2 | P a g e

Table of Contents

Specifications .............................................................................................................................................. 4

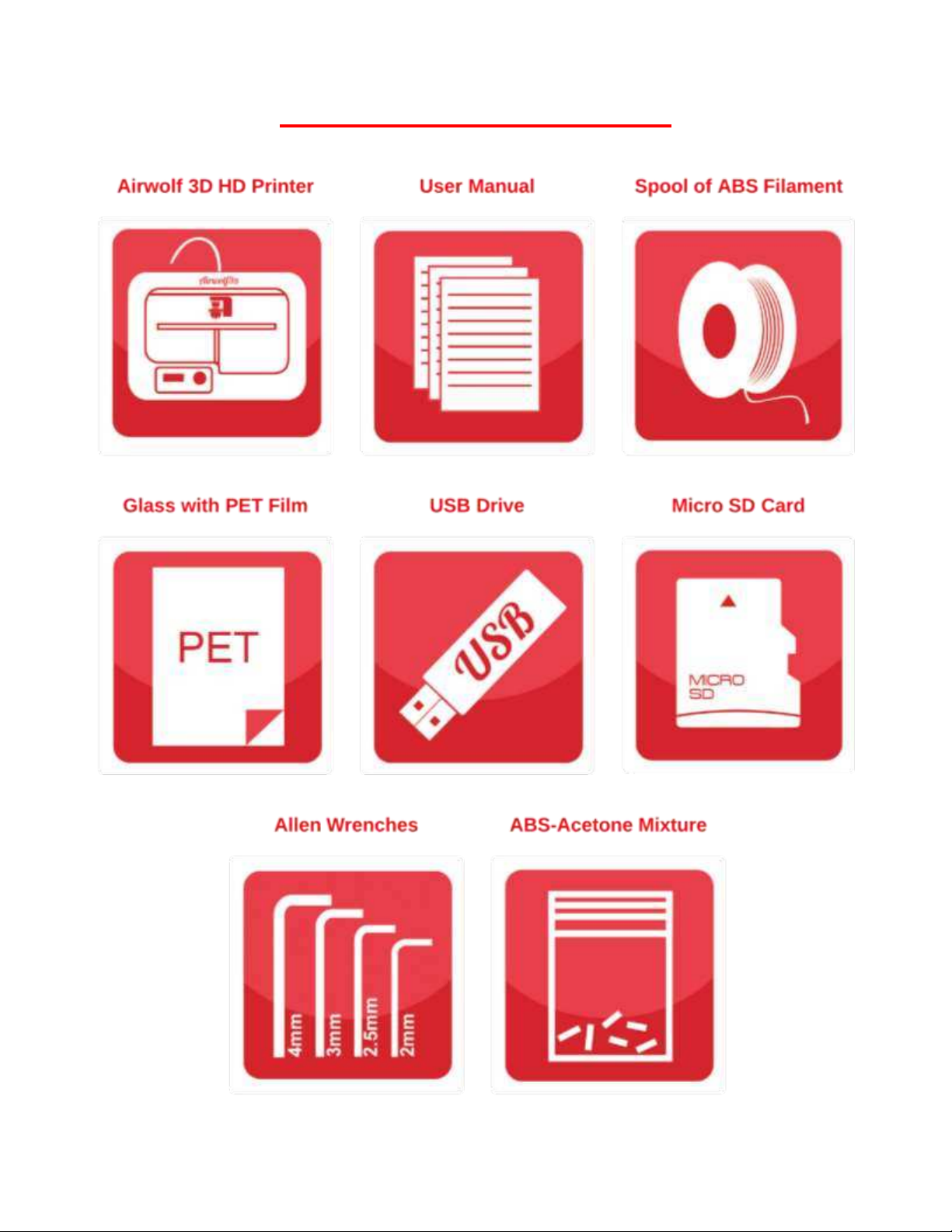

Unboxing the Printer................................................................................................................................... 5

Box Contents ........................................................................................................................................... 5

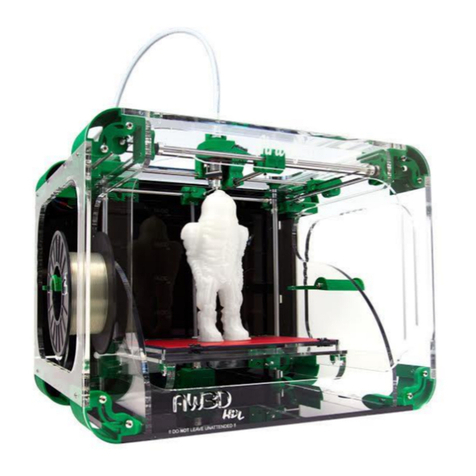

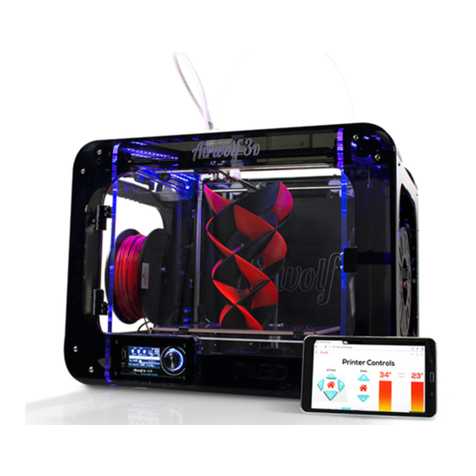

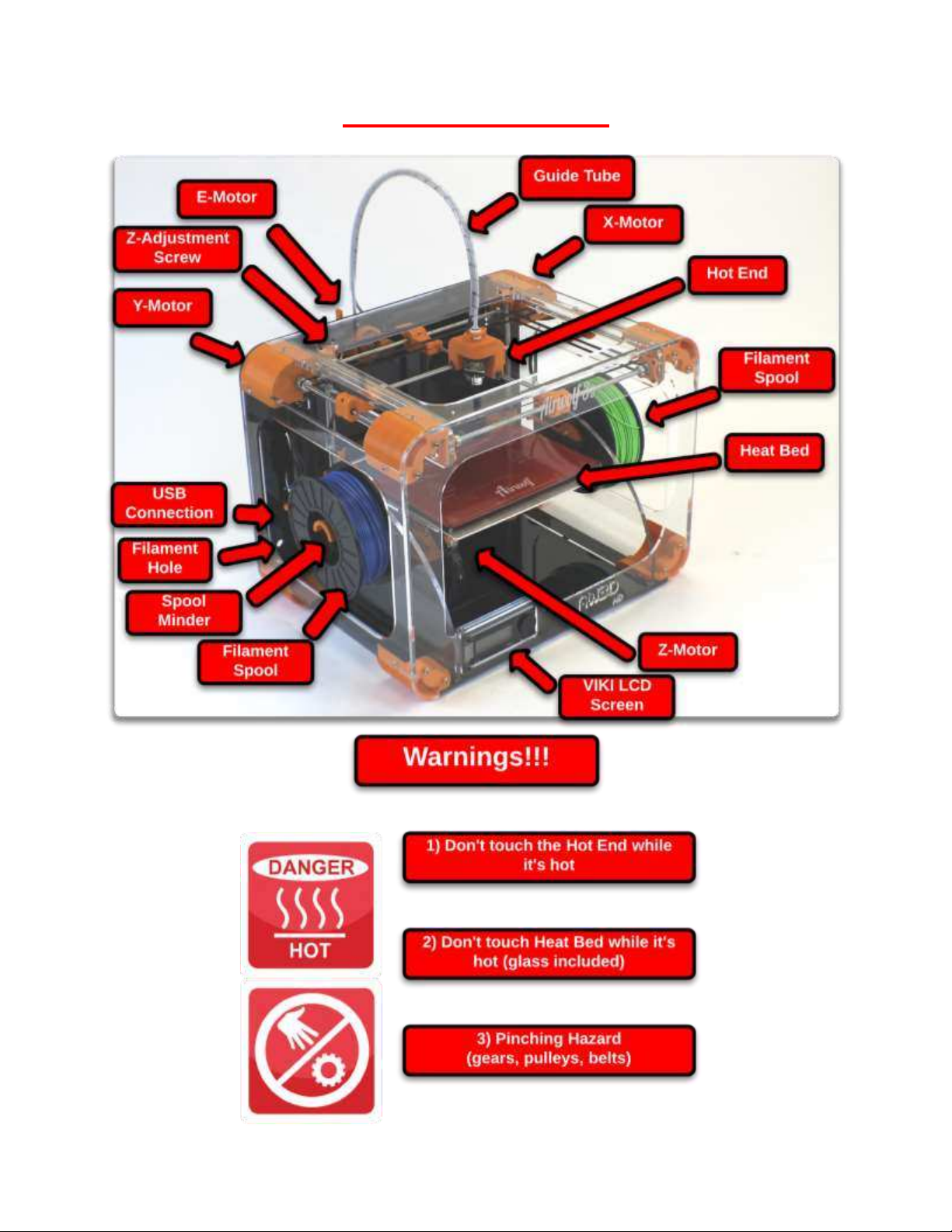

Part Directory.............................................................................................................................................. 6

How it Works............................................................................................................................................... 7

Extruder Assembly .................................................................................................................................. 7

Hot End and Heat Bed Motion ................................................................................................................ 7

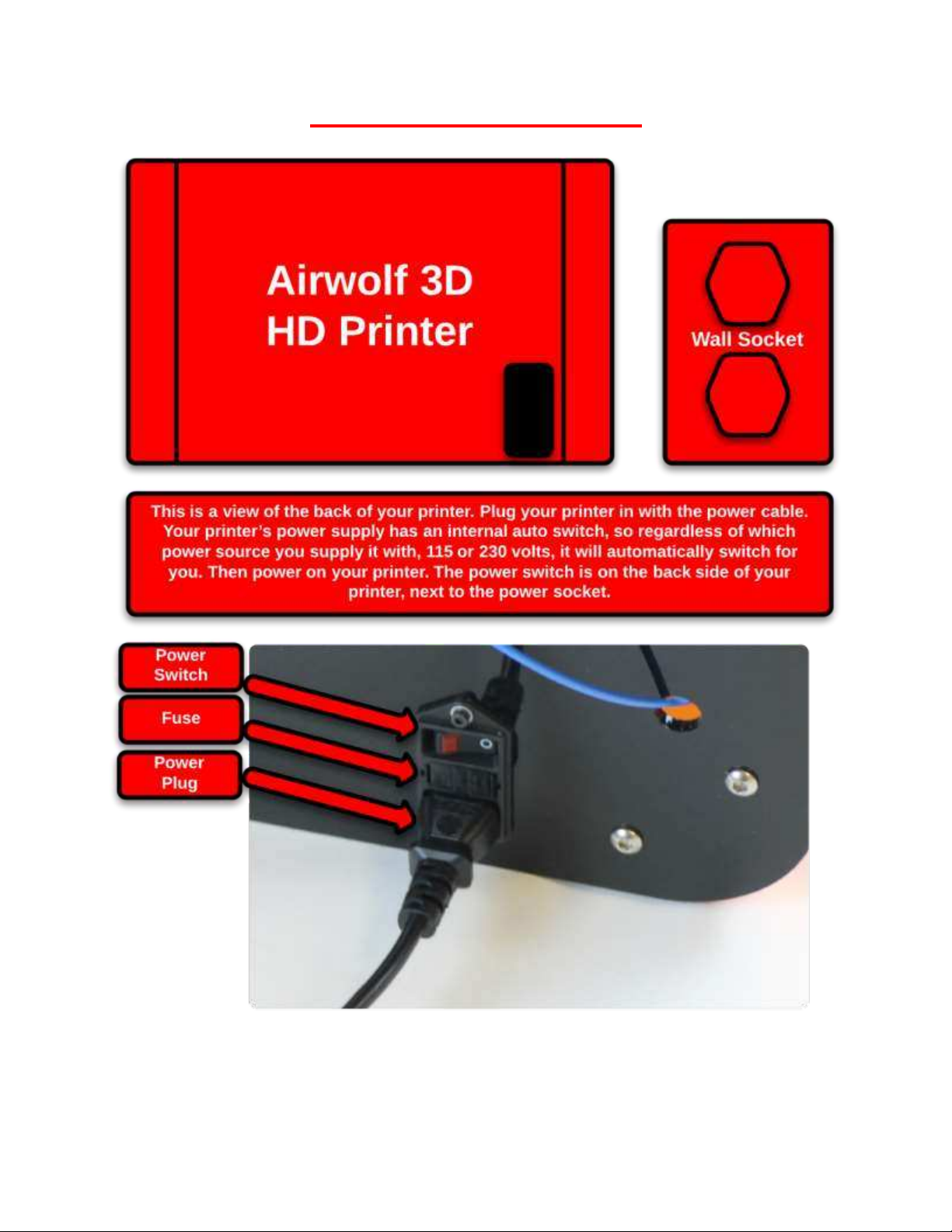

Plug In & Turn On........................................................................................................................................ 8

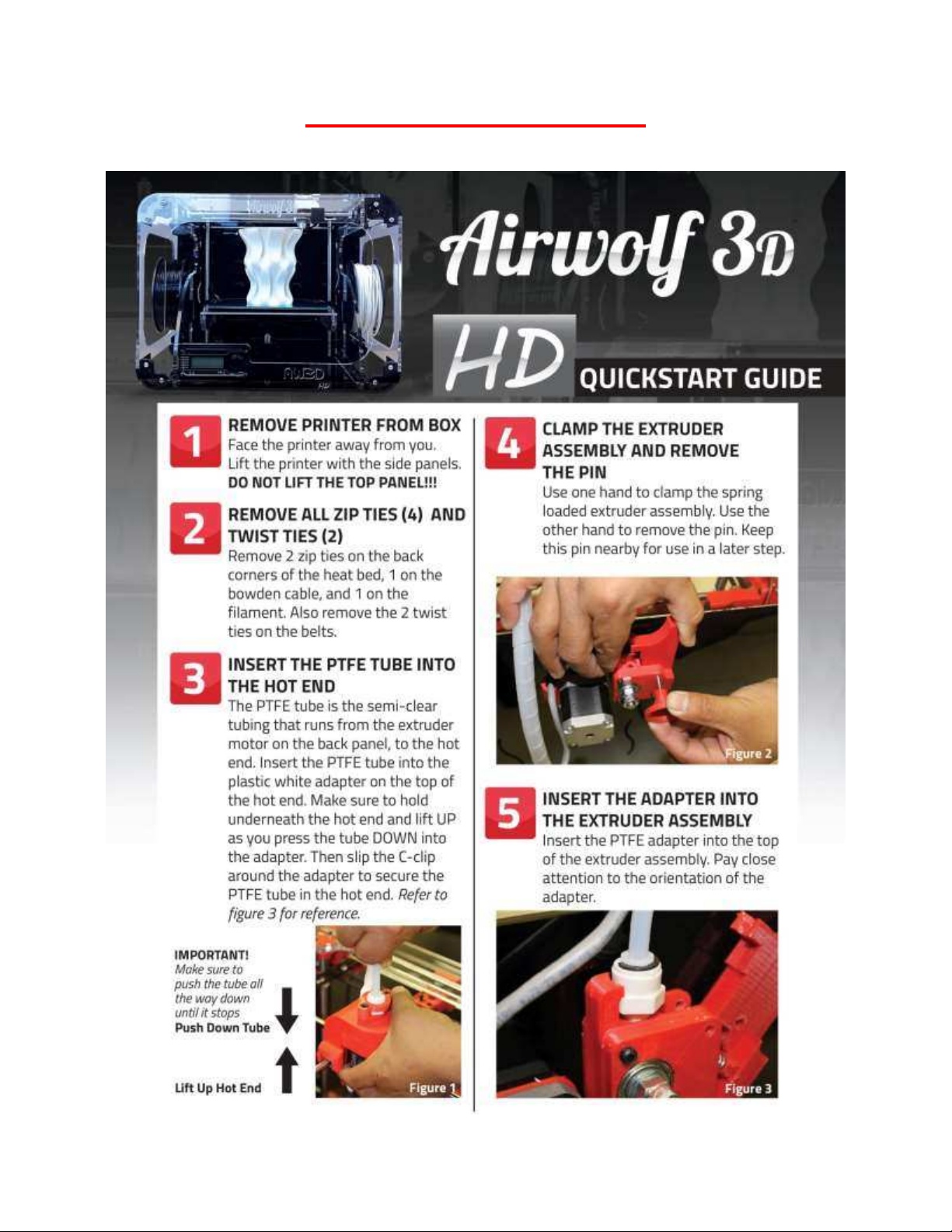

Pre-Printing Steps ....................................................................................................................................... 9

Quick Start Guide .................................................................................................................................... 9

Quick Start Guide (contd.)..................................................................................................................... 10

1) Leveling the Heat Bed ....................................................................................................................... 11

First Print & Calibration......................................................................................................................... 12

First Print & Calibration (contd.) ........................................................................................................... 13

2) Loading Filament............................................................................................................................... 14

E G O‘ GOO........................................................................................................................ 15

4) The First Layer ................................................................................................................................... 15

5) LED Lights .......................................................................................................................................... 15

VIKI LCD Screen ......................................................................................................................................... 16

VIKI: Introduction .................................................................................................................................. 16

VIKI: Home Screen................................................................................................................................. 16

VIKI: Layout............................................................................................................................................ 17

VIKI: How To .......................................................................................................................................... 18

RAMBo Driver ........................................................................................................................................... 19

Setup (Windows 8 Only)........................................................................................................................ 19

Installation (PC Only)............................................................................................................................. 20

5 Steps to Printing..................................................................................................................................... 23

1) Download or Design a 3D Model ...................................................................................................... 24

2) Convert to STL File Type.................................................................................................................... 25

3) Netfabb: Layout (STL Clean Up) ........................................................................................................ 25

3) Netfabb: How To (STL Clean Up)....................................................................................................... 26

4) Slicing ................................................................................................................................................ 27