1. Use the shielded cable between the sine-wave filter

and frequency converter.

2. Keep the unshielded cable away from the mains

cable. The two cables should not be run in parallel.

3. If the installation requires to route the motor cables

and mains cables in parallel, keep a distance of at

least 45cm between the two cables. Separate the

cables by placing them in different cable trays or in

different sections of a cable tray.

4. Use continuous cable trays and avoid “ladder-type”

cable trays.

5. Route the motor cable along the metallic grounded

conductors such as cable trays, rails from the

building structure, pipes, etc.

3.1.7 Grounding Concept

•Do the common grounding between AFE and

motor drives.

•The output filters and LCL should have low

impedance grounding to the AFE and motor

frequency drives.

•Ensure low impedance between entire crane

construction and the cabinets and the transformer.

•Use only one connection to the transformer.

3.1.8 Cooling and Airflow

Cooling

Cooling can be obtained, by using the cooling ducts in the

bottom and the top of the unit, by taking air in and out of

the back of the unit or by combining the cooling

possibilities.

Duct cooling

A dedicated option has been developed to optimize instal-

lation of IP00/chassis frequency converters in Rittal TS8

enclosures utilizing the fan of the frequency converter for

forced air cooling of the backchannel. The air out of the top

of the enclosure could but ducted outside a facility so the

heat losses from the backchannel are not dissipated within

the control room reducing air-conditioning requirements of

the facility.

Please see Installation of Duct Cooling Kit in Rittal enclosures,

for further information.

Back cooling

The backchannel air can also be ventilated in and out of the

back of a Rittal TS8 enclosure. This offers a solution where

the backchannel could take air from outside the facility and

return the heat losses outside the facility thus reducing air-

conditioning requirements.

NOTE

The ideal cooling air is dry and clean. When the air from

outside is used, filter mats and long air inlets could prevent

the dirty air problem. The condensation inside the frequency

converter, from the humid air, may require the drain outlet.

NOTE

Adoor/top fan(s) is required on the enclosure to remove the

heat losses not contained in the backchannel of the

frequency converter and any additional losses generated

from other components installed inside the enclosure. The

total required air flow must be calculated so that the

appropriate fans can be selected. Some enclosure manufac-

turers offer software for performing the calculations (i.e.

Rittal Therm software). If the VLT is the only heat generating

component in the enclosure, the minimum airflow required

at an ambient temperature of 45oCfor the D3 and D4 frame

sizes is 391m3/h (230cfm). The minimum airflow required at

an ambient temperature of 45oC for the E2 frame size is

782m3/h (460cfm).

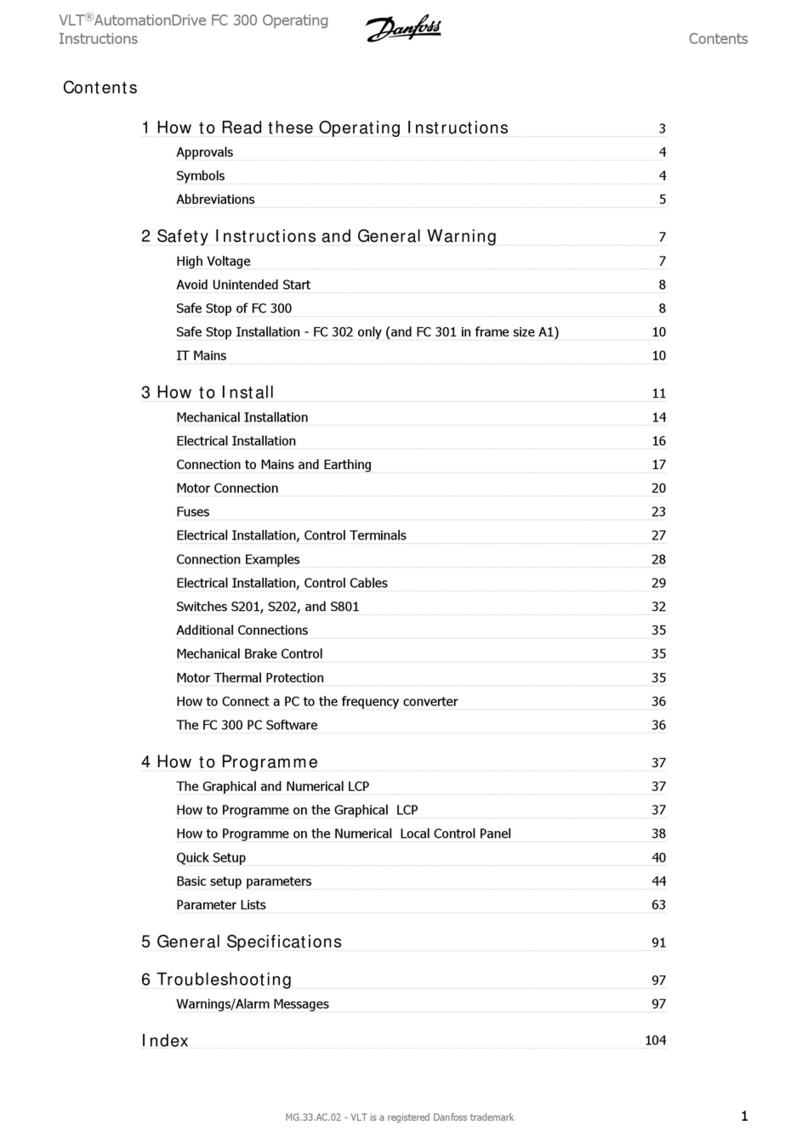

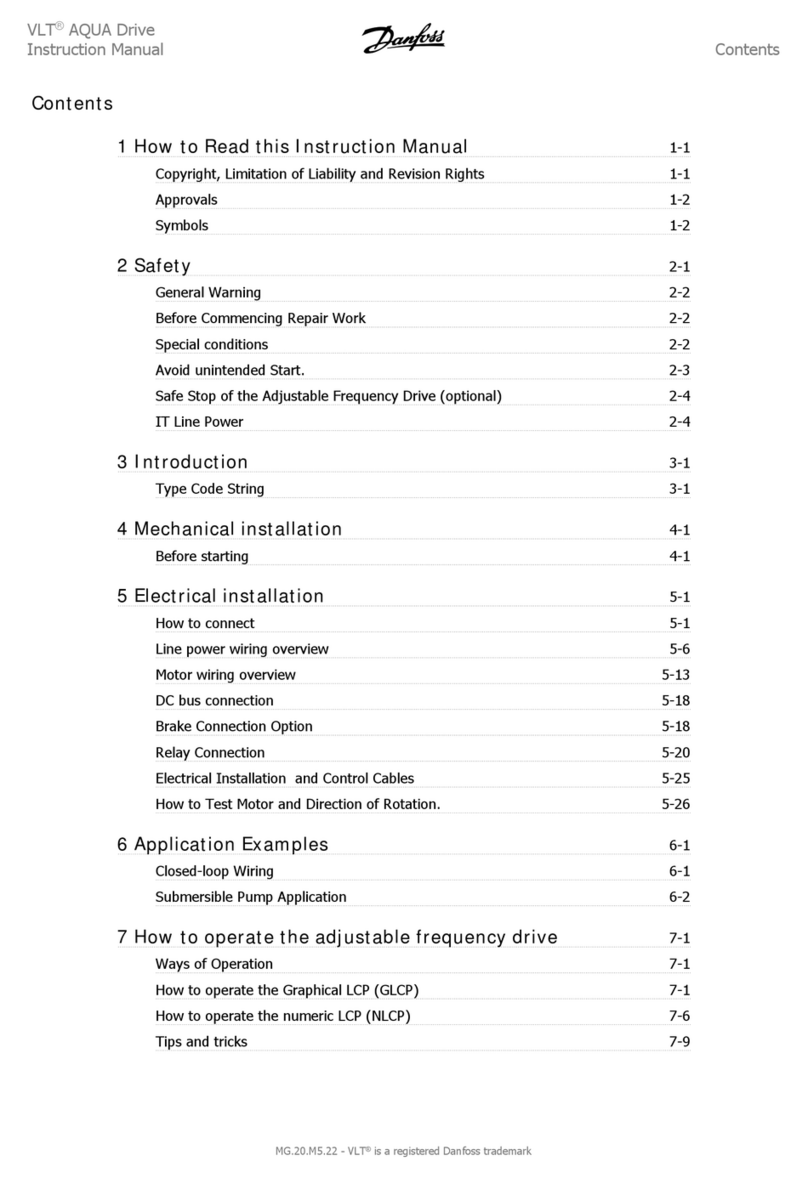

Airflow

Table 3.1 shows the necessary airflow over the heat sink.

Enclosure

protection Frame size Door fan(s)/

Top fan airflow

Heatsink fan(s)

IP21 / NEMA 1

IP54 / NEMA 12

D1 and D2 170m3/h (100

cfm)

765m3/h (450

cfm)

E1 P250T5,

P355T7,

P400T7

340m3/h (200

cfm)

1105m3/h (650

cfm)

E1P315-

P400T5, P500-

P560T7

340m3/h (200

cfm)

1445m3/h (850

cfm)

IP21 / NEMA 1 F1, F2, F3 and

F4

700m3/h (412

cfm)*

985m3/h (580

cfm)*

IP54 / NEMA 12 F1, F2, F3 and

F4

525m3/h (309

cfm)*

985m3/h (580

cfm)*

IP00 / Chassis D3 and D4 255m3/h (150

cfm)

765m3/h (450

cfm)

E2 P250T5,

P355T7,

P400T7

255m3/h (150

cfm)

1105m3/h (650

cfm)

E2 P315-

P400T5, P500-

P560T7

255m3/h (150

cfm)

1445m3/h (850

cfm)

* Airflow per fan. Frame size F contain multiple fans.

Table 3.1 Heatsink Air Flow

Crane System Design VLT®Active Front End AFE 302 Operating Instructions Liebherr

MG.33.X2.02 - VLT®is a registered Danfoss trademark 9

33