Chziri ZVF9V-M User manual

Manufacturer: Wenzhou Ziri Electrical Technology Co.,Ltd.

Add: NO.62-70 , Daqiao Road , Liushi Town ,Yueqing City , 325604. Zhejiang ,China .

Tel: +86-577-27863300

Http://www.chziri.com

Manufacturer: Wenzhou Ziri Electrical Technology Co.,Ltd.

Add: NO.62-70 , Daqiao Road , Liushi Town ,Yueqing City , 325604. Zhejiang ,China .

Tel: +86-577-27863300

Http://www.chziri.com

User's Manual

ZVF9V-M Vector Inverter

MM

Foreword

Thank you very muchfor your purchase of theinverter

ZVF9V-Mseries.

This manual introduces the installation, operation,

function setting, trouble shootingand etc.of the

inverter ZVF9V-M series..

Incorrect installation oruse may result in damage or

other accidents. Do read all instructions in detail

before installing or operating.

Please forward this manual to theend user,and keep

it handy forquick reference.

If there are any doubts or questions, please contact

the Technical Service Center of Our Company.

Table of Contents

Table of Contennts

Chapter 1 Safety Instruction......................................... P1

1.1 Safety Symbols and Definitions .................................P1

1.2 Application Range .................................................... P2

1.3 Installation Ambient ..................................................P2

1.4 Cautions for Installing................................................P3

1.5 Cautions for Operation ..............................................P5

Chapter 2 Introduction to the Product.......................... P8

2.1 Product Inspection upon Arrival ............................... P8

2.2 Demonstration of the Model .......................................P8

2.3 Specifications Label ..................................................P9

2.4 Models and Specifications .........................................P9

2.5 Technical Indications ...............................................P10

Chapter 3 Installing and Wiring .................................P13

3.1 Inverter Mounting and Installing ..............................P13

3.2 Inverter Wiring .......................................................P15

3.3 Wiring Diagram for Inverter System..........................P22

Chapter 4 Operation Panel and its Operation .............P24

4.1 Operation Panel and Description .............................. P24

4.2 Monitoring Parameter Display..................................P30

Table of Contennts

Table of Contents

Chapter 5 Operation of the Inverter ............................P32

5.1 Trial Operation ........................................................ P32

5.2 Cautions for Operation..............................................P34

Chapter 6 Introduction to Function Parameters.......... P36

6.1 Tables for Function Parameters ............................... P36

6.2 Detailed Instruction of Function Parameters...............P58

Chapter 7 CommonProblems, Anomalies and Troubleshooting. .. P1 13

7.1 Diagnostic Trouble Codes and Troubleshooting........P113

7.2 Anomalies and Solutions..........................................P117

Chapter 8 Inverter Inspection and Maintenance........P119

8.1 Inspection and Maintenance....................................P119

8.2 Replacement of the Inverter Wearing Parts.............. P123

8.3 Storage of the Inverter ........................................... P124

Chapter 9 OutlineDimensions & Mounting Dimensions.... .P1 25

9. 1 Inverter Outline Dimensions & Mounting Dimensions .. .. .. .. P1 25

9. 2 Operator Panel Outline Dimensions& Mounting Dimensions.. .. P1 26

Chapter 10 Quality Warranty..................................... P127

Appendix Optional Parts Choosing............................P128

User's Warranty..........................................................P130

-1--1-

Chapter 1 Safety Instructions

Chapter 1 Safety Instructions

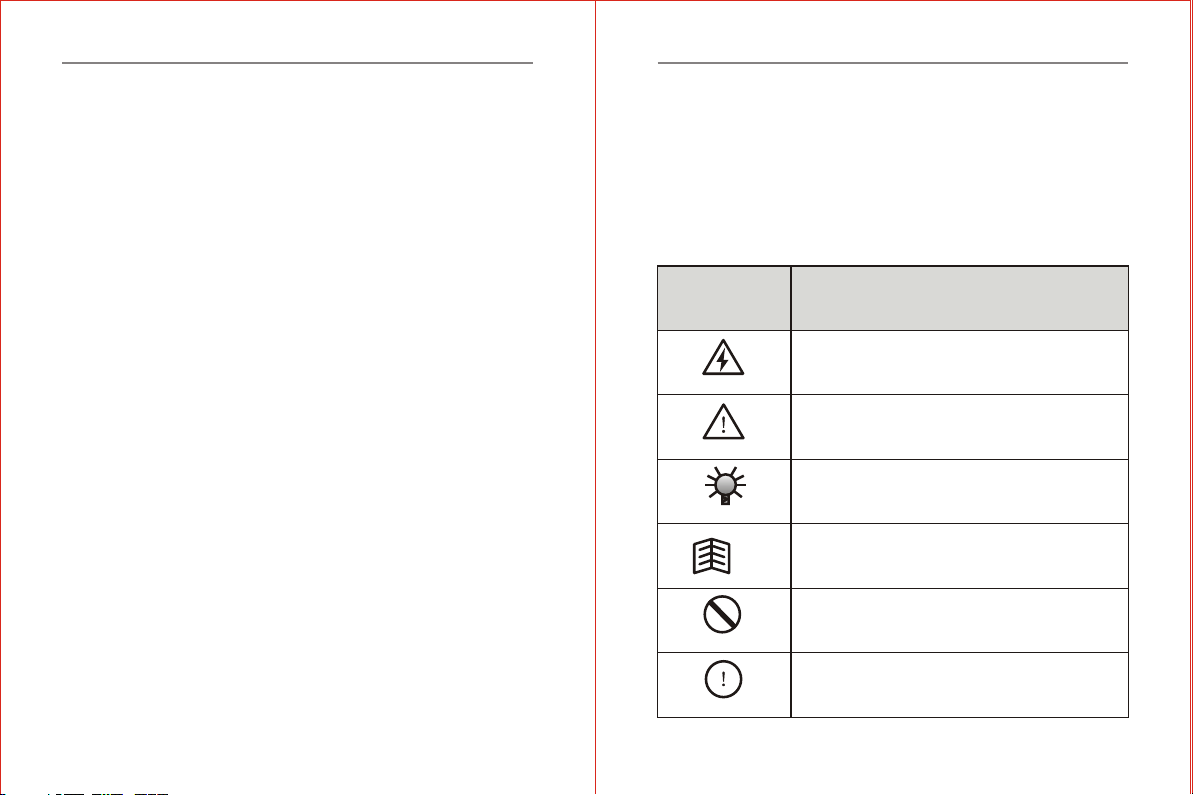

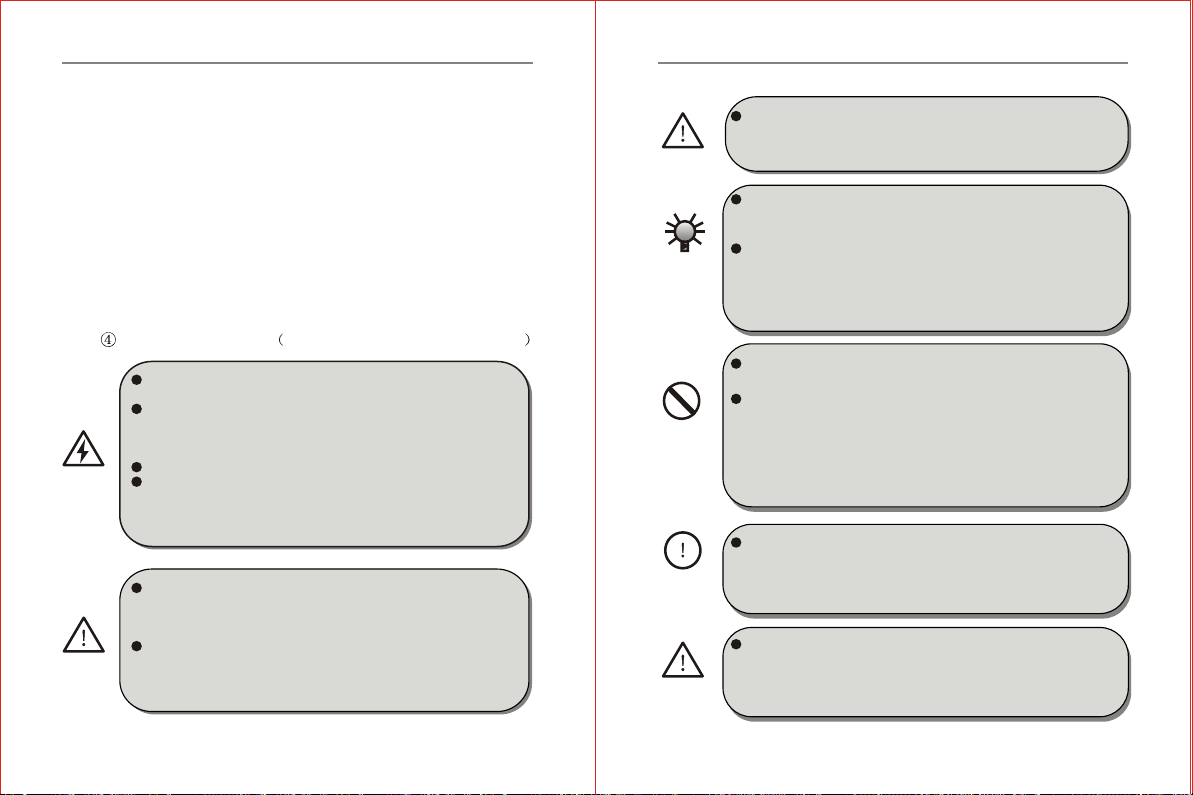

Safety Symbols Symbol Definitions

HAZARD

This symbol indicates hazardous HIGH VOLTAGE.

Any incorrect operation may result inserious damage

to the equipment or death topersonnel.

WARNING

CAUTION

TIP

FORBIDDEN

COMPULSORY

This symbol indicates that any incorrectoperation can

result in damage to the equipmentor minor to moderate

injury to personnel.

This symbol calls your attention tofollow the

instructions while in operation or inuse.

This symbol calls attention to someuseful messages

for the user.

This symbol indicates anything forbidden todo.

This symbol indicates something must do.

1.1 Safety Symbols and Definitions

The safety instructions described in this manual are very important. To avoid

any error that may resul t in damage to equipment, injury to personnel or loss

of property, do read and clearly understand all of the safety symbols, symbol

definitions and be sure to observethe indicated safety instructions below.

1.2 Application Range

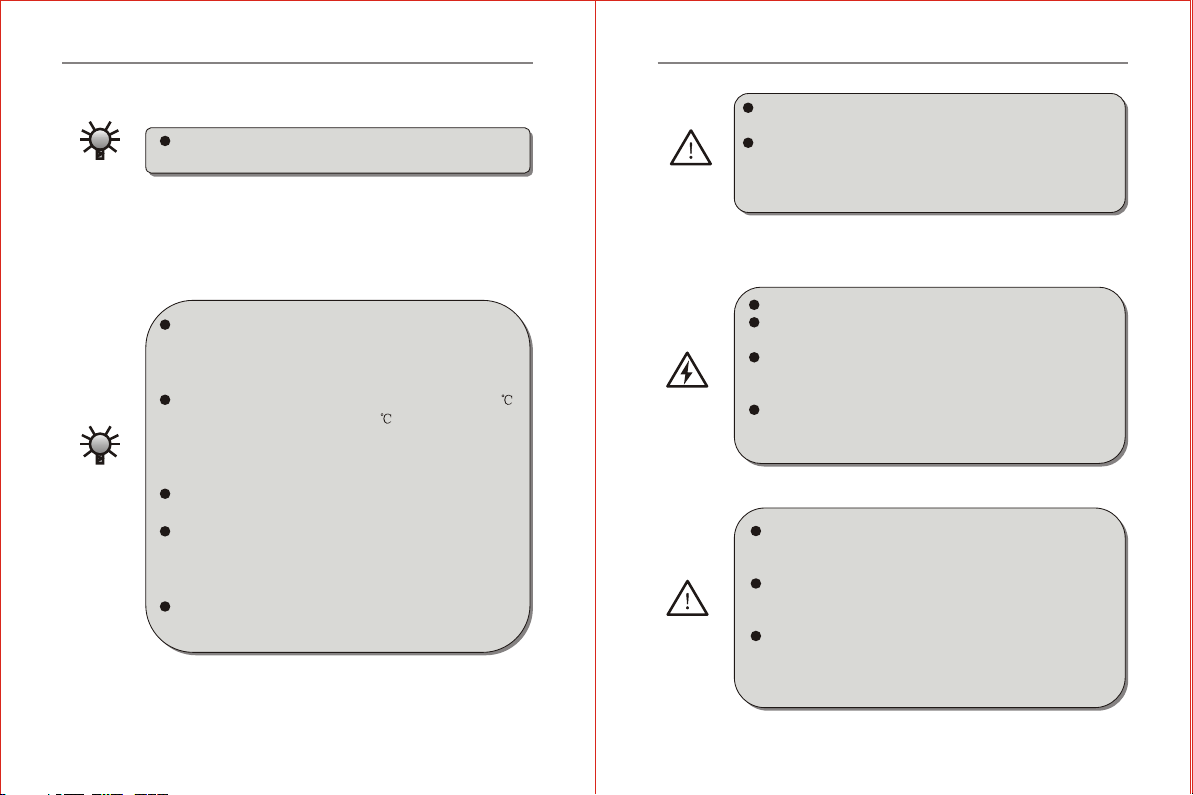

1.3 InstallationAmbient

Chapter 1 Safety Instructions

This inverter isapplicable to general industrial purpose

three-phase ACasynchronic electric motor.

Be sure to install the inverter in a well-ventilated indoor

location. To getthe best cooling effect, it isrecommended

to fix the inverter vertically, and extra ventilation devices

are needed when installed horizontally.

Be sure that the ambient temperature is between -10~40 .

If the temperature is higher than 40 , forced heat radiation

or derating is needed from theexternal. It is recommended

not to usethe inverterin sucha hightemperature. Otherwis e, it

may greatly reducethe servicelifeof the inverter.

The ambient humidity is required to be lower than 90%

without dew condensation.

The inverter shall be installed ina place where thevibration

is less than 0.5G. Otherwise, itmay fall andcause damage

to the equipment. It is also noted worthy that the inverter could

not bear any sudden bump.

The inverter should be kept away from electromagneti c

interference (EMI), flammable and explosive ambient.

CAUTION

CAUTION

-2--2-

1.4 Cautions forInstalling

Chapter 1 Safety Instructions

Be sure toinstall the inverter on metallic materials (i.e.,

Metal). Otherwise, thereis in thedanger of fire.

Be sure not to let the foreignmatter enter into the inverter,

such as wire clippings,spatter fromwelding, metal (zinc or

ferrous) meshavings and etc. Otherwise,there is thedanger

of gettingburned due toshort circuit.

Do not operateelectrical equipment withwet hands.

Do not operate wiringunless the powersupply is completely

off.

Do not open the front cover or perform wiring while

the inverter ispowered ON. Otherwise,there is the danger

of electric shock.

Do wait at least5 minutes afterthe power isdisconnected

before performing thework of wiringor inspection. Otherwise,

there is thedanger of electricshock.

Do not installor operate ifthe inverter isdamaged or has

parts missing to prevent injury to personnel or loss of

property.

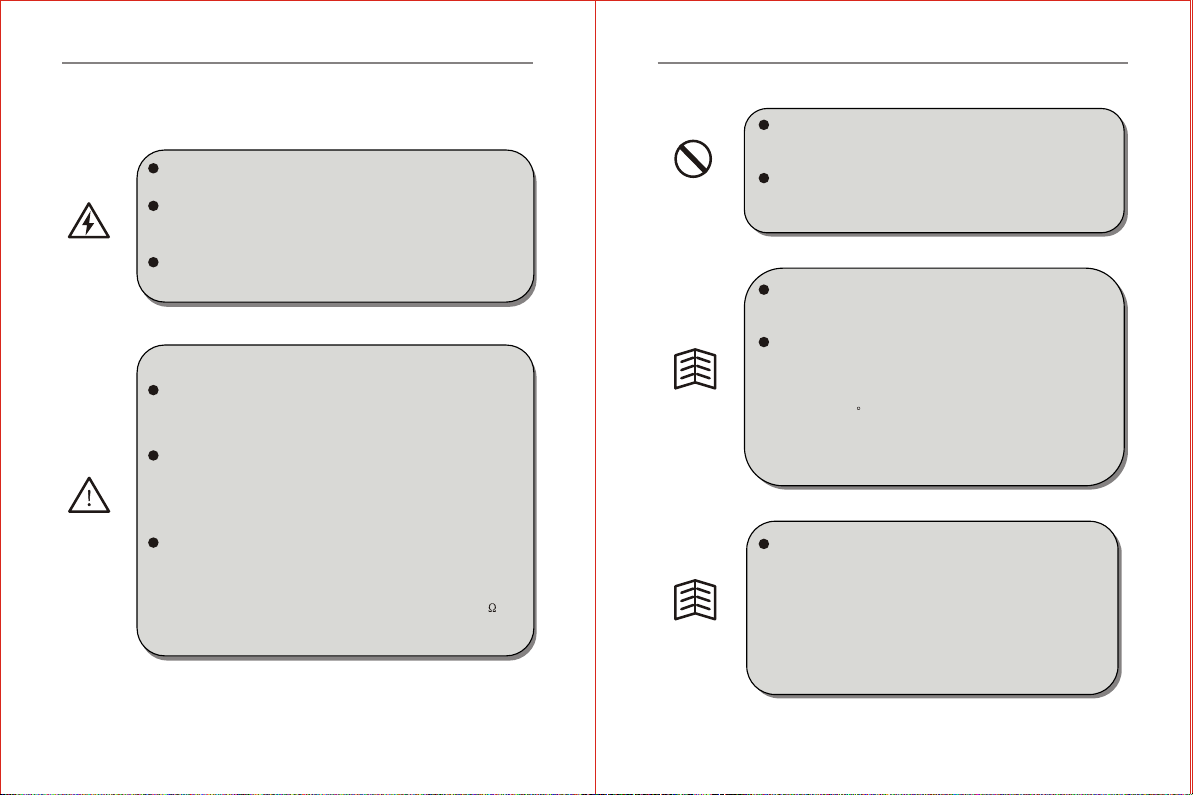

The main loop terminal should betightly connected to the

cable. Otherwise, theinverter may bedamaged due toloose

contact.

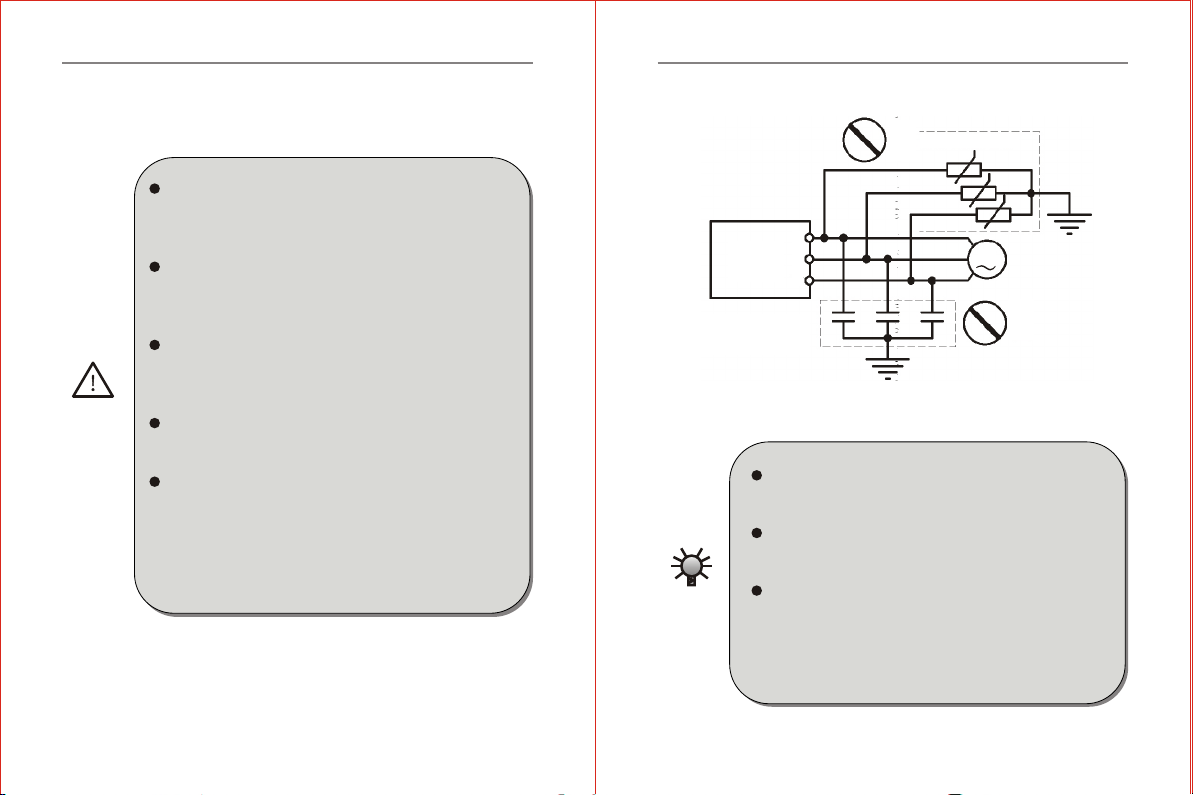

The ground term inal must be reliably andproperly grounded

to ensure security. Toavoid common ground impedance,

multi-piece inverters should be groundedwith one shared

point, as shownin the Figure1-1.

WARNING

HAZARD

WARNING

-3--3-

Inverter Inverter Inverter

Proper

grounding

method

Grounding bus bar

(Connect to the ground at theshared point)

Three-phase

AC

Power Supply

FORBIDDEN

Figure 1-2

Figure 1-1

Chapter 1 Safety Instructions

DO NOT connect control terminals (except terminals mar ked

"TA","TB" and "TC") to AC 220V power supply, which

may cause damage to the inverter.

DO NOT connect AC power supply to the outputterminals

marked "U", "V" and "W". Otherwise, it may cause damage

to the inverter, as shownin the Figure 1-2.

DO install a no-fuse circuit breakeror leakage protective

circuit breaker in the side ofinverter input power supply

to prevent expanding of accident due to an inverterproblem.

FORBIDDEN

COMPULSORY

-4--4-

INVERTER

1.5 Cautions forOperation

Chapter 1 Safety Instructions

It is not suitable to install an electromagnetic contactorin the

side of output power supply, because the operation of open

and close tothe contactor when the motor is running may

cause damage to the inverter arising from over-voltage

produced during this process. But itis still necessary to install

a contactor if one of thefollowing three points occurs:

1. The system of frequency converting governor used to control

energy-saving usually works at a rated rotation speed.To run the

governor economically, thereis a must toremove the inverter.

2. The inverter participates in some import procedure and cannot

stop operating for a long period of time.To realize free shift

in various control systems and improvethe reliability of these

systems, there is a must toinstall a contactor.

3. When an inverter controls severalmotors, there is amust to

install a contactor.

Caution: DO NOT operate the contactorif there is output of the

inverter.

Do not operate electrical equipment withwet hands.

An inverter stored formore than half a year shouldbe given

power up test before use so thatthe main circuit filter capacitor

couldbe recovered. When the inverter is in the stateof powerup,

it is necessary to raise the voltage gradually tothe ratedvalue

with a voltage regulator. Generally, the charging time should

be controlled within 2 hours. Otherwise, thereis the danger

of electric shock or exposure.

Do not touch the inner sideof the inverter while the po wer

is ON, nor put any foreign matter, i.e., rod or other matter

inside the inverter.Otherwise, it may resultin serious damage

to the equipment or electric shock.

Do not open the front cover while the inverter is powered

ON. Otherwise, there is the dangerof electric shock.

Be careful to select the Restart Mode. Otherwise, there is

the danger of personnel death.

CAUTION

-5--5-

HAZARD

R

S

T

U

V

W

GGG

Forbidden

Forbidden

Inverter

Power factor

compensation

capacitor

Surge current sink

Figure 1-3

Chapter 1 Safety Instructions

When the inverter runs at a frequencyhigher than 50Hz, Make

sure it iswithin the speed range acceptable by your motor

bearing and mechanical device.Otherwise,there is the danger

of damage to the motor.

It is not advisory to run thereduction box, gear and other

mechanism that need lubricating at lowspeed for a longperiod.

Otherwise, it may reduce the servicelife ofthese equipment

or even damage the equipment.

Ageneral motor should be derated before use due to less

effective of heat dissipation when itruns at a low frequency.

If it is a constant torque load, then a forced method or a special

variable frequency motor should be usedto release heat.

DO cut off the power supply ofan inverter set aside fora long

time to avoid foreign matter orother things enterin it which

may cause damage to the inverteror even lead to fire.

The output voltage of inverter is PWM impulse wave. DO

NOT install a capacitor or surge current sink(i.e., a varistor)

in the inverter output port. Otherwise,there isthe danger of

fault tripping of the inverter or damage to itspower elements.

DO remove such kind of thingsif already installed. See the

Figure 1-3 below.

WARNING

-6--6-

Chapter 1 Safety Instructions

Motor insulation should be checked before the inverter is

used for the first use or reused after along-term idle. Be sure

the insulation resistance measured is nolower than 5M?

If the inverter is used beyond the range of allowableworking

voltage, then an extra step-up orstep-down voltage transformer

shall be configured.

Due to thin air in a place where the altitude ishigher than

1,000m , the heat dissipation of inverter willbe less effective.

Hence derating should be done before use.In general, when

the height rises by 1,000m, therated voltage of theinverter

shall reduce by 10%.

CAUTION

-7--7-

U

V

W

M

Inverter Model

Design Number

Serial Type Code

Vector Type V

Type Code

Mini Type M

ZVF9V-M0015T4MDR

Name

Inverter Model

Adaptive Motor Power

Input Power Rating

Output Power Rating

Product Number

Chapter 2 Introduction to the Product

2.1 Unpacking and Inspection uponArrival

This product is guaranteed a high level of quality with strict outgoing

inspection,crushproof and shockproof packaging.But this does not preclude

damage tothe product due to heavy collision or strongextrusion.So it

is necessary to u npack the inverter upon arrival and perform these steps:

Check w hethe r there is a defor med or damag ed casing;or any shattered

component.

Check the specifications label of theinverter and make sureitmatches

the product part number you've ordered.

Check whether the items inthe packing list are in readiness or not.

If there is any problem with the above-mentioned contents,please

contact the supplier or Our Companyimmediately.

Chapter 2 Introduction to the Product

2.2 Demonstration of the Model

Motor Power Code

1.5KW 0015

"DR"indicates there is a

braking unit inside.No

"DR",no braking unit

inside.

M:Integration Module

S:Schism Module

VoltageClass Code

220V 2

380V 4

Voltage Phase Number Code

Single Phase S

Three Phase T

Figure 2-1 InverterModel Demonstration

-8--8-

2.3 Specifications Label

Figure 2-2 Inverter Specifications Label

Table 2-1 InverterModels and Specifications

2.4 Models andSpecifications

Inverter Models

M:Mini type

Input

Voltage

V

Rated

Output Current

A

Adaptive

Motor

Power(KW)

ZVF9V-M0007T2/S

ZVF9V-M0015T2/S

ZVF9V-M0022T2/S

ZVF9V-M0007T4

ZVF9V-M0015T4

ZVF9V-M0022T4

220

220

220

380

380

380

4.0

7.5

10.0

2.3

3.7

5.0

0.75

1.5

2.2

0.75

1.5

2.2

-9--9-

Chapter 2 Introduction to the Product

Item Item Description

150% 1 minute; 180% 1 second;200% transient protection

Optimal space voltage vector PWM modulation

Speed sensorless vector control(SVC)

digital setting:Max.frequency 0.01%

Analog setting:Max.Frequency 0.2%

Overload capacity

Modulation method

Control method

Frequency accuracy

Control function

Digital setting:0.01Hz

Analog setting:Max.Frequency 0.1%

Frequency

resolution

0.00 10.00Hz

Starting frequency

Automatic torque lifting:Tolift the torque a

utomatically according to the output current.

Hand-operated torque lifting:Range:0.1 30.0%

Torque lifting

Setting range:0 150%.The inverter output

frequency can be auto-regulated within thisrange

acdording to the motor load soas to reducethe speed

variation of the motor due toload fluctuation.

Slip compensation

0.1 3600.0 sec/min,which can be set insequence.

Acceleration/

deceleration time

1.0 15.0 KHz

Carrier frequency

Jog frequency range:0.01 400.0Hz Jog

acceleration/deceleration time, 0.1~3600.0 can be set.

Jog function

1.linear curve; 2.quadratic curve(conic);

3.User defined V/F curve

V/F curve

Three-phase 0 input voltage VAC

0.00 400.00Hz

Rated voltage

Frequency

Ouput

Rated voltage,frequency Single/three-phase 220VAC,three-phase 380VAC,50Hz/60Hz

Input

Allowable voltage

range

Voltagefluctuation range:-20% +20%

Voltage unbalance rate 3%; frequency fluctuation 5%

Auto optimize V/F curve according toload

fluctuation to realize energy-saving operation.

Automatic

energy-saving

operation

Control function

-10--10-

Chapter 2 Introduction to the Product

Item Item Description

When the network voltage changes,it canregulate

PWM output automatically to maintain constant

voltage.

Auto voltage

regulation(AVR)

This can form a convenient closed-loopcontrol

system(CLCS),and is applicable to pressure control,

flow control and other process control.

Built-in PID

Control function

operator panel control,external terminal control

and COM control

Operating command

Panel potentiometer setting,operator panel

setting,external terminal up/down setting,analog

voltage signal or external potentiometer setting,

analog current signal setting,analog assembly

setting,485 COM setting and etc.

DC braking

Forward/Reverse signal,multiple speed signal,

failure signal,reset signal and etc.

Input Signal

Programmable relay,open-collector output,failure

signal output and etc.

Output signal

This can realize the output offrequency,current and

other physical quantity by outputting 0 10V or

0 20mA DC signal and0 10KHz digital signal.

Multi-function

analog and digital

ouput terminal

Operating function

With an external braking resistor,the maximum

braking torque may reach 100%.

Dynamic braking

This can be selected when themotor starts or stops

with the action frequency of 0 20Hz,action current

level of 0 100% and actuation time of 0 30 sec.,

which can be set in sequence.

DC braking

Braking function

-11--11-

Chapter 2 Introduction to the Product

2.5 Technical Indications

Table 2-2 DscriptionSummary for Technical Indications

Item Item Description

Input open-phase protection,over-current protection,

overload protection,under voltage protection,

overheating protection and etc.

Protection function

Real-time display the running state,monitoring

parameters,function parameters,diagnostic trouble

codes(DTC)and other information of the inverter.

LED,LCD display

Brake assembly,remote operator panel,connecting

wire,communication panel

Matching parts

Indoor location free from direct exposureto sunlight,

high humidity or dew condensation,high levelsof

dust,corrosive gas,explosive gas,inflammable gas,

oil mist,salt and etc.

Place to be used

Below 1,000M

Altitude

Ambient

-10 +40 [Bare Machine:-10 +50 ]

Ambient Temperature

20 90%RH without dew condensation

Humidity

0.5G

Vibration

-20 +60

Storage Temperature

Ip20

Forced air cooling

wall mounted

Protective Class

Cooling system

Installation

Structure

-12--12-

Chapter 2 Introduction to the Product

Air outlet >10cm

>>

>

Air outlet Air outlet

Air inlet

Air inlet

Inverter Inverter

Induced

spacer

Chapter 3 Inverter Installation and Wiring

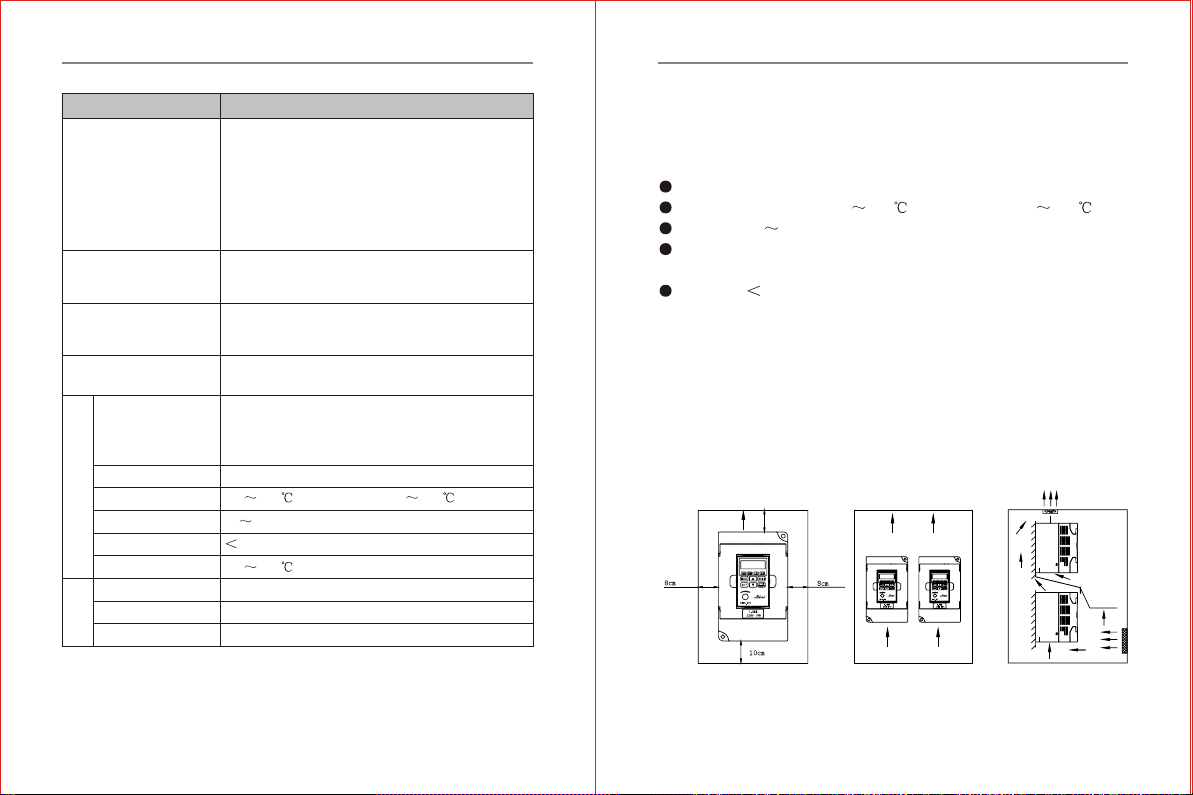

3.1 Installation

3.1.1 Use the inverter in the following environmental conditions:

Altitude:Maximum 1000m above sea level

Ambient Temperature:-10 +40 [Bare Machine:-10 +50 ]

Humidity:20 90%RH(Non-condensing)

Ambient:Indoor places free from direct exposure to sunlight,dust,

corrosive gas,flammable gas,oil mist,steam,drip and salt.

Vibration: 0.5G

3.1.2 Installation Space and Direction

To get bettercooling effect and for the convenience ofmaintenance,the

inverter shall be installed vertically with enough space left(refer to the

figure 3-1).When two or more invertersare fixed in the same cabinet,it

is recommended to fix them inparallel and horizeontally to reduce heat

produced by them(refer to thefigure 3-2).When there is a mustto fixthem

vertically,please fix aninsulating board between t hem so that the heat

produced by the lower one couldnot have direct influence on the upper

one(refer to the figure 3-3).

Chapter 3 Inverter Installation and Wiring

Figure 3-1 Demonstration

of Installation Space

Figure 3-2 Demonstration

of Multi-piece Parallel

Installation

Figure 3-3 Demonstration

of Multi-piece Vertical

Installation

-13--13-

Other functions

Leap frequency, Jog function,counter, trace to

rotating speed, instant shutdown restarting,

Frequecny upper/lower limitation , acceleration/

deceleration mode regulating, frequency meter and

voltmeter output, multiple speed/program operation,

two-wire/three wire control,vibration frequency

control, Multi-function input terminal selection,

Failure auto reset and 485COM.

Chapter 3 Inverter Installation and Wiring

3.1.3 Installation Instructions

Do not install oroperate if the inverter is damaged or has

parts missing to prevent injury from personnel or loss of

property.

Be sure the main loop terminals should be tightly connected

to the cable. Otherwise, the inverter may be damaged arising

from loose connection.

Be sure that the ground terminals of the inverter and the

motor must be properly grounded. Multi-piece inverter

should be grounded at one sharedpoint.

Be sure to install a no-fuse circuit breaker orleakage protective

circuit breaker in th e side of inverterinput power supply to

prevent expanding of accident due toan inverter problem.

Inst all the in verter i n a proper place with moderate temperature.

The higher the ambient temperature is, the shorter the service

life of the inverter is.

Keep any other heat-producing equipment as far away from

the inverter as possible. When installingthe inverter in an

enclosure,maintainthe clearance around the inverter and

verify the temper ature is withinthe allowable range.

WARNING

FORBIDDEN

CAUTION

-14--14-

3.2 InverterWiring

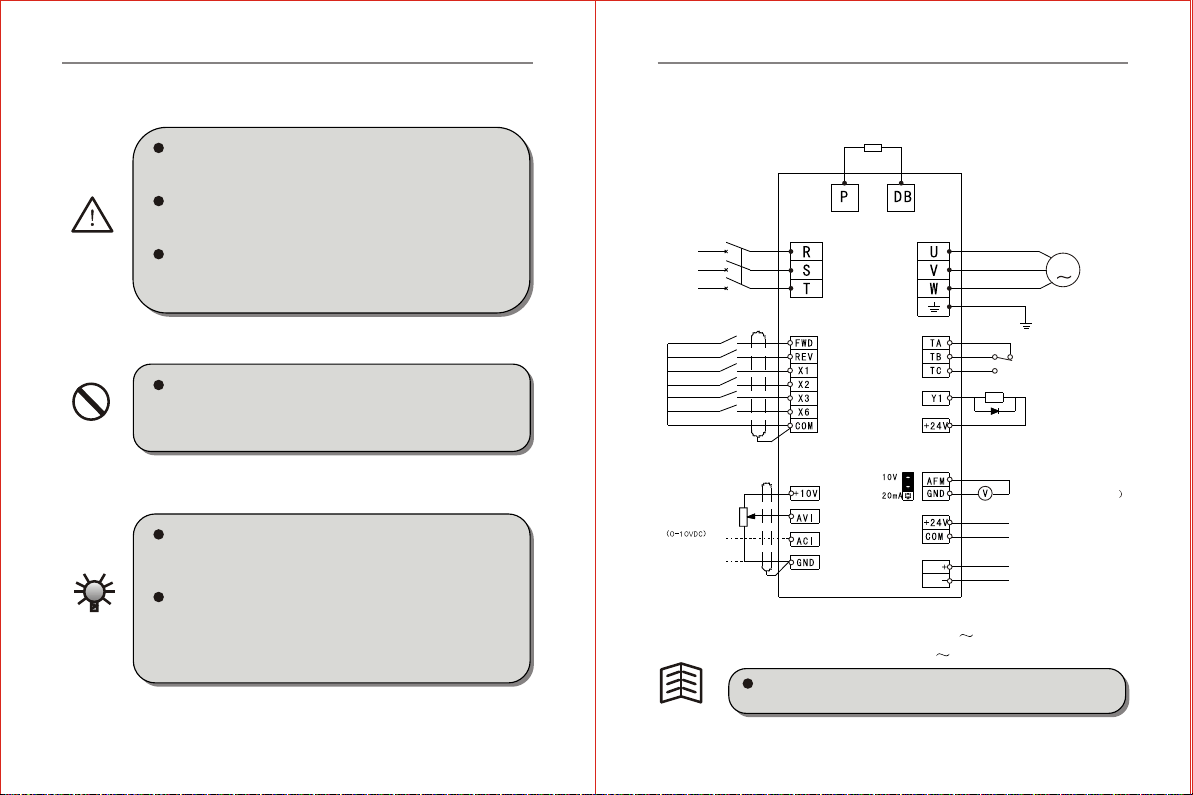

3.2.1 Basic Wiring Diagram for the Inverter

Fig.3-4 Basic Wiring Diagram

Applicable to Model:ZVF9V-M0007T2/S2 M0022T2/S2

ZVF9V-M0007T4 M0022T4

Chapter 3 Inverter Installation and Wiring

-15--15-

Braking Resistor

Three-phase

AC Input

Power Supply

Terminal X1

Terminal X2

Terminal X3

Terminal X6

Public Terminal

Potentiometer

Input or Analog

Voltage Input

Analog

Current Input

(0-20mA)

Fault Relay Output

TA-TB on when normal.

TA-TC on when failure.

Open collector

Output

Analog Signal Output

(0-10VDC or 0-20mA

24 Power Supply

Output Port

485 COM Port

MCCB

SG

SG

M

Forward Running

Reverse Running

JP2 is used to realize switching betweenanalog output voltage

and current.

Tips

3.2.2 Cautions forWiring

Wait atleast 5 minutes after power OFFbefore opening the

front cover of the inverter.

Verifythe charge indicator lamp isOFF before proceedin g

the work, and be sure that the voltage valueof the main loop

terminal P and DC isless than 36VDC.

The internal wiring of the invertershould be operated only

by authorized qualified personnel.

Verify therated input voltage of the inverteris matched with

AC power supply. Otherwise, there is the possibility of

damage to the inverter.

Be sure to installa non-fuse circuit breaker in the input

power supply sideof the inverter to prevent expanding of

accident due to an inverter problem, which may cause

damage to the distribution equipment orlead to fire.

Be sure to connect the ground terminal and the motor casing

to the ground wire which must be copper core. Thediameter

of the copper core should conform to the relevant national

standard. The ground resistance shouldbe less than 10 .

Chapter 3 Inverter Installation and Wiring

HAZARD

WARNING

-16--16-

Chapter 3 Inverter Installation and Wiring

DO NOT connect AC powersupply to the output terminals

marked "U", "V" and "W". Otherwise, therewill be damage

to the inverter.

DO NOT connect control terminals (except terminals marke d

"TA","TB" and "TC") toAC 220V powersupply, which

may cause damage to the inverter.

FORBIDDEN

When the open-ended output terminal of the collector

connects to any inductive load, i.e., the relay coil,do insert

a diode at each end ofthe load in parallel.

The control wire in the inverter or thecontrol cabinet should

be at least 100mm away fromthe power cable. DO NOT put

them in the same metallic channel.If the signal wire and

the power cable need to intersect,they should intersect at

an angle of 90 . The control wire mustadopt STP (shielded

twisted pair wire); the shielded layermust connect to the

terminal GND; and the power wire is recommended touse

metallic shielded cable.

Tips

The unavoidable strong electromagnetic interference of

the inverter mayhave bad influence on all the electrical

equipment and meters in the same environment. To reduce

interference, the outputcable of theinvertercan be inserted

in the metal pipe connecting to the groundor in the metallic

shielded cable, and connect the metallicshielded layer to

the ground. In addition, a magneticloop puton the output

cable is also effective to reduceinterference.

Tips

-17--17-

Chapter 3 Inverter Installation and Wiring

3.2.3 Instruction onMain Circuit Terminals

1. The maincircuit terminals areshown as in the figure 3-5~3-6.

Fig.3-5 Diagram 1for Main Circuit Terminals

Applicable t0 Model

Earthing

Single phase 220V power input

R S T

Connect with

three-phase AC motor

Connect with the

braking resistor

Fig.3-6 Diagram 1for Main Circuit Terminals

Three-phase 220/380V power input

ZVF9V-M0007T2/S2 M0022T2/S2

ZVF9V-M0007T4 M0022T4

-18--18-

Earthing

2 Function Description onMain Circuit Terminals

The three-phase input power supply connect tothe terminals

(R, Sand T) do not differ on phase sequence and can be

conn ect ed arbitrarily.

If the motor counterrotates (reverses) when the output

terminals U, V and Wconnect to three-phase motor, just

exchange two phases of U, Vand W arbitrarily.

Terminal Symbols Function Description

Power supply inputterminals connecting tothree-

phase 380V or220V ACinput

Power supply inputterminals connecting tosingle-

phase 220VAC input

Inverter output terminalsconnecting to three-phase

AC motor

External braking resistorterminals connecting to

both ends ofthe external brakingresistor

RST

LN

UVW

PDB

Chapter 3 Inverter Installation and Wiring

G Ground terminal connecting to the ground

Tips

-19--19-

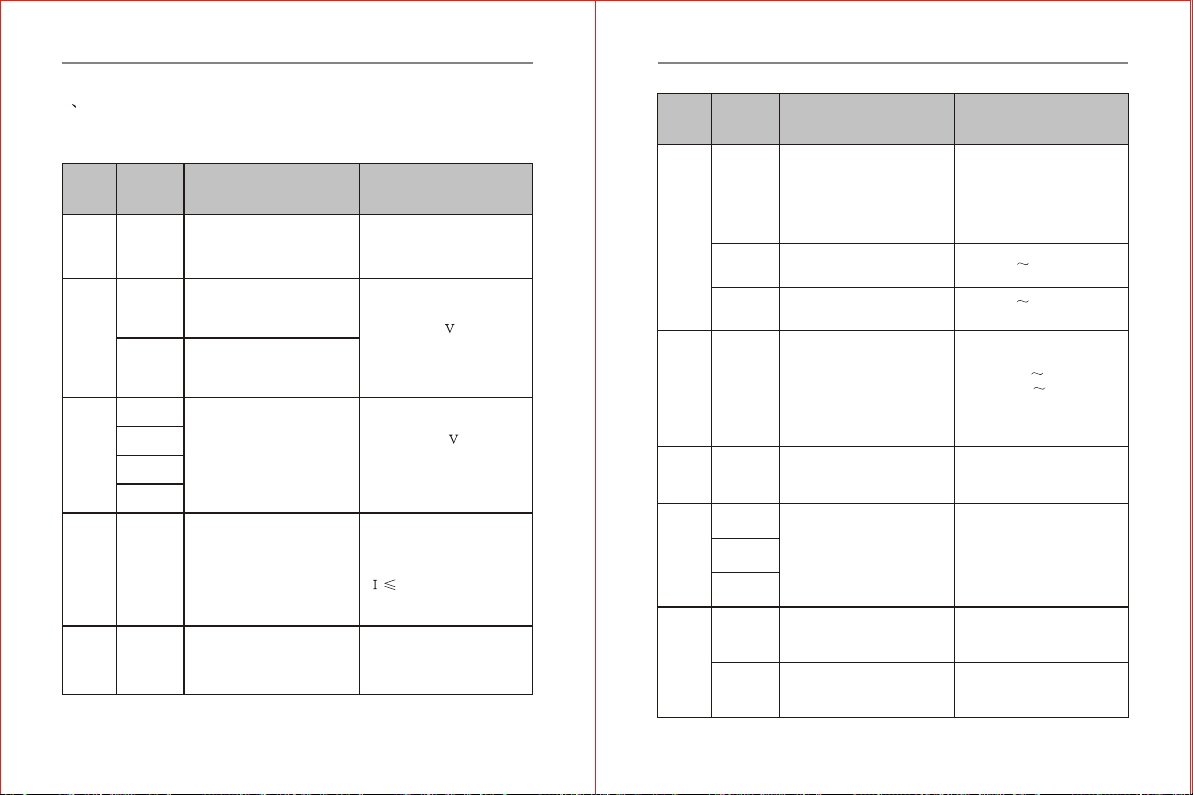

3.2.4 Description ofterminals on the control circuit

1 The terminal ofcontrol circuit shownin Fig 3-7.

Fig 3-7 Terminals of controlcircuit

Chapter 3 Inverter Installation and Wiring

2 Description on ControlCircuit Terminals

Table 3-2Function Description onControl Circuit Terminals

Types Terminal

Symbols Function Description Electrical Specifications

Public

Port

Digital signal public

terminal

Forward when FWD-COM

short circuit, decelerate and

stop when FWD-COM is open.

Running Control

Terminal

Reverse when FWD-COM

short c ircuit , decelerate and stop

when FWD-COM is open.

INPUT, 0~24 power level,

low level valid, 5mA

Multi-function

Input Terminal

X1

X2

X3

X6

COM

FW D

REV

Multi-function

Output Terminal

Multi-function open-

collector output is defined as

on-off output terminal, whose

function is set by the

parameter F4.07 with

reference of COM.

Valid onlywhen there is a

short circuit between Xn (n=

1, 2,3, 6)and COM. The

functions can be set by the

parameter F4.00~F4.05

separately.

Y1

INPUT, 0~24 power

level, low level valid,

5mA

OUTPUT, Maximum

Current Load

50mA

Analog signal public

terminal

GND

Public

Port

-20--20-

Types Terminal

Symbols Function Description Electrical Specifications

Chapter 3 Inverter Installation and Wiring

External analog preset

power supply connecting to

potentiometer together with

terminal GND and AVI.The

frequency can be set as

required.

INPUT,10V DC voltage

+10V

AVI

Analog Input

Terminal

Analog voltage signal input,

with reference of GND. INPUT,0 10V DC voltage

Analog current signal input,

with reference of GND

INPUT,0 20mA DC

current

ACI

Programmable analog voltage

ouuput connecting to the

voltmeter of frequency meter

with corresponding output

ranging from "0"to the maximum

frequency,with reference of GND.

AFM

Analog Output

Terminal

OUTPUT,0 10V DC

voltage or 0 20mA

DC current

communication

port

+24V

TA

24VDC-100mA

24VDC Power Supply

Output(Control Power

Supply)

Power

supply

Interface

Relay contact output.When

normal,Ta-TB turns onand

TA-TC turns off.When there

is action,TA-TB turnsoff

and TA-TCturns on.This

function is set by F4.09.

TB

TC

Contact rated value:

250VAC-3A

250VAC-1A

30VDC-1A

Programmable

Output Terminal

Communication Signal

Positive Port

Communication Signal

Negative Port

SG+

SG-

-21--21-

Chapter 3 Inverter Installation and Wiring

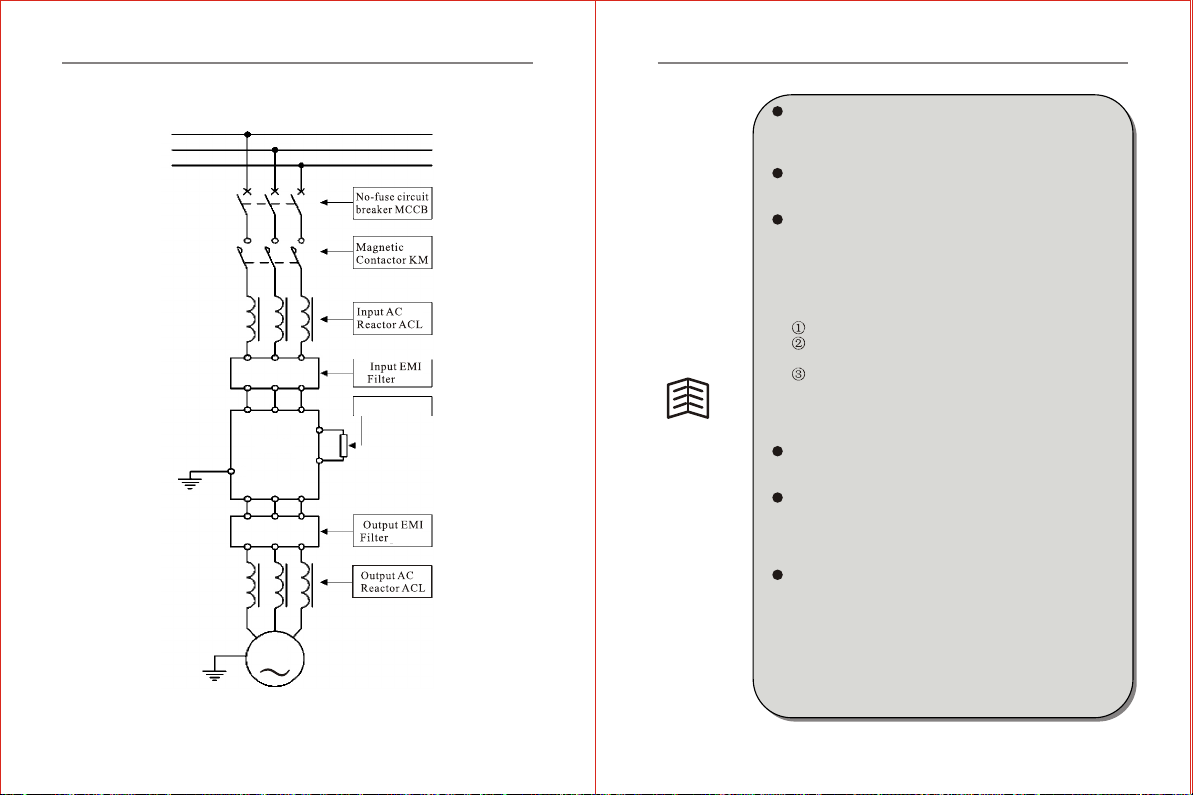

3.3 Wiring Diagram for InverterSystem

Fig.3-8 Connection betweenthe Inverter and Optional Accessories

-22--22-

Exteral Breaking

unit

INVERTER

UVW

G

RST

P

DB

M

The circuit breaker has the function of over-current

protection,which can avoid extension of external

equipment failure. Dopay attention to the capacity of

circuit breaker when installing.

The magnetic contactor is used todisconnect fro m the

main power supply in case ofinverter failure, and prevent

restarting after power-off or inverterfailure.

The input ACreactor can reduce influence arising from

unbalance of three-phaseAC power supply, improve the

power factor of the inverter inputside and reduce damage

to the inverter when it isconnected to large capacity motor

which may result in damage tothe rectifier circuit.It is

necessary to configure an AC reactor when any of the

following occurred:

The power supply unbalance exceeds3%.

The power capacity is 500KVA atleast and it is more

than 10 times as the invertercapacity.

The power factor is used tocompensate the connection

or disconnectio n of the capacity, and sudden fluctuation

of network voltage caused by otherreasons.

It is recommended to install areactor with deratingvoltage

of 3%.

The inputand output EMI filters are used to minimize

the magnetic or radio frequency interference (RFI)

produced by the network or theinverter.

The brake assembly is usedto consume the energy fed

back by some heavy potential energy or inertia load to

the inverter, so as to avoid inverter trippingarising from

over-tension pumping voltage while giving a quick

shutdown to the inverter.

The output AC reactor can filter out with effect the higher

harmonic compon ents in the inverter output currentand

reduce theelectromagnetic interference (EMI) due to

ultraharmonics. Also, it canimprove current waveform,

decrease noise and temperature rise ofa running motor

and enhance the stability of motor running. To avoid

influence of leakage current dueto distributed capacity

of the cable, it is necessaryto install an output AC reactor

if the motor cable is longer.

Chapter 3 Inverter Installation and Wiring

Tips

-23--23-

Chapter 4 Operator panel and its Operation

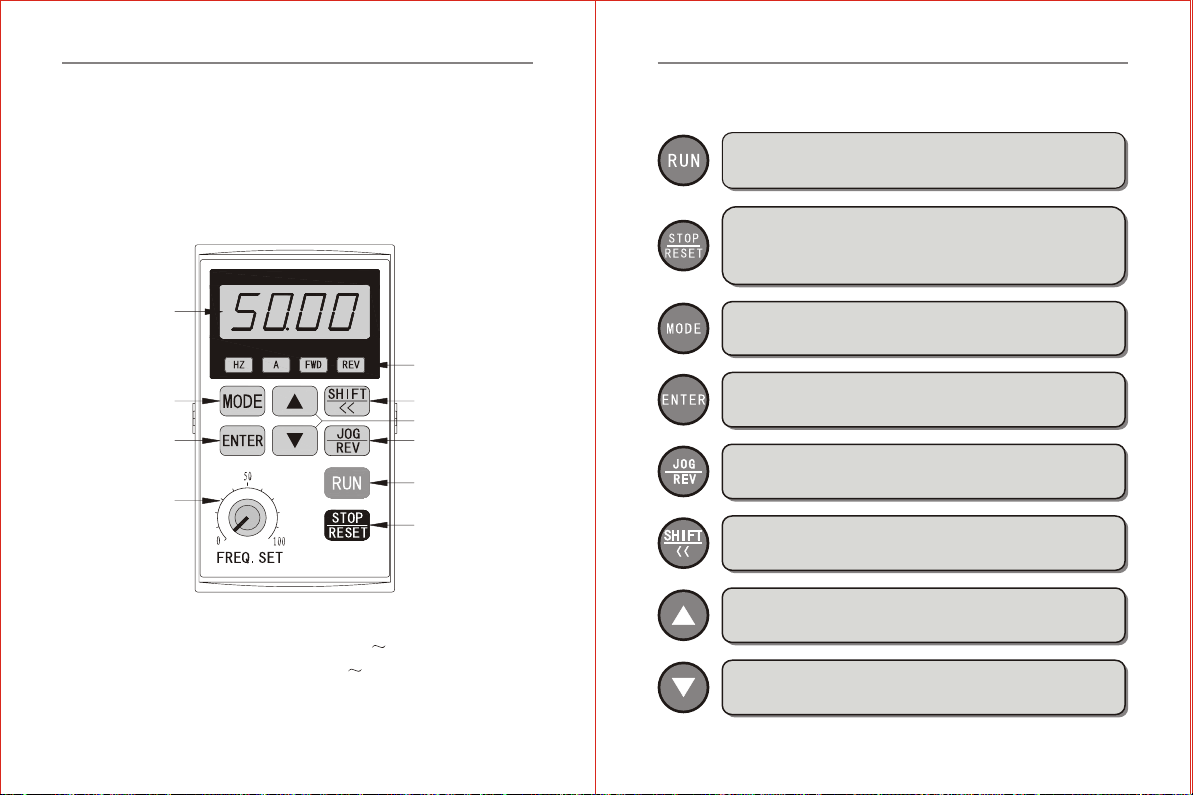

4.1 Operator Paneland Description

The inverter ZVF9Vseries has 3kinds of operationpanels,The standard

M Type have potentionmeterwhen out of factory.

4.1.1 Operator PanelOutlay

Applicable to Model:

LED display area

Display the

running status

ENTER/STORE Key

MODE Key

Potentionmeter Key

SHIFT/MONITOR Key

LED display area,

display frequency,

current, parameters,

error and etc.

UP/DOWN Key

RUN Key

STOP/RESET Key

JOG/REVERSE Key

Chapter 4 Operator panel and its Operation

ZVF9V-M0007T2/S2 M0022T2/S2

ZVF9V-M0007T4 M0022T4

-24--24-

4.1.2 Function Descriptionon Keys

Run key: When the operating instruction is to select operator

panel control (F0.04=0), press this keyand the inverter begins

to run.

Stop/Reset key: When the operating instruction is toselect operator

panel control (F0.04=0), the inverter is in normal running. Press

this key to stop run ning. When the inverter is in the stateof failure

alarming,press thiskey to solve failure and return to the normal

status.

Mode shifting key: Press this key to realize mode switching from

monitoring parameter to function parameter.

Enter/Store key: Press this key to confirm the current status of the

inverter or save the current parametervalue.

Jog/Reverse key: Press this key to realize jogor reservefunction,

and decide jog or reverse functionby selecting the parameter F0.23.

The factory default setting is jogfunction.

Shift/Monitor key: When a data needs modifying, press this key

to select the modifier bit ofthe data. In the status of monitoring,

press this key to display thestatus parameter.

Up key: Press this key, thedata or parameter code will goup. Press

and hold it, the modifying speedupward will rise.

Down key: Press this key, the data or parameter code will go down.

Press and hold it on, themodifying speed downward will rise.

Chapter 4 Operator panel and its Operation

-25--25-

Chapter 4 Operator panel and its Operation

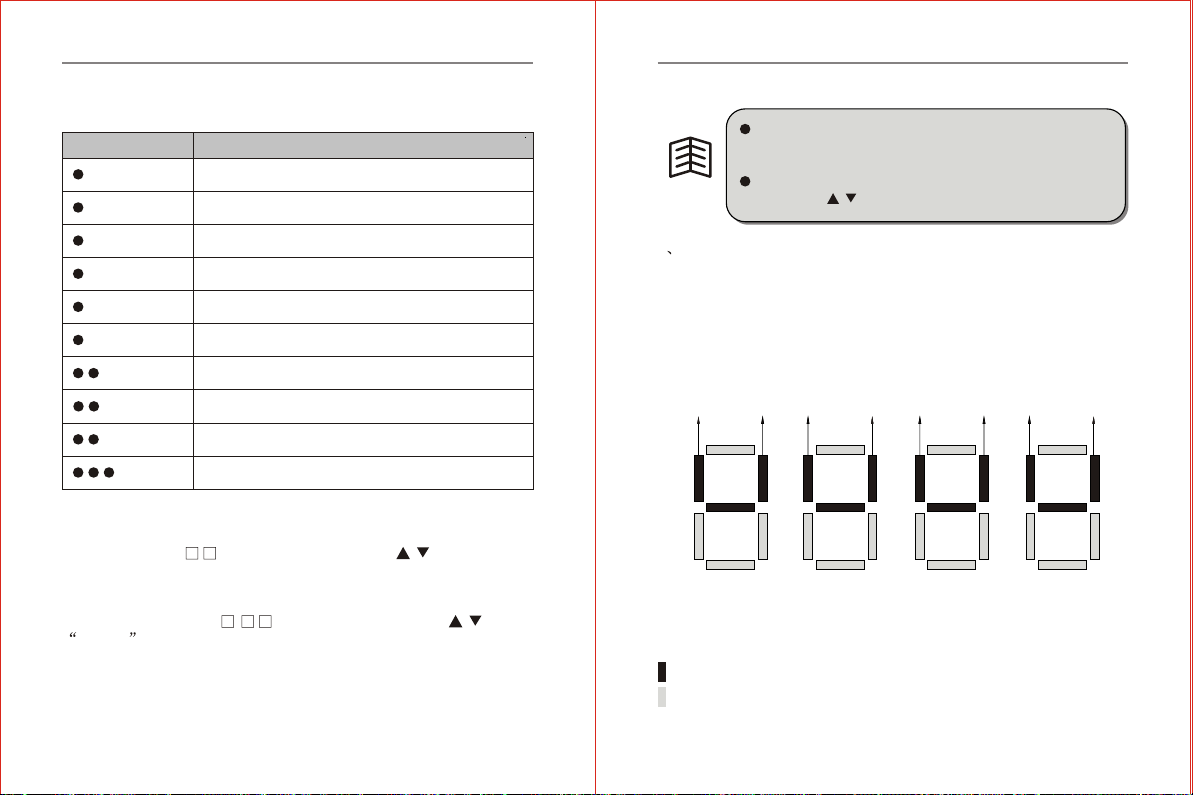

4.1.3 Function Descriptionon Operator Panel Indicator Lights

Table 4-1LED Status Description

Display Status Function Description

When this indicatorlight is switchedON, LED displays

frequency data.

When this indicatorlight is switchedON, LED

displays current data.

When this indicatorlight is switchedON, LED

displays voltage data.

When this indicatorlight is switchedON, the inverter

is in thestate of forwardrunning.

When the indicatorlights is switchedON, the inverter

is in thestate of reverserunning.

When these 2indicator lights areswitched ON

simultaneously, therotary speed willbe displayed.

When these 2indicator lights areswitched ON

simultaneously, thepercentage will bedisplayed.

When these 2indicator lights areswitched ON

simultaneously, thelinear speed willbe displayed.

When these 3indicator lights areswitched ON

simultaneously,temperature willbe displayed.

4.1.4 Working mode anddisplay status ofthe function keyboard

1. Mode ofMonitoring State

Press "M ODE" key, the inverter ente rs into the monitoringstate mode

(LED displays Fd ). Under thismode, press / to decide what

to be monitored(i.e., a running parameter or failurerecord).

2. Mode ofFunction Status

Repress "MODE" key, the inverter will enter the mode of function

status (LED displaysF . ). Underthis mode, press / or plus

SHIFT key to decidethe function parameter to be checked or

modified.

3. Power On/OffDisplay

The LED displaysP.oFFwhen the inverter startenergize orpowered off

properly.

Hz

A

V

ALM

FWD

REV

Hz&A

Hz&V

A&V

Hz&A&V

-26--26-

In any event, the operator panelwill automatically return to

the Monitoring Mode if there is no key entry in 2 continuous

minutes.

In the mode of monitoring, the frequencyvalue will be modified

by pressing / on the operator panel when setting F0.01=1.

4 The correspondence between display symbols ofthe parameter

Fd14 and external inputterminal status in themonitoringmode

is shown below:

Terminal

Status

Terminal

Status

Terminal

Status

Terminal

Status

Terminal

Status

Terminal

Status

Terminal

Status

Terminal

Status

Fig. 4-3 Relationshipbetween input terminal

status and displaysymbols in monitoring mode

: Terminal turns ON,valid input of terminal

: Terminal turns OFF, invalid input of terminal

FWD REV X5 X6 X3 X4 X1 X2

Tips

Chapter 4 Operator panel and its Operation

-27--27-

4.1.5 Use ofOperator Panel

Parameter modification inthe monitoring status(modify the motor

rotating speed fromFd00 to Fd04).

Initializing

Modification of parametervalue for function codes (modify the

parame ter value for F2.19jog function from10.00Hz to 20.00Hz).

Initializing

Chapter 4 Operator panel and its Operation

-28--28-

Initializing

Modification of parametervalue for function codes (modify the

parameter value forF0.01 frequency setting mode from 1to 0)

Parameter initializing (restoreto the factory default setting)

indicates the digital

tube is flickering;

indicates the digital

tube is notflickering.

Initializing

Tips

Chapter 4 Operator panel and its Operation

-29--29-

Chapter 4 Operator panel and its Operation

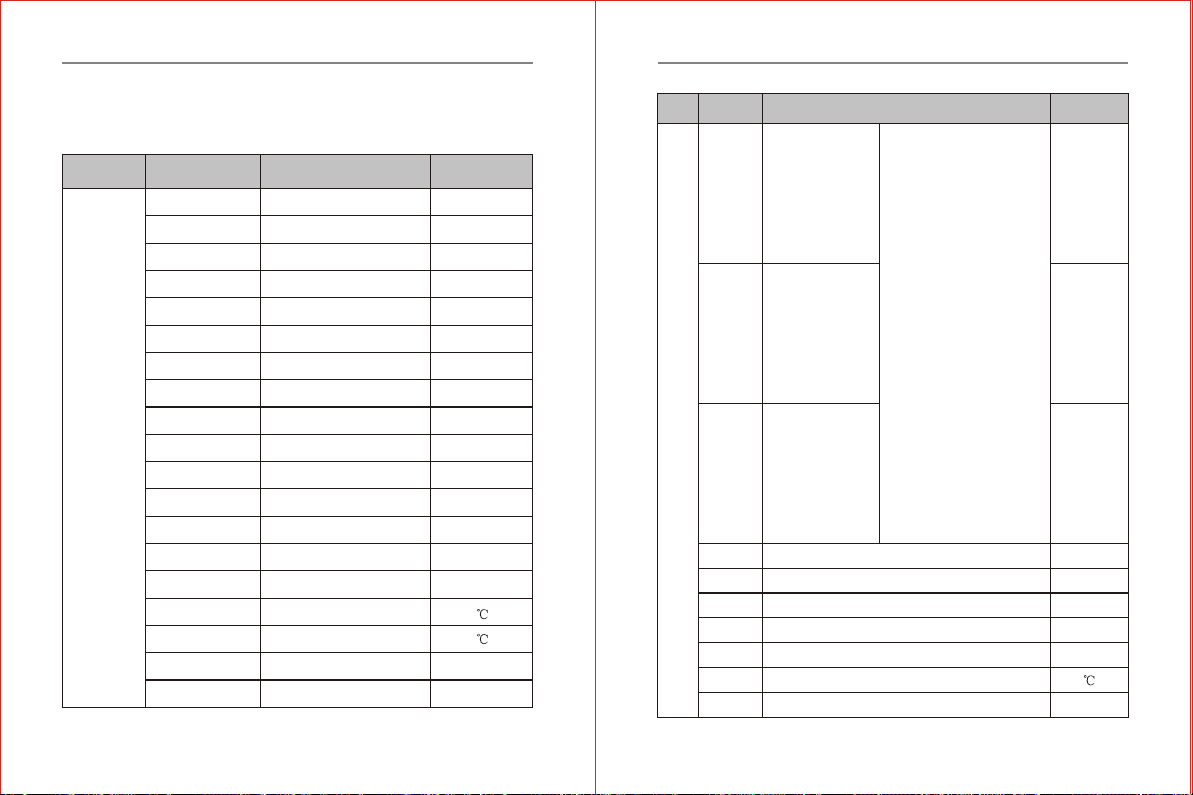

Table 4-2Monitoring Parameter LEDDisplay List

4.2 Monitoring ParameterDisplay

Category Display Code Name Unit

Monitoring Display Parameters

Output frequency

Setting frequency

Output current

Output voltage

Motor rotation speed

Running linear speed

Setting linear speed

DC bus barvoltage

Input voltage

PID set value

PID feedback value

Analog inputAVI

Analog inputACI

Impulse input frequency

Input terminal status

Radiator temperature

Module temperature

Current counter value

Setting counter value

Hz

Hz

A

V

r/min

m/s

m/s

V

V

V

mA

KHz

Fd00

Fd01

Fd02

Fd03

Fd04

Fd05

Fd06

Fd07

Fd08

Fd09

Fd10

Fd11

Fd12

Fd13

Fd14

Fd15

Fd16

Fd17

Fd18

-30--30-

Monitoring Display Parameters

1st diagnostic

failure codes

2nd diagnostic

failure codes

3rd diagnostic

failure codes

0:OC-1 Acceleration

running over current

1:OC-2 Deceleration

running over current

2:OC-3 Steady-speed

running over current

3:OU-1 Acceleration

running over voltage

4:OU-2 Deceleration

running over voltage

5:OU-3 Steady running

over voltage

6:OU-4 Over voltage when

power off

7:LU Under voltage of running

8:LP Input side open-phase

9:SC Power module failure

10:OH Radiator over heat

11:OL Inverter overload

12:OL Motor overload

13:EF external equipment

failure

14:CE-1 COM error

15:CE-2 Remain

16:CE-3 Current detection error

17:CE-4 Keyboard

communication failure

18:CPU failure

Output frequency of the last failure

Setting frequency of the last failure

Output current of the last failure

Output voltage of the last failure

DC bus bar voltage of thelast failure

Module temperature of the last failure

Software version

Category

Display Code

Name Unit

Fd19

Fd20

Fd21

Fd22

Fd23

Fd24

Fd25

Fd26

Fd27

Fd28

Hz

Hz

A

V

V

Chapter 4 Operator panel and its Operation

-31--31-

-32--32-

Chapter 5 Operation of Inverter

5.1 TrialOperation

5.1.1 Safety Instructionon Trial Operation

The following stepsshould be inspectedand confirmed beforethe trial

operation of theinverter:

Be sure the application ambien t and installationfor the inverter is

in accordance withthe requirements specified in Clause 3.1.

Be sure themain circuit iscorrectly wired. Theinput power supply

of theinvertermust beconnected to the terminalR, S and T(orL,

N. The output terminal U, Vand W must be connectedto the motor.

Be sure theground terminal is reliably and properlygrounded.

Be sure allthe switches and terminals are inproper state ofoff or

shut down.

Be sure there isno short cuttingor short toground of allthe terminals

and electrified parts.

Be sure allthe terminals, connectorsand screws are tightly fastened .

Be sure themotor has no other loads.

5.1.2 TrialOperation

Try thisstep only aftercareful inspection asmentioned in theclause

5.1.1.While in trialoperation, it issuggested that the motor hasvacant

load to avoid damage to this mechanicalequipment arising fromincorrect

operation. During trial operation, if theoperating instruction isF0.04,

then the RUN/STOP key control (factory default setting) ofthe operator

panel must beselected. The trialoperationstepsmust befollowed as

shown in thetable 5-1 below.

Chapter 5 Operation of Inverter

Table 5-1Trial OperationSteps

Order Operation Description

Switch on, inverter

energized.

When energized, the inverter isin the

state of readiness and LED displays

0.00Hz.

Press / till LED

displays 5.00Hz.

Set the frequency to 5.00Hz. Thisstep

can be left out if thedisplayed frequency

is already 5.00Hz when energized.

Press RUN .

Motor begins rotating, the frequency displayed

on the inverter LED raises from 0.00Hz to 5.00Hz,

and the built-in cooling fan begins working.

Keep a close eye on the

following points:

if there is any abnormal

vibration or noise when the

motor runs.

if there is any tripping or

other abnormality of the

inverter.

If the motor runs in the

correct direction.

if the value for rotation

speed and frequency is

correct.

If there is any anomaly ortripping, stop

running immediately and cut offthe

power supply. Please referto Chapter 7,

find the trouble causes, then proceedtrial

operation again after troubleshooting.

If the motor runs in thewrong direction,

change arbitrary two-phase connection

of the output terminal U,V or W.

Go to the next step ifeverything is

normal.

Press continuously till

LED displays 50.00Hz.

The motor accelerates rotating and the displayed

frequency rises from 5.00Hz to 50.00Hz. Go to

the next step if everything is normal.

Press continuously till

LED displays 0.00Hz.

The motor decelerates rotating and the displayed

frequency falls from 50.00Hz to 0.00 Hz. Go to

the next step if everything is normal.

Press STOP .

The inverter stops outputting, the motor stops running

and the trial operation ends. If everything is normal,

please repeat the operation for several times.

2

3

4

5

6

7

Chapter 5 Operation of Inverter

-33--33-

-34--34-

All the inverter functions are determinedby set parameters.The

parametersof inverter ZVF9V-M series consist of thefunction codes

F0.00~FA.12, seethe detail inChapter6 ofthis manual.The displayed

parameter value ofeach function code is the factory defaultvalue of

the inverter beforeEX factory,which can bemodified by the user

accordingto hisneeds. It isnoteworthy that a user shall change the

relative function parameterswhen he amends a parameter because

some of theparameters are inter-related.It is not recommended to

modify the setparameter value if there is nospecial requirement, for

the factory defaultsetting has beendone properly.Otherwise,thismay

cause damage tothe inverter orequipment due to error parameter.

In case thereis an error alternation ofthe parameter, please initialize

the parameter withreference to theoperation method in the clause

4.1.5 Parameter Initializing Restoring Factory DefaultSettings .

Do not open thefront cover whilethe inverter is powered ON.

Otherwise, there isthe danger of electric shock.

Do not touchthe inner sideof the inverter while the power is

ON, nor put any foreign matter, i.e., rodor other matterinside

the inverte r. Otherwise, itmay result inserious damage tothe

equipment or death to personnel.

Do not operatethe inverter withwet hands.

If Retry Modeis set, please put a warning sign like "KEEP

CLEAR" or "HAZARD"in an eye-catching place before the

equipment to avoid suddenrestartof theequipment aftera trip

stop that may result in injury to personnel.

5.2 Cautions forOperation

If the inverter runsat a frequencyhigher than 50Hz, DOconfirm

it is within the speed range acceptable by yourmotor bearing

and mechanical device. Otherwise, there is the danger of

damage to themotor.

Derating should be donebefore use dueto less effective of heat

dissipation when ageneral motor runs at a low frequency. If

it is aconstant torque load, then a forced method ora special

variable frequency motorshould be used to release heat.

HAZARD

WARNING

Chapter 5 Operation of Inverter

DO cut offthe power supply of an inverterset aside for a long

time toavoid foreign matter or other things enter in itwhich

may cause damage to the inverter or even lead to fire.

If the inverter is used beyondthe range of allowable working

voltage, then an extra step-up orstep-down voltage transformer

shall be configured.

Due to thin air in a placewhere the altitude is higher than 1,000m,

heat dissipation of the inverter will be less effective. Hence

derating should be performed before use. In general, when t he

height rises by 1,000m, the rated voltage of theinverter shall be

reduced by 10%.

DO NOT touch the radiator or charging resistor of the inverter

with hand(s). Otherwise, there is the possibility of getting scalded.

DO NOTproceed direct start-stop operation frequently with a

contactor or any other switch devices in the inverter input side.

As large charging current exists inthe main circuit of the inverter,

frequent power-on/off may produce cumulativeeffect resulting

in heat fatigue ofinverter components and great reduction of

service life of the inverter.

In case abnormalities occur,such as smoke, off odor, strange

sound and so on, DO cut offthe power supply immediately,

overhaul the equipment or turn to the agent for help via phone

call.

The contactor KM1 and KM2 mustbe designed in interlocked

manner to realize converting between power frequency and

variable frequency.It is forbiddento close synchronously.

Otherwise,it may lead to permanent damage to the inverter.

WARNING

CAUTION

FORBIDDEN

COMPULSORY

WARNING

Chapter 5 Operation of Inverter

-35--35-

This manual suits for next models

6

Table of contents

Other Chziri Inverter manuals

Popular Inverter manuals by other brands

BARRON

BARRON EXITRONIX Tucson Micro Series installation instructions

Baumer

Baumer HUBNER TDP 0,2 Series Mounting and operating instructions

electroil

electroil ITTPD11W-RS-BC Operation and Maintenance Handbook

Silicon Solar

Silicon Solar TPS555-1230 instruction manual

Mission Critical

Mission Critical Xantrex Freedom SW-RVC owner's guide

HP

HP 3312A Operating and service manual