Chziri ZVF200-M User manual

User's Manual

ZVF200-M Vector Inverter

User's Manual

ZVF200-M Vector Inverter

Manufacturer: Wenzhou Ziri Electrical Technology Co.,Ltd.

Add: NO.66 , Daqiao Road , Liushi Town ,Yueqing City , 325604. Zhejiang ,China .

Tel: +86-577-27863300

Http://www.chziri.com

Manufacturer: Wenzhou Ziri Electrical Technology Co.,Ltd.

Add: NO.66 , Daqiao Road , Liushi Town ,Yueqing City , 325604. Zhejiang ,China .

Tel: +86-577-27863300

Http://www.chziri.com

Thank you verymuch for yourpurchase of theinverter

ZVF200-M series.

This manual introduces the installation, operation,

function setting, troubleshooting and etc.of the inverter

ZVF200-M series..

Incorrect installation or use may result in damage or

other accidents. Doread all instructionsin detail be

fore installing or operating.

Please forward thismanual to the end user, and keep

it handy for quick reference.If there areany doubts

or questions, please contact the Technical Service

Center of Our Company

Foreword Table of Contents

Chapter 1 Safety Instruction..................................................P1

1.1 Safety Symbolsand Definition ............................................P1

1.2 Application Range .............................................................P2

1.3 Installation Ambient ..........................................................P2

1.4 Cautions for Installing........................................................P3

1.5 Cautions for Operation .......................................................P5

1.6 Cautions for Disposing .......................................................P8

Chapter 2 Introduction to the Product....................................P9

2.1 Inspection upon Arrival ........................................................P9

2.2 Demonstration ofthe Model ................................................P9

2.3 Specification Label ..........................................................P10

2.4 Outside Drawing& Structure.............................................P10

2.5 Models and Specifications ................................................P11

2.6 Technical Indication .........................................................P12

Chapter 3 Installation and Wiring ......................................P15

3.1 Installation ......................................................................P15

3.2 Remote control keypads and wiring connection ..................P16

3.3 Wiring Diagram ...............................................................P18

3.4 Inverter SystemWiring .....................................................P25

Chapter 4 Operationpanel and Operation ...........................P26

4.1 Operation Panel and Description ..................................... .P26

Tableof Contents

-1-

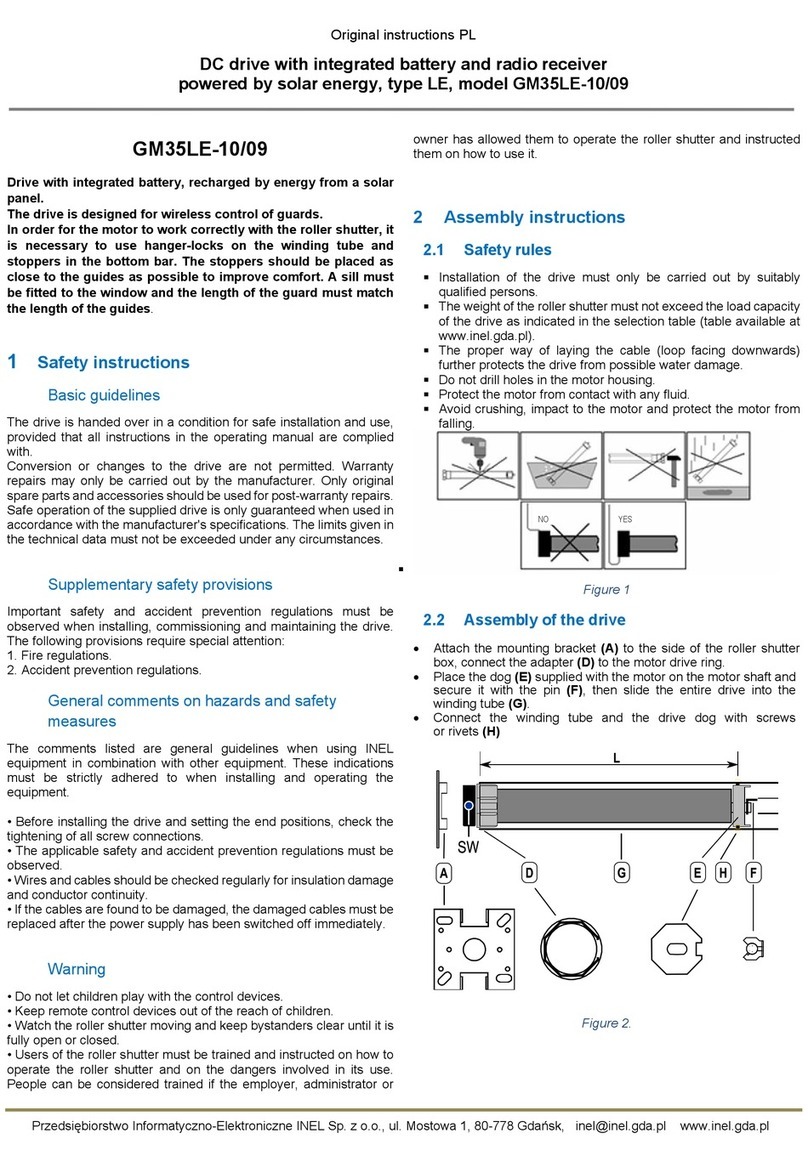

1.1 Safety Symbols and Definition

The safety instructions described in this manual arevery important. Toavoid

any error that may resul t indamage to equipment, injury to personnel orloss

of property, do readand clearly understand all of the safety symbols, symbol

definitions and be sure to observe the indicatedsafety instructions below.

Chapter 1 Safety Instruction

Safety Symbols

HAZARD

WARNING

CAUTION

TIP

Symbol Definitions

This symbol indicates hazardous HIGH VOLTAGE.

Any incorrect operation may result in serious damage

to the equipment or death to personnel.

This symbol indicates that any incorrect operation can

result in damage to the equipment or minor to moderate

injury to personnel.

This symbol calls your attention to follow the instructions

while in operation or in use.

This symbol calls attention to some useful messages

for the user.

FORBIDDEN

COMPULSORY

This symbol indicates anything forbidden to do.

This symbol indicates something must do.

Chapter 1 Safety Instruction

Tableof Contents

Chapter 5 InverterUse ............................................................P31

5.1 Trial Operation ...................................................................P31

5.2 Examples of Use..................................................................P34

Chapter 6 Parameters ............................................................P40

6.1 Schedule of Function Parameters ........................................P40

6.2 Description of Parameters Settings ......................................P60

Chapter 7 Common Fault & Anomalies and Solutions............P120

7.1 Fault Code Information.....................................................P120

7.2 Anomalies and Solutions...................................................P124

Chapter 8 Inverter Inspection and Maintenance..................P126

8.1 Inspection and Maintenance...............................................P126

8.2 Replacement of the Inverter Wearing Parts......................... P130

8.3 Storage of the Inverter .......................................................P131

Chapter 9 Outline & Mounting Dimension............................P132

9.1 Inverter Outline Dimensions& Mounting Dimensions ........P132

9.2 Operation Panel Outline Dimension and Mounting Hole

Dimension ........................................................................P134

Chapter 10 Quality Warranty...............................................P135

Appendix..............................................................................P136

Appendix 1 Optional Parts Selection........................................P136

Appendix 2 EMI Protection.....................................................P138

Appendix 3 RS485 communication protocol.............................P145

Appendix 4 Inverter User's Warranty Bill.................................P159

-2- -3-

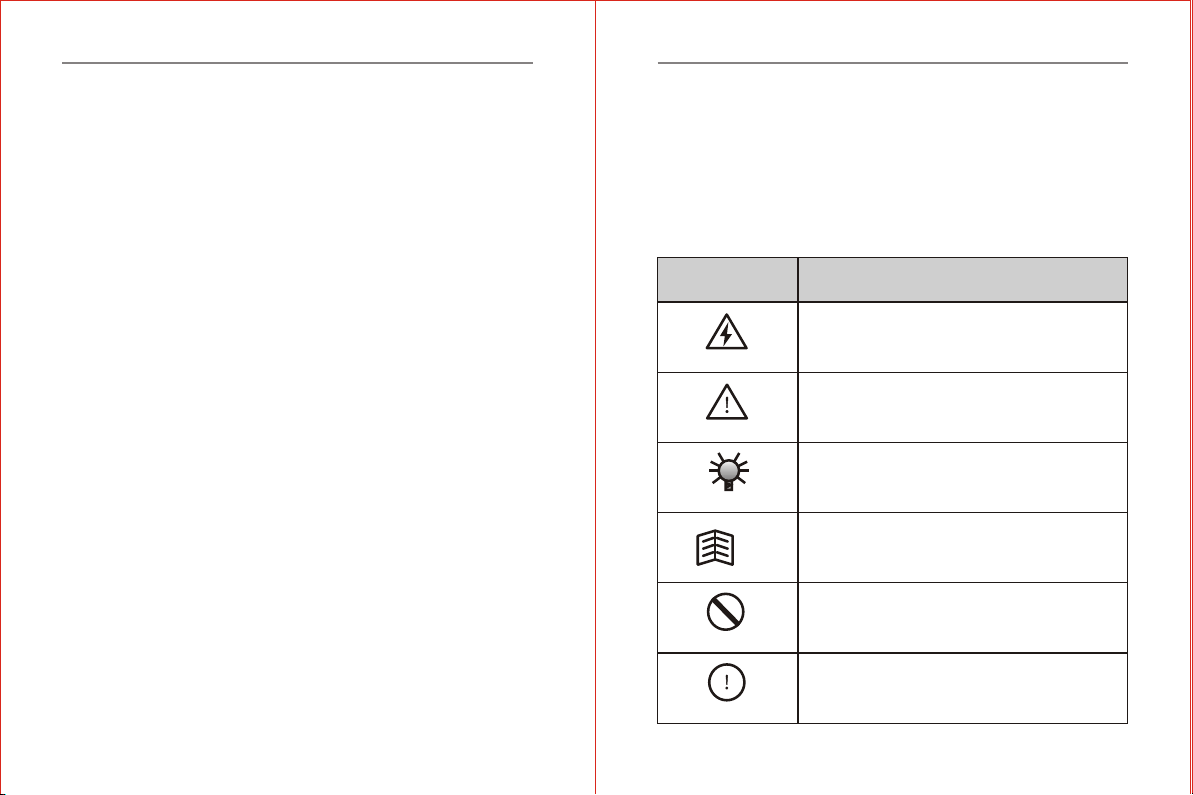

Chapter 1 Safety InstructionChapter 1 Safety Instruction

CAUTION

WARNING

1.3 Installation Ambient

1.2 Application Range

1.4 Cautions for Installing

CAUTION

This inverter is applicable to generalindustrial purpose

threephase AC asynchronic electricmotor.

This inverter can not be used in the equipment that may result

in threat or injury to personnel due to inverter trouble orerror,

such as nuclear power control equipment, aviation equipment,

transportation equipment, life supporting system, safety

equipment, weapon system and etc. Please consult Ziri Company

before using it for special purposes.

This product is made under st rict quality control and supervision.

But when used in some key equipment, protective measures

should be taken to avoid further extension of accident due to

inverter trouble.

Be sure to install the inver ter in a well-ventilated indoor location.

To get the best cooling effect, it is recommended tofix the inverter

vertically, and extra ventilation devices are neededwhen installed

horizontally.

Be sure that the ambient temperatureis between -10~45 .If the

temperature is higher than 40 , please removethe upper cover. If

the temperature is higher than 50 , forced heat radiation orderating

is needed from the external. It is recommended not to use the

inverter in suc h a high temperature. Otherwise, it may greatly

reduce the service life of the inverter.

The ambient humidity is required to be lower than 90% without

dew condensation.

The inverter shall be installed in a place where the vibration is

less than 0.5G. Otherwise, it may fall and cause damage to the

equipment. It is also noteworthy that theinverter could not bear

any sudden bump.

The inverter should be kept away from electromagneticinterference

(EMI), flammable and explosive ambient.

WARNING

Be sure to install the inverter onmetallic materials (i.e., metal).

Otherwise, there is the danger of fire.

Be sure not to let the foreignmatter enter into the inverter, such as

wireclippings, spatter from welding, metal (zinc or ferrous)

meshavings and etc.Otherwise, there is the danger of getting

burned due to short circuit.

HAZARD

Do not operate electrical equipment withwet hands.

Do not operate wiring unless thepower supply is com pletely

off.

Do not open the front cover or perform wiring while the inverter

is powered ON. Otherwise, there is thedanger ofelectric shock.

Do wait at least 10minutes after the power is disconnected

before performing the work of wiring orinspection. Otherwise,

there is the danger of electric shock.

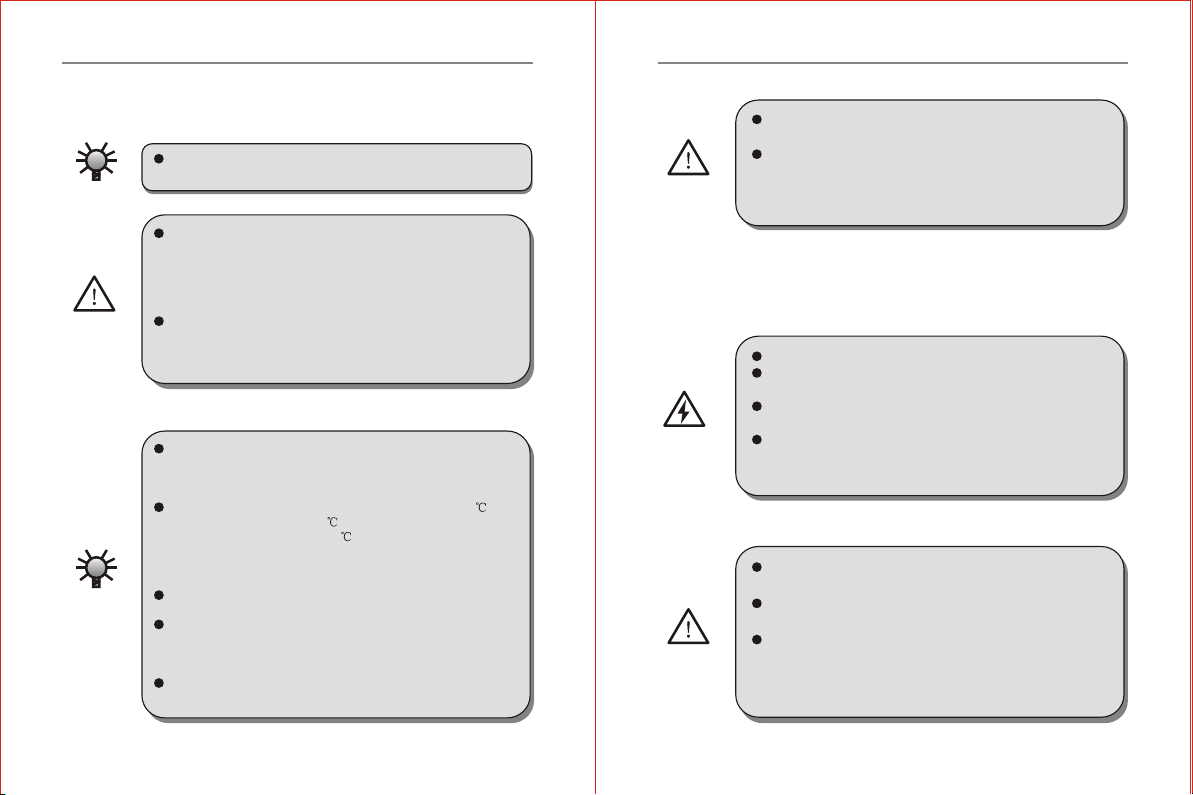

WARNING

Do not install or operate if theinverter is damaged or has parts

missing to prevent injury to personnel orloss of property.

The main loop terminal should be tightly connected to the cable.

Otherwise, the inverter may be damaged dueto loose contact.

The ground terminal must be reliablyand properly grounded to

ensure security.To avoid commonground impedance, multipiece

inverters should be grounded at one shared point, as shown in

the Figure 1-1.

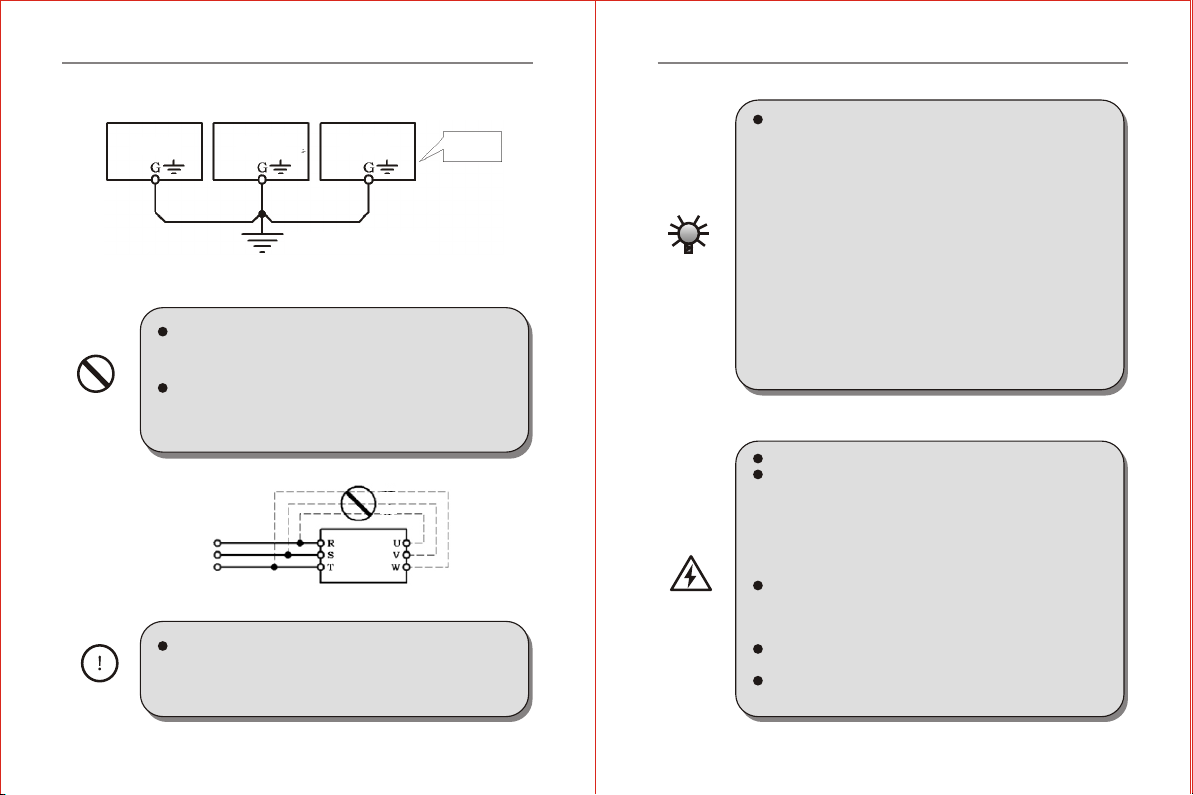

FORBIDDEN

COMPULSORY

CAUTION

Inverter Inverter Inverter Proper

grounding

method

Grounding with bus bar

(Connect to the groundat the same point)

Three-phase

AC

Power Supply

FORBIDDEN

Figure 1-2

Figure 1-1

DO NOT connect control terminals (except termina ls marked

"TA", "TB"and "TC") to AC220V power supply, which may

cause damage to the inverter.

DO NOT connect AC power supply to the output terminals

marked "U", "V"and "W". Otherwise, i t may c ause damag e

to the inverter, as shownin theFigure 1-2.

DO install a no-fuse circuit breaker or leakage protective

circuitbreaker in the side of inverter input power supply to

prevent expanding of accident due to aninverter problem.

It is not advisable to install anelectromagnetic contactor in the

side of output power supply, because the operation of open and

close to the contactor when the motor is runn ing may cause

damage to the inverter arisingfrom over-voltageproducedduring

this process. But it is still necessary to install acontactor if ther e

have one situation of the following three points:

1. The system of frequency inverter used to controlenergy saving

usually works at a rated rotation speed. To run the inverter

economically, there is amust to remove the inverter.

2. The inverter participates in some important procedure and cannot

stop operating for a long period oftime. To realizefree shift in

various control systems and improve the reliability of these

systems, there is a must to installa contactor.

3. When an inverter controls severalmotors, there is a must to in

stall a contactor.

Caution: DO NOT operate the contactor if there is output of the

inverter.

1.5 Cautions for Operation

Do not operate electrical equipment withwet hands.

An inverter stored fo r a year or longer should be given powerup

test before use so that the maincircuit filter capacitor could be

recovered.When the inverter is in the state of power up,it is

necessary to raise the voltage gradually tothe rated value wit h

a voltage regulator. Generally, the charging time should be

controlled within 1~2 hours. Otherwise, there is the danger of

electric shock or exposure.

Do not touch the inner sideof the inverter while the power is

ON, or put any foreign matter, i.e., rod orother matter inside

the inverter. Otherwise, it may result in serious damage to the

equipment or death to personnel.

Do not openthe front cover while the inverter is powered ON.

Otherwise, there is the danger of electricshock.

Be careful to select the RestartMode. Otherwise, there is the

danger of personnel death.

-5-

-4-

INVERTER

HAZARD

Chapter 1 Safety InstructionChapter 1 Safety Instruction

FORBIDDEN

Forbidden

Forbidden

Inverter

Power factor

compensation

capacitor

Surge current sink

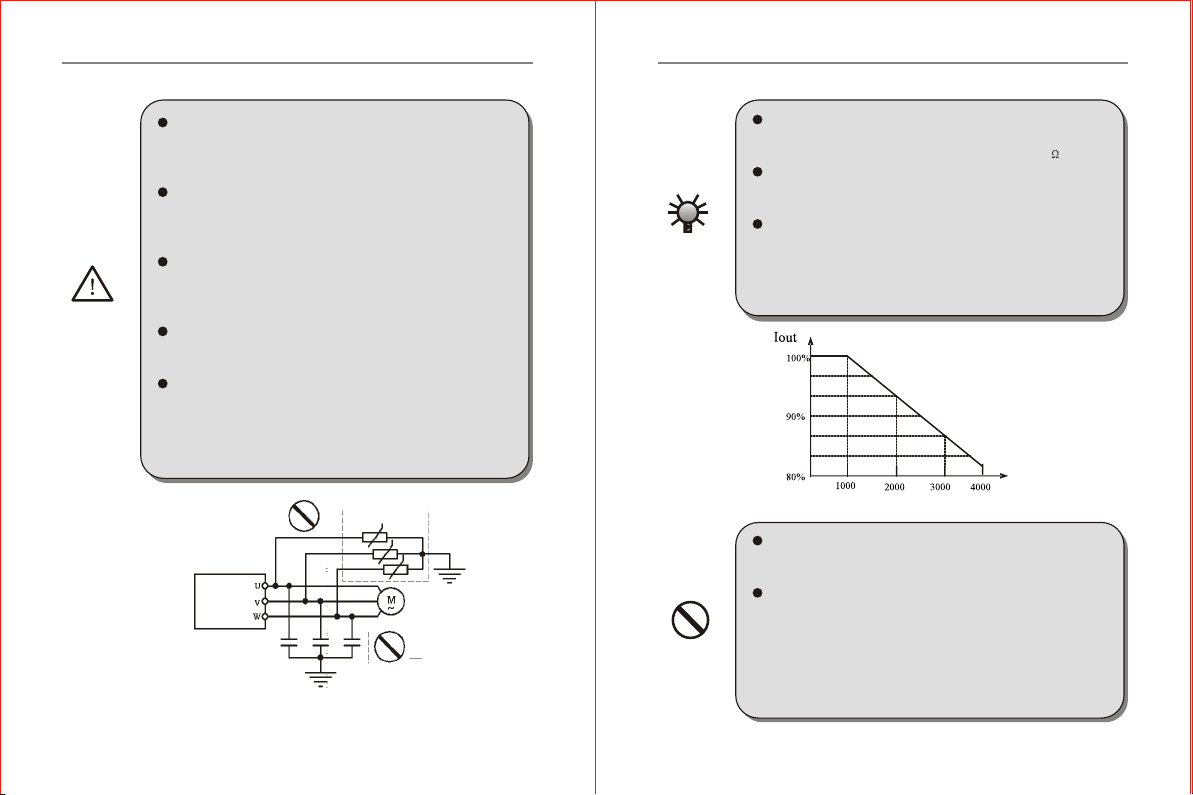

Figure 1-3

M

Figure 1-4 Diagramof Inverter Derating Curve

WARNING

If the inverter runsat a frequency higher than 50Hz, DO confirm

it is within the speed range acceptable by your motor bearing and

mechanical device. Otherwise, there is the dangerof damage to

the motor.

It is not advisory to run the reduction box, gear and other

mechanism that need lubricating at low speed for a long period.

Otherwise, it may reduce the service life of these equipment or

even damage the equipment.

A general motor should be derated beforeuse dueto lesseffective

of heat dissipation when it runs at a low frequency.If it is a constant

torque load, then a forced method or a special variable frequency

motor should be used to release heat.

DO cut off the power supply of an inverter set aside fora long

time to avoid foreign matter or other things enter in it which may

cause damage to the inverter or evenlead to fire.

The output voltage of inverter isPWM impulse wave. DO NOT

install a capacitor or surge current sink (i.e., a varistor) in the

i nverter output po rt. Otherwise, there is the danger of fault tripping

of the inverter or damage to its power elements. DO removesuch

kind of things if already installed. Seethe Figure 1-3 below.

CAUTION

Motor insulation should be checked before the motor is used

for the first use or reused after along-term idle. Be sure the

insulation resistance measured is no lower than5M .

If the inverter is used beyondthe range of allowable working

voltage, then an extra step-up or step-down voltagetransformer

shall be configured.

Due to thin air in a place wherethe altitude is higherthan 1,000m,

the heat dissipation of inverter will be less effective. Hence

derating should be done before use. Ingeneral, whenthe height

rises by 1, 000m, the rated voltage of the inverter shall reduceby

10%. Refer to the Figure 1-4 fordetails of the derating curve.

DO NOT touch the radiator orcharging resistor of the invert er

with hands. Otherwise,there is the possibility of getting

scaled.

DO NOT proceed directstart-stop operation frequently with a

contactor or any other switch devices inthe inverter input side.

As large charging current exists in the main circuit of the

inverter,frequency power-on/off mayproduce cumulative effect

resulting in heat fatigue of inverter components and great

reduction of service life of the inverter. See the detail inthe

Figure 1-5.

-7-

-6-

Chapter 1 Safety InstructionChapter 1 Safety Instruction

Chapter 1 Safety Instructions

COMPULSORY

1.6 Cautions for Disposing

WARNING

CAUTION

Chapter 2 Introduction to the Product

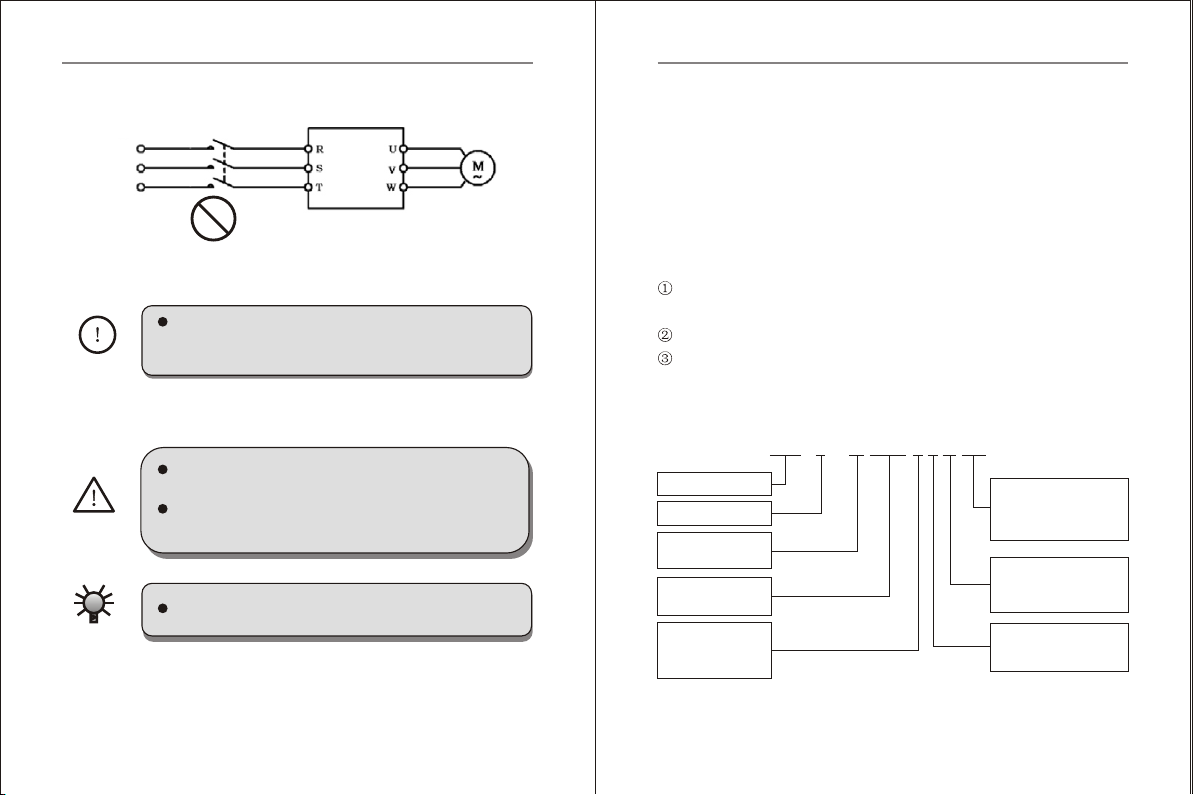

Three-phase AC Power Supply

Inverter

Forbidden

On

Off

2.1 Inspection uponArrival

The inverter haveexcellent quality assurance system . Passed through

strict test before shipment .and made a crash ,shock or other package

treatment . Butwe can not rule out the inverter subject tostrong shock or

extruded during transportation . Please check andconfirm the products as

flows when openthe package .

Check whether thecase of inverteris deformed or damaged . or the

components are damagedor drop off .

Check the label ofinverter are matchedwith the productthat you ordered.

Check weather theitems of packing list are complete .

Chapter 2 Introduction to the Product

2.2 Demonstration ofthe Model

ZVF 200 - M 0015 T 4 M DR

Inverter Model

Design Number

Type Code

Mini Type M

Motor Power Code

1.5KW 0015

''DR''indicates there is a

braking inside.No ''DR'',

no braking inside.

M: Integrated Module

S:Discrete Module

Voltage Class Code

220V 2

380V 4

Voltage Phase Code

Single Phase S

Three Phase T

Figure 2-1 Inverter Model Demonstration

-9-

Figure 1-5

In case abnormalities occur, such as smoke, off odor, strange

sound, DO cutoff the power supply immediately,overhaul the

equipment or turn to the agent forhelp via phone call.

Exposure may happen when the electrolyticcapacitor (ELCC)

of the inverter burns. Be careful tocope with it.

The plastic parts on the operator panel will give off tox ic gas

when getting burned. Be careful to copewith it.

Dispose damaged inverter as industrial waste.

-8-

-11-

-10-

2.3 Specification Label

Name

Inverter Model

Adaptive Motor Power

Input Power Rating

Output Power Rating

INVERTER

MODEL

POWER

INPUT

OUTPUT

: ZVF200-M0015T4MDR

: 1.5KW

: 3PH 380VAC50/60Hz

: 3PH 4.0A 0-400Hz

Figure 2-2 InverterSpecifications Label

2.4 Outside Drawing& Structure

Figure 2-3 ModelAOutside Drawing

3. Digital Keypad

6. Input OutputTerminal

2. Bottom Cover

5. Lower Shell

8. Fan

Figure 2-4 ModelAStructural Representation

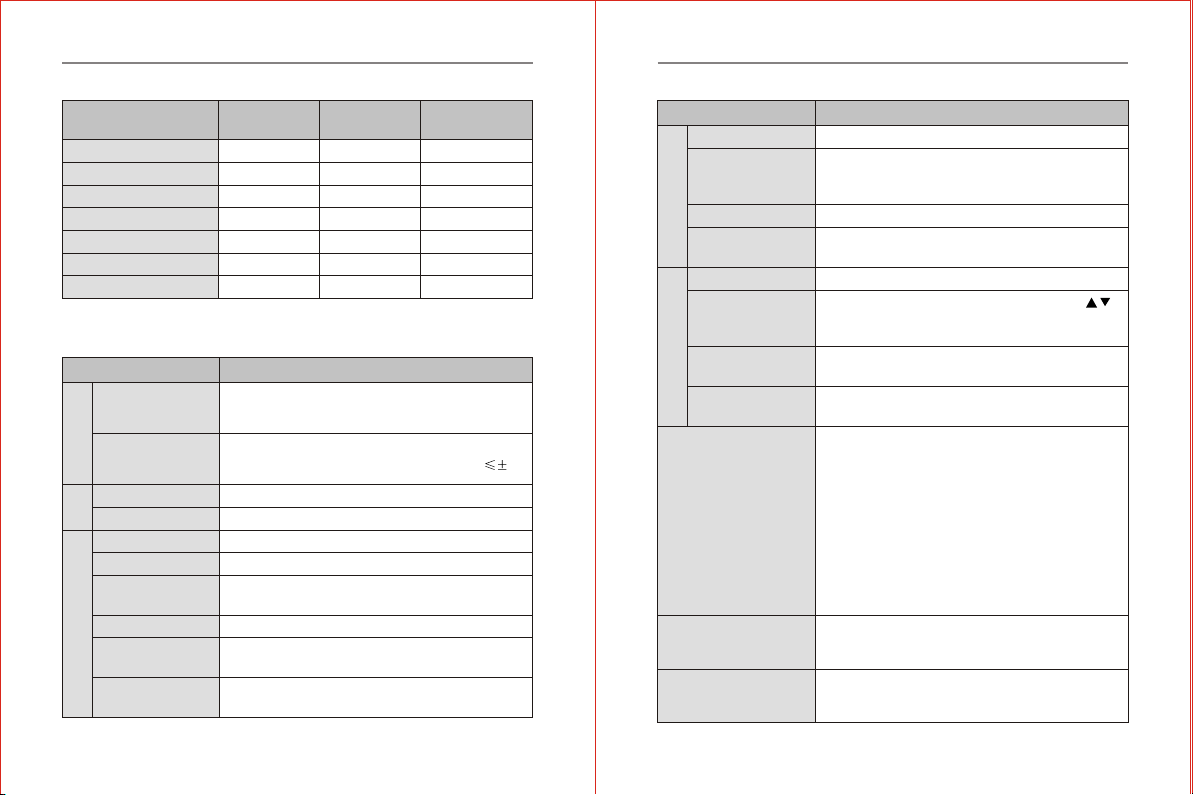

2.5 Models andSpecifications

Table 2-1Inverter Models and Specifications

Inverter Models

(ZVF200-M)

Input Voltage

(V)

Rated output

current (A)

Adaptive Motor

Power (KW)

ZVF200-M0004T2/S2

ZVF200-M0007T2/S2

ZVF200-M0015T2/S2

ZVF200-M0022T2/S2

ZVF200-M0037T2

220

220

220

220

220

2.5

5.0

7.0

10.0

17.0

0.4

0.75

1.5

2.2

3.7

4. Upper Shell

7. Power Terminal

1. Upper Cover

Chapter 2 Introduction to the ProductChapter 2 Introduction to the Product

-13-

-12-

Inverter Models

(ZVF200-M)

Input Voltage

(V)

Rated output

current (A)

Adaptive Motor

Power (KW)

ZVF200-M0055T2

ZVF200-M0007T4

ZVF200-M0015T4

ZVF200-M0022T4

ZVF200-M0037T4

ZVF200-M0055T4

ZVF200-M0075T4

220

380

380

380

380

380

380

25.0

3.0

4.0

5.0

8.5

13

18

5.5

0.75

1.5

2.2

3.7

5.5

7.5

Item Item Description

Rated voltage

frequency

Allowable Voltage

range

Single phase/Three phase220VAC. Three phase

380V.50HZ/60HZ

Voltage fluctuate range: 220V:180V~264V ;380V:342~528V.

Voltage unbalance rate:<3%. Frequency fluctuation: 5%

Input

0~ three phase input AC voltage

0.1~400HZ.

Rated voltage

Frequency

Output

Modulation mode SPWM (sinusoidal PulseWidth modulation)

Control mode V/F control & sensorlessvector control

Digital setting :0.1HZ. Analog setting :Max.

Frequency x0.1%.

Frequency

resolution

Overload capacity 150% of rated currentfor 1 minute

Including the auto-torque .Auto-slipcompensation .

Start torque can be150% at 5.0HZ.

Torque

Characteristic

0.1~600 seconds ( 2 independment setting for

Accel/Decel time )

Acel/Decel Time

Control Function

Item Item Description

Adjustable V/F Pattern

V/F pattern

Operation frequency 0~50HZ . Output 0~100 %

rated current .

Starting time 0~5 seconds. Stop time 0-25seconds

DC Breaking

1.0~15.0KHZ

Carrier frequency

Stall prevention level

Frequency setting

20%~200% setting of ratedcurrent of inverter

according to the motorload characteristic

Control Function

Keypad .External terminal control . COM Serial control

Command

Keypad potentiometer setting . Operation panel

setting . external Terminal UP/DOWN setting .

Analog signal setting . 485 COM Setting.

Frequency setting

0-10VDC singal . Outputfrequency . current .output.

Multi-function

analog output

Programmable relay . opencollector output . Fault

signal output .

Output signal

Operation Function

AVR.Over voltage . Over-current stall prevention .

3-Groups fault records .Reverse inhibition .

Momentary Power loss restart. DC braking .

Auto torque& slip compensation. acceleration/

deceleration. S- curve .autotuning . adjustable

carrier frequency.Frequency limits . Parameterlock

/reset. Vector control . PIDcontrol . Counter .remote

control .MODBUS communication .Abnormal reset ,

Abnormal restart . energy saving running .sleep/

revival function . 1st/2nd frequency source selection .

Other Function

2.6 Technical Indication

LED Display can show the inverterrunning status. monitor

parameters. function parameters .errorand ect.

Optional parts selection braking assembly,remotekeypad and connection

cable and soon.

Chapter 2 Introduction to the ProductChapter 2 Introduction to the Product

-15-

-14-

Item Item Description

<0.5G

Vibration

Storage temperature -20 to 60

Ambient

IP20

Forced air cooling

Wall mounted

Protection Level

Cooling mode

Installation

Structure

Chapter 3 Installation and Wiring

3.1 Installation

3.1.1 Use theinverter in the following environmental conditions:

Altitude: Maximum 1000mabove sea level

Ambient Temperature: -10~+45 [Bare Machine: -10~+50 ]

Humidity: 20~90% RH(Non-condensing)

Ambient: Indoor places free from direct exposure to sunlight, dust,

corrosive gas, flammablegas, oil mist,steam, drip andsalt

Vibration: <0.5G

3.1.2 Installation Spaceand Direction

Toget better coolingeffect and convenienceof maintenance, the

inverter shall beinstalled vertically with enough space left (refer to the

figure 3-1). Whentwo and two more inverters are fixed in the same cabinet,

it is recommendedto fix them in parallel and horizontally to reduce heat

produced by them (refer to the figure3-2).When thereis amust to fix them

vertically, pleasefix an insulating board between them so that the heat

produced by the lower one could not have direct influence on theupper

one (refer tothe figure 3-3)

Figure 3-1 Installation

Space

Figure 3-2 Multi-piece

Parallel Installation

Figure 3-3 Multi-piece

Vertical Installation

Chapter 3 Installation and Wiring

Over Current .Over current.Under voltage .external

fault .Overload. Ground fault.Overheating .

Protection Function

Altitude 1000m or less.Keep from corrosive gas.

liquid and dust

Installation location

Ambient Temperature -10 to 40 ( -10 to 50 without blind plate )

Ambient Humidity Below 90% RH (no-condensing).

Ambient

Chapter 2 Introduction to the Product

-17-

-16-

Fig. 3-4

STPE 2.Install the optional interface boardat the position of keypad.(as

shown in the figure 3-5).

Fig. 3-5

3.2 Remote control keypads andwiring connection

STEP 1.Hand on thenotch of the two sides( rightand left) of the keypad and

pull it up by inward,remove thekeypad.(as shown in the figure 3-4).

STEP 3.Insert the optionalcable with the grounding side intothe slot of

interface board. (as shown in thefigure 3-6).

Fig. 3-6

STEP 4.Put the dismantledkeypad into the installation frame .Fix and

fasten it . Put the otherside cable insert into the keypad .(as shown in the

figure 3-7).

Fig. 3-7

Chapter 3 Installation and WiringChapter 3 Installation and Wiring

-19-

-18-

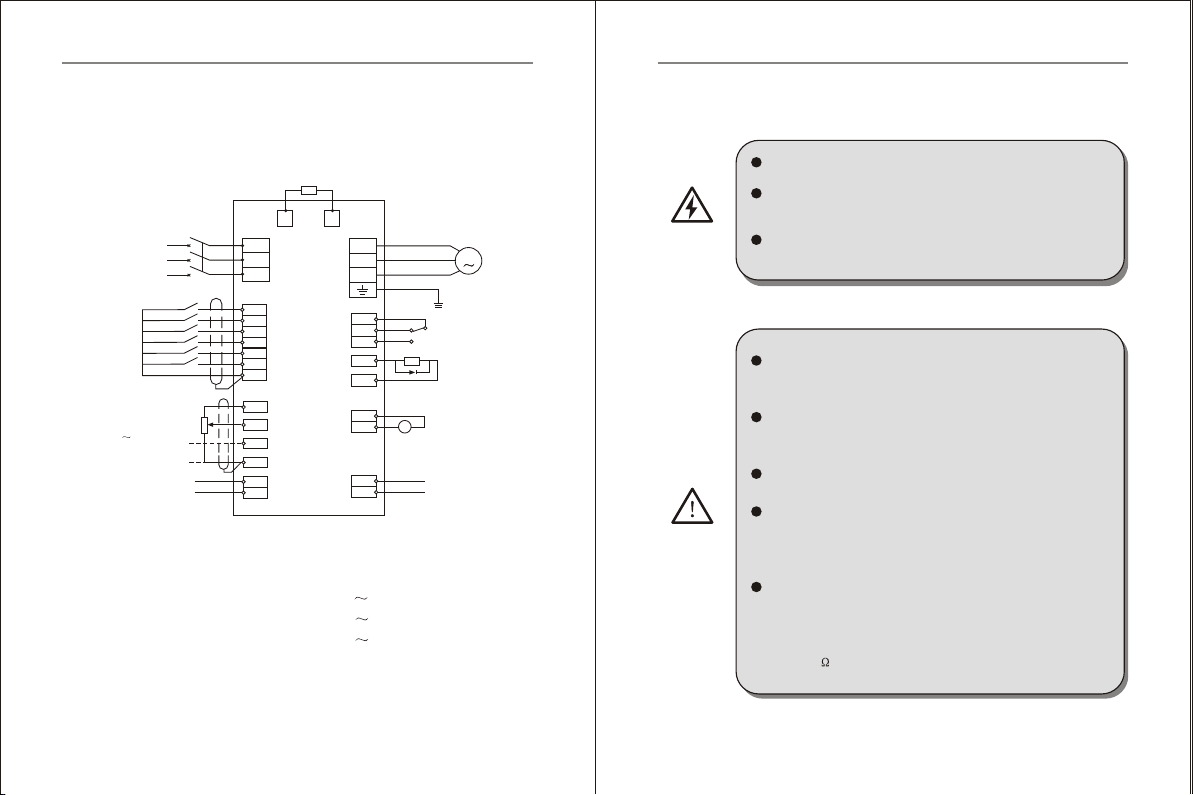

3.3 Wiring Diagram

3.3.1 Basic Wiring Diagram

Model : ZVF200-M0004S2 M0022S2

ZVF200-M0004T2 M0055T2

ZVF200-M0007T4 M0075T4

V

PDB

R

S

T

R

V

W

TA

TB

TC

Y1

12V

X1

X2

X3

X4

X5

X6

GND

AFM

GND

12V

COM

10V

AVI

AC1

GND

SG+

SG-

Braking Resistor

Fault Reley Output

M

TA-TB on when normal

TA-TC on when failure

Open collector

Output

Analog Signal Output

(0-10VDC)

12V Power supply

output Port

MOCB

Three phase

AC inpul

Power supply

Forward/Stop

Reverse/Stop

Reset

Multi-stage speed 1

Multi-stage speed 2

Multi-stage speed 3

Public Terminal

Potentiometer

Input or analog

Voltage Input

(0 10VDC)

Analog Current

Input (0-20mA)

485 COM Port

3.2.2 Cautions forWiring

HAZARD

Waitat least 10 minutes after powerOFF before opening

the front coverof the inverter.

Verify thecharge indicator lampis OFFbeforeproceeding

the work,and be surethat the voltage value of the main

loop terminal Pand DC- isless than 36VDC.

Theinternal wiring of the inverter should be operated

only by authorizedqualified people.

Verifythe rated inputvoltage of the inverter is matched

with AC power supply. Otherwise,there is thepossibility

of damage tothe inverter.

Install in orderand only operate wiring after finishing

main parts install ation. Otherwise, there is an electric

shock or damageto the inverter.

Do not performover-voltage withstand tothe inverter,

for this hadbeen done properlybefore EX-factory.

Be sure toinstall a no-fuse circui t breake r in the i nput

power supply side ofthe inverter to prevent expanding

of accident dueto an inverterproblem, which may cause

damage to thedistribution equipment orlead to fire.

Be sureto connect the ground terminal and the motor

casing to the ground wire whichmust be copper core.The

diameter of thecopper core should conform tothe relevant

national standard. Theground resistanc e should be less

than 10 .

WARNING

Fig.3-8

Chapter 3 Installation and WiringChapter 3 Installation and Wiring

-21-

-20-

When theopen-ended output terminal of the collector

connects to any inductive load,i.e., therelay coil,do

insert a diodeat each endof the load in parallel.

The control wire in the inverter orthe control cabinet

should be atleast 100mm away from the power cable.

DO NOTput them in thesame metallic channel. If t he

signal wireand the power cable need to intersect, they

should intersect at an angleof 90 . The control wire

must adopt STP(shielded twisted pairwire); theshielded

layer must connectto the terminalGND; and the power

wire is recommendedto use metallicshielded cable.

TIP

TIP

The unavoidable strongelectromagnetic interferenceof

the inverter mayhave bad influenceon all the electrical

equipment andmeters inthe same environment. To reduce

interference, the output cable of the inverter can be

inserted in themetal pipe connectingto the ground or in

the metallic shielded cable, andconnect the metallic

shielded layer to the ground.In addition, amagnetic loop

put on the output cable is also effective to reduce

interference.

TIP

Input power RST disorder ,it can connectany one arbitrary

When inverter runsthe direction ofmotor isnot sameas

your required direction.Please change any twoof three

iuput motor wires

When inverter have disconnector toprotect current leakage.

In order to avoidsomething wrong withdisconnect ,please

choose current leakage above 200mA and fi nish it

within more than 0.1 second

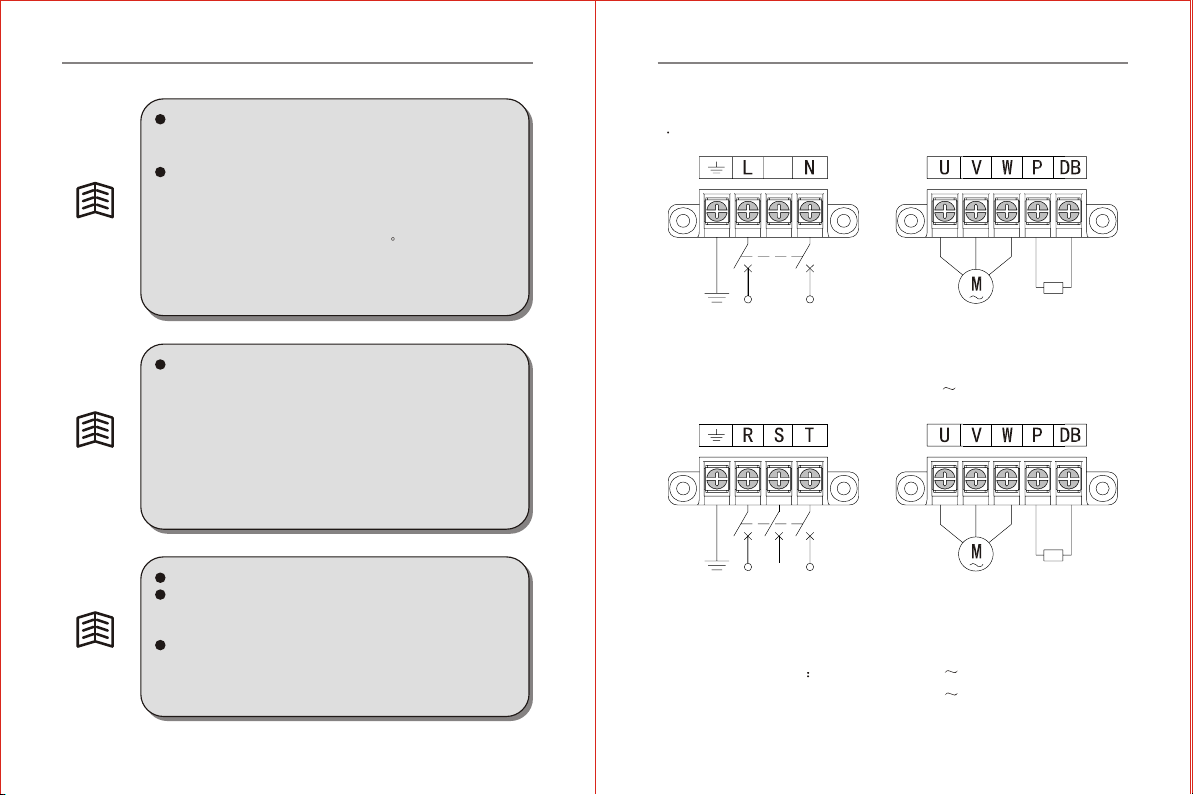

3.3.3 Instruction onMain Circuit Terminals

1 The main circuit terminals are shown as in the figure 3-9~3-10.

Fig.3-9 Diagram 1for Main CircuitTerminals

Earthing Single phase

220V input

Connect with the

braking resistor

Fig.3-10 Diagram 2for Main CircuitTerminals

Model ZVF200-M0004T2 M0055T2

ZVF200-M0007T4 M0075T4

Connect with

three-phase AC motor

Model: ZVF200-M0004S2 M0022S2

Earthing Three-phase

220V/380V Input

Connect with

three-phase AC motor

Connect with the

braking resistor

Chapter 3 Installation and WiringChapter 3 Installation and Wiring

-23-

-22-

2 Function Description on Main Circuit Terminals

Terminal Symbols Function Description

AC line inputterminals, connecting with three-

phase 380V or220V ACinput

AC line inputterminals, connecting with single-

phase 220VAC input

Inverter output terminalsconnecting with

three-phase AC motor

RST

LN

UVW

PDB

G Ground terminal connectingto the ground

External braking resistorterminals, connecting with

two side ofthe external braking resistor

3.2.4 Description ofterminal of thecontrol circuit

1.The terminal ofcontrol circuit shown in Fig 3-11.

Fig 3-7 Controlcircuit terminal

Type Terminal

Symbols Function Description Electrical Specifications

X1

X2

X3

X4

X5

X6

Xn (n=1, 2, 3,6)-GND is

Validonly when there isa

short circuit Thefunctions

can be set bythe parameter

P38 P42

INPUT, 0~12Vpower level

low level valid, 10mA

Multi-function

Input Terminal

Multi-function open collector

output is defined as on-off

output terminal, whose function

is set by the parameterP45

with reference of GND

OUTPUT, Maximum

Current Load I 50mA

Multi-function

Output Terminal

Y1

Analog signal public

terminal

Public

port

GND

External analog preset power

supply, connecting to

potentiometer together with

termianl GND andAVI.The

frequency can be set as

required

Output,10VDC

+10V

Analog voltage singal input,

with reference of GND Input .0 10VDC

AVI

Analog current Singal input,

with reference of GND Input .0 20mA

ACI

Program mable Analog voltage

output P43 with reference of

GND

Output .0 10VDC

AFM

Analog Input Output terminal

2. Description ofthe control circuitterminal

Chapter 3 Installation and WiringChapter 3 Installation and Wiring

-25-

-24-

Type Terminal

Symbols Function Description Electrical Specifications

Power

port

12V 12VDC output(control

power) 12VDC 100mA

Relay contact output.

when normal TA andTB ON,

TA-TC off.Action TA and

TB off,TA-TCON.Set by P46

Contact rated value

NO 250VAC-5A

NO 250VAC-3A

Programmable

output terminal

TA

TB

TC

Communication singal

positive port

Communication singal

negative port

SG+

SG-

COMMUNICATION

PORT

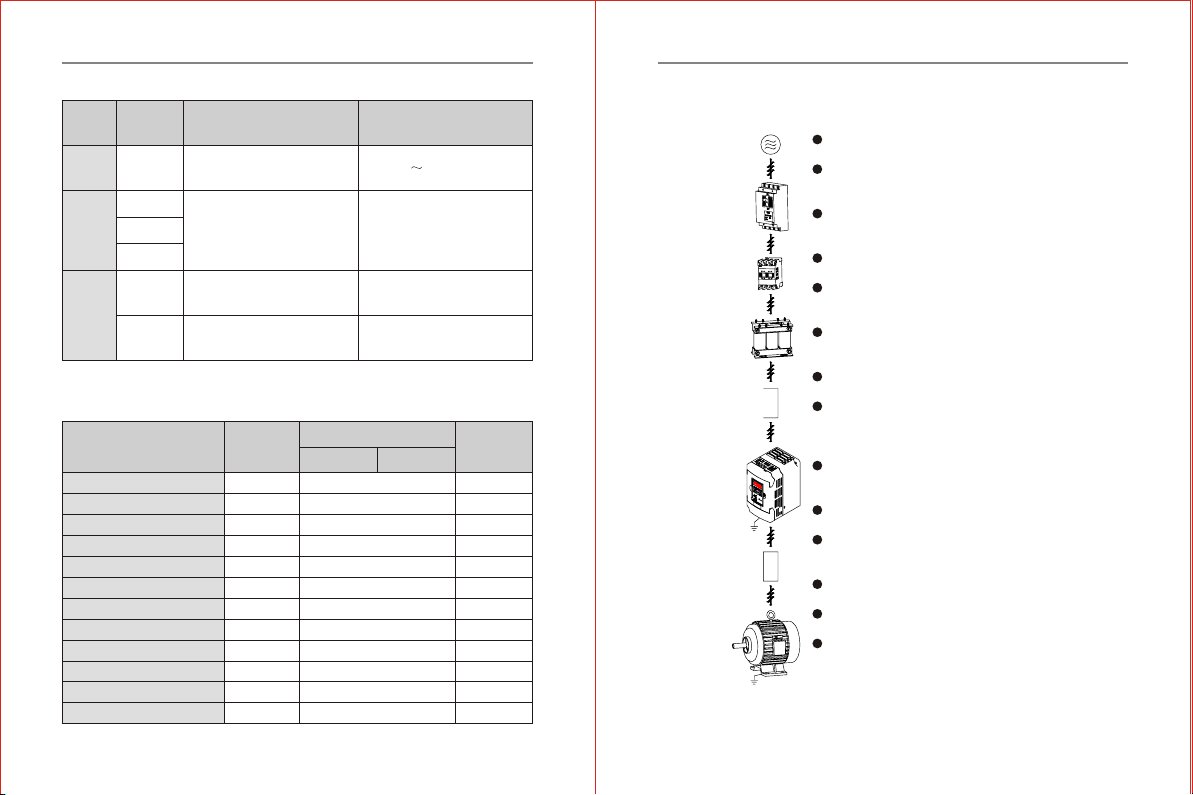

Inverter Models Break

Switch (A)

2

Main Circuit mm Control

2

Wire (mm )

Input Wire Output wire

ZVF200-M0004T2/S2

ZVF200-M0007T2/S2

ZVF200-M0015T2/S2

ZVF200-M0022T2/S2

ZVF200-M0037T2

ZVF200-M0055T2

ZVF200-M0007T4

ZVF200-M0015T4

ZVF200-M0022T4

ZVF200-M0037T4

ZVF200-M0055T4

ZVF200-M0075T4

5/15

10/20

20/30

30/50

40

50

5

10

15

20

30

40

2.5

2.5

2.5

4

6

6

2.5

2.5

2.5

4

4

6

0.75

0.75

0.75

0.75

0.75

0.75

0.75

0.75

0.75

0.75

0.75

0.75

3.4 Inverter SystemWiring

Power Supply

Please follow the specificpower supply requirem ent

shown in .Avoid theinverter damage .

Be sure toinstall No-Fuse breaker between the AC

power and inverter .

No-Fuse breaker

Make sure use theNo-fuse that matched with the rated

voltage and currentof theinverter for ON/OFFcontrol.

and for the inverterprotection .

No-Fuse breakers can notused as START orSTOP control.

Magnetic contactor

Please do not usea magnetic contactor as theI/O switch

of the inverter thiswill reduce the operatinglife cycle

of theAC inverter .

Please do notuse the magnetic contactor as START

and STOPof the inverter .

AC Input Reactor

AC linereactor should be installedwhen thepower

supply capacity is500kVA.

Used to improve theinput power factor,to reduce

harmonics and provide protectionfrom ACline

disturbances. (Surge,switchingspike, power flick,etc.)

Input Filter

There have inductive loadbeside the inverter .The input

filter should be installed.

Inverter

The ACinput line connect withR.S.T or L.N. Nophase

different .

The output connect withU.V.W .It onlychange anytwo

phase among the three phases ifthe inverter run forward.

while the motorrun reverse .

The output terminalcan not connect withAC inputline.

Avoidthe inverter damage .

Good connection with earthground .

Output filter

It's necessary to installon the inverter output side when

the inverter interfered by the sensitive equipment.and

can reduce the electromagneticinterference.

Power Supply

No-Fuse

breaker

Magnetic

contactor

AC Input

Reactor

Input Filter

Inverter

Output filter

Three phase

motor

Fig.3-12

Chapter 3 Installation and WiringChapter 3 Installation and Wiring

Capacity of breakswitch and section area of wire

-27-

-26-

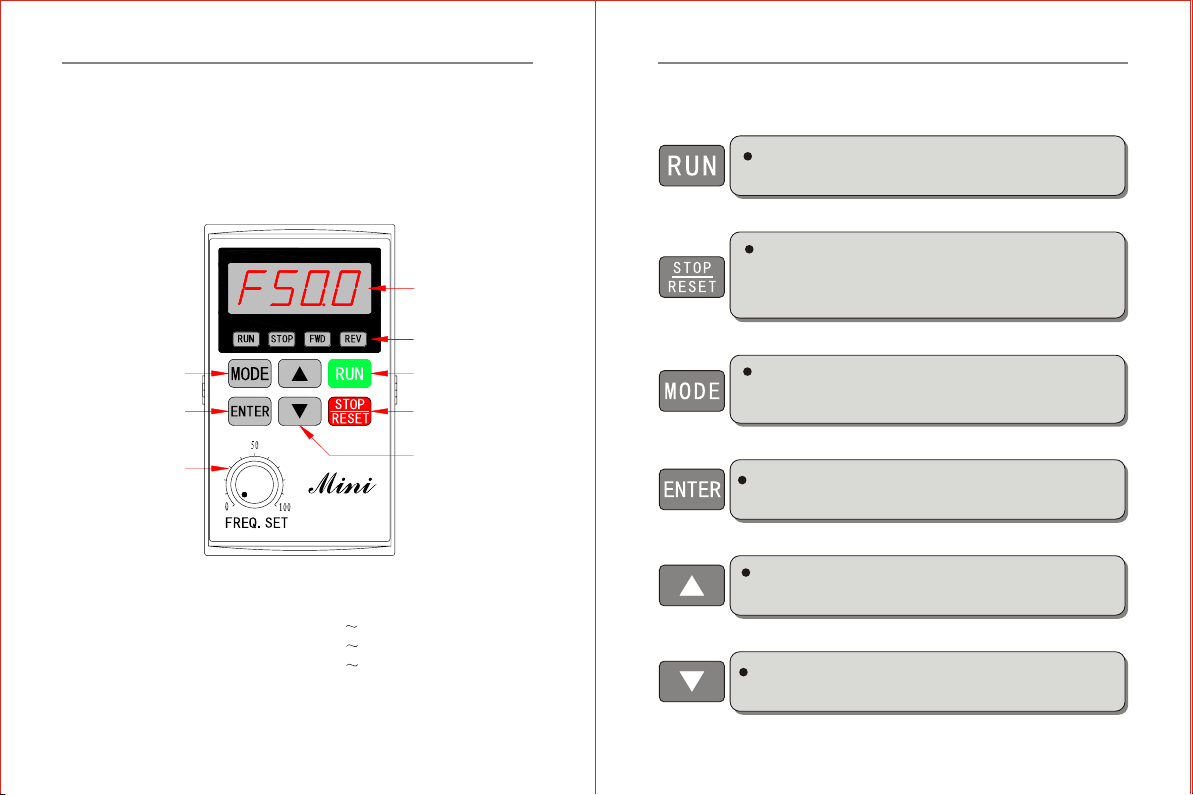

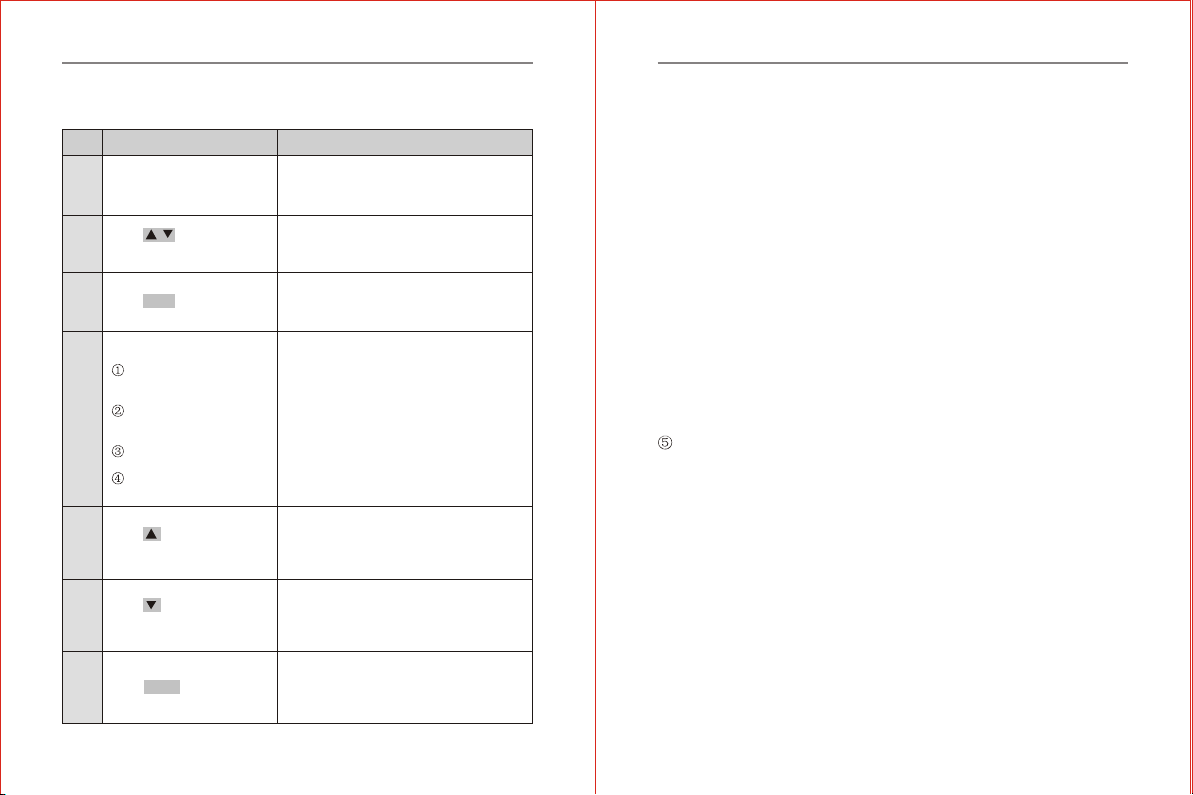

Chapter 4 Operation panel and Operation

4.1.1 Operation Panel

4.1 Operation Paneland Description

4.1.2 Function Descriptionon Keys

Run Key. When the run command selected bey the keypad control

(P01=00).Press this key and the inverter start running .

STOP/RESET key. when the run command is selected by the keypad

control .(P01=00). The inverter is under normal running. Press this key

to stop running.When the inverter is in the state of failure alarm.Press

this key remove the fault .and return to the normal status .

Program/Function mode key Press this key to displays the AC drive

status, setting frequency .output current . FW D/REV. pa ram ete rs

settings and so on.

E nter/Store key. Press this key to confirm the current status of the inverter

or save the current parameter value.

Up key. Press this key, the data or parameter code will go up. Press and

hold it, the modifying speed upward will rise.

Down key. Press this key, the data or parameter code will go down. Press

and hold it, the modifying speed downward will rise.

ENTER/STORE Key

MODE Key

program/function mode

LED display

display frequency,

current, parameters,

error and etc.

RUN Key

STOP/RESET Key

LED Indicates

Lamp lights during RUN,

STOP,FWD & REV

operation.

UP and DOWN Key

Panel Potentiometer

Fig.4-1 ZR06 OperationPanel Description

Model: ZVF200-M0004S2 M0022S2

ZVF200-M0004T2 M0055T2

ZVF200-M0007T4 M0075T4

Chapter 4 Operation panel and Operation Chapter 4 Operation panel and Operation

-29-

-28-

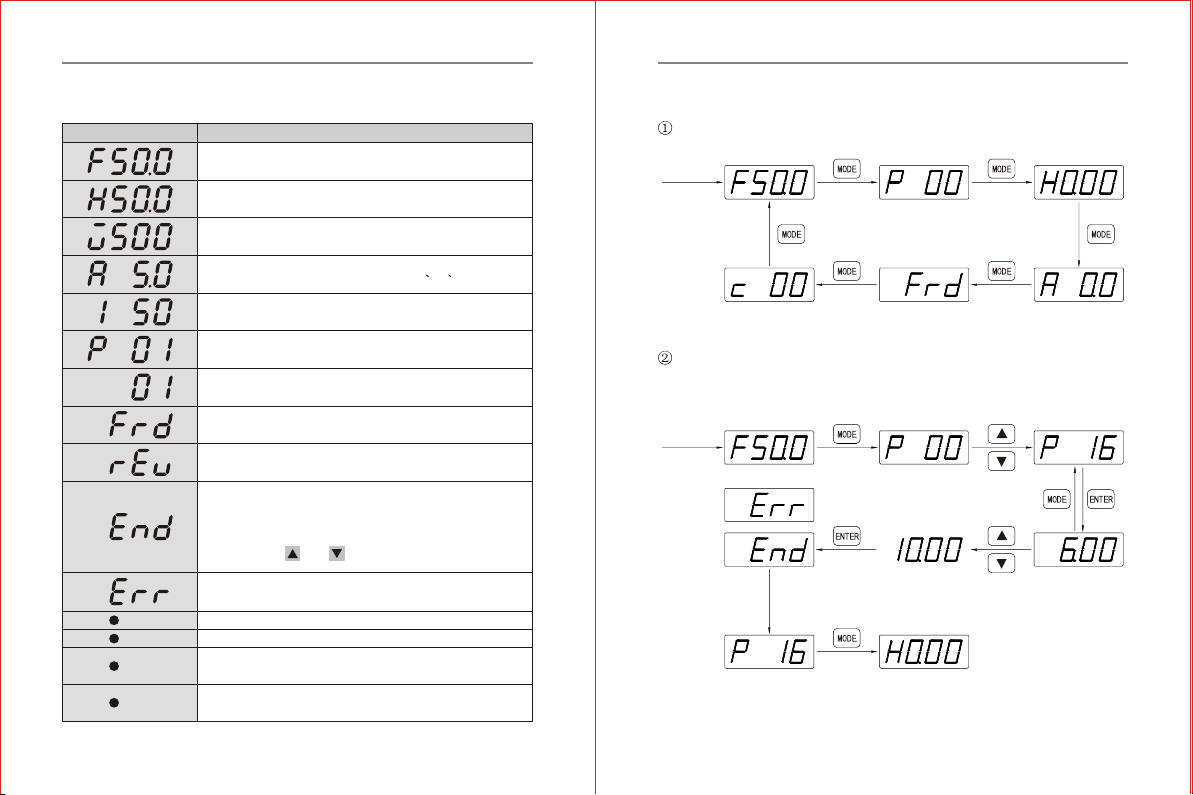

4.1.3 Function Descriptionon Operation PanelIndicator Lights

Display Status Function Description

The ACdrives master frequency.

The actual running frequency

The customer unit(V)

The output current presetat terminal U V W

Run program automatic

Parameter item

Parameter value

the inverter is inthe state of forwardrunning.

the inverter is inthe state of reverserunning

"End" displays for approximately1 second if inputhas been

accepted. Aftera parameter value hasbeen set, the new

value is automaticallystored in memory. To modify an

entry, usethe and keys.

"Err" displays, if theinput is invalid.

When the light is ON,inveter is running

When the light is ON,inverter will stop

When the light is ON, the inverteris in the state of forward

running

When the light is ON, theinverter is in the state of reverse

running.

RUN

STOP

FWD

REV

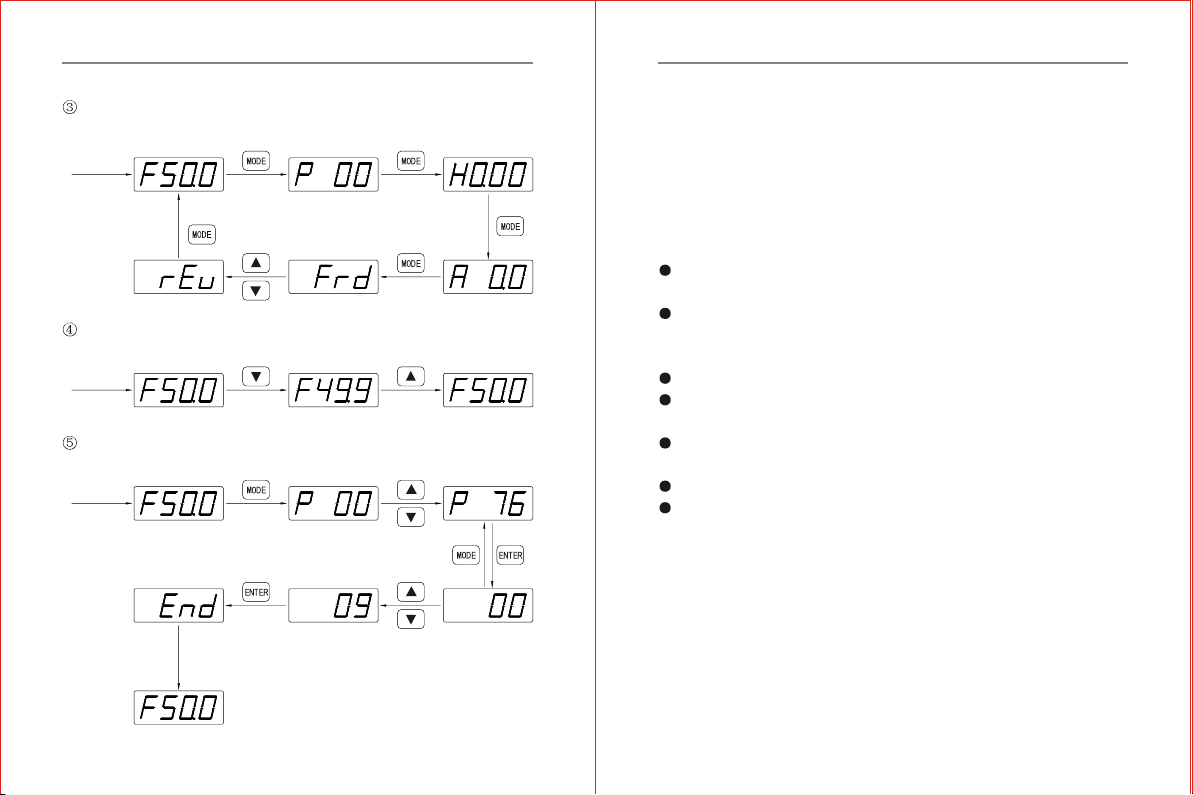

State parameter view

Modification of parametervalue (modify the parameter value for P16

jog function from 6.00Hz to 10.00Hz).

Initializing

Initializing

Data fault

Data right

For a second

4.1.4 Use ofOperation panel

Chapter 4 Operation panel and Operation Chapter 4 Operation panel and Operation

-31--30-

When running modeis controlled by keypads, revise the methods of

running direction

Initializing

Press two times

When frequency isset by key up and down

Initializing

Parameter initializing (restoreto the factorydefault setting 50.00Hz)

Initializing

Data right

For a second

Chapter 5 Inverter Use

5.1 TrialOperation

5.1.1 Safety Instructionon Trial Operation

The following steps should be inspected and confirmed beforethe trial

operation of theinverter:

Be sure theapplication ambient andinstallation for the inverter is in

accordance with therequirements specified inClause 3.1.

Be sure themain circuit iscorrectly wired. The inputpower supply of

the inverter mustbe connected tothe terminal R, Sand T or L,N. The

output terminal U, V and W mustbe connected tothe motor.

Be sure theground terminal isgood grounded.

Be sure all the switches and terminals are in proper state of off or

shut down.

Be sure thereis no shortcircuit or shortto ground of allthe terminals

and electrified parts.

Be sure allthe terminals, connectorsand screws aretightly fastened.

Be sure themotor has noother loads.

5.1.2 TrialOperation

Try thisstep only aftercareful inspection as mentioned in the clause

5.1.2. While in trial operation, it is suggested that the motor without

load to avoid damage to this mechanical equipmentarising from incorrect

operation. During trial operation, if the operating instruction is P01,

then the RUN/STOP key control (factory default setting)of the operation

panel must be selected. The trial operation steps must be followed as

shown in thetable 5-1 below.

Chapter 5 Inverter Use

Chapter 4 Operation panel and Operation

-33--32-

Table 5-1Trial OperationSteps

Order Operation Description

After energized, the inverter is in the state

of readiness and LEDdisplays F50.00Hz.

the built-in cooling fanbegin to work.

Motor begins running, the frequency

rise from H0.00Hz toH5.00Hz, under the

frequency monitor

If there is anyanomaly or tripping, stop

running immediately and cut off thepower

supply.

Please refer toChapter 7, find the trouble

causes, then proceed trialoperation again

after troubleshooting.

If the motor runsin the wrong direction,

change arbitrary two-phase connectionof

the output terminal U,V orW.

Go to the nextstep if everything isnormal.

The motor accelerates rotating and the

displayed frequency rises from H5.00Hz to

H50.00Hz. Go to thenext step if everything

is normal.

The motor decelerates rotatingand the

displayed frequency falls from H50.00Hz to

H0.00 Hz.Go to thenext step if everything

is normal.

Theinverter stops outputting,the motor

stops running and the trial operationends.

If everything is normal,please repeat the

operation for severaltimes.

Switch on, inverter

energized.

Press RUN .

Keep a close eyeon the

following points:

if there is anyabnormal

vibration or noise whenthe

motor runs.

if there is anytripping or

other abnormality of the

inverter.

If the motor runsin the

correct direction.

if the value forrotation

speed and frequency iscorrect.

Press continuously till

LED displays F50.00Hz.

Press continuously till

LED displays F0.00Hz.

Press STOP.

1

Set the frequency toF5.00Hz. This stepcan

be left out ifthe displayed frequency is

already F5.00Hz when energized.

Press / till LED

displays F5.00Hz.

2

3

4

5

6

7

5.1.3 Cautions forOperation

All the inverterfunctions are determined by set parameters. The

parameters of inverter ZVF200 series consist of the function codes

P00~P157, see the detail in Chapter 6 of this manual. The displayed

parameter value ofeach function code is the factory default value of the

inverter before EXfactory, which can be modifiedby the useraccording

to his needs. It is noteworthy that a user shall changethe relative function

parameters when heamends a parameter because some of the parameters

are inter-related . It is not recommended tomodify the setparameter value

if there isno special requirement, for the factory default setting has been

done properly. Otherwise, this may cause damage to the inverter or

equipment due toerror parameter.

In case thereis an erroralternation of theparameter,please initialize

the parameter withreference to the operation method in the clause 4.1.4

Parameter Initializing RestoringFactory Default Settings.

Chapter 5 Inverter UseChapter 5 Inverter Use

-35--34-

P00-Master frequency sourceselection .

If the setvalue 04 Panel Potentiometer setting.

P01-Source of operationcommand .

If the valueis 0 keypad control

Run or stopthe inverter with or keyson theoperation panel.

Adjust thespeed by turningthe potentiometer on the operate panel .

Three-phase

AC Power

Supply

Relay Failure

Output

Voltage Output

V

M

MCCB

R

S

T

U

V

W

G

TA

TB

TC

GND

AFM

5.2.2 Eg.2: Startand stop theinverter with theexternal terminal ,

feed the frequencywith external potentiometer .

5.2.1 Eg. 1:Run or stopthe inverter withoperation panel, andfeed the

frequency with panelpotentiometer .

P00-Master frequency sourceselection .

The set value01 is external voltage or external potentiometer value .

P01-Source of operationcommand .

If the value is 01- Externalterminal control .

P38- The inputterminal X1.2 function selection .

The value 00-Two Wirerunning control

P39-Input terminal X3function selection .05-External reset input.

X1-GND switch on. The motorrun forward .

X2-GND switch on . The motorrun reverse .

X1 X2-GND both switch onor switch offat the same time.The inverter

will stop .The fault alert X3-GND switch on . the fault reset.

The speed controlby the regulating value of AVI .(controlled by

4.7-10K/2W potentiometer control.)

Fig. 5-2

Relay Failure

Output

Voltage Output

R

S

T

U

V

W

G

TA

TB

TC

GND

AFM

Forward

Reverse

Reset

FWD

REV

X1

COM

+10V

AVI

GND

Fig.5-1

Three-phase

AC Power

Supply

MCCB

5.2 Examples ofUse

This manual providesthe following examplesfor users' referenceon

the use ofinverter.

VV

MM

Chapter 5 Inverter UseChapter 5 Inverter Use

4.7-10K/2W

This manual suits for next models

12

Table of contents

Other Chziri Inverter manuals