8

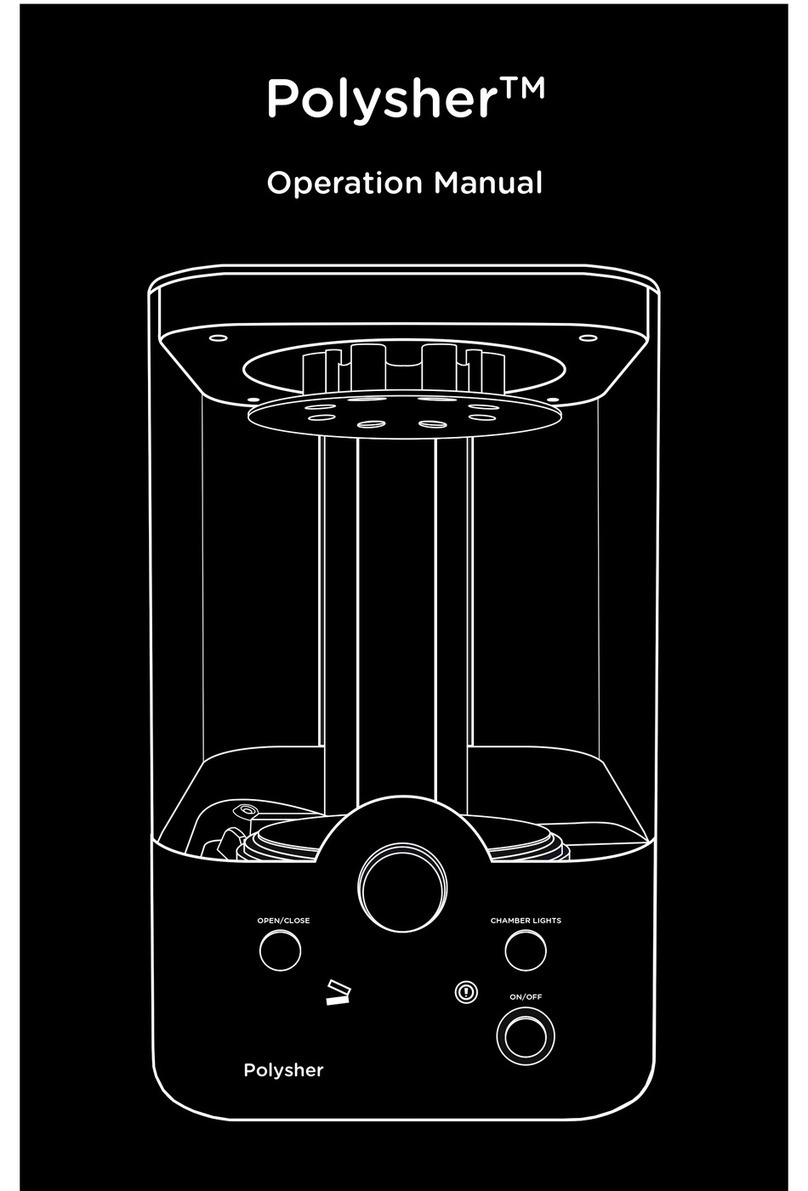

ON/OFF: Press the button to power on the PolysherTM. Long press to turn off the

PolysherTM.

OPEN/CLOSE: Push the button once to raise the platform of the PolysherTM. Press

again to lower the platform. Press again during the movement to stop the action.

Control Dial: Twist the dial clockwise to start a polishing cycle. Dial clicks in 5 minute

increments displayed by the lights above. Twist left to decrease the time or all the way

to stop the polishing cycle. Press dial in during a polishing cycle then twist left or right

to change the nebulizer light color.

Chamber Casing: Provides an air tight enclosure around the PolysherTM while giving

visibility to your part.

Nebulizer: The nebulizer cartridge is where liquid alcohol from the reservoir is

turned into a ne aerosol that polishes your printed part. Inside the cartridge is a

micromachined metal disc that vibrates hundreds of thousands of times per second. A

sponge wick conducts the liquid solvent to the disc. The nebulizer unit can be removed

by gently pulling up. To insert a replacement nebulizer, align the pins and gently press

down.

Reservoir: Collects and stores alcohol feeding the wicking sponge and nebulizer.

Reservoir Cover: Your PolysherTM comes with two reservoir covers. One for use during

operation with slots (“grate” style) to allow alcohol to ow through. The other is for use

during storage to minimize alcohol evaporation.

Turn Table/Platform: Holds your PolySmoothTM part during polishing. Turn Table

rises up with platform to give access to polished parts. To remove the platform, use the

handles on either side.

Chamber Lights: Press once to turn on the chamber lighting. Press again to turn off

the chamber lighting. Chamber lights take 1-2 seconds to fully dim, press the button

during this time to set current illumination.

Nebulizer Warning Light: Indicates a malfunction with the nebulizer, this could

mean: a bad connection between the nebulizer and port, or a broken nebulizer that

needs replacing. A polishing cycle cannot be started while this light is on. See the

Troubleshooting section of this User Manual for instructions on how to correct these

conditions.

Chamber Seal Warning Light: Indicates an air leak in the chamber. Readjust the

chamber casing to ensure that it sits properly on the PolysherTM. A polishing cycle

cannot be started while this light is on.

DC Power In: The port for the DC power cable is located on the back of the PolysherTM.

ESSENTIAL PARTS OF THE POLYSHERTM

1

2

3

4

5

6

7

8

9

10

11

12