Choc Edge Choc Creator V2.0 Plus User manual

Choc Edge

1

Choc Edge

2

Contents

Part 1 - Product Introduction 3 - 4

1. Part Names

2. Product Parameters

Part 2 - Melting Chocolate 5 - 8

1. Melting Process

2. Precautions

Part 3 - Printer Operation 9 - 22

1. Function Introduction

2. Operation Procedure

3. Precautions

4. Parts List

Part 4 - Software Installation and Use 22 - 40

1. Software Installation

2. Software Use

3. Frequently Asked Questions

4. Appendix A&B

Part 5 - After-Sales Service 41

Choc Edge

3

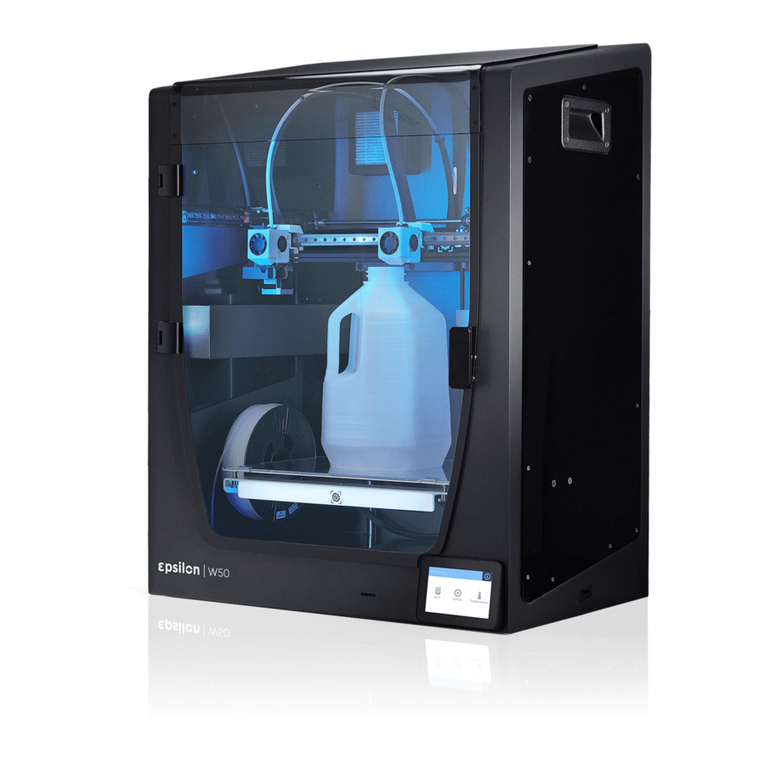

Cover

Part 1 Product Introduction

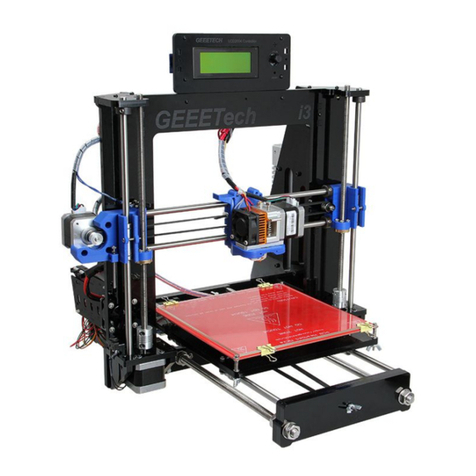

1.1. Equipment Introduction

Emergency

Stop Button

Power Switch

Power Cord

Connection

USB Input

Terminal

Power

Computer Cord

Connection

Touch Screen

Stylus Holder

5’LCD Touch Screen

Printing

Platform

Plastic Cup

Holder

Print Head

Choc Edge

4

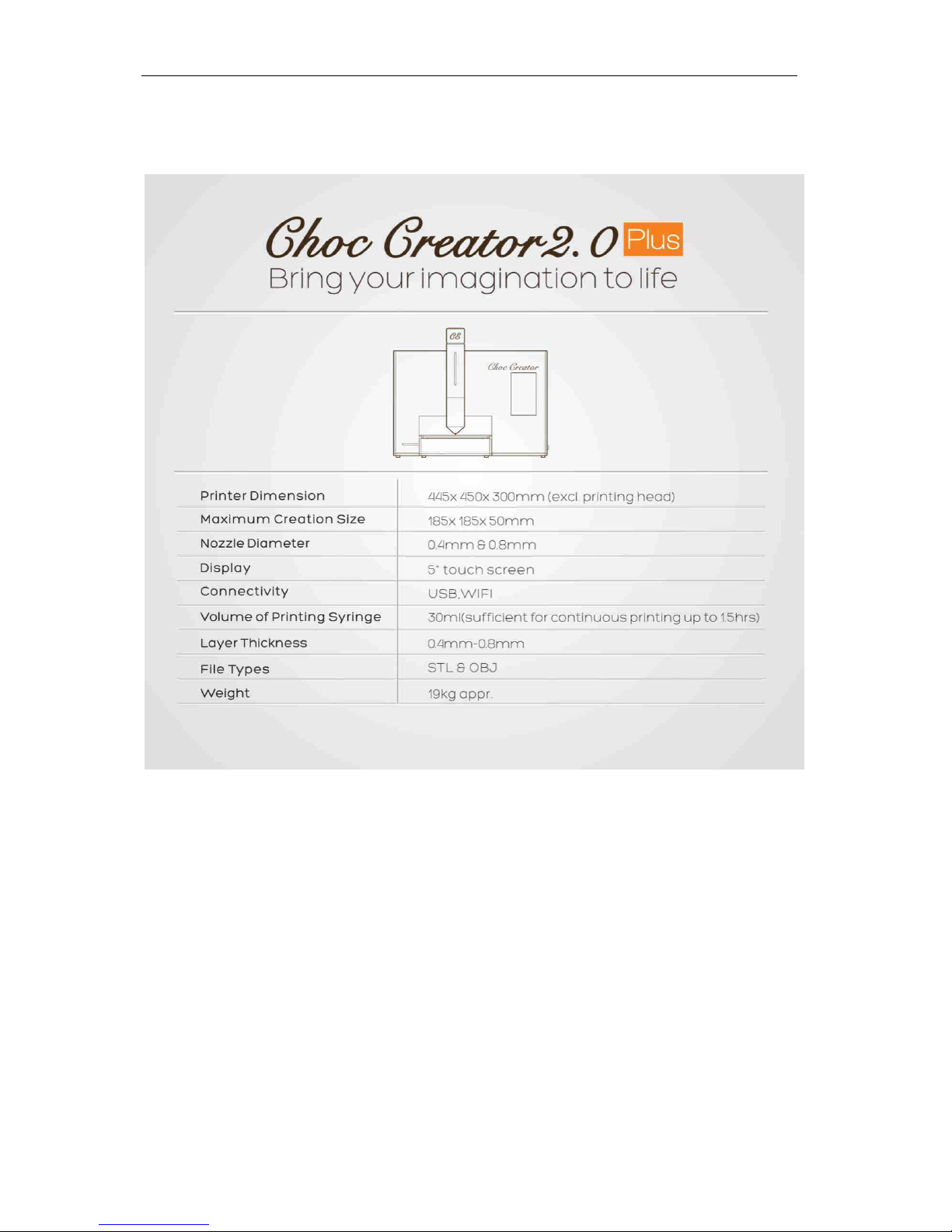

1.2. Product Specifications

Choc Edge

5

Part 2 Melting Chocolate

The process of melting chocolate is critical to the entire process of chocolate printing

as it affects the quality of the printed result.

2.1. Melting Process

Specifications of suggested Melting Pot equipment:

Rated Voltage: Both low and high voltage units available / Weight: 3kg / Chocolate Capacity: 2.5kg

Recommended chocolate: CALLEBAUT 811NV : Recommended for the UK, Europe, USA, etc

CALLEBAUT 2815NV : Recommended for Asia Pacific (See image below)

2.1.1 Prepare the melting pot, chocolate callets, and stirrer.

Note: The amount of chocolate callets required will depend on the situation, but approximately

one fifth of a pot of chocolate callets should be adequate. Be sure to cover the pot with the

lid to maintain the temperature. In an exhibition situation the chocolate beans may need to

be melted quickly due to time restraints. (This can be done by raising the temperature up to

70°C for a short period of time and then lowering the temperature down to 32°C.)

CHOCOLAIERE Melting Pot

811NV (Cocoa Solid % may vary)

2815NV (Cocoa Solid % may vary)

Choc Edge

6

2.1.2 Switch on the Melting Pot appliance and set the temperature between 45-50°C. Pour the

chocolate callets into the pot. (See Figure 2.1.2 below)

2.1.3 Heat the chocolate for a few minutes while stirring intermittently, and lower the

temperature to 32°C when all the chocolate callets have melted. Immediately after lowering

the temperature, add a small amount of fresh chocolate callets and stir the mixture well in

order to ensure the chocolate is evenly heated. The chocolate is ready to use when it is

completely smooth. (See Figure 2.1.3 below)

2.1.4 Attach the green nozzle from the provided tool box onto the end of the syringe, making sure

that the syringe piston is all the way down and there is no air inside the syringe. Start slowly

loading the melted chocolate into the syringe at a slow and steady pace. Try not to let any

air get into the syringe. (See Figure 2.1.4 below)

Note: Try not to let any air get into the syringe when loading as this will affect the printing quality.

During the loading process, a squeaking noiseindicates that air is getting into the syringe, so the

piston should be gently pushed down until a small amount of chocolate is purged to help remove

the air. After successfully removing any air, loading can continue. Hold the syringe facing

downwards after the loading process and gently push the piston until chocolate starts coming out

–This is to make sure there is no air in the tip of the syringe. Wipe off any excess chocolate.

Figure 2.1.2

Figure 2.1.3

Choc Edge

7

2.1.5 Exchange the green nozzle with a metal nozzle and prepare to install the syringe in the

printer. (See Figure 2.1.5 below) (See Figure 2.1.5.2 below for syringe details)

Important: You should regularly examine your nozzles. If you should damage your nozzles (or you are

unsure of their strength, shape and integrity) do not use them –Replace them.

Figure 2.1.5

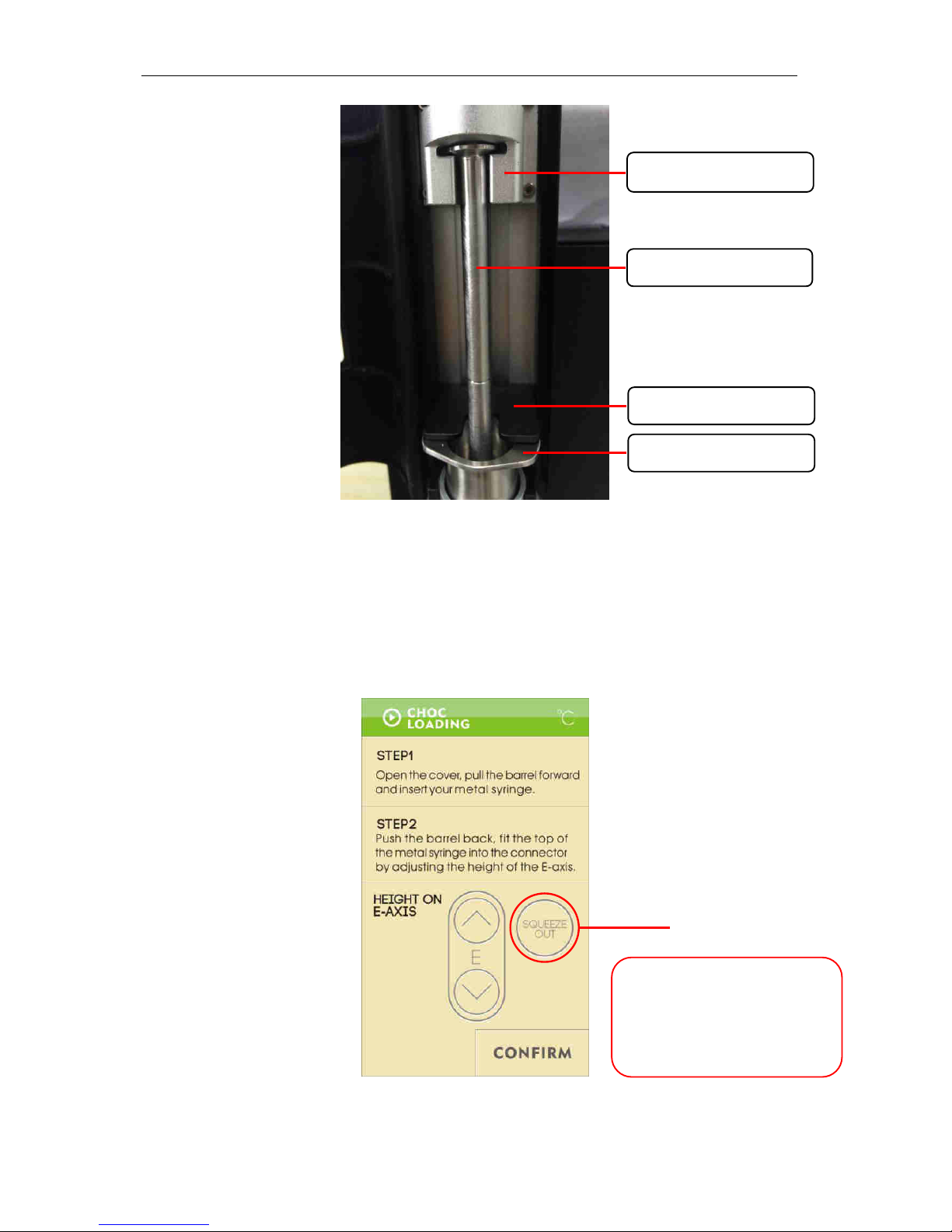

①Nozzle Plunger 30ML Mark 15ML Mark Piston O-shape Ring Syringe

Additional: The top part of the Syringe (with the finger grip) is referred to as the Flange.

Figure 2.1.4

Figure 2.1.5.2

Choc Edge

8

2.2 Please Note

2.2.1 The amount of chocolate put into the pot during the first step of the melting process

determines how long the process will take. If you want to speed up the melting process use

less chocolate and increase the temperature while stirring frequently. After adding fresh

callets to the melted chocolate, stir continuously. By following the steps above the melting

process will be relatively shortened.

2.2.2 Before loading a syringe, the chocolate needs to have completely melted with no granules

visible when stirring –any remaining granules can cause a blockage during printing.

2.2.3 In order to increase the loading efficiency and achieve the best printing quality, it is not

recommended to continuously reuse the same chocolate.

2.2.4 It is recommended that the syringe be cleaned immediately after use by using the provided

brush in the tool box. This is to prevent the rubber bung getting stuck in the syringe.

2.2.5 In order to ensure the best printing results, it is recommended to use the same or similar

chocolate (see picture above) that Choc Edge uses for printing, noting that printing results

can be affected by the varying melting temperatures of different types and brands of

chocolate.

Choc Edge

9

Part 3 Printer Operation

Note: After connecting to a power source, it is necessary to release the emergency stop

button (the large red button on the right side of the machine) otherwise the machine will

not operate.

3.1 Function Introduction

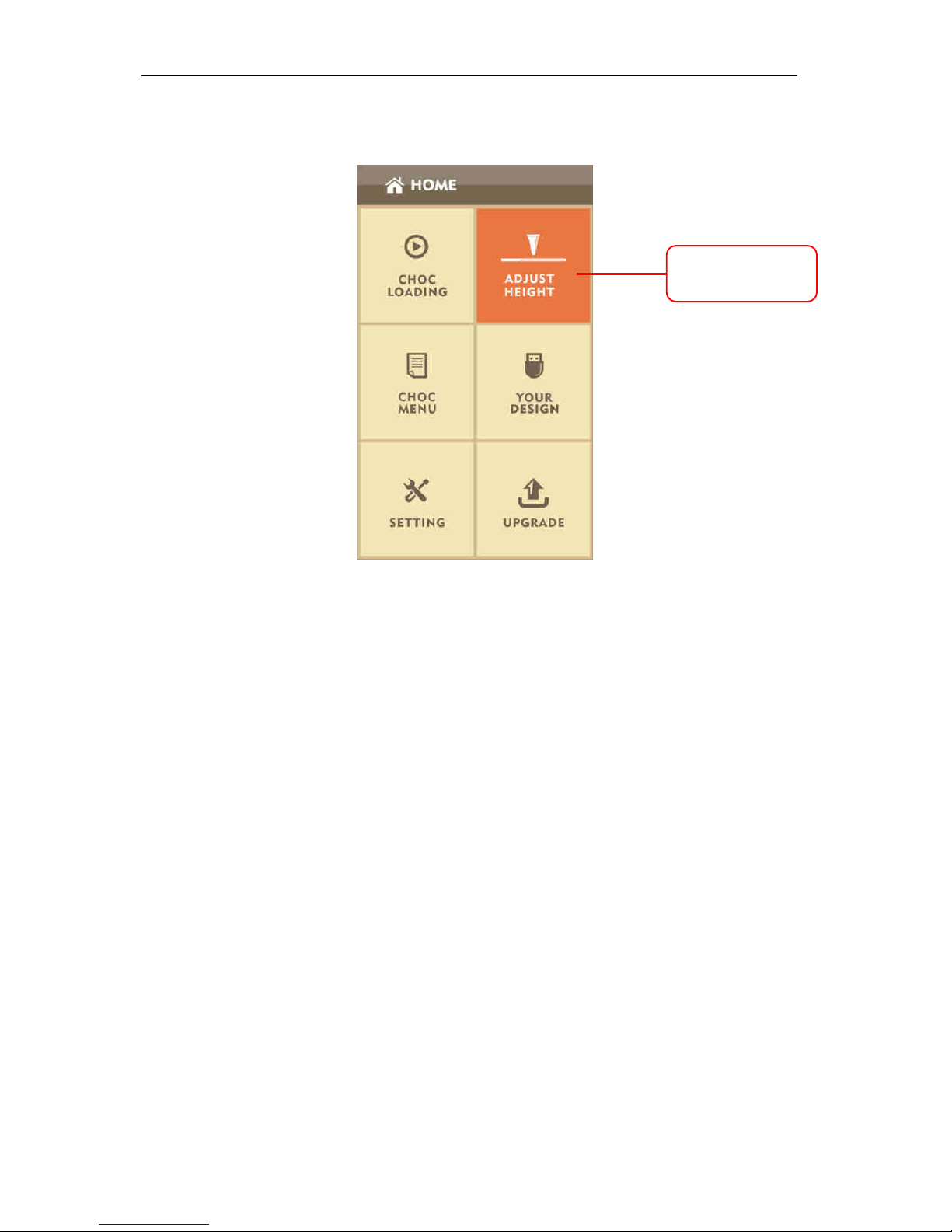

All functions can be accessed from the HOME screen. (See Figure 3.1 below)

3.2 Operating Procedure

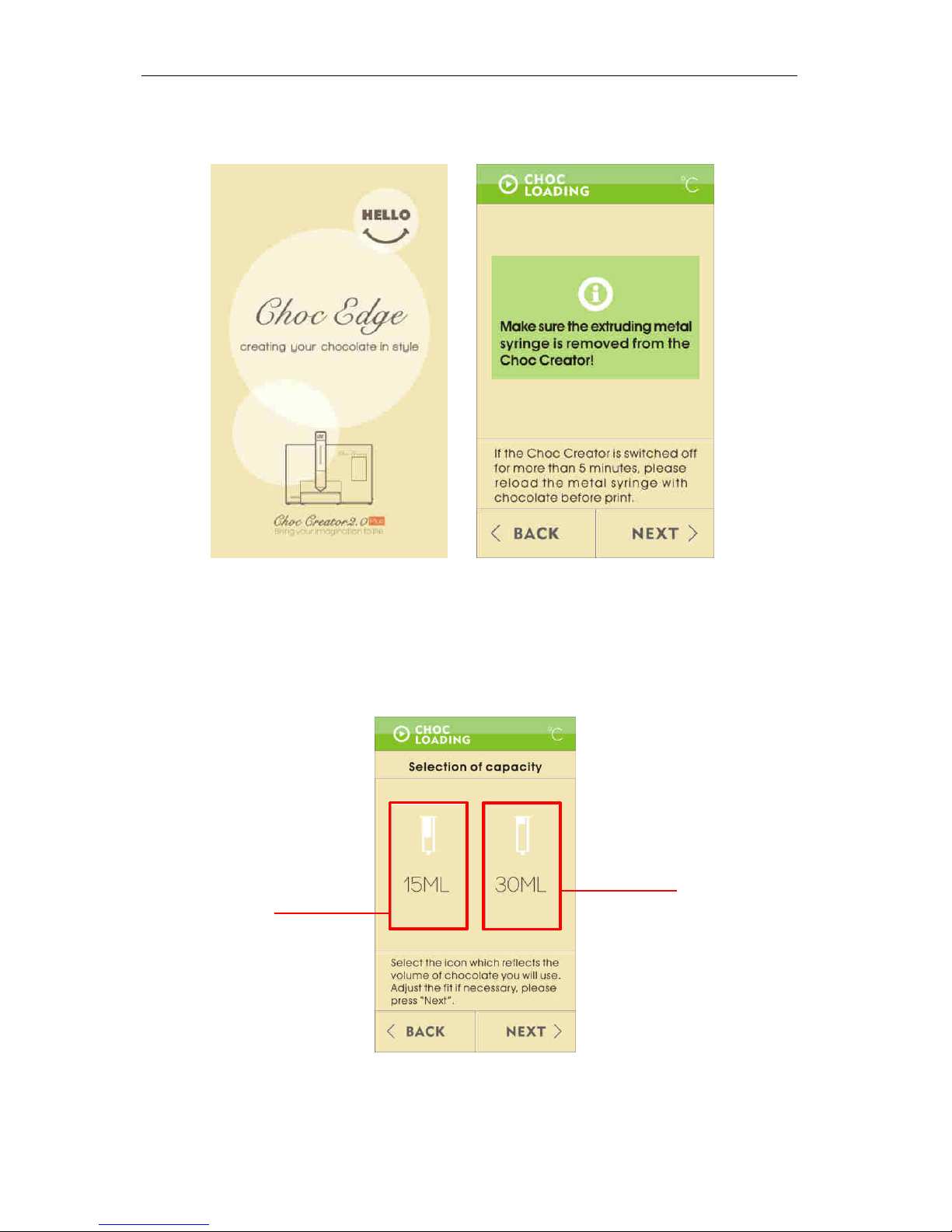

3.2.1 Upon starting up, the machine will initialize and calibrate itself. (See Figure 3.2.1 below)

Safety Note: During the calibration, the Print Head and Printing Platform will move.

Do not touch any parts of the printer during calibration and make sure there are no

foreign objects on or around the printing platform upon starting up.

Note: Make sure there is no syringe inside the print head when starting the machine.

Previously used syringes should be removed before starting the machine.

(See Figure 3.2.1.2 below)

Chocolate

Loading

Choose pre-stored

design files

Set up including:

levelling the platform,

temperature set up, and

restore to factory settings

Adjust

height

Choose files

from a USB

flashdrive

System

update

Figure 3.1

Choc Edge

10

Figure 3.2.1.2

Figure 3.2.1

Calibration will take approximately 20 seconds.

Afte the aliatio has fiished, the fist Choc Loadig screen will be displayed.

3.2.2 Press Nextto move on to the next screen.

3.2.3 Choose 15ML or 30ML depedig o the amount of chocolate in the syringe, with

30ml being maximum capacityad the pites E-axis will move and set itself to the

selected height. (See Figure 3.2.3 below)

Figure 3.2.3

Press 15 ml

for half a syringe

Press 30 ml

for a full syringe

Choc Edge

11

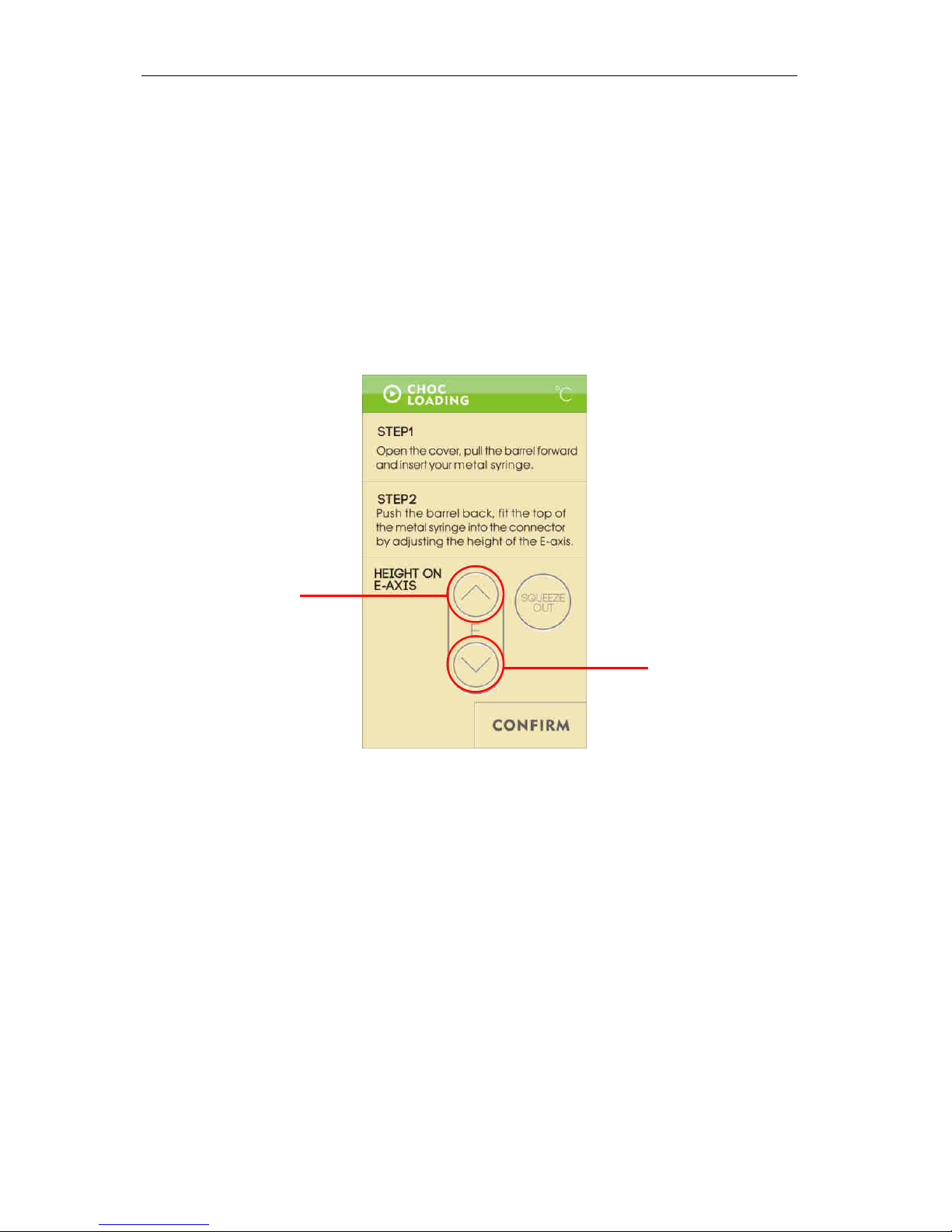

3.2.4 Press Nextto move on to the next screen.

Note: 15ml and 30ml marks can be seen on the syringe, which match with the position on

the piston rod. An adjustment to the exact amount of chocolate in the syringe can be

made on the next screen by pressing the ↑and ↓keys.

3.2.5 Open the print head cover, pull the barrel forward and insert the syringe into the barrel.

3.2.6 O the Cho Loadig see elo Figure 3.2.6), press the ↓key on the touch screen

et to Height o E-axisand the E-axis will move down.

3.2.7 Afte the E-ais eahes the desied positio, push the ael ak ito plae ad lok the top

of the sige od ito plae, adjustig the fit pessig the ↓ ke if eessa.

Press UP

to move E-axis up

Press DOWN

to move E-axis down

Figure 3.2.6

Choc Edge

12

3.2.8 Pull out the plastic cup holder and place one of the cups from the tool box into the holder.

This will collect any chocolate waste.

3.2.9 Close the print head cover and press the ↓key several times to check if the chocolate is

being successfully squeezed out or not. After the chocolate stops dripping, press Drop

Retraction Squeeze Out ad then press Confirm. “ee Figure 3.2.9 below)

Figure 3.2.9

E-axis (connector)

Flange Connector

Syringe Rod (Piston)

Figure 3.2.7

Drop Retraction

“ueeze Out

Flange (of syringe)

Dop Retatio pies the ozzle

by pushing the chocolate towards the

ozzle’s tip efoe etatig to the

value of 0.5mm.

Depending on requirements, it can be

pressed once, twice or not at all.

Choc Edge

13

3.2.10 After pessig Confirm, the screen will jump back to the home page from which you can

choose Adjust Height “ee Figure 3.2.10 below):

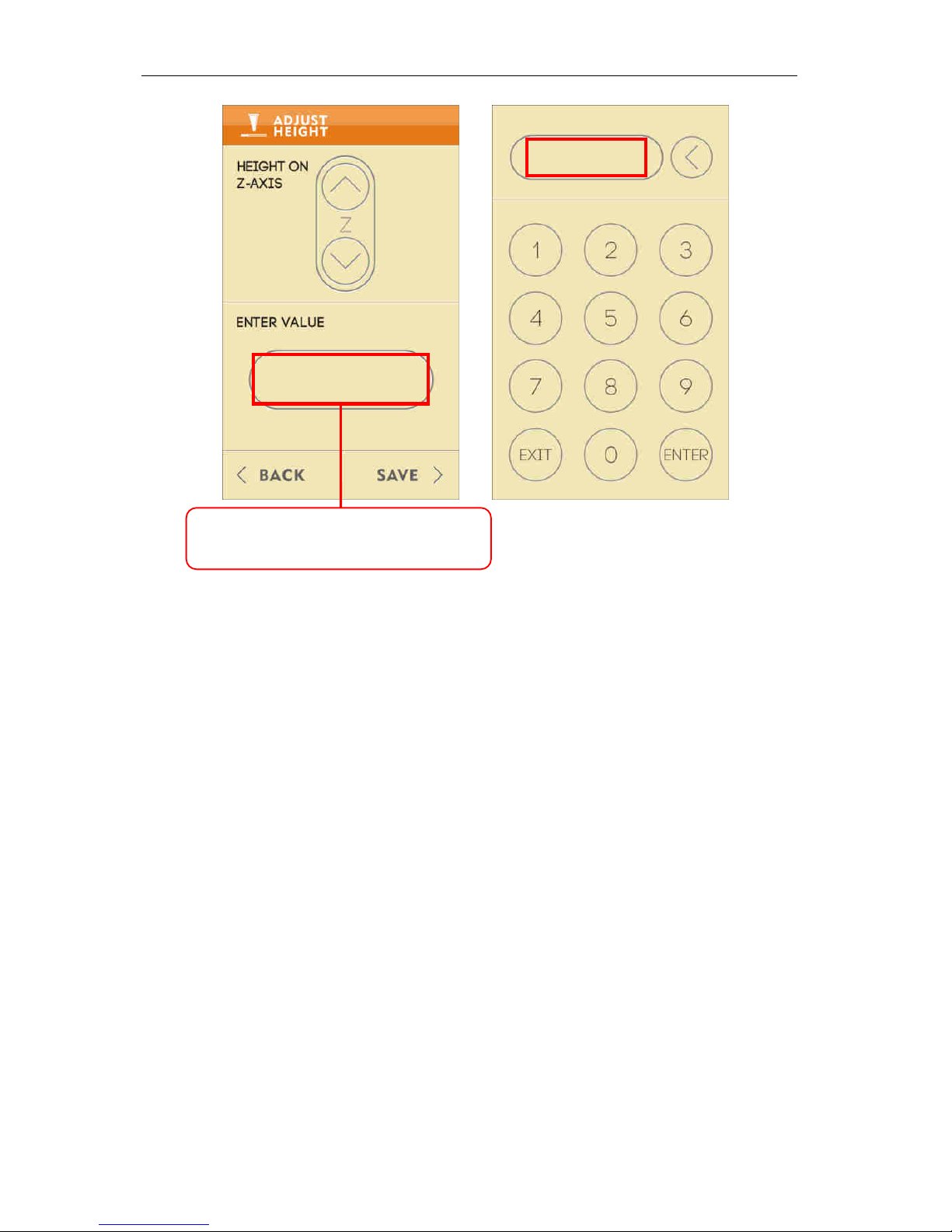

3.2.11 On the Adjust Height (of Z-Axis screen, you have two options for lowering the Z-axis.

(See Figure 3.2.11 below)

Option 1: Continuously press the ↓key until the Z-axis reaches the value of 40.

From there, you can gently tap the ↓key to fine tune to (e.g.) 42.

This option may be more suitable for first time users.

Option 2: Pess the Ete Value utto oe to ete the ueial pad see.

(See Figure 3.2.11.2 below)

Enter the value of 40 into the numerical window.

Note: For Option 2, a value of no more than 40 can be entered at this time.

This is to prevent novice users from lowering the nozzle too close to the

printing platform. Fine tuning to (e.g.) 42 can still be done after the Z-axis

has moved down into the position of 40.

Adjust the height

of the E-Axis

Figure 3.2.10

Choc Edge

14

3.2.12 On the next screen, press the ↑ or ↓keys until the gap between nozzle and printing

platform is approximately 2mm, which is a suitable starting height when using a 0.8mm

nozzle. If 2mm appears to be too high for your design, try 1.5mm. [ Hint: A food-safe metallic

disc from the tool box can be used as a height guide - The disc is 0.5mm thick, so your nozzle should

be positioned approximately 1.5mm above this disc. If your nozzle touches the disc or is close to it,

your nozzle is too low; Raise the nozzle up by 1mm or more. ]

Once the desired height is set, press Save.

3.2.13 After setting the height, the screen will jump back to the home page automatically.

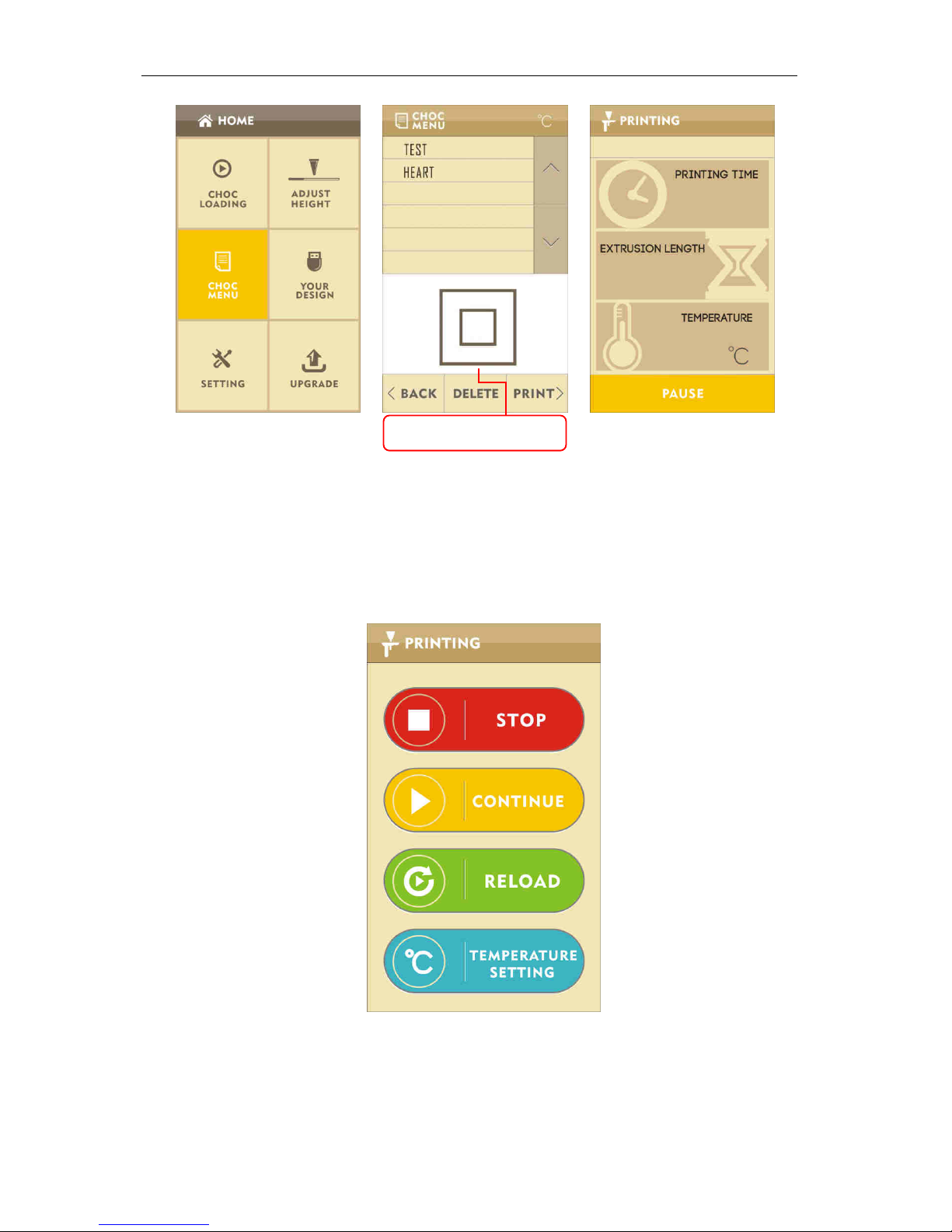

From here, choose Pre-stored design files, select one of the 12 printing files and press

Print to start the machine printing. (See Figure 3.2.13 below)

4 0

Press ENTER VALUE to manually key in a

specific value using the numerical pad

Figure 3.2.11

Figure 3.2.11.2

Choc Edge

15

Figure 3.2.13

B pessig Pause, Stop, Continue, Reloadand Temperature Settingfunctions can be

selected. (See Figure 3.2.13.2 below).

Figure 3.2.13.2

The Reloadprocess is that which has been introduced above in article 2.1.4.

Pre-stored designs

Choc Edge

16

3.2.14 On the HOME screen, the design files saved onto a USB flash drive can be printed by

seletig YOU‘ DE“IGN. “ee Figure 3.2.14 below)

Figure 3.2.14

3.2.15 If you want to move a file from a USB flash drive to the printers iteal eo,

press Saveand the Confirm. The files will be automatically saved in CHOC MENU as

pre-stored files.(See Figure 3.2.15 below)

Figure 3.2.15

Choc Edge

17

Note: If the files on the USB are imported as pre-stored design files, the files can no longer be

edited.

3.2.16 If the name of an imported file is the same as that of a pre-stored file, you will be asked

whether or not you would like to Replace the file. Choose Confirm to replace the

file or Back to cancel the import and rename the file to import again.

(See Figure 3.2.16 below)

3.2.17 If the printing file exceeds the printing size, you will be prompted that the File exceeds

printing size, in which case you can choose Retry to try again or press Backto

return to the last screen. (See Figure 3.2.17 below)

Figure 3.2.17

Figure 3.2.16

Choc Edge

18

3.2.18 When files cannot be recognized by the machine, a File eo notification will appear on

see. A Data errorprompt means that the file you are using has been corrupted. You can

pess Retryto try again or go back to the last screen. (See Figure 3.2.18 below)

3.2.19 If the system needs to be updated, you can do so by pressing System update, selecting the

update file from a USB flash drive and pessig Confirm. The system will be updated within

a few minutes. (All users will be notified if their system requires an update.)

(See Figure 3.2.19 below)

Figure 3.2.19

Figure 3.2.18

Choc Edge

19

3.3 Note

3.3.1 Before using your Choc Creator for the first time, please check the printing platform is level

to make sure it has not been affected by shipping of the machine. If the platform appears to

need adjustment, refer to the video on the provided USB flash drive.

3.3.2 Clean the syringe after every use in order to avoid the rubber bung sticking inside the

syringe. If it does stick, put the entire syringe into a bowl of hot water (°C) for a few minutes

and pull the rubber bung out with a pair of tweezers. When the rubber bung wears out, it

can be replaced with the spare that is provided in the tool box.

3.3.3 Eletiit euieet: The opeatig oltage of the Cho Ceatos poe adapte is

between 100-240V. An unstable voltage or exceeding the range of the operating voltage can

damage the power adapter. A damaged power adapter will not light up when plugged in.

3.3.4 Before printing, put a piece of paper on the platform and fasten it in place using the four

magnets from the tool box. Displacement of the paper will affect the quality of printing.

Additionally, try to avoid placing the magnets close to the metallic nozzle. Placing the four

magnets on all four corners of the paper is the best option.

3.3.5 When printing for the first time, test the machine by printing a square. A Test Square file is

included as one of the pre-loaded design files. (see Figure 3.3.5 below)

Figure 3.3.5 (Actual photographs)

Choc Edge

20

3.3.6 If the room temperature is cold (lower than 8°C), the machine will need to be run

continuously in order to stop the chocolate from solidifying in the nozzle. Use the dredge

needle in the tool box to unblock the nozzle if the chocolate has solidified inside it.

3.3.7 If ou istakel go to the Loadig page afte opletig a pit ad ould like to pit

aothe, pess Next tie skippig the poess of hoosig 5l o 3l ad pess

Confirm. Please ote that the height of the pit head eeds to e set agai afte doig

this. (Adjusting procedure refers to the 3.2 Operating Procedure).

3.3.8 When printing files other than the pre-stored files, import the 3D model (STL or OBJ format)

and use the Cho Pit softae poided o the U“B flash die to geeate G-code files

on a computer. G-code files can then be printed either by connecting the computer to the

printer, or by placing them onto a USB flash drive. When using a USB flash drive, plug the

U“B flash die ito the pite ad pess U“B files. Choose the file ou at to pit ad

pess Print. If ou at to sae the file to the pites iteal eo, pess Import

ad Confirm, ad the file ill e autoatiall saed i Pe-stoed files.

3.3.9 If the sste eeds to e updated, pess “oftae Update, hoose the update file ad

pess Confirm. Custoes ill e ifoed Cho Edge if thei sste euies

updating).

3.3.10 If anything unusual occurs during printing, press the emergency stop button and the

machine will stop instantly. Releasing the button does not make the machine continue

printing from where it stopped. After pressing the emergency stop button, the machine will

need to be powered off and restarted. The printer will not work until the emergency stop

button has been released. (See Figure 3.3.10 below)

Figure 3.3.10

Table of contents