8

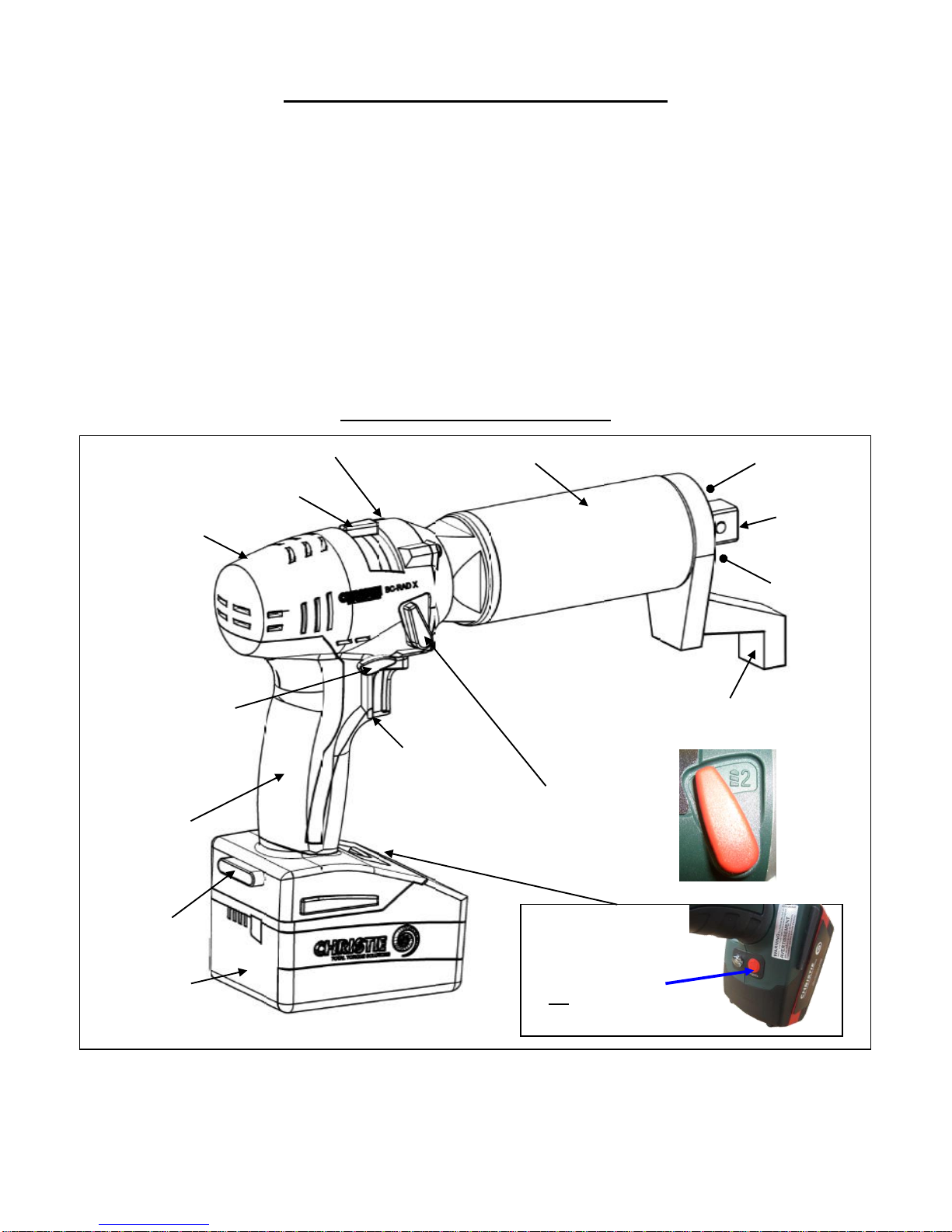

OPERATING THE WRENCH

1) Fit the wrench with the correct size impact socket to suit the bolt to be tightened and retain with ring

and pin system

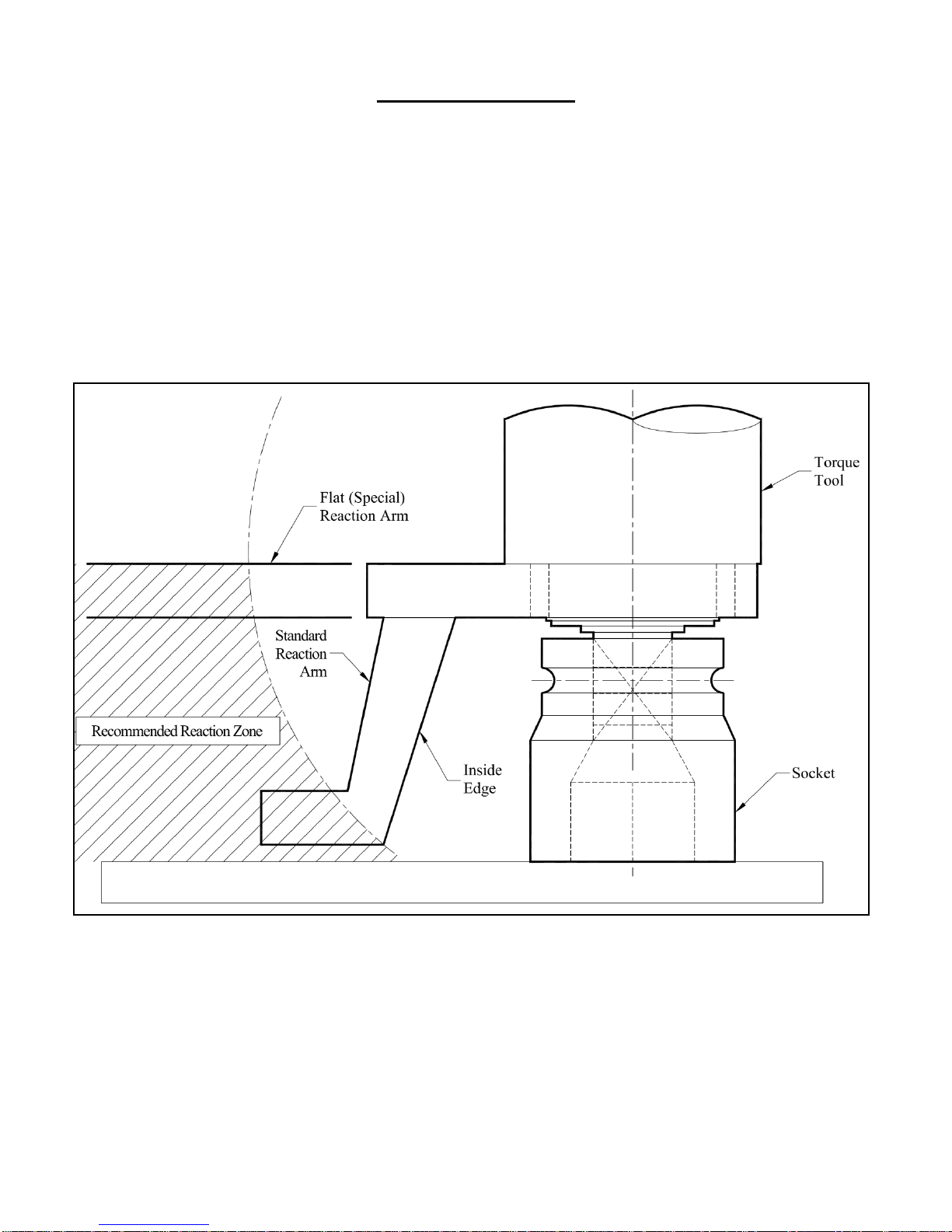

2) Rotate the handle to convenient position relative to the reaction arm.

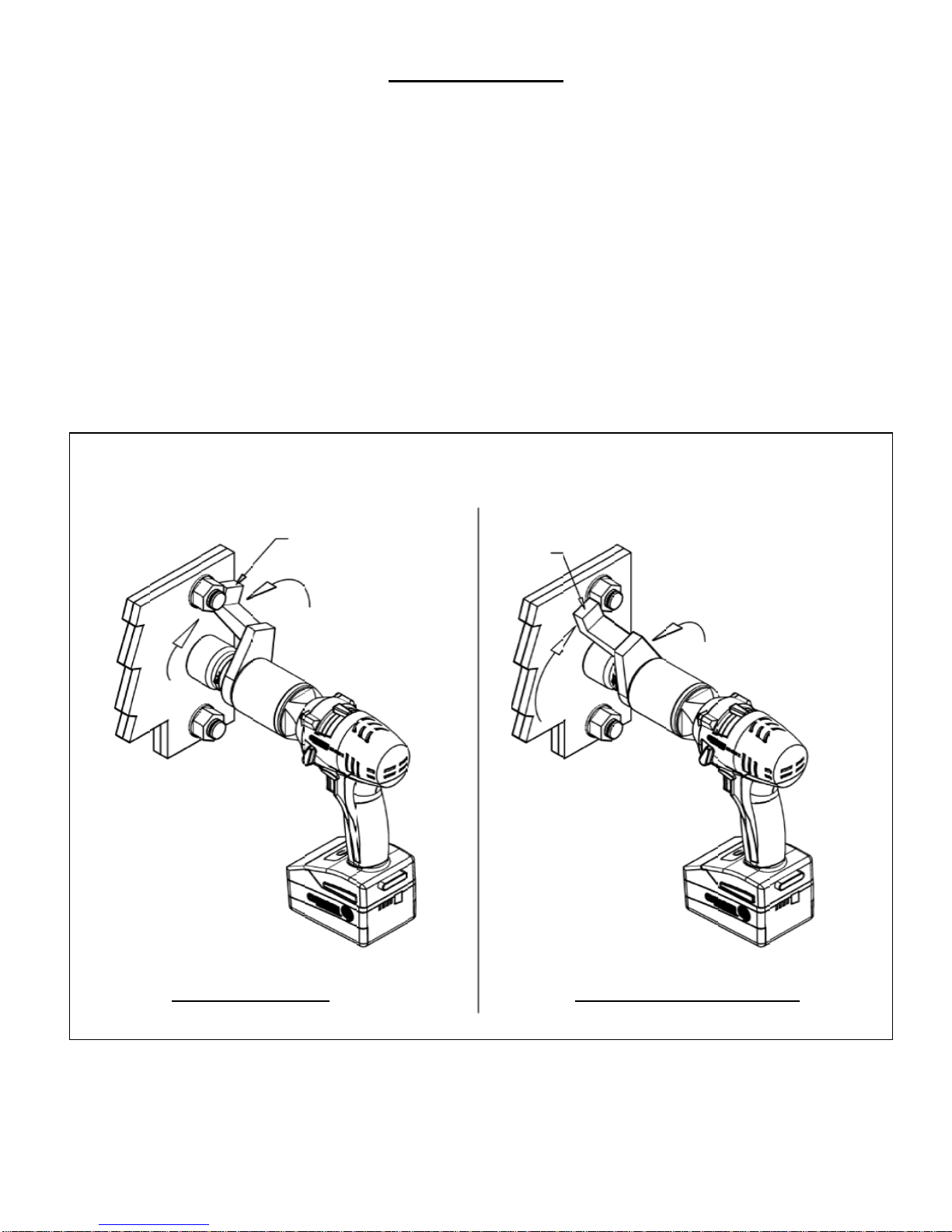

3) Fit the tool onto the bolt to be tightened / un-tightened with the reaction arm adjacent to the reaction

point (See “Torque Reaction” Section)

4) Move the Direction Selector Switch (D) from the neutral position and into either forward or reverse

as required.

5) Squeeze the Trigger (C) to bring the reaction arm into contact with the reaction point.

6) Fully press the Trigger (C) and keep pressed until the clutch slips producing a pronounced ratcheting

sound. When this happens release the Trigger (C) Immediately. If the trigger is released before the

wrench clutch slips, full torque will not be applied to the bolt. Once the clutch slips do not “blip” the

trigger, or incorrect torque will be applied. Damage to tooling will result if the clutch is allowed to

slip for extended periods of time.

7) In use this tool must be supported at all times in order to prevent unexpected release of a fastener or

component failure.

8) If during the un-tightening process the fastener does not release, and the clutch slips continuously, a

tool of greater torque capacity must be used. Damage to tooling will result if the clutch is allowed to

slip for extended periods of time.

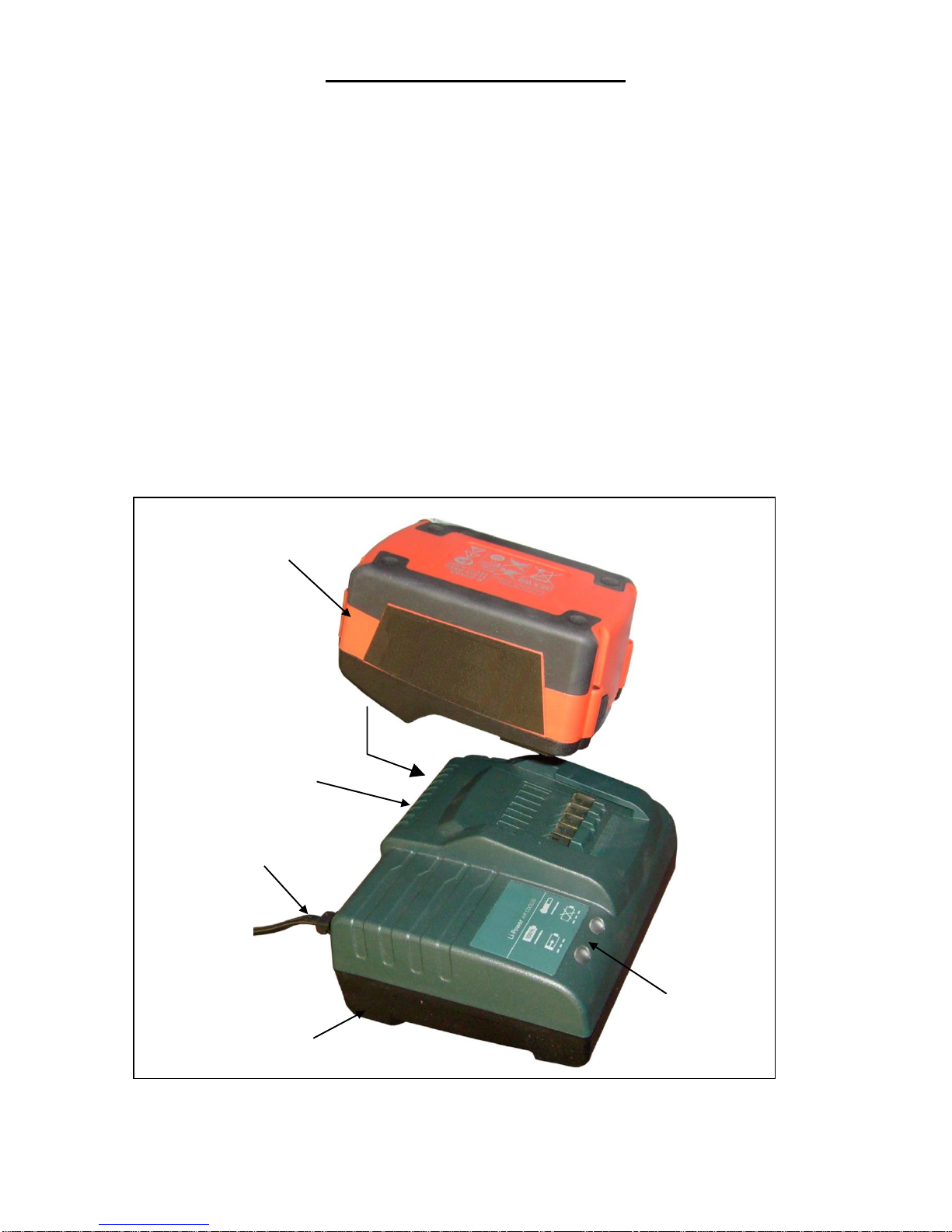

9) If during tightening or un-tightening the tool stops rotating, but no ratcheting sound is heard from the

clutch, the torque has Not been achieved. Release the trigger and replace or recharge the battery and

re-tighten the fastener(s).

10)Remove tool from bolt.

IMPORTANT: For applications of a critical nature, BC-RAD-X wrenches must be torque checked

daily.

If breakdown, malfunction or damage occurs do not attempt to repair, contact w.

Christie (Industrial) LTD immediately on +44 (0)1709 55 00 88

MAINTENANCE AND RECALIBRATION

To prevent premature failure and ensure confidence in torque supply, it is recommended that this

equipment is serviced and calibrated at least on an annual basis, by W. Christie (Industrial) LTD.

There are no user serviceable parts. If any failures, breakdown, malfunction or damage occurs do not

attempt to repair, contact W. Christie (Industrial) LTD immediately on +44 (0)1709 55 00 88

W. Christie (Industrial) LTD Offer a torque checking system (run down fixture) for sale or hire to

monitor the torque output of all torque tools between annual calibration dates.