8

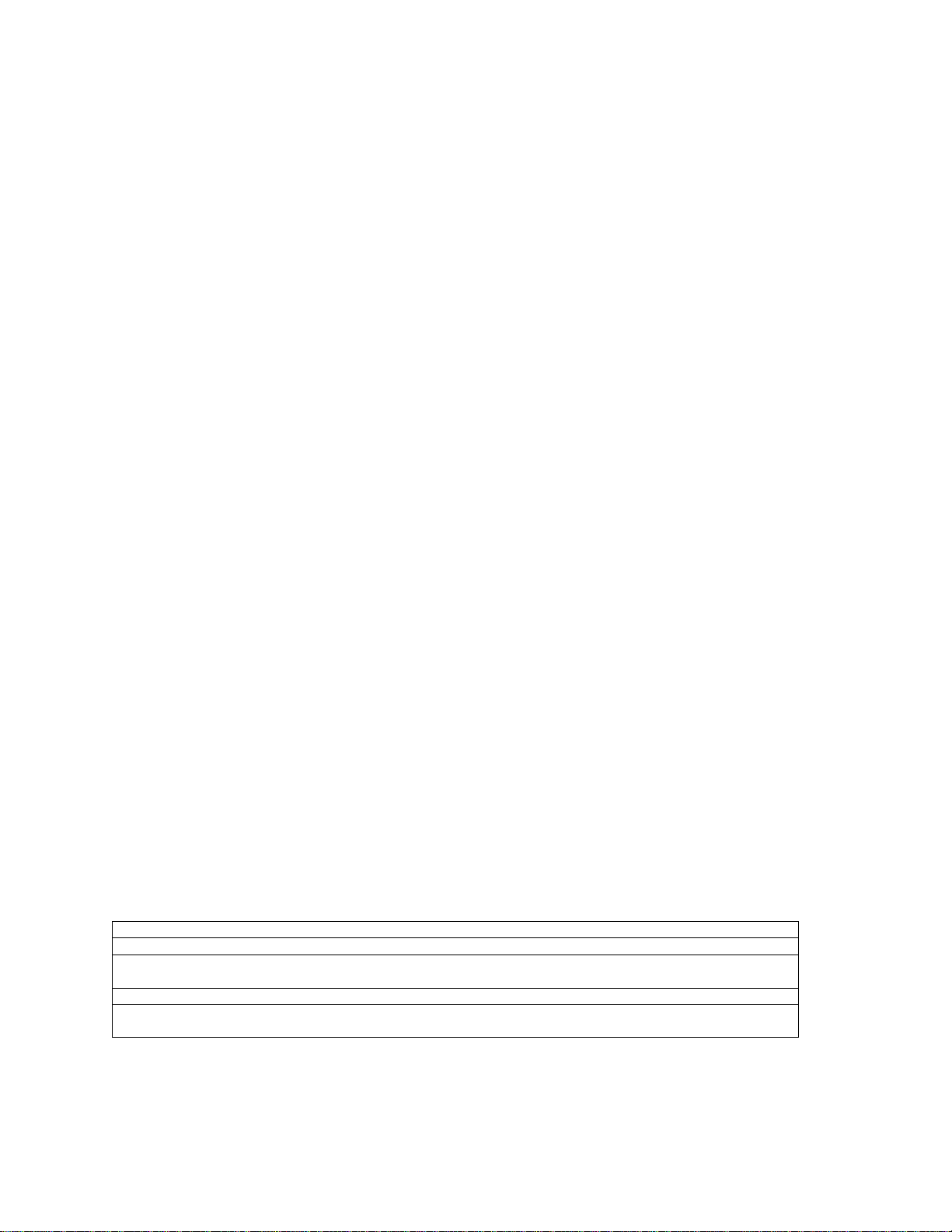

Index No. Part No. Description Size Qty

17 ..............BP1248N-17.............. Counter Weight Assembly....................................... ......................................2

18 ..............BP1248N-18.............. Stand Assy............................................................... ......................................2

19 ..............TS-1492041 .............. Hex Cap Screw........................................................M12x40.........................6

20 ..............TS-2311121 .............. Hex Nut ...................................................................Full M12........................6

21 ..............BP1248F-21.............. Rod Gauge Assembly.............................................. ......................................1

22..............BP1248N-22..............Box, Adj. Assembly.................................................. ......................................1

23 ..............BP1248N-23.............. Bushing (2) .............................................................. ......................................2

24 ..............BP1248N-24.............. Base Assembly........................................................ ......................................1

25..............BP1248N-25..............Bolt Adj. Assembly................................................... ......................................2

26 ..............BP1248N-26.............. Holder...................................................................... ......................................2

27 ..............TS-1506021 .............. Socket Head Cap Screw..........................................M12x25.........................5

28 ..............BP1248F-28.............. Swivel Pin Assembly................................................ ......................................2

29 ..............BP1248N-29.............. Yoke Assy (R.H)...................................................... ......................................1

30 ..............BP1248N-30.............. Yoke Assy (L.H)....................................................... ......................................1

31 ..............BP1248N-31.............. Clamp Handle (R.H) ................................................ ......................................1

32 ..............BP1248N-32.............. Clamp Handle (L.H)................................................. ......................................1

33 ..............BP1248N-33.............. Scale........................................................................ ......................................1

34 ..............BP1248N-34.............. Hold Down Assembly............................................... ......................................1

35 ..............TS-1506021 .............. Socket Head Cap Screw..........................................M12x25.......................12

36 ..............TS-1491081 .............. Hex Cap Screw .......................................................M10x50.......................24

37-1...........BP1248N-37-4 .......... Joint Open ...............................................................5"...................................5

37-2...........BP1248N-37-3 .......... Joint Open ...............................................................4"...................................2

37-3...........BP1248N-37-2 .......... Joint Open ...............................................................3”...................................5

38 ..............TS-1491061 .............. Hex Cap Screw........................................................M10x40.......................12

39-1...........BP1248N-39-4 .......... Holder, Finger..........................................................5"...................................5

39-2...........BP1248N-39-3 .......... Holder, Finger..........................................................4"...................................2

39-3...........BP1248N-39-2 .......... Holder, Finger..........................................................3”...................................5

40-1...........BP1248N-40-4 .......... Washer, Finger........................................................5"...................................5

40-2...........BP1248N-40-3 .......... Washer, Finger........................................................4"...................................2

40-3...........BP1248N-40-2 .......... Washer, Finger........................................................3”...................................5

41-1...........BP1248N-41-1 .......... Finger.......................................................................5"...................................5

41-2...........BP1248F-39.............. Finger.......................................................................4"...................................2

41-3...........BP1248F-38.............. Finger.......................................................................3”...................................5

42 ..............TS-2311121 .............. Hex Nut ...................................................................Full M12......................10

43 ..............TS-2361121 .............. Lock Washer............................................................M12.............................10

44 ..............TS-2360121 .............. Flat Washer .............................................................M12...............................1

45 ..............BP1248N-45.............. Bracket Bar.............................................................. ......................................1

46 ..............BP1248N-46.............. Insert Clamp Bar...................................................... ......................................1

47 ..............BP1248N-47.............. Cotter Pin ................................................................2.5x18...........................1

48 ..............BP1248N-48.............. Stop Collar............................................................... ......................................1

49 ..............TS-1505021 .............. Socket Head Cap Screw..........................................M10x20.........................2

50 ..............TS-2360121 .............. Flat Washer .............................................................M12...............................1

51 ..............TS-2311121 .............. Hex Nut....................................................................M12...............................1

52 ..............BP1248N-52.............. Spring Pin................................................................5x30..............................2

53 ..............TS-1525041 .............. Socket Set Screw ...................................................M10x20.........................2

54 ..............TS-1506071 .............. Socket Head Cap Screw..........................................M12x50.........................2

55 ..............TS-2311241 .............. Hex Nut ...................................................................Full M24........................4

56..............BP1248N-56..............Clip Ring 38............................................................. ......................................2

57 ..............TS-1506041 .............. Socket Head Cap Screw..........................................M12x35.........................2

58 ..............BP1248N-58.............. Knob Lock................................................................ ......................................2

59 ..............BP1248N-59.............. Bushing (1) .............................................................. ......................................2

60 ..............BP1248N-60.............. Angle Scale.............................................................. ......................................1