2

GENERAL SAFETY

The improper use of hydraulic equipment is unsafe and may result in personal injury. It is important that

operators have read, understood and comply with all instructions in this user guide.

If more than one individual is involved in the operation of the equipment then all must read the operators

handbook. Good communication must be established to prevent accidents or misunderstandings.

Operators must be equipped with the following personal protective equipment (PPE):-

Eye Protection (Safety Glasses / Goggles)

Safety Footwear (Steel Toe Cap Boots)

Heavy Gloves

Impact quality sockets must be secured to the tool square drive by means of a pin and ring combination.

Care must be taken not to exceed the maximum working pressure of the equipment. See the torque chart

provided. Failure or breakup of components may result in personal injury.

Take care not to stand on, run over or trip over hydraulic hoses. Injury may result. To minimise danger

ensure that these lines are not run across walkways, ladders, roadways and doorways, etc and that people

likely to pass through the working area are aware of the danger.

To prevent entanglement with moving parts operators must not wear loose clothing, ties, jewellery etc…

Long hair must be tied back.

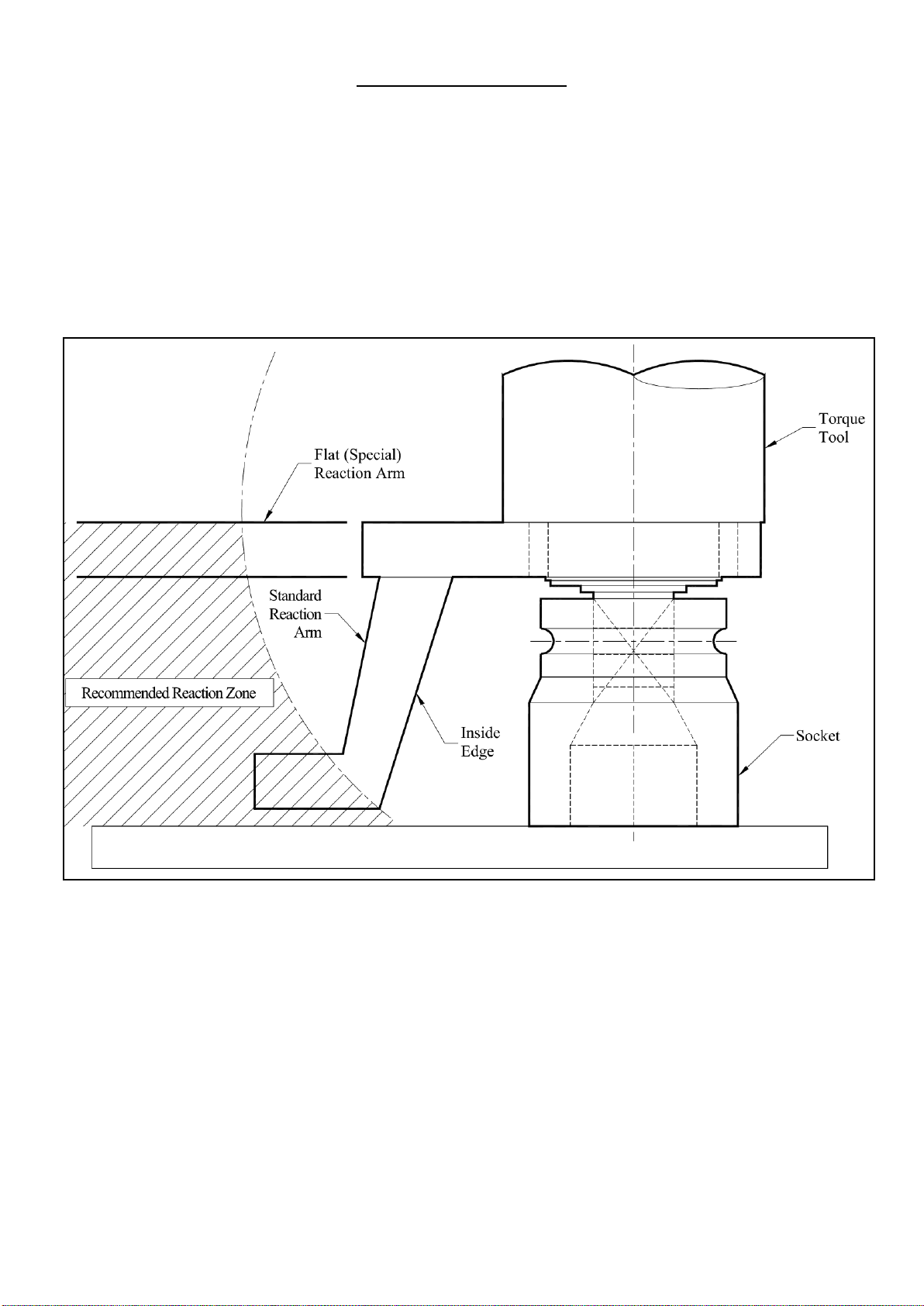

Always keep hands, fingers and body parts clear of the reaction foot at all times. Trapping in this area can

result in serious personal injury.

Before use, check the hydraulic hoses are not cut, split, kinked or damaged in any way. If in doubt Do not

use.

All hydraulic equipment and ancillary products should be inspected for damage and irregularities prior to

use. If in doubt Do not use.

Never lift or drag hoses or cables. This weakens the swagings and puts unnecessary stress on threads and

fittings. Subsequent failure may result in causing injury.

The end user of this equipment should carry out their own risk assessments prior to operating.

CAUTION: ANY MODIFICATION TO THE EQUIPMENT OR CHANGE OF USE BY

ANYONE OTHER THAN W. CHRISTIE WILL INVALIDATE W. CHRISTIE

(INDUSTRIAL) LTD KEY RESPONSIBILITIES AS A MANUFACTURER &

INVALIDATE WARRANTY, UNLESS PRIOR WRITTEN CONSENT IS

RECEIVED FROM W. CHRISTIE (INDUSTRIAL) LTD.