*50 1055*6.5

1000

12*50*32

CLS-190P Multi 6*9 1494*996*50 1214*6.5 12*50*32

CLS-230P Multi 6*10 1650*990*50 1020*6.5 12*50*32

CLS-270P Multi 6*12 1968*996*50 1688*6.5 12*50*32

CLS-170M Mono 6*12 1580*808*50 1300*6.5 12*50*35

module type Cell type Cell

quantity module dimension

A*B*C(mm)

Install hole dimension

E*F(mm)

Cable Length

(mm)

Profile cross-section size

H*C*I(mm)

CLS-170P Multi 6*8 1335*990*50 1055*6.5

1000

12*50*32

CLS-190P Multi 6*9 1494*996*50 1214*6.5 12*50*32

CLS-230P Multi 6*10 1650*990*50 1020*6.5 12*50*32

CLS-270P Multi 6*12 1968*996*50 1688*6.5 12*50*32

CLS-170M Mono 6*12 1580*808*50 1300*6.5 12*50*35

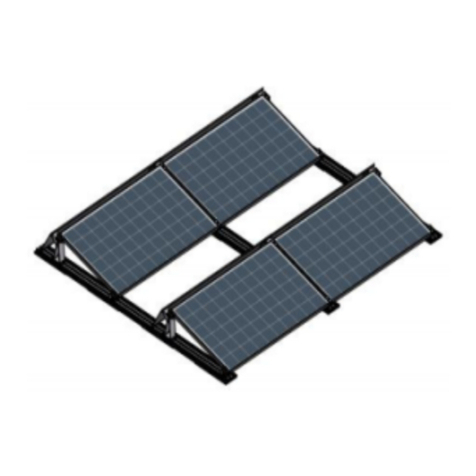

Clamp fitting (portrait orientation): Use a certain number of clamps to fix the modules on the mounting rail.

The module clamps should not come into contact with the front glass and must not deform the frame. Be

sure to avoid shadowing effects from the module clamps. The module frame is not to be modified under

any circumstances. When choosing this type of clamp-mounting method, please be sure to use at least four

clamps on each module, two clamps should be attached on the long sides of the module. Depending on the

local wind and snow loads, additional clamps may be required to ensure the module can bear the load. The

applied torque should be about 8 Newton-meters. Please find detailed mounting information in the below

illustration

Table of contents

Popular Solar Panel manuals by other brands

Solarbayer

Solarbayer NANOSOL 135 Product information

Korax Solar

Korax Solar KS-90 installation guide

Yingli Solar

Yingli Solar YGE 245 Series Installation and user manual

AEROCOMPACT

AEROCOMPACT CompactFLAT SN10 Assembly instructions

Jackery

Jackery SolarSaga 100 user guide

Curtech

Curtech CT-K35 user manual