3

2

Important Safety Instructions

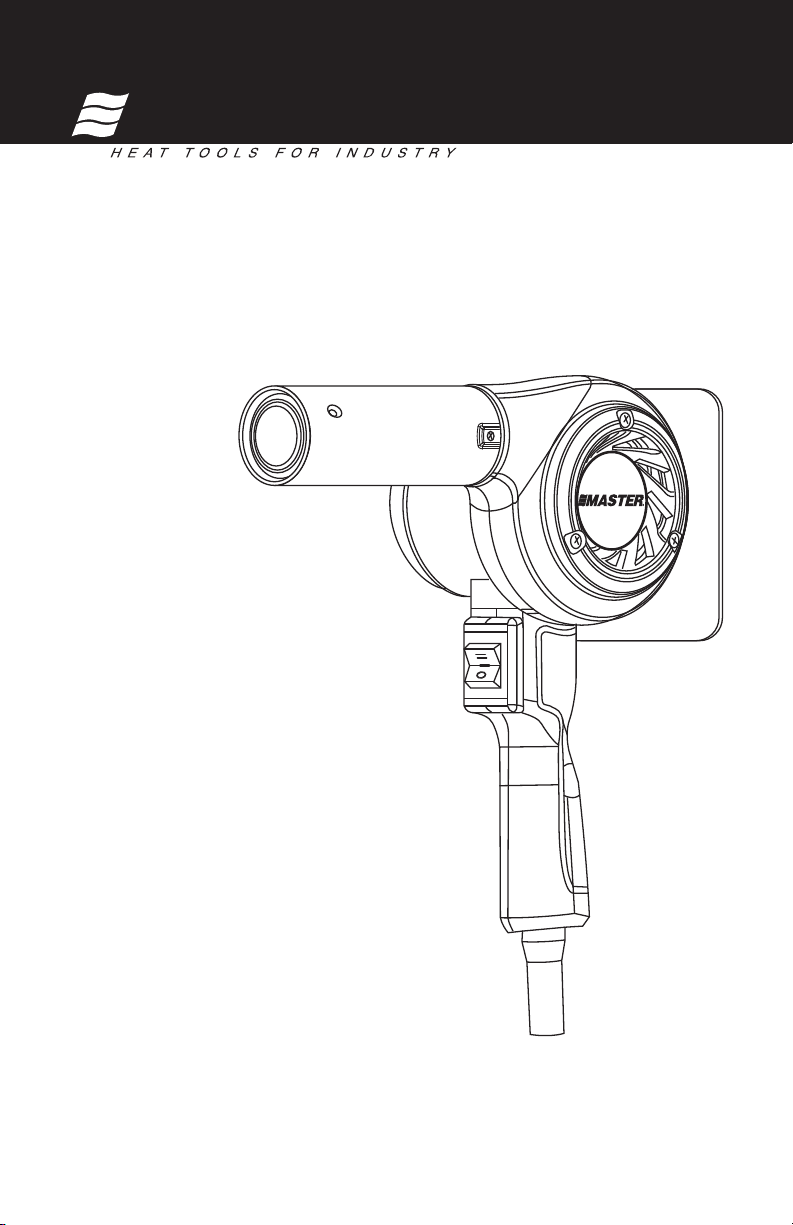

Our Master Heat Gun® and Master Varitemp® Heat Gun feature a heavy

duty, industrial quality design, with industry leading heat and airow, that

gets any job done faster.

To reduce the risk of re or explosion, electric shock and the

injury to persons, read and understand all instruction included

in this manual. Be familiar with the controls and proper usage of

equipment.

• Withaheatgun,aswithallotherheat

tools, keep a re extinguisher handy

and observe all sensible re precautions.

• Keepguninconstantmotion. Do not

stop or dwell in one spot.

• Useextremecautioniftheotherside

of the material being scraped is not

accessible, such as house siding. The

hidden side could catch re if it becomes

too hot. Some buildings contain highly

ammable materials behind siding, oors,

facia, soffit boards and other panels.

Check these areas before applying heat

and do not use a heat tool if ammable

materials are present or if you are unsure

of the hidden material.

• Donotusenearsurfaceswithcracks

or near metal pipes or ashing. Heat

may be conducted behind the work

surface and ignite hidden material. The

ignition of hidden materials may not be

readily apparent and can result in property

damage and injury.

• Donotuseelectrictoolinthe

presences of ammable liquids or

gases.

• Donotusenearcombustiblematerials

such as dry grass, leaves and paper which

can scorch and catch re.

IMPORTANT SAFETY INSTRUCTION

WARNINGThis heat gun produces

extreme high temperatures (as high as

1400ºF). It must be used with caution to

prevent combustible materials from igniting.

Indicates a hazardous situation, if not avoided could result in death or serious injury.

ImportantSafetyInformation•Readallsafetyinformationbeforeoperating

equipment. Save these instructions.

ImportantSafetyInformation•Readallsafetyinformationbeforeoperating

equipment. Save these instructions

• Thenozzlebecomesveryhot. Do not

lay the heat gun on ammable surfaces

when operating the gun or immediately

after shutting the gun off. Always set the

heat gun on a at surface so that the

nozzle tip is directed upward and away

from the supporting surface.

• Donottouchthenozzle until the tool has

cooled.

• Donotusethegunasahairdryer.

• Toolsandpaintscrapingsbecomevery

hot. To avoid burns, use work gloves

when scraping.

• Alwaystreatthehotairunitswiththe

same respect as an open ame.

• Donotworkinwetareasorexposethe

heat gun to rain.

• Guardagainstelectricshockby

preventing body contact with grounded

surfaces such as pipes, radiators, ranges,

aluminum ladders or other grounded

devices.

• Donotabusetheelectriccord. Never

carry the heat gun by the cord or yank on

the cord to disconnect it from the power

supply. Keep the electric cord away from

heat, oil and sharp edges.

• Useextensioncordsratedforoutdoor

use. If an extension cord is damaged or

otherwise unsuitable for use, replace it

with a new cord.

• Disconnectheatgunfrompower

supply when not in use. Store indoors in

a dry place and out of reach of children.

• Keepworkareawelllightedandclean.

• Donotoverreach,especiallywhen

working on ladders. Keep proper footing

and balance at all times. Be certain

ladders being used are sturdy, stable and

on a rm surface and erected at a safe

working angles.

• Avoidpowerlines

• Keepmovableitemssecureandsteady

while scraping.

• Alwaysuseprotectiveeyewearwhen

working.

PERSONSREMOVINGPAINTSHOULD

FOLLOWTHESEGUIDELINES:

WARNING Extreme care should

be taken when stripping paint. The

peelings, residue and vapors of paint

may contain lead, which is poisonous.

Any paint applied before 1950 is likely

to contain lead. Any paint manufactured

before 1977 may contain lead. Once

the paint is deposited on the surface,

hand-to-mouth contact can result in the

ingestion of lead. Exposure to even

low levels of lead can cause irreversible

brain and nervous system damage.

Young unborn children are particularly

vulnerable to lead poisoning.

Before beginning any paint removal

process, you should determine whether

the paint you are removing contains

lead. This can be done by your local

health department or by a professional

who uses a paint analyzer to check the

lead content of the paint to be removed.

LEAD-BASEDPAINTSHOULDONLY

BEREMOVEDBYAPROFESSIONAL

ANDSHOULDNOTBEREMOVED

USINGAHEATGUN.

WARNING This product when used

for soldering and similar application, can

expose you to LEAD, which is known to

the State of California to cause cancer

and birth defects and other reproductive

harm.

• Stayalertandusecommonsense

when operating any tools.

• Usecautionwhenoperatingthehot

air gun. Keep the hot air gun moving as

excessive heat will generate fumes which

can be inhaled by the operator.

• Keepfoodanddrinkoutofthework

area. Wash hands, arms and face and

rinse mouth before eating or drinking. Do

not smoke or chew gum or tobacco in the

work area.

• Movetheworkpieceoutdoors.If this

is not possible, keep the work area well

ventilated. Open the windows and put an

exhaust fan in one of them. Be sure the

fan is moving the air from inside to outside.

• Removeorcoveranycarpets,rugs,

furniture, clothing, cooking utensils and

air ducts.

• Placedropclothsintheworkareato

catch any paint chips or peelings. Wear

protective clothing such as extra work

shirts, overalls and hats.

• Workinoneroomatatime.Furnishings

should be removed or placed in the center

of the room and covered. Work areas

should be sealed off from the rest of the

dwelling by sealing doorways with drop

cloths.

• Children,pregnantorpotentially

pregnant women and nursing mothers

should not be present in the work area

until the work is done and all cleanup is

complete.

• Wearadustrespiratororaduallter

(dust and fume) respirator mask which

has been approved by the Occupational

Safety and Health Administration (OSHA),

the National Institute of Safety and Health

(NIOSH), or the United States Bureau

of Mines. These masks and replaceable

lters are readily available at major

hardware stores. Be sure the mask ts.

Beards and facial hair may keep masks

from sealing properly. Change lters often.

DISPOSABLEPAPERMASKSARENOT

ADEQUATE.