CHINSC ELECTRIC SVF-G7 Series User manual

SVF-G7

SVF-G7

SVF-G7

SVF-G7 Series

Series

Series

Series High-performance

High-performance

High-performance

High-performance Vector

Vector

Vector

Vector

Control

Control

Control

Control General-purpose

General-purpose

General-purpose

General-purpose Frequency

Frequency

Frequency

Frequency

Inverter

Inverter

Inverter

Inverter

Operation

Operation

Operation

Operation Manual

Manual

Manual

Manual

Material Version :V6.0

Date of F iling :2012-08-10

Company Standard :

:

:

:Q/0300SSC 001-2012

CHINSC ELECTRIC (CHINA) CO., LTD. could supply all-round

technology support for clients. T he users could contact the nearby

agency or customer service center of CHINSC ELECTRIC

(CHINA) CO., LTD. , and also could contact the manufacturer

directly.

A ll rights reserved. Any alteration is made without notice.

Head office: CHINSC ELECTRIC (CHINA) CO., LTD.

Customer h otline: 86-0533-6285662

Service h otline: 86-13375338006 ;

86-13375338007

URL: www.chinsc.com

Content SVF-G7 Series Frequency Inverter Operation Manual

I

Content

CHAPTER

CHAPTER

CHAPTER

CHAPTER 1

1

1

1 SAFETY

SAFETY

SAFETY

SAFETY AND

AND

AND

AND NOTES

NOTES

NOTES

NOTES

.........................................................................

.........................................................................

.........................................................................

.........................................................................

1

1

1

1

1.1 S AFETY DEFINITION

........................................................................................

1

1.2 S AFETY NOT ES

................................................................................................

1

1.3 N

OTES

.........................................................................................................

5

CHAPTER

CHAPTER

CHAPTER

CHAPTER 2

2

2

2 SPECIFICATIONS

SPECIFICATIONS

SPECIFICATIONS

SPECIFICATIONS AND

AND

AND

AND SELECTION

SELECTION

SELECTION

SELECTION

....................................................

....................................................

....................................................

....................................................

9

9

9

9

2.1 N AMING RULE

..............................................................................................

9

2.2 N AMEPLAT E

..................................................................................................

9

2.3 M ODEL AND TECHNICAL PARAMETER S

.............................................................

10

2.4

T

ECHNICAL SPECIFICATION

.............................................................................

11

2.5 P RODUCT OUTLINE AND INSTALLATION HOLE SIZES

............................................

16

2.5.1 0.4KW~18.5KW Outline and Outer Size of Hang Machine Plastic

Casing Frequency Inverter

.........................................................................

16

2.5.2 22KW~450KW Outline and Outer Size of Hang Machine Metal

Casing Frequency Inverter

.........................................................................

18

2.5.3 0.4KW~450KW Installation Hole Size of Hang Machine G/P

Frequency Inverter

....................................................................................

19

2.5.4 Outline Size of Keyboard Operation Panel

.......................................

20

2.6 S ELECTION OF BRAKING PACKAGE

...................................................................

20

2.7 S ELECTION OF DC R EACT OR

...........................................................................

21

2.8 F REQUENCY I

NVERTER

DAILY MAINT ENANCE

.....................................................

22

2.8.1 Daily Maintenance

........................................................................

22

2.8.2 Routine Checking

..........................................................................

23

2.8.3 Replacing of Quick-wearing Parts

....................................................

24

2.8.5 Warranty Instructions

......................................................................

25

2.9 S ELECTION GUIDE

........................................................................................

26

CHAPTER

CHAPTER

CHAPTER

CHAPTER 3

3

3

3 MECHANICAL

MECHANICAL

MECHANICAL

MECHANICAL AND

AND

AND

AND ELECTRICAL

ELECTRICAL

ELECTRICAL

ELECTRICAL INSTALLATION

INSTALLATION

INSTALLATION

INSTALLATION

.............................

.............................

.............................

.............................

27

27

27

27

3.1 M ECHANICAL INST ALLATION

........................................................................

27

3.1.1 Installation Environment

...............................................................

27

3.1.2 Installation Space

..........................................................................

27

3.1.3 Cover Removing Way

....................................................................

29

3.2 E LECTRICAL INST ALLATION

...........................................................................

31

3.2.1 External Electrical Component Selection:

.....................................

31

3.2.2 Instructions For External Electrical Components

..............................

32

3.2.3 Method Of Connecting Wire

............................................................

34

3.2.4 Main Circuit Terminals and Wiring

...................................................

36

3.2.5 Control Circuit and Wiring

................................................................

38

CHAPTER

CHAPTER

CHAPTER

CHAPTER 4

4

4

4 KEYBOARD

KEYBOARD

KEYBOARD

KEYBOARD OPERATION

OPERATION

OPERATION

OPERATION AND

AND

AND

AND DISPLAY

DISPLAY

DISPLAY

DISPLAY

.......................................

.......................................

.......................................

.......................................

44

44

44

44

Content SVF-G7 Series Frequency Inverter Operation Manual

II

4.1 I NTRODUCTION OFKEYBOARD OPERATION AND DISPLAY INT ERFACE

..................

44

4.1.1 Descriptions of Key Function

............................................................

44

4.1.2 Descriptions of Function Indicators

..................................................

46

4.2 P OWER ONS

TATE

........................................................................................

47

4.3 D ESCRIPTIONS OF FUNCTION CODE CHECK AND MODIFICATION METHOD

..............

47

4.4 C HECKING METHOD OF S

TATE

PARAMET ER

.......................................................

49

4.5 P ASSWORD SET UP

........................................................................................

49

4.6 F AULT S RESET

..............................................................................................

49

4.7 A

UTO

-LEARNING OF M

OTOR

PARAMET ERS

........................................................

50

CHAPTER

CHAPTER

CHAPTER

CHAPTER 5

5

5

5 FUNCTION

FUNCTION

FUNCTION

FUNCTION PARAMETER

PARAMET ER

PARAMET ER

PARAMET ER SIMPLE

SIMPLE

SIMPLE

SIMPLE LIST

LIST

LIST

LIST

.............................................

.............................................

.............................................

.............................................

52

52

52

52

CHAPTER

CHAPTER

CHAPTER

CHAPTER 6

6

6

6 FUNCTIONAL

FUNCTIONAL

FUNCTIONAL

FUNCTIONAL PARAMETER

PARAMET ER

PARAMET ER

PARAMET ER DETAIL

DETAIL

DETAIL

DETAIL

...............................................

...............................................

...............................................

...............................................

100

100

100

100

6.1 F0 B ASIC FUNCTION GROUP

.....................................................................

100

6.2 F1 S TART -S

TOP

CONTROL GROUP

..............................................................

113

6.3 F2 VF C ONTROL PARAMET ER GROUP

............................................................

119

6.4 F3 G ROUP VECT OR AND

T

ORQUE CONTROL PARAMET ER

...................................

123

6.5 F4 G ROUP INPUT SIGNAL GROUP

.................................................................

129

6.6 F5 G ROUP OUTPUT SIGNAL GROUP

..............................................................

135

6.7 F6 G ROUP MULTI -SPEED AND PLC P ROGRAM RUN

.........................................

143

6.8 F7 G ROUP PROCESS PID P ARAMET ER

...........................................................

147

6.9 F8 G ROUP COMMUNICATION PARAMET ER

.....................................................

152

6.10 F9 G ROUP HUMAN -COMPUT ER INT ERFACE

...................................................

154

6.11 FA G ROUP ENHANCEMENT FUNCTION GROUP

..............................................

156

6.12 FB G ROUP PROT ECTION FUNCTION GROUP

..................................................

160

6.13 FC G ROUP APPLICATION PARAMET ER GROUP 1

............................................

164

6.14 FD G ROUP APPLICATION PARAMET ER GROUP 2

............................................

164

6.15 FE G ROUP FREQUENCY INVERT ER NOUMENON PARAMET ER GROUP

..................

164

6.16 FF G ROUP MONITORING

V

ARIABLE GROUP

..................................................

165

CHAPTER

CHAPTER

CHAPTER

CHAPTER 7

7

7

7 COMMUNICATION

COMMUNICATION

COMMUNICATION

COMMUNICATION PROTOCOL

PROTOCOL

PROTOCOL

PROTOCOL

....................................................

....................................................

....................................................

....................................................

170

170

170

170

7.1 C OMMUNICATION ALLOCATION

....................................................................

170

7.2 P ROT OCOL FORM

.......................................................................................

170

7.3 P ROT OCOL FORM INSTRUCTION

....................................................................

170

7.3.1 Data type

.......................................................................................

170

7.3.2 Salve machine address

...................................................................

170

7.3.3 Read function code

........................................................................

171

7.3.4 Write operation function code

.......................................................

175

7.3.5 Abnormal Responding Function Code

............................................

178

7.4 CRC PARITY

..............................................................................................

181

CHAPTER

CHAPTER

CHAPTER

CHAPTER 8

8

8

8 TROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTING

.....................................................................

.....................................................................

.....................................................................

.....................................................................

182

182

182

182

8.1 F AULT S AND ACTIONS

..................................................................................

182

Content SVF-G7 Series Frequency Inverter Operation Manual

III

8.2 C OMMON FAULT AND HANDLING METHODS

....................................................

187

CHAPTER

CHAPTER

CHAPTER

CHAPTER 9

9

9

9 EMC

EMC

EMC

EMC

..............................................................................................

..............................................................................................

..............................................................................................

..............................................................................................

189

189

189

189

9.1 D EFINITION

............................................................................................

189

9.2 EMC S TANDARD INTRODUCTION

...............................................................

189

9.3 EMC D IRECTION

.......................................................................................

190

9.3.1 Harmonic Influence

........................................................................

190

9.3.2 EMI and Installation Notes

.............................................................

190

9.3.3 Handle interference of the environment to interfere the drive

......

190

9.3.4 Handle interference generated by drive to interfere the environment

................................................................................................................

190

9.3.5 Leakage current and its processing system

....................................

191

9.3.6 Note of installing EMC input filter in the power input side

............

192

APPENDIX

APPENDIX

APPENDIX

APPENDIX 1

1

1

1 INSTRUCTION

INSTRUCTION

INSTRUCTION

INSTRUCTION OF

OF

OF

OF STANDARD

STANDARD

STANDARD

STANDARD EXPANSION

EXPANSION

EXPANSION

EXPANSION CARD

CARD

CARD

CARD SC-EXT1-IO

SC-EXT1-IO

SC-EXT1-IO

SC-EXT1-IO

........................................................................................................................

........................................................................................................................

........................................................................................................................

........................................................................................................................

194

194

194

194

APPENDIX

APPENDIX

APPENDIX

APPENDIX 2

2

2

2 INSTRUCTION

INSTRUCTION

INSTRUCTION

INSTRUCTION OF

OF

OF

OF RELAY-OUTPUT

RELAY-OUTPUT

RELAY-OUTPUT

RELAY-OUTPUT EXPANSION

EXPANSION

EXPANSION

EXPANSION CARD

CARD

CARD

CARD

SC-EXT2-R

SC-EXT2-R

SC-EXT2-R

SC-EXT2-R

........................................................................................................

........................................................................................................

........................................................................................................

........................................................................................................

198

198

198

198

APPENDIX

APPENDIX

APPENDIX

APPENDIX 3

3

3

3 INSTRUCTION

INSTRUCTION

INSTRUCTION

INSTRUCTION OF

OF

OF

OF MULTIFUNCTIONAL

MULTIFUNCTIONAL

MULTIFUNCTIONAL

MULTIFUNCTIONAL INPUT

INPUT

INPUT

INPUT EXPANSION

EXPANSION

EXPANSION

EXPANSION CARD

CARD

CARD

CARD

SC-EXT3-S

SC-EXT3-S

SC-EXT3-S

SC-EXT3-S

........................................................................................................

........................................................................................................

........................................................................................................

........................................................................................................

200

200

200

200

Chapter 1 Safety and Notes SVF-G7 Series Frequency Inverter Operation Manual

2

Chapter 1 Safety and Notes SVF-G7 Series Frequency Inverter Operation Manual

1

Chapter

Chapter

Chapter

Chapter 1

1

1

1 Safety

Safety

Safety

Safety and

and

and

and Notes

Notes

Notes

Notes

1.1 Safety Definition

In this manual, safety precautions divide the following two categories:

!

Danger

Operations without following instructions can cause personal injury or

death.

!

Attention

Operations without following instructions can cause personal injury or

damage to product or other equipment.

1.2 Safety notes

!

Danger

Before Installations

1. Please don't operate the

damaged and incomplete drive.

O therwise there is a danger of

human injury 2.Please use the

insulation motor which class is

above B , otherwise, there is

electric shock danger.

Chapter 1 Safety and Notes SVF-G7 Series Frequency Inverter Operation Manual

2

!

Danger

Installing

1. Please install the drive on

fire-retardant material, r eserve

the drive away from combustible

materials , otherwise, it would

cause fire alarm!

2.If more than two drives are

parked in the same cabinet, in

order to the cooling effect of

Drive, please note that

installation position and refer

to chapter 3 which is

mechanical and electrical

installation.

3. Don't allow Conductors

and screws to fall inside the

drive, otherwise there is a

danger of damage.

Chapter 1 Safety and Notes SVF-G7 Series Frequency Inverter Operation Manual

3

!

Danger

Wiring

1. Only the electrical engineering

personnel shall wire the drive ,

otherwise, there is electric shock

danger.

2. Between the drive and power

must have circuit a breaker ,

otherwise, it would cause fire

alarm!

3. Never wire the drive unless the

input AC supply is totally

disconnected , otherwise, there is

electric shock danger.

4. The drive must be properly

earthed to reduce electrical

accident , otherwise, there is

electric shock danger.

5. Don

’

s connect the input

power supply to output

terminals U, V and

W

,

otherwise, it would cause the

damage of frequency

inverter.

6. Wiring must accord with

EMC requirements and the

region safety standards.

Please refer to the manual

that advised about using wire

line diameter. Otherwise

accidents may occur.

connected into DC between bus (+)

danger of fire.

Before power on

Reserve supply voltage and rated

voltage of the drive in the same level,

sure the input and output wiring

and check buffer circuit.

Otherwise, the drive may be damaged.

2. Before power on, please make

sure that the cover is installed.

Otherwise, can lead to electric

shock.

3. The products already have

done a penetrative test, if

redone, it may cause

accident.

4. Please refer this manual

provided circuit to correct

connection peripheral

accessories, to reduce

electrical accident.

Chapter 1 Safety and Notes SVF-G7 Series Frequency Inverter Operation Manual

4

!

Danger

After power on

1. After power on, please don ’ t

open the cover of the drive, in

order to avoid electric shock.

2. Don ’ t touch the drive and

peripheral circuit with wet hands.

3. Don't touch the drive

’

s

terminals including the control

terminals with bare hands.

4. Initial power on, the drive is

checking the safety of its external

circuit with strong electric, so

please don't touch the drive

’

s

terminals U 、V、W and the

motor

’

s terminals.

5. When the motor is

parameters. Otherwise accidents may

6. Please don't randomly

change the factory

parameters of the drive,

otherwise, will damage the

drive.

Operating

1. Please Reserve far away from

it, if restart the drive. Otherwise

there is human injury.

2. Don ’ t touch the cooling fans

and discharge resistance with

bare hands to test temperature.

Otherwise, has burn dangerous.

3. Amateur technicians do not

detect the signal during

operating. O r it may cause a

personal injury or damaged.

4. Don't allow matters to fall

inside the running drive,

otherwise it may be

damaged;

5. Please don ’ t use contactor

to control drive start-stop, in

order to reduce the damage.

Chapter 1 Safety and Notes SVF-G7 Series Frequency Inverter Operation Manual

5

!

Danger

Maintaining

1. Please don ’ t charge for

equipment repair and

maintenance. Otherwise, have

shocking danger;

2. Perform the maintenance and

repair job after confirming that

the DC Bus voltage is below

36V,

in order to avoid electric

shock.

3. Unprofessional trained

personnel do not charge the

repair and maintenance job.

Otherwise caused human injury

or damaged.

1.3 Notes

�

Insulation checking of m otors

Before using the drive, the insulation of the motors must be checked,

especially, if it is used for the first time, if it has been stored

for a long time or regularly check. This is to reduce the risk of the

drive from being damaged by the poor insulation of the motor. When

checking ,must make sure the motors and the drive is separated, Please

use 500V insulation tester to measure the insulating resistance. It

should not be less than 5M Ω .

�Motor thermal protection

If the ratings of the driven motor are not in compliance with the drive,

especially, the drive rated power more than motor rated power, be sure

Chapter 1 Safety and Notes SVF-G7 Series Frequency Inverter Operation Manual

6

to adjust the protective threshold or to install thermal relay before

the motor to ensure the motor is properly protected.

�Operate a bove power frequency

This drive can provide 0Hz~600Hz output frequency. If the user need

to run the motor above rated frequency, please consider the

affordability of mechanical devices.

�

The mechanical device r esonance

T he drive system may encounter mechanical resonance with the load when

operating within certain band of output frequency. Skip frequencies

have been set to avoid it.

�

Motor heat and n oise

The output voltage is in PWM wave with some harmonics. Therefore,

temperature rise, noise and vibration of motor are higher than 50Hz.

�Varistors o r c apacitors u sed t o i mprove t he p ower f actor

Don't connect any varistor or capacitor to the output terminals of the

drive, because the drive's output voltage waveform is PWM, otherwise

tripping or damaging of components may occur; in addition, don't

install circuit breaker or contactor at the output side of the drive.

�Circuit b reakers c onnected to the input/output of the drive

If contactor is connected between the input power supply and the

motor, Please don ’ t use contactor to control drive start-stop. If it must

be done, interval time should not less than one-hour. If frequently

charging and discharging, the life of the internal capacitance of the

drive will be reduced. If circuit breaker or contactor needs to be

connected between output side of the drive and the motor, be sure to

operate these circuit breakers or contactor when the drive has no

output, to avoid damaging of the drive.

�Using outside the range of rated voltage

The drive is unsuitable to be used out of the specified range of

Chapter 1 Safety and Notes SVF-G7 Series Frequency Inverter Operation Manual

7

operation voltage; otherwise, it may be damaged. If need, please use

suitable voltage regulation device.

�Change from 3-phase to 2-phase

It is not recommended to change the drive from 3-phase input to 2-phase

input. Otherwise it will lead to failure or damaged.

�

Protection against lightning strike

There are transient surge suppressors inside the Drive which protects

it against lighting strike. Department for frequent thunder and

lightning, users should install the drive front-end protection.

�Derating due to a ltitude

Derating must be considered when the drive is installed at high altitude,

greater than 1000m. Because of the thin air, the cooling effect of drive

is deteriorated. Please contact our technical advice in this case.

�Special usage

If users need the wiring diagram, such as common DC bus, without in

the manual, Please consult our company.

�Disposing u nwanted d rive

The capacitors may explode when they are burnt. Poisonous gas may be

generated when the plastic parts like front covers are burnt. Disposing

method: Please dispose the Drive as industrial waste.

Adaptive motor

1) If the motor isn ’ t the four-pole squirrel-cage asynchronous induction

motor. Please select the drive according to the rated current of the motor.

I f you choose the permanent magnet synchronous motor, please consult our

company.

2) Because the cooling fan of non-inverter mo tor is coaxial connection wit h

its rotor shaft connection, if the speed of the motor is reduced, the cooling

effect of the fan is deteriorating, if the motor may become overheating in

the situation, please change to inverter motor or install another fan.

Chapter 1 Safety and Notes SVF-G7 Series Frequency Inverter Operation Manual

8

3) The drive has built-in adaptive motor standard parameters, According to

the actual situation, identify parameters or modify default of the motor

to meet the actual value as far as possible; otherwise, it will affect the

operating results and the protection of property.

4) Because the cable or the inside motor short circuit can cause the drive

alarm, and even explosion. Therefore, the initial installing motor and cable

must be done insulating short-circuit test. Note, when doing the test, make

sure the drive and the tested part be completely disconnected.

Chapter2 Specifications and Selection SVF-G7 Series Frequency Inverter Operation Manual

9

Chapter

Chapter

Chapter

Chapter 2

2

2

2 Specifications

Specifications

Specifications

Specifications and

and

and

and Selection

Selection

Selection

Selection

2.1 Naming R ule

SVF

-G7-G 7.5/P

11

T 4 B

CHINSC VFD Series

Code

Type

G

General type

Adapter motor power

Corresponding relation

Code

Adapter motor

power

(

KW

)

0 . 4

……

450

0 . 4

……

450

Code

Braking Unit

Null

B

Null

Including braking unit

Code

Input voltage level

T 4

Three phase

380 v

±

15

%

Fan

&

pump type

P

F igure 2-1 Naming rule

2.2 Nameplate

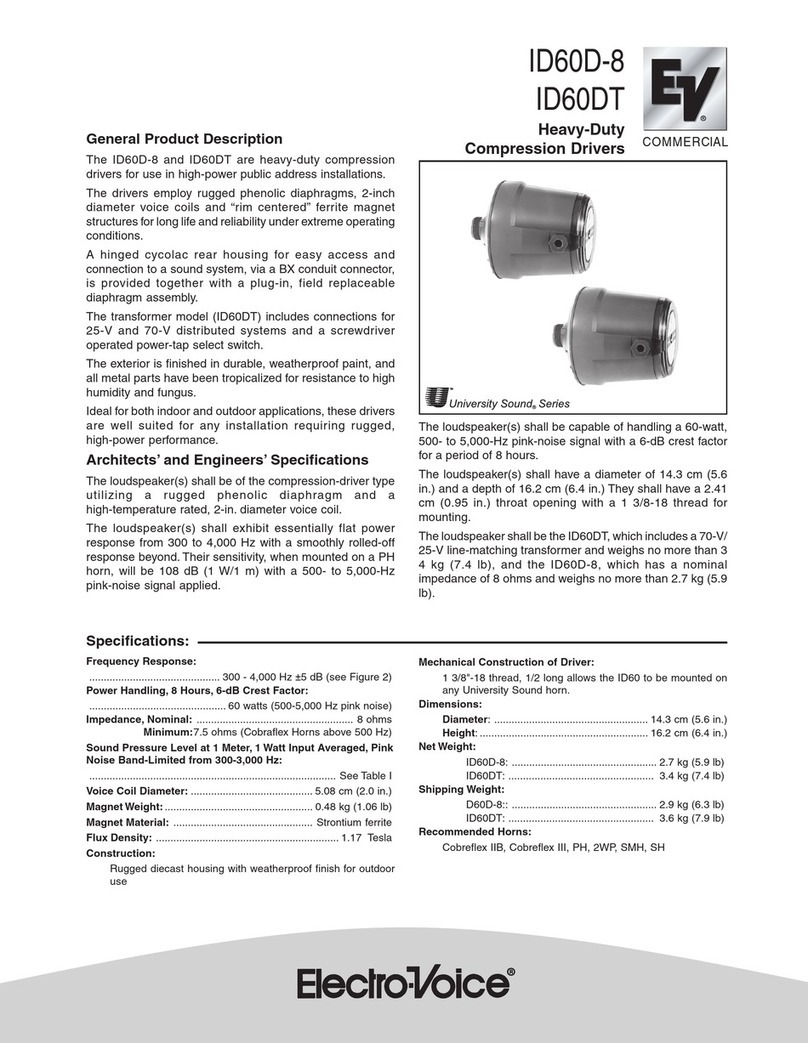

MODEL

:

SVF

- G 7 - G 7 . 5 / P

11

T 4 B

INPUT

:

AC

3

PH

380 V ±

15

%

50

/

60

Hz

OUTPUT

:

AC

3

PH

0 -

380

V

0 -

600

HZ

1 7 / 2 5

A

S / N :

CHINSC ELECTRIC

(

CHINA

)

CO

.

,

LTD

Figure 2-2 Nameplate

Chapter2 Specifications and Selection SVF-G7 Series Frequency Inverter Operation Manual

10

2.3 Model and T echnical P arameter

s

T

able2-1 SVF-G7 frequency inverter model and technical parameters

VFD Model Input V

P

capacity(KVA)

Input

C(A)

Output

C(A)

Motor

P(KW)

SVF-G7-G0.4T4B

3Phase

380V

Range :

± 15%

1.0 2.4 1.2 0.4

SVF-G7-G0.75T4B 1.5 3.4 2.5 0.75

SVF-G7-G1.5T4B 3.0 5.0 3.7 1.5

SVF-G7-G2.2T4B 4.0 5.8 5.0 2.2

SVF-G7-G3.7/P5.5T4B 5.9 10.5 9/13 3.7/5.5

SVF-G7-G5.5/P7.5T4B 8.9 14.6 13/17 5.5/7.5

SVF-G7-G7.5/P11T4B 11.0 20.5 17/25 7.5/11

SVF-G7-G11/P15T4B 17.0 26.0 25/32 11/15

SVF-G7-G15/P18.5T4 21.0 35.0 32/37 15/18.5

SVF-G7-G18.5/P22T4 24.0 38.5 37/45 18.5/22

SVF-G7-G22/P30T4 30.0 46.5 45/60 22/30

SVF-G7-G30/P37T4 40.0 62.0 60/75 30/37

SVF-G7-G37/P45T4 57.0 76.0 75/90 37/45

SVF-G7-G45/P55T4 69.0 92.0 90/110 45/55

SVF-G7-G55/P75T4 85.0 113.0 110/150 55/75

SVF-G7-G75/P93T4 114.0 157.0 150/176 75/93

SVF-G7-G93/P110T4 134.0 180.0 176/210 93/110

SVF-G7-G110/P132T4 160.0 214.0 210/253 110/132

SVF-G7-G132/P160T4 192.0 256.0 253/300 132/160

SVF-G7-G160/P185T4 231.0 307.0 300/340 160/185

SVF-G7-G185/P200T4 242.0 350.0 340/380 185/200

SVF-G7-G200/P220T4 250.0 385.0 380/420 200/220

SVF-G7-G220/P250T4 280.0 430.0 420/470 220/250

SVF-G7-G250/P280T4 355.0 468.0 470/520 250/280

SVF-G7-G280/P315T4 396.0 525.0 520/600 280/315

SVF-G7-G315/P350T4 445.0 590.0 600/640 315/350

SVF-G7-G350/P400T4 500.0 665.0 640/690 350/400

Chapter2 Specifications and Selection SVF-G7 Series Frequency Inverter Operation Manual

11

SVF-G7-G400/P450T4 565.0 785.0 690/800 400/450

2.4 Technical Specification

Table2-2 SVF-G7 Frequency Inverter Technical Specifications

Item Specification

Input Rated voltage T4 series: Three phase 380v, ± 15%

Frequency 50/60Hz ± 5%

Output Voltage Three phase 0-380V

Frequency 0-600Hz

Overload

ability

Type G: 150% rated current for 1

minute, 180% rated current for 2

second;

Type P: 120% rated current for 1

minute, 150% rated current for 2

second.

Heat

D issipation

Cooling type Forced Cooling

Temperature

protection

Heatsink temperature >8 5 ℃trip

protection against overheat

Fan control

Heatsink temperature> 50 ℃, fan

forced operation, frequency inverter

continue work

Control

Performance

Control mode

Open-loop vector control, V/F

control, Torque Control

Start torque Open-loop vector control: 0.5Hz

180%;

Chapter2 Specifications and Selection SVF-G7 Series Frequency Inverter Operation Manual

12

VF control :0.5Hz 150%

Speed range Open-loop vector control: 1:200;

VF control :1:100

Speed control

precision

Open-loop vector control: ± 0.2%;

VF control :± 0.5%

Torque control

precision

Open-loop vector control: ± 5%

T

orque

response time

Open-loop vector control: <20ms

Function Channel of

operation

command

Keyboard control ,terminal control

,

communication control

Start mode D irect start, DC injection braking

before start, speed tracking before

start

DC injection

braking

Start DC injection braking, stop DC

injection braking

Dynamic

braking

Built-in braking unit < = 1 5 kw, get

external braking unit>1 8.5 kw

Frequency

source choice

Keyboard digital frequency setting,

analog V1 setting, analog V2

setting, Keyboard potentiometers

setting, Multiple speed operation

setting,

PID control setting,

telecommunications setting, PLC

program operation setting, HDI

High Speed Pulse setting

Chapter2 Specifications and Selection SVF-G7 Series Frequency Inverter Operation Manual

13

Main and

auxiliary

frequency

combination set

Just main frequency setting, just

auxiliary frequency setting,

QUICK/JOG or terminal switching

selection, main frequency +

auxiliary frequency, main frequency

- auxiliary frequency, maximum,

minimum, could realize

Frequency overlay and fine

adjustment function

Frequency

resolution

Keypad setting:0.01Hz; Analog

setting: 0.1 %

Carrier

frequency

0.5Khz~15.0Khz, both PWM mode

could be chosen

Acc/Dec time 0.1~3600.0s

Multiple VF

curve

Linear V/F curve, 2.0 times power

drop torque V/F curve, custom V/F

percentage (can realize manual

energy saving control), multipoint

VF curve.

Built-in PID Built-in PID controller, apply to

process control occasion such as

water or gas supply. Meanwhile the

sleep wake up function could save

energy to the great extent possible.

Simple PLC

operation

16 segment goal setting, frequency

or mode of percentage setting could

be chosen, each segment of

operation time and direction could

Chapter2 Specifications and Selection SVF-G7 Series Frequency Inverter Operation Manual

14

be set separately, and realize timing

stop function.

Speed tracking, Cut-off restart, fault

recovery, Automatic torque

promotion, the motor

’

s parameters

auto-learning , Pendulum frequency

operation, hopping frequency,

UP/DOWN control,

AVR,

Over - voltage stalling protection,

rapid current-limiting, Instant power

down and drop frequency operation

Input

Output

Signal

Analog input V1:0~10V

V2:4~20 mA or 0~10V, Select

through JP2 jumper

Keyboard potentiometer input:

0~5V

Analog output FM1:0~10V or 0~20 mA , Select

through JP9 jumper

FM2:0~10V or 0~20 mA , Select

through JP10 jumper . Need the

support of SC-EXT1- IO expansion

cards

Digital input Standard configuration S1~S6, can

expand S7~S10 through

SC-EXT3-S expansion cards. A total

of 30 kinds of function could be

selected.

Digital output Standard configuration 2 channel

Chapter2 Specifications and Selection SVF-G7 Series Frequency Inverter Operation Manual

15

including SP1, SP2 electrode

output;

1 channel relay output T1;

Expanding 4 channel relay output

T2~T5 through SC-EXT2-R

expansion cards.

High-speed

pulse input

HDI: 0~50.0Khz, support by

expansion cards SC-EXT1- IO

High-speed

pulse output

HDO: 0~50.0Khz, support by

expansion cards SC-EXT1- IO

Communication

Port

Communication

protocol

Based o n RS485 hardware, support

standard MODBUS protocol, should

match expansion cards

SC-EXT1- IO

Expansion

C ards

3 type

expansion cards

Standard expansion cards

SC-EXT1- IO, Relay expansion

cards SC-EXT2-R (can realize one

drives 2 function) , Multifunctional

input expansion card SC-EXT3-S,

refer to the explanation in Appendix.

Display

F unctions

Five digital

tube display

Can monitor the operation state of

frequency inverter flexibly and

conveniently; can set normal

monitoring parameters separately

when operation and stop .

Protect ion

F unction

25 kinds of

protection

function s

I ncluding over - voltage ,

o ver - current, overheat, overload,

under-voltage, short circuit , ground

This manual suits for next models

27

Table of contents

Other CHINSC ELECTRIC DC Drive manuals

Popular DC Drive manuals by other brands

Eaton

Eaton PowerXL DH1 Applications manual

Danfoss

Danfoss VLT Active Front End AFE 302 operating instructions

ThyssenKrupp

ThyssenKrupp TW63 operating manual

Pentair

Pentair PENTEK PSD25PB Installation and operation manual

ABB

ABB ACS355 series Quick installation and start-up guide

Bosch

Bosch Rexroth ROTATRAC eGFT 8000 10 Series manual