Solarbayer NANOSOL 135 User manual

PRODUCT INFORMATION

Solar collector NANOSOL 135

Technical descripon

Carefully read the safety instrucons before commencing the installaon. It’s for your own safety.

Please follow the structural instrucons if the installaon locaon of the solar system is above 600m sea level or possibly

exposed to large amounts of snow (higher than zone 4). The installaon needs to be carried out on a roof that is capable of be

aring that load. The stac bearing capacity needs to be checked on site before the installaon.

The collectors can either be transported vercally or horizontally. Aenon: Breakage of glass. Store the collectors in a dry and

shadowy place. The protecons of the manifolds have to be removed before the solar collectors are exposed to the sun and

heat themselves.

Working on the roof

Appropriate safety measures have to be arranged. Familiarize yourself with the general regulaons of accident prevenon for

construcon work of your professional associaon or let yourself be instructed by an appropriate person.The following aspects

have to be respected to achieve a secure installaon of the solar system:

• always use fall protecon while working on a roof

• respect safety regulaons when using a ladder

• while working on roof coverings with corrugated sheets the risk of breaking through exists

• secure workplaces on steep roofs

• safety clearances have to be met if an aerial pipeline leads across the roof

up to 1.000 V >1m, more than 1.000 V to 11.000 V >3m, with unknown voltage >5m.

• always wear safety goggles and gloves while working with an angle grinder

• Flat plate collectors can achieve a staonary temperature of over 200°C due to incident light. The risk of burns exists

at the connecons of flow and return. Always cover the collectors on sunny days during the installaon

• Even regular daylight might cause the fluid in the collector to vaporize. This vapor leaks from the collector connecons.

Possible risk of scalding

Aenon: glass

• Don’t extent mechanical pressure on the glass covering. Glass splinters might evoke cuts

• Wear safety goggles and gloves while installing the solar system to avoid injuries due to possible damages

Connecon

• According to DIN, a safety valve must be installed in the cold water inlet. This must not be lockable.

• According to the state of the art, a water filter must be installed in the cold water inlet.

• The domesc hot water temperature in the pipe network has to be taken to a maximum of 60 °C for normal operaon

by taking suitable measures to limit (use of suitable anscalding devices at the drawoffpoints).

With exisng lightning protecon system: minimum distance from this device: 1 meter

cf.: BDH (Federal Industrial Associaon of Germany House, Energy an Environmental Technology e. V., informaon sheet n° 34)

2© Solarbayer GmbH (213859)

PRODUCT INFORMATION Satellite collector NANOSOL 135

Safety regulaons

CAUTION:

When there is the risk of frost, the collector needs to be drained completely!

The builtin magnesium anode protects the domesc water tank from corrosion.

The anode must be checked every 8 to 12 months and replaced if necessary

© Solarbayer GmbH (213859)

3

PRODUCT INFORMATION Satellite collector NANOSOL 135

data unit NANOSOL 135

storage capacity L 135

empty weight kg 64

cold water inlet / hot water outlet 3/4"

Anode plug 1"1/4

collector area m20,966

calibraon of pressure relief and non return valve bar 7

maximum working pressure bar 6

maximum tesng pressure bar 9

light transmission of methacrylate % 92

heat loss coefficient W/K 6.85

mechanical load kg/cm2160

temperature range °C 20 / +90

*Height at 35 ° installaon angle with horizontal installaon

852

552

13°

35°

965

940

1080

1042

Connecon for electric heang rod

TECHNICAL DATA

4© Solarbayer GmbH (213859)

PRODUCT INFORMATION Satellite collector NANOSOL 135

GENERAL INFORMATIONS

1.1 Use of the appliance

This appliance provides users with domesc hot

water, exploing solar energy and it can be used in

dependently or as a backup to convenonal hot

water system. It is:

•Ecological: Because it is polluon free and environ

mentally safe.

• Easy to be installed: Thanks to its frame it can be

located in any place. Furthermore, it needs neit

her electrical supply nor electrical components

such as: storage baeries, pumps and control

boxes.

• Cheap and economical: In installaon and main

tenance.

Panel has a square shape. Its small size in comparison

with its large storage capacity, the fact that it does

not need any electromechanical devices and its frame

make the installaon easier nearly anywhere.

This appliance is manufactured using high quality we

atherresistant materials that have been selected on

the one hand to increase solar energy absorpon, on

the other hand to make the working life of the appli

ance longer, thus reducing maintenance costs.

On demand it can even be equipped with a heater

element.

ATTENTION:

A magnesium anode, that is placed

inside the tank, protects the whole

appliance against galvanic corrosion. It has to be

replaced every 812 months.

A pressure relief and non return valve protects

the tank against excessive pressure due to the vo

lume increase of water while heang; moreover

it prevents domesc hot water from flowing back

into the cold water circuit. The lack of a suitable

pressure relief valve causes the warranty on the

storage tank to be invalided.

1.2 Descripon of components

The appliance is a storage solar water heater made

up of 4 parts:

•In the upper part there are 2 methacrylate cupo

las, a special material that increases the green

house effect, having a transparency coefficient

higher than crystal.

•In the lower part there is 1 ABS treated tray ex

ternally coated with a film of methacrylate; it is

internally insulated with expanded polyurethane

with closed cells to avoid heat losses.

•The storage tank is in steel internally coated with

enamel (2 injecon of enamel). Its external sur

face is coated with a black highly selecve paint.

Its special shape and structure make the tank

highly resistant to pressure, avoiding any possible

breakage due to frost

•The external frame is in hot dipped galvanised

steel. It can be posioned easily, according to the

user’s needs and adjusted with different angles.

Its easy way of operang and the fact that it does not

need any maintenance intervenons are the main pe

culiaries of Panel.

Enamelling is the best treatment that can be done

on steel tanks that, because of their use, come in con

tact with sanitary hot water. First of all it protects

from the natural galvanic corrosion that inevitably de

velops inside the tank; furthermore it limits the ad

herence and the prolificaon of bacterium

© Solarbayer GmbH (213859)

5

PRODUCT INFORMATION Satellite collector NANOSOL 135

1.3 Safety devices

Pressure relief and non return valve

The protecon from overpressure or overheang

foresees the expulsion of a given mass of water in

case the pressure inside the tank exceeds 6 bar in

order to bring the pressure back to opmum values.

At the same me a given mass of cold water will get

into the tank lowering the temperature of water.

Warning labels

Some labels stuck on the appliance highlight some

important warnings.

Each dangerous point is marked with a suitable label.

Keep the labels clean and legible; replace those that

are missing or damaged.

ATTENTION:

Danger of serious burns! If the

appliance is located in a place easily

accessible to people, do not approach it during

the day because there could be a high tempera

ture. Keep children away from the water heater,

fencing the appliance if necessary.

ATTENTION:

If the appliance is installed in Italy,

the pressure relief valve supplied

with the appliance must be replaced with a safety

group in accordance with the UNI rule EN

1487:2002 (as required by The Memorandum N°

9571 dated 26/03/03 issued by Ministry of Pro

ducve Assets G.U. N° 87 of 14/04/03). In case

of noninstallaon of a safety group in compli

ance with the rule EN 1487, the manufacturer will

be exempted from any warranty claim on the

tank.

ATTENTION:

If the discharged hot water due to

overpressure may damage nearby

objects, we suggest to foresee a suitable draining

system in order to avoid any problem. The water

inside the tank can reach very high temperatures

(over 60 °C): for this reason in order to avoid any

risk of burning it is necessary to install a water

mixer expecially when we foresee to use the hot

water taking it directly from the panel.

6© Solarbayer GmbH (213859)

PRODUCT INFORMATION Satellite collector NANOSOL 135

2.1 Installaon recommendaons

The total daily measured value of the incident radia

on is 26.7 MJ/m2at an ambient temperature of

34.8 °C. We advise not to install the appliance in cli

mac areas where the radiaon value is higher than

the abovequoted one.

The appliance has to be installed by professional and

qualified people who are responsible for the applica

on of safety regulaons in force and can carry out,

not only a proper set up of the appliance, but also the

necessary tests before commissioning the plant.

2.2 Packaging

The appliance is delivered packaged in a wooden box

with appropriate protecon. A pressure relief and

non return valve and an envelope containing this boo

klet are delivered with the appliance.

2.3 Sizing

Before installing the appliance, knowing exactly how

it will be used is very important in order to avoid an

under sizing of the whole plant. The right sizing de

pends on the user’s needs.

Useful advices:

•One appliance is suitable to produce enough do

mesc hot water for two people.

•We suggest to install at least two units (the hot

water produced by the first one is quite oen wa

sted during the water distribuon).

•If the solar system is well sized, it is possible to

use the domesc hot water produced by the ap

pliance for a longer period throughout the year,

thus increasing the user’s savings

•If for economic reasons an undersized system is

carried out, foresee brackets for other units, in

order to make a possible subsequent installaon

of more appliances easier and quicker.

•Domesc hot water consumpon: On average

about 910 litres of water flow offa tap every mi

nute (every 10 minutes = 100 litres of water. This

equals to 3/4 of the overall storage capacity of

the appliance).

2.4 Installaon and locaon

of the appliance

The water heater is delivered in a packaging. It is sup

plied with the installaon manual and with a pressure

relief valve (to be replaced with a pressure relief and

nonreturn valve in accordance with the rule EN 1487

in case the panel is installed in Italy). Once the appli

ance is out of the packaging, place it exactly where it

has to be installed paying aenon while handling it:

use the special handles in order to avoid to compro

mise the ghtness of the black seal that fixes the cu

polas to the tray. At this stage, connect the cold and

hot tubes, placing the pressure relief valve on the cold

water inlet. Then fill the tank. In all storage solar

water heaters the absorbing surface (cupola) must al

ways be exposed to the sun. The best posioning of

the solar water heater is SOUTHWARDS.

In order to use all the hot water stored in the tank, a

35° installaon is advised. This angle makes water

straficaon easier: in this way, beeing the hot water

outlet in the upper part of the tank, it is possible to

use nearly all the hot water. Moreover, thanks to this

angle, sun rays are perpendicular to the appliance du

ring the hoest part of the day.

Suggeson for a good installaon:

•If possible, always connect the hot water outlet of

the appliance to the cold water inlet of conveno

nal hot water systems such as gas boilers, boilers

with calorifier or fireplaces. In this way you will be

nefit at best from solar energy: the solar water

heater will act as an efficient heat integrator.

•In order to avoid useless heat losses, we advise to

locate the solar water heater close to point where

users withdraw hot water.

•If the appliance is located in public places, we sug

gest to install a thermostac water mixer and a

token dispenser to keep down the hot water con

sumpon.

INSTRUCTIONS

© Solarbayer GmbH (213859)

7

PRODUCT INFORMATION Satellite collector NANOSOL 135

Excellent inclinaon

Inclinaon and load resistance

The holes of the solar water heater frame allow three

different inclinaons according to needs:

•AA: 13° inclinaon in comparison with the hori

zontal line

•BB: 26° inclinaon in comparison with the hori

zontal line

•CC: 35° inclinaon in comparison with the hori

zontal line

Maximum bearable load:

•Snow (Sk): 100 kg/m2

•Wind (Vm): 110 km/h

The panel has to be installed only in those areas

where Skand Vmhave values lower than the above

stated ones.

The entry of the pipes into the building has to be

resistant against rain and condensaon: make sure

that the pipes coming out from the building and that

will have to be connected to the “cold water inlethot

water outlet” of the panel, are realized in such a way

to be resistant against rain and condensaon, in order

to avoid annoying infiltraons that would damage the

walls of the building.

Filling up

Once you connect the pipelines of the building to the

“cold water inlethot water outlet” of the panel, ma

king sure that either the pressure relief valve that is

supplied with the appliance (in case the unit is instal

led abroad) or a hydraulic safety group conforming to

the rule EN 1487:2002 proceed to fill up the tank by

simply opening the faucet placed along the cold

water supply duct.

Starng

Appliance is a simple storage panel needing neither

pumps, nor control boxes. Therefore it needs no igni

on.

Informaon about the commissioning of the plant

Once the appliance is installed, it will be enough to

fill up the tank and to wait that the sunrays, engraving

on the cupolas, warm the water stored inside the

tank.

Since the water may reach very high temperatures

(7075 °C), in order to avoid any danger of burning, it

is necessary to foresee the installaon of a water

mixer, parcularly in the case the hot water outlet is

not directly connected to points having their own

water mixer.

In a sunny summer day, Appliance can give more than

200 litres of sanitary hot water at a temperature of

about 40 °C with repeated collecng. Therefore it can

sasfy the demands of 2 people.

On the other hand, in the winter season it can be

used as preheater, connecng it in series to an al

ready exisng water heater or heang boiler.

8© Solarbayer GmbH (213859)

PRODUCT INFORMATION Satellite collector NANOSOL 135

Examples of possible posioning:

Installaon on a vercal wall:

In order to make the kind of installaon shown effi

cient, it is necessary to invert the cold water inlet and

the hot water outlet.

The pressure relief and nonreturn valve has always

to be fied on the cold water inlet).

2.5 Connecon and pipework

Pipes insulaon

We suggest to insulate the cold water pipe to the

water heater and the hot water pipe from the water

heater, because they could freeze during the winter

me.

The insulaon of the tubes can be obtained by using

some covering in expanded elastomer.

Pipe secon

The advisable pipe secon is 1/2”. However, if the ap

pliance is a long way from the point where hot water

is used, a 3/4” pipe secon is suggested.

Solar water heater located in a garden and connected

to the domesc hot water system.

Solar water heater located on a roof and directly con

nected to users.

Solar water heater located on a roof and connected

to a heang boiler.

Solar water heater located on a flat roof (or on a bal

cony).

Solar water heater mounted on a outer wall.

© Solarbayer GmbH (213859)

9

PRODUCT INFORMATION Satellite collector NANOSOL 135

Fing of the pressure relief and non return valve

The pressure relief and non return valve supplied with

the appliance must be fied to the cold water inlet (the

arrow on the valve must be poinng towards the tank),

without any intercepon between the valve and the

water heater (1).

This valve has a double funcon:

•safety funcon: it allows the discharge of the

water stored inside the tank in case the pressure

exceeds the limit fixed by the valve seng.

•nonreturn funcon: it avoids that, because of

the high pressure that may arise inside the tank,

the hot water flows back along the cold water

tube.

Fing of the drain valve

The fing of a drain valve (2) is recommended to

empty the tank: it has to be installed between the

safety valve and the appliance.

ATTENTION:

If the appliance is installed in Italy,

the pressure relief valve supplied

with the appliance must be replaced with a safety

group in accordance with the UNI rule EN

1487:2002 (as required by The Memorandum N°

9571 dated 26/03/03 issued by Ministry of Pro

ducve Assets G.U. N° 87 of 14/04/03). In case

of noninstallaon of a safety group in compli

ance with the rule EN 1487, the manufacturer will

be exempted from any warranty claim on the

tank.

2.6 Installaon o the appliance

Installaon of a single unit

If just one appliance is installed, it has to be connected

to the water system directly.

Installaon of several appliances in a row

If several units are to be installed, the appliances have

to be connected as shown in the diagram. Foresee

just one pressure relief and non return valve that

has to be fied to the cold water inlet of the first ap

pliance.

Frame

To give the water heater the right angle, use support

brackets and screws included in the frame. Once you

have determined the right angle of installaon, you

have to match the hole in the bracket with the hole

in the frame (1): then insert the bolt and ghten the

nut (2). To give the appliance an angle different from

the ones foreseen by the manufacturer, drill the

frame in order to obtain the desired angle.

2.7 Magnesium Anode

To extend the working life of the appliance, respect

the following parameters, as foreseen by the Euro

pean Direcve 98/83/CE (regarding the quality of

water intended for human use):

• overall water hardness: included between 15

and 50 °F (in parcolar where water has under

gone a soening or desalisaon treatment)

• chloride:s 25 mg/l (max. value 200 mg/l)

• pH: included between 6,5 and 9,5

• conducibility: 400 μS/cm (max. value 2500 μS/cm)

10 © Solarbayer GmbH (213859)

PRODUCT INFORMATION Satellite collector NANOSOL 135

Where water does not suite the above parameters,

the warranty will decay automacally.

The solar water heater is equipped with a magnesium

anode (1) that protects the tank against galvanic cor

rosion.

It has to be replaced every 812 months.

To replace the anode:

• close the water supply

• reduce pressure in the water system opening a

hot water tap

• remove the anode protecon

• unscrew the anode holder

• remove the old anode and replace it with the new

one

• screw the plug being sure that the ghtness is

granted

• close the hot water tap

2.8 Possible operaon defects

If the hot water producon of the appliance is not

enough, there can be several reasons:

Improper installaon of the panel

• remember that this device must be installed with

orientaon to the SOUTH and inclinaon of 35°

to the horizontal and in areas where we do not

create shade during the day.

Incorrect panel

• a connuous sampling of hot water by different

users does not allow water inside the tank to heat

up. Being a panel storage, water should be stan

ding in the tank unl it is warmed

Undersizing system than the real situaon

• if a single device is required to reach more users

(bathrooms and kitchens) on different floors of a

building with long pipes, the plant is undersized;

you need to add one or more panels or to make a

series connecon with a possible water heater or

boiler.

Hole in the tank

• This incident, due to the non replacement of the

magnesium anode, causes the tray to be filled up

by water. As a consequence the insulaon in ex

panded polyurethane becomes soaked with water

and the whole appliance has to be replaced

Breaking of one cupola (of of both)

• The breaking of one or both cupolas, with the

consequent making of consensaon between

them, lowers the efficiency of the appliance. The

cupolas will have to be replaced.

Making of condensaon between the cupolas

• If the making of condensaon between the cupo

las is not due to their breaking but to the release

of the black gasket that fixes the cupolas to the

tray or to the wear of the silicone used to grant

the ghtness, it is necessary to remove the cupo

las, dry them fully and reassemble them using a

non acec silicone to seal in order to avoid any

chemical reacon that may damage the cupolas.

2.9 How to use the appliance

• Never empty the tank to avoid any risk of brea

king of the inner cupola and the subsequent con

dense formaon, that prevents the sun from

warming water.

• In case the tank has be emped and the appliance

is lewithout water, protect it with Opaque ma

terials.

• Empty the tank only if the outer temperature

falls below 20 °C, in order to avoid possible da

mage caused by ice.

• If there is a STOP COCK on input COLD WATER,

this should never be closed.

• If the appliance remains exposed to the sun for

long me without using water and it is not instal

led a water mixer aer the appliance itself, it is

necessary to be careful about the danger of

burns due to the high temperature of the water.

2.10 Maintenance intervenons

Cleaning of the solar water heater

In storage solar water heaters the transparent outer

cupola has to be as clean as possible, because dust

and dirness prevent sun rays from warming water at

best. As a result, the solar water heater efficiency

would be reduced considerably.

To clean the cupola use a wet and socloth: when

scratched the cupola lost its transparency.

© Solarbayer GmbH (213859)

11

PRODUCT INFORMATION Satellite collector NANOSOL 135

The general and special quality and test regulaons are only applicable in

combinaon with the applicable laws, regulaons and norms and their

secons that refer to the scope of applicaon of quality regulaons for

solar systems. The most recent version is to be kept as basis for the quality

regulaons:

BGI 656 Personal protecve equipment against falls – correct use,

BGR 203 Working on roofs,

BGV A1 Accident‐Prevenon Regulaon Principles of Prevenon,

BGV A2, A3 Electrical Installaons and Equipment,

BGV C22 Construcon work,

Chemicals Act (ChemG),

DIN 1055 Acons on structures,

DIN EN 1057 Copper and copper alloys Seamless, round copper tubes for

water and gas in sanitary and heang applicaons,

Technical rules of DVGW,

DIN EN 12449 Copper and copper alloys Seamless, round tubes for

general purposes,

DIN EN 1652 Copper and copper alloys Plate, sheet, strip and circles for

general purposes

DIN EN 127351 Copper and copper alloys Seamless, round copper tubes

for air condioning and refrigeraon Part 1: Tubes for piping systems,

DIN 1988 Codes of pracce for drinking water installaons(TRWI); general

informaon,

DIN 1988–4 Codes of pracce for drinking water installaons (TRWI);

drinking water protecon and drinking water quality control,

DIN EN 806 13 Specificaon for installaons inside buildings conveying

water for human consumpon,

DIN EN 1717 Protecon against polluon of potable water installaons and

general requirements of devices to prevent polluon by backflow,

DIN 4753 – 1 Water heaters, water heang installaons and storage water

heaters for drinking water,

DIN 4753 – 11 Water heaters and hot water systems for drinking and ser

vice water; indirect heat exchangers; requirements, tesng and marking,

DIN EN 1991 Teil 13 Eurocode 1,

DIN EN 1991 Teil 14 Eurocode 1,

DIN 1946 Venlaon systems (VDI venlaon code),

DIN 4102 Fire behaviour of building materials and building components,

DIN 4807 Expansion vessels,

DIN 53384 Tesng of plascs; arfical weathering or exposure in laboratory

apparatus; exposure to UVradiaon,

pr DIN EN 12897 Water supply Specificaon for indirectly heated unven

ted (closed) storage water heaters,

DIN EN 129751 Thermal solar systems and components Solar collectors

Part 1: General requirements,

DIN EN 129752 Thermal solar systems and components Solar collectors

Part 2: Test methods (including corrigendum AC:2002),

DIN EN 129761 Thermal solar systems and components Factory made

systems Part 1: General requirements,

DIN EN 129762 Thermal solar systems and components Factory made

systems Part 2: Test methods,

DIN V ENV 129771 Thermal solar systems and components Custom built

systems Part 1: General requirements for solar water heaters and

combisystems,

DIN V ENV 129772 Thermal solar systems and components Custom built

systems Part 2: Test methods,

BDH Inforamon sheet n° 34: Operaonal safety of solar thermal systems,

DIN V ENV 129773 Thermal solar systems and components Custom built

systems Part 3: Performance test methods for solar water heater stores,

DVGW – worksheet GW2 Connecng copper pipes for gas and water

installaons

KTW – recommendaon 16,

DVGW – worksheet W 270 Reproducon of microorganisms on materias

for drinking water – Test methods and rang,

DVGW – worksheet W 551 „Potable water heang systems; technical

measures for the decrease of legionella growth; planning, formaon,

operaon and restoraon of potable water systems“,

EU Pressure equipment direcve PED 97/23/EC,

EEC direcve 89/336/EEC Electromagnec compability,

EEC direcve 73/23/EEC Low voltage,

EEC direcve 89/292/EEC Machinery,

EU direcve 67/548/EEC classificaon, packaging and labelling of dange

rous substances,

EU direcve 91/155/EEC safety documents,

Ordinance on Hazardous Substances (GefStoffV),

RALGZ 429, Roof construcon,

RALRG 641/1, Copper pipe,

RALRG 641/2, brazing solder and brazing flux and solder paste for copper,

RALRG 641/3, sosolder, solder flux and solder paste for copper,

RALRG 641/4, Capillary soldered fings made of copper pipes,

RALGZ 655, Pipe supports,

Regulaon guidline of the ZVDH (German Central Associaon of the

Roofing Trade),

Technical Rule for Hazardous Substances (TRGS 519),

Energy Saving regulaon EnEV on energy saving thermal insulaon and on

energy efficiency in buildings,

VDI 2067 Economic efficiency of building installaons,

VDI 6002 Solar heang for potable water,

VDI 20351 Prevenon of damage in water heang installaons

Scale formaon in domesc hot water supply installaons and water

heang installaons,

VDI 20352 Prevenon of damage in water heang installaons

Waterside corrosion,

Regulaon on the classificaon on substances hazardous to water

(VwVwS),

Drinking water Ordinance (TrinkwV).

Instrucons for lightning protecon

The general principles for protecon against lightning are stated in DIN EN

62305 part 3 / VDE 01853053 (protecon against lightning, physical

damage to structures and life hazard) and in supplementary sheet 2

(Photovoltaic and solar thermal systems).

If a lightning protecon system is installed on a structure as external

lightning protecon the collectors and its installaon rails have to be

connected to the protecon system. A specialist for lightning protecon

has to check if either the solar system is within the range of a lightning

protecon system or what arrangements have to be met. Aenon: It is

not

allowed to draw a conducve connecon between the collector and the

exisng lightning protecon system (danger of launching the lightning into

the house!) A safety clearance of approx. 0,5 m from the collector array to

the conducve parts of the lightning protecon system has to be

maintained to all sides. The exact calculaon of the safety clearance is

stated in DIN EN 62305 part 3. If it is impossible to keep up the safety

clearance a specialist for lightning protecon has to realize the necessary

regulaons.

Furthermore it has to be considered: If the lightning protecon is outdated

and no longer in accordance with the norm, the right of connuance expi

res due to the mounng of the collectors. In this case the lightning protec

on system has to be revised.

Source: informaon sheet no. 34, march 2009, Operang Reliability of

Solar Thermal Systems. For further informaon see: www.BDHKoeln.de

Overload protecon: In order to protect the collector sensor and the

control unit against overload you can install an overload arrester. Nearby

lightning might induce voltage peaks which can destroy the sensor or the

control unit. Protecve diodes limit the damage caused by overload to a

minimum. Solarbayer control units are regularly equipped with an overload

protecon.

Potenal equalizaon: The solar system is to be connected to the

structure’s exisng potenal equalizaon by a specialist.

When planning and mounng, it is always the most recent version of this guidlines and regulaons that has to be paid aenon to!

Further applicable regulations for solar thermal systems

This manual and the pictures and drawings within

are protected by the copyright of SOLARBAYER GmbH.

Technical changes and errors reserved.

Valid is the most recent version of this handbook which can always be found on our homepage

www.solarbayer.de

This translaon has been provided for informaonal use only.

Solarbayer GmbH

Preith, Am Dörrenhof 22

85131 Pollenfeld

Phone +49 8421 935980

Fax +49 8421 9359829

info@solarbayer.de

www.solarbayer.de

System technology made in Bavaria

I

Storage systems

I

Fresh water systems

I

Wood log boiler

I

Solar systems

I

Heat pumps

Table of contents

Popular Solar Panel manuals by other brands

Viessmann

Viessmann VITOSOL 100-F SV1B Technical data manual

JAROLIFT

JAROLIFT TDSW-01 Original assembly and operating instructions

Samlexpower

Samlexpower ADJ-28 owner's manual

Peimar SRL

Peimar SRL Peimar installation manual

LG

LG LG N9C-G4 Series installation instructions

NOMA

NOMA 011-2031-8 instruction manual

HelioZenit

HelioZenit HELIOMOTION PV-3 Quick assembly guide

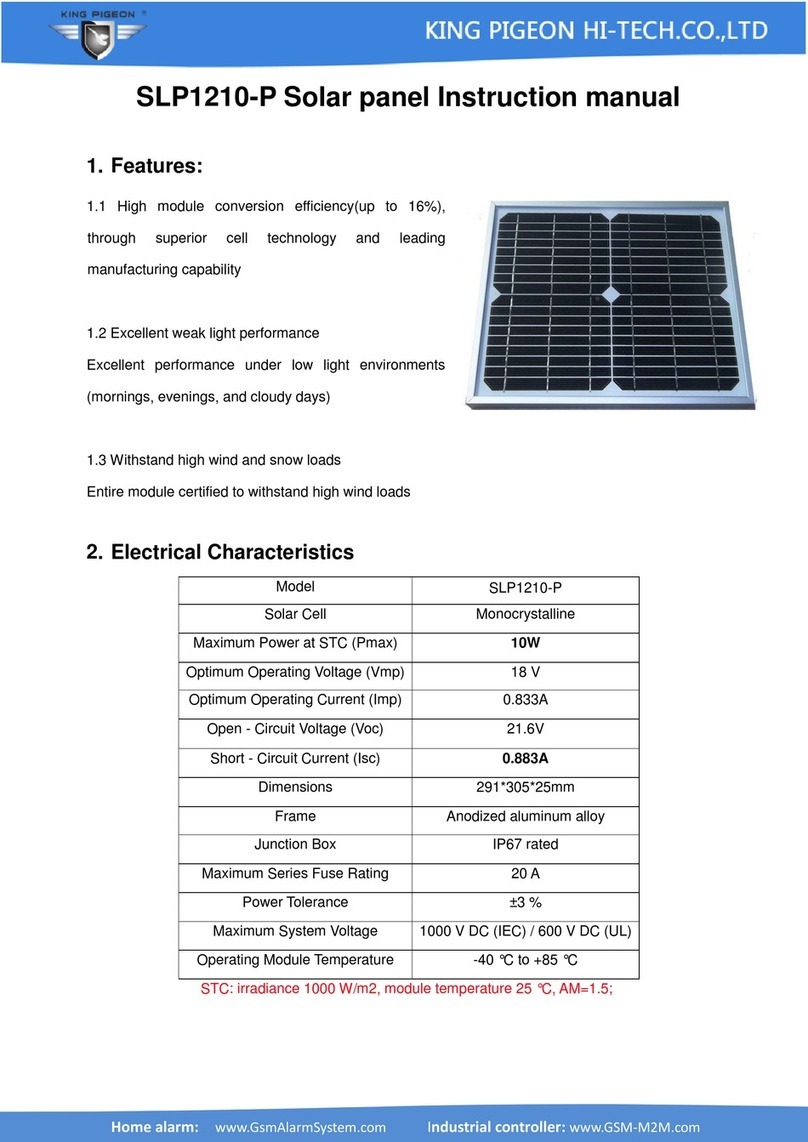

King Pigeon

King Pigeon SLP1210-P instruction manual

Wasserstein

Wasserstein Solar Panel for Wyze Cam Outdoor user manual

Panasonic

Panasonic HIT VBHN330SA17 General installation manual

Carbest

Carbest M85280 Installation and operating instruction

SunWare

SunWare TX-Solar installation manual