Chziri ZVF9V-G/P User manual

User's Manualfor

ZVF9V-G/PVector Inverter

User's Manualfor

ZVF9V-G/PVector Inverter

Add.: 8 GandeRoad, Tahui,Shihudang Town,

Songjiang District, Shanghai201600, China

Tel.: 0086-021-57844525

Http://www.chziri.com

Manufacturer: Wenzhou Ziri Electrical

Technology Co.,Ltd.

Add.: Santiaoqiao IndustrialZone, Xiangyang

Town,YueqingCity 325604, Zhejiang,China

Tel: +86-577-27871155

Publication Notes

Ziri ElectricalTechnologyCo.,Ltd.

March 2009

All partsof theinverter ZVF9Vseries, including the

software, layout design,circuit boarddesign and

user s manualare reserved byZiri Electrical

TechnologyCo.,Ltd. (hereinafter referredto as"ZIRI

Company").Any unauthorized transfer, excerptsor

copying, inpart orin whole,is prohibitedor persecuted.

All thecontents inthis manual arefor reference only.

The software programand contents ofthe munualis

subject tochange orupgrade without priornotice.

Please browse ZIRIcompany s websitefor detailor

contact itdirectly.

If thereare anydoubts ormistakes inthis manual,ZIRI

Company claims immunityfrom them

Thank youvery muchfor yourpurchase ofthe inverter

ZVF9V series.

This manualintroduces theinstallation, operation,function

setting, troubleshooting andetc. ofthe inverterZVF9V

series..

Incorrect installationor usemay resultin damageor other

accidents. Doread allinstructions indetail beforeinstalling

or operating.

Please forwardthis manualto theend user,and keepit handy

for quickreference.

If thereare anydoubts orquestions, pleasecontact the

TechnicalService Centerof ZIRICompany.

Foreword

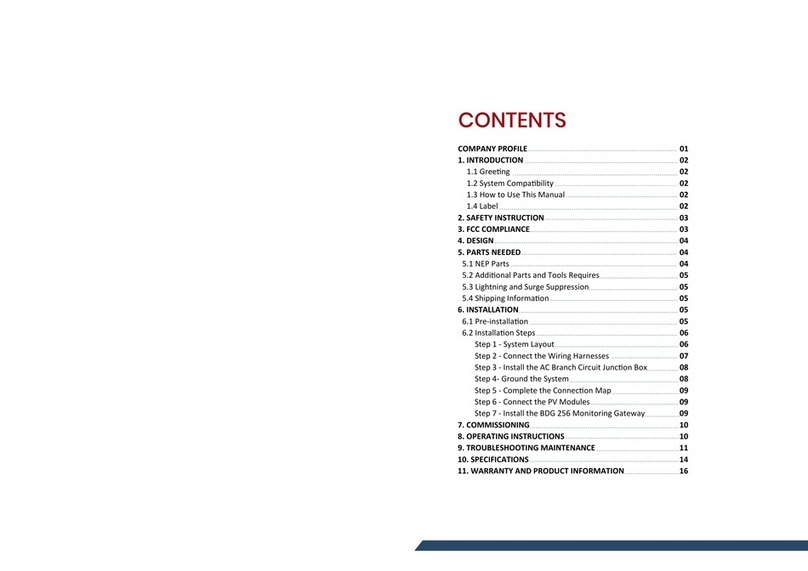

Tableof Contents

Tableof Contents

Table ofContents Table ofContents

Chapter 1 Safety Instruction ............................................ P1

1.1 Safety Symbols and Definitions ............................................P1

1.2 Application Range ................................................................ P2

1.3 Installation Ambient ..............................................................P2

1.4 Cautions for Installing............................................................P3

1.5 Cautions for Operation ........................................................P5

1.6 Cautions for Disposing ..........................................................P8

Chapter 2 Introduction to the Product.................................... P9

2.1 Product Inspection upon Arrival ........................................ P9

2.2 Demonstration of the Model ...................................................P9

2.3 Specifications Label ..............................................................P9

2.4 Outline and Structure ............................................................P9

2.5 Models and Specifications ...................................................P10

2.6 Technical Indications ............................................................P13

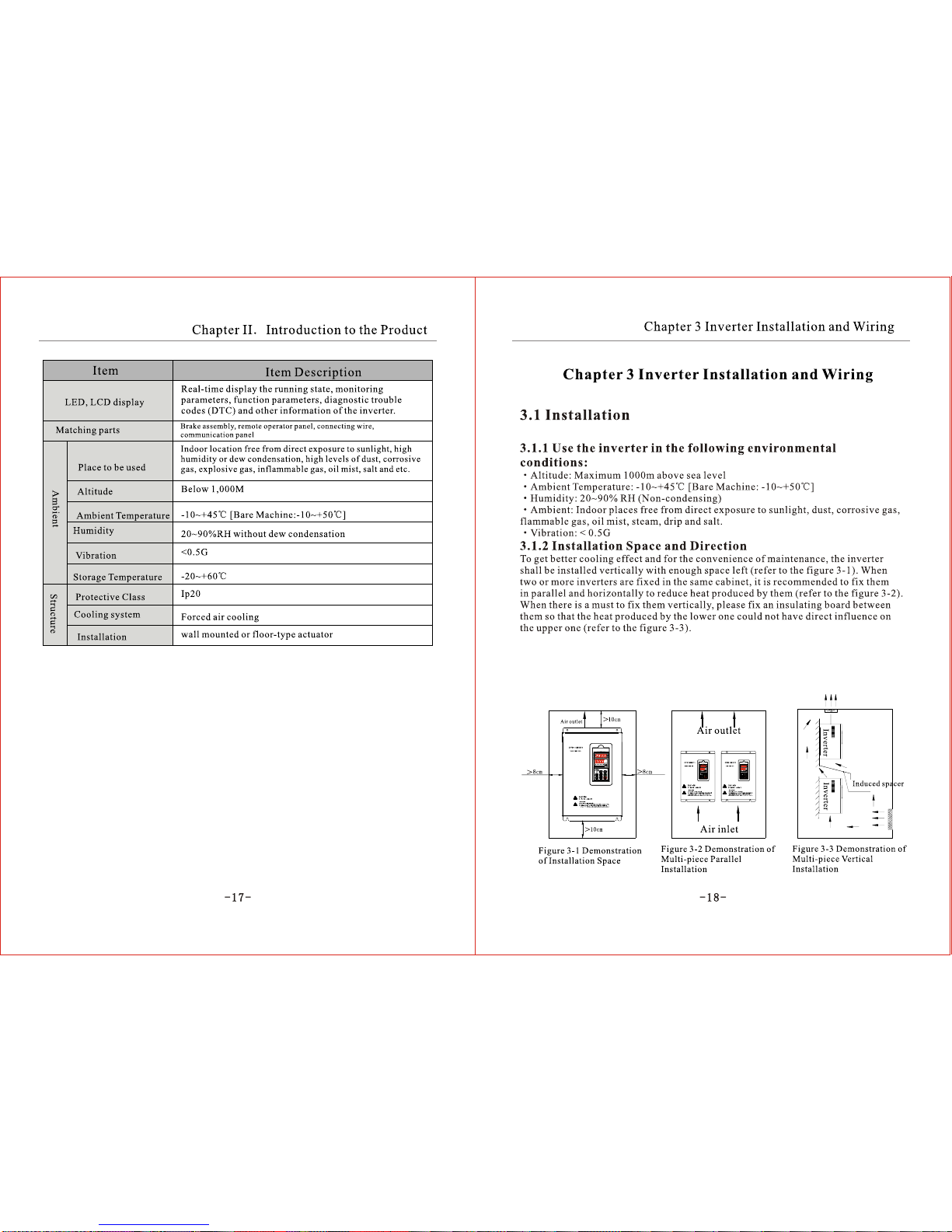

Chapter 3 Installing and Wiring ..........................................P18

3.1 InverterMounting andInstalling .............................................P18

3.2 Inverter Spare Parts Installing and Dismantling .....................P20

3.3 Inverter Wiring ...................................................................P25

3.4 InverterSystem Wiring ...........................................................P36

Chapter 4 Operation Panel and its Operation ........................P40

4.1 OperationPanel andthe Instruction ....................................... P40

4.2 Displayof MonitoringParameters ...........................................P47

4.3 Display of Trouble Parameters ............................................. P49

Chapter 5 Operation of the Inverter ...................................................P50

5.1 Trial Operation ................................................................................. P50

5.2 Cautions for Operation ..................................................................P52

5.3 Operation Examples .........................................................................P54

Chapter 6 Introduction to Function Parameters ........................... P61

6.1 Tables for Function Parameters ..................................................... P62

6.2 Detailed Instruction for Function Parameters ................................P80

Chapter 7 Common Problems, Anomalies and Troubleshooting ..P135

7.1 Diagnostic Trouble Codes and Troubleshooting ...........................P135

7.2 Anomalies and Solutions .................................................................P138

Chapter 8 Inverter Inspection and Maintenance ..............................P139

8.1 Inspection and Maintenance .........................................................P139

8.2 Replacement of the Inverter Wearing Parts ................................. P142

8.3 Storage of the Inverter ....................................................................... P143

Chapter 9Outline Dimensions& MountingDimensions ..................P144

9.1 InverterOutline Dimensions& MountingDimensions ........................P144

9.2 OperatorPanel OutlineDimensions &Mounting Dimensions.............P148

Chapter 10Quality Warranty ................................................................ P151

10.1 Inverter Quality Warranty ................................................................ P151

Appendices ............................................................................................P152

Appendix 1 Optional Parts Choosing .......................................................P152

Appendix 2 EMI Prevention .................................................................. P155

Appendix 3 User's Parameter Amendment Record ..............................P161

Appendix 4 Warranty ..............................................................................P164

Tableof Contents

Tableof Contents

Table ofContents Table ofContents

Chapter 1 Safety Instruction ............................................ P1

1.1 Safety Symbols and Definitions ............................................P1

1.2 Application Range ................................................................ P2

1.3 Installation Ambient ..............................................................P2

1.4 Cautions for Installing............................................................P3

1.5 Cautions for Operation ........................................................P5

1.6 Cautions for Disposing ..........................................................P8

Chapter 2 Introduction to the Product.................................... P9

2.1 Product Inspection upon Arrival ........................................ P9

2.2 Demonstration of the Model ...................................................P9

2.3 Specifications Label ..............................................................P9

2.4 Outline and Structure ............................................................P9

2.5 Models and Specifications ...................................................P10

2.6 Technical Indications ............................................................P13

Chapter 3 Installing and Wiring ..........................................P18

3.1 InverterMounting andInstalling .............................................P18

3.2 Inverter Spare Parts Installing and Dismantling .....................P20

3.3 Inverter Wiring ...................................................................P25

3.4 InverterSystem Wiring ...........................................................P36

Chapter 4 Operation Panel and its Operation ........................P40

4.1 OperationPanel andthe Instruction ....................................... P40

4.2 Displayof MonitoringParameters ...........................................P47

4.3 Display of Trouble Parameters ............................................. P49

Chapter 5 Operation of the Inverter ...................................................P50

5.1 Trial Operation ................................................................................. P50

5.2 Cautions for Operation ..................................................................P52

5.3 Operation Examples .........................................................................P54

Chapter 6 Introduction to Function Parameters ........................... P61

6.1 Tables for Function Parameters ..................................................... P62

6.2 Detailed Instruction for Function Parameters ................................P80

Chapter 7 Common Problems, Anomalies and Troubleshooting ..P135

7.1 Diagnostic Trouble Codes and Troubleshooting ...........................P135

7.2 Anomalies and Solutions .................................................................P138

Chapter 8 Inverter Inspection and Maintenance ..............................P139

8.1 Inspection and Maintenance .........................................................P139

8.2 Replacement of the Inverter Wearing Parts ................................. P142

8.3 Storage of the Inverter ....................................................................... P143

Chapter 9Outline Dimensions& MountingDimensions ..................P144

9.1 InverterOutline Dimensions& MountingDimensions ........................P144

9.2 OperatorPanel OutlineDimensions &Mounting Dimensions.............P148

Chapter 10Quality Warranty ................................................................ P151

10.1 Inverter Quality Warranty ................................................................ P151

Appendices ............................................................................................P152

Appendix 1 Optional Parts Choosing .......................................................P152

Appendix 2 EMI Prevention .................................................................. P155

Appendix 3 User's Parameter Amendment Record ..............................P161

Appendix 4 Warranty ..............................................................................P164

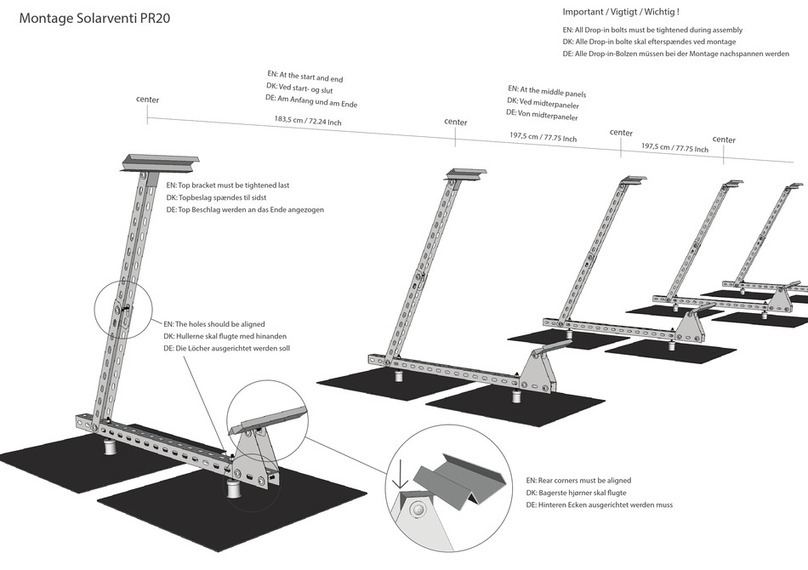

Chapter 1 Safety Instructions Chapter 1 Safety Instructions

Chapter 1 Safety Instructions

1.1 Safety Symbolsand Definitions

The safety instructionsdescribed in thismanual are veryimportant. To

avoid any errorthat may resultin damage toequipment, injury topersonnel

or loss ofproperty, doread and clearlyunderstand all ofthe safety symbols,

symbol definitions andbe sure toobserve the indicatedsafety instructions

below.

Safety Symbols Symbol Definitions

HAZARD

This symbol indicateshazardous HIGH VOLTAGE.

Any incorrect operationmay result inserious damage to

the equipment ordeath to personnel.

WARNING

CAUTION

TIP

FORBIDDEN

COMPULSORY

This symbol indicatesthat any incorrectoperation can

result in damageto the equipmentor minor tomoderate

injury to personnel.

This symbol callsyour attention tofollow the

instructions while inoperation or inuse.

This symbol callsattention to someuseful messages

for the user.

This symbol indicatesanything forbidden todo.

This symbol indicatessomething must do.

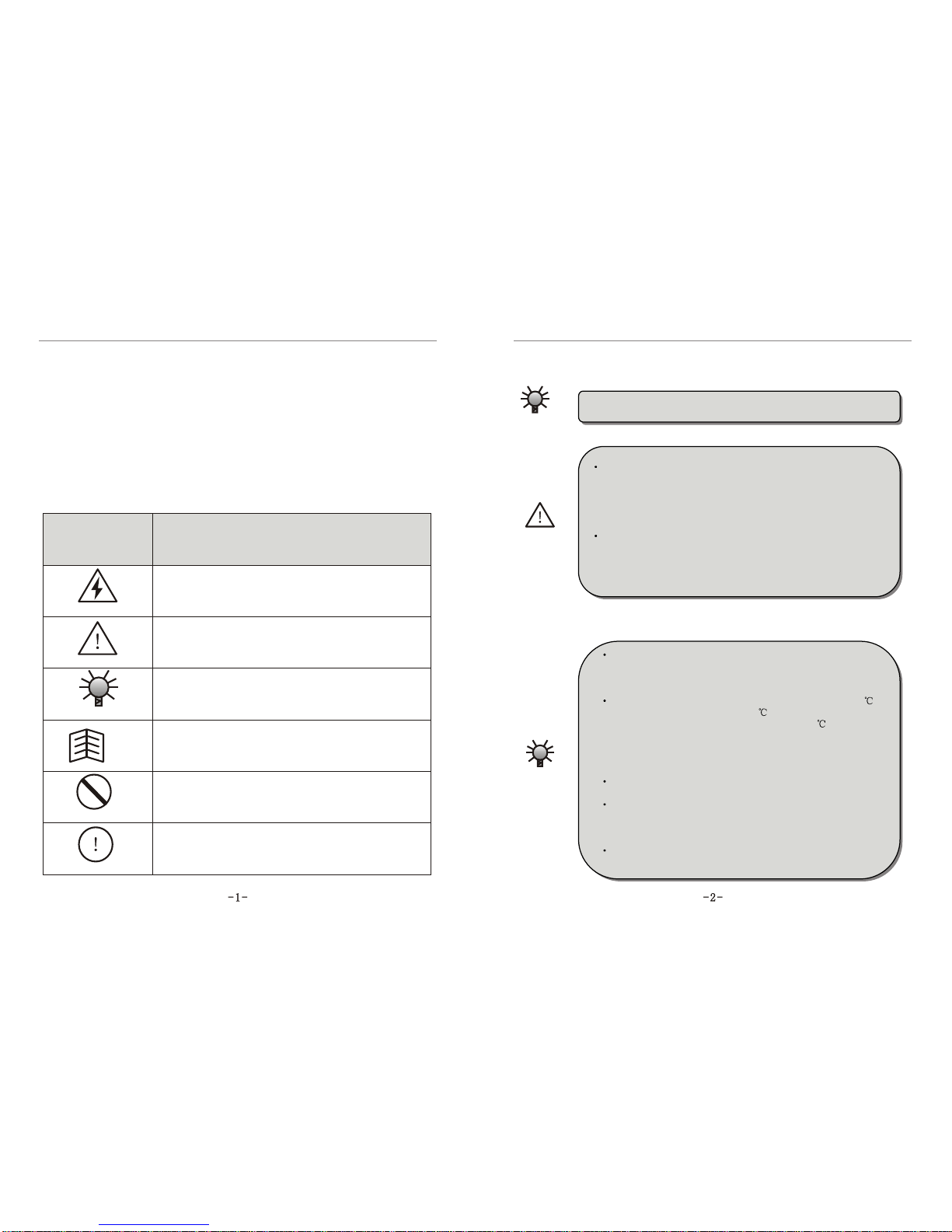

CAUTION

This inverter isapplicable to generalindustrial purpose three-

phase ACasynchronic electric motor.

1.2 ApplicationRange

WARNING

This inverter cannot be usedin the equipmentthat may result

in threat orinjury to personneldue to invertertrouble or error,

such as nuclearpower control equipment,aviation equipment,

transportation equipment, lifesupporting system, safety

equipment, weapon systemand etc. Pleaseconsult Ziri Company

before using itfor special purposes.

This product ismade under strictquality control and

supervision. But whenused in somekey equipment, protective

measures should betaken to avoidfurther extension ofaccident

due to invertertrouble.

1.3 InstallationAmbient

CAUTION

Be sure toinstall the inverterin a well-ventilatedindoor

location. To get thebest cooling effect, it isrecommended to

fix the invertervertically,and extra ventilationdevices are

needed when installedhorizontally.

Be sure thatthe ambient temperatureis between -10~45 .

If the temperatureis higher than40 , please removethe

upper cover.If the temperatureis higher than50 , forced

heat radiation orderating is neededfrom the external.It is

recommended not touse the inverterin such ahigh

temperature. Otherwise, it may greatlyreduce the servicelife

of the inverter.

The ambient humidityis required tobe lower than90%

without dew condensation.

The inverter shallbe installed ina place wherethe vibration

is less than0.5G. Otherwise, itmay fall andcause damage to

the equipment. Itis also noteworthythat the invertercould

not bear anysudden bump.

The inverter shouldbe kept awayfrom electromagnetic

interference (EMI), flammable and explosiveambient.

WARNING

Chapter 1 Safety Instructions Chapter 1 Safety Instructions

Be sure toinstall the inverteron metallic materials(i.e., metal).

Otherwise, there isthe danger offire.

Be sure notto let theforeign matter enterthe inverter,such as wire

clippings, spatter fromwelding, metal (zincor ferrous) meshavingsand etc.

Otherwise, there isthe danger ofgetting burned dueto short circuit.

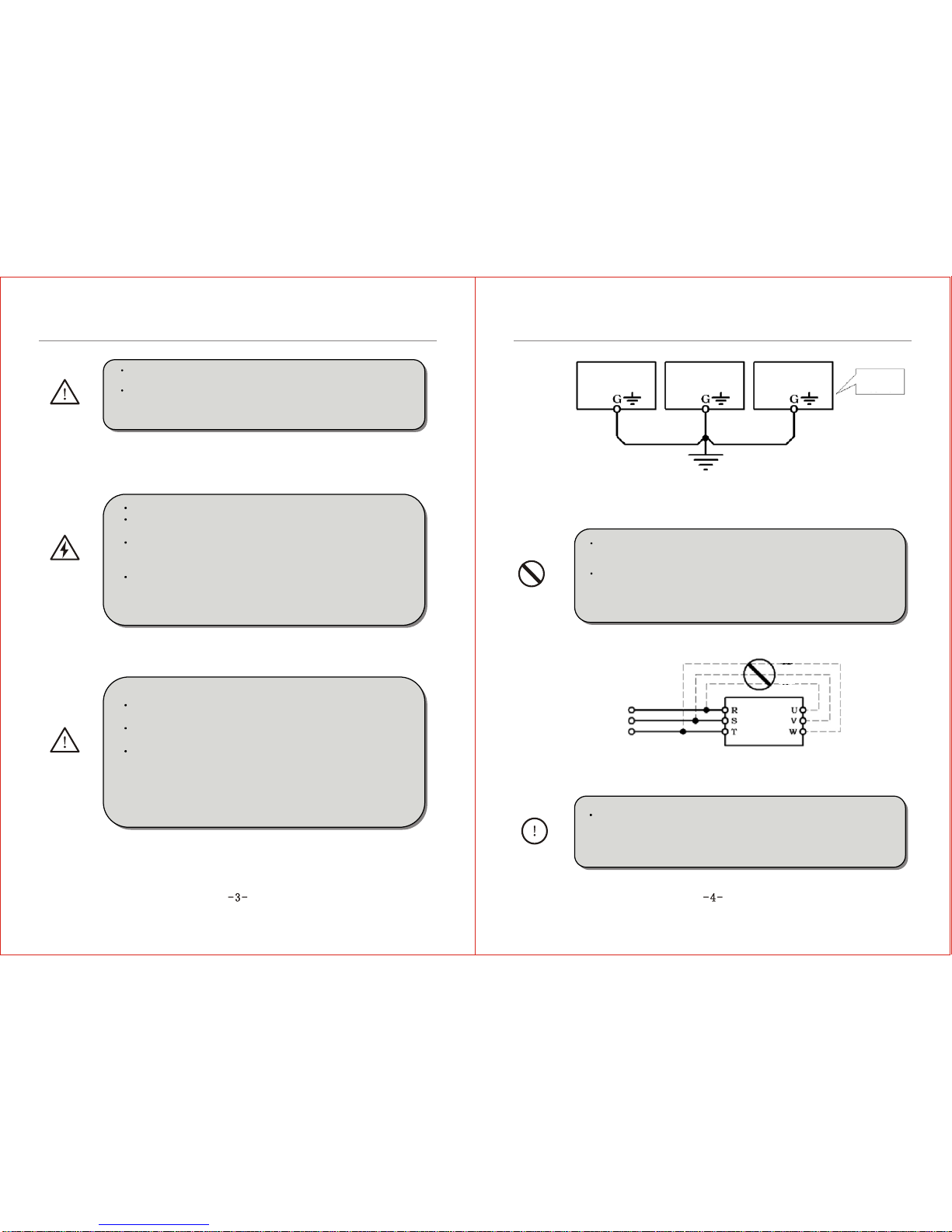

1.4 Cautionsfor Installing

HAZARD

Do not operateelectrical equipment withwet hands.

Do not operatewiring unless thepower supply iscompletely

off.

Do not openthe front coveror perform wiringwhile the

inverter is poweredON. Otherwise, thereis the dangerof electric

shock.

Do wait atleast 10 minutesafter the poweris disconnected

before performing thework of wiringor inspection. Otherwise,

there is thedanger of electricshock.

WARNING

Do not installor operate ifthe inverter isdamaged or hasparts

missing to preventinjury to personnelor loss ofproperty.

The main loopterminal should betightly connected tothe cable.

Otherwise, the invertermay be damageddue to loosecontact.

The ground terminalmust be reliablyand properly groundedto

ensure security.Toavoid common groundimpedance, multi-

piece inverters shouldbe grounded atone shared point,as shown

in the Figure1-1.

Inverter Inverter Inverter Proper

grounding

method

FORBIDDEN

Grounding bus bar

(Connect to theground at theshared point)

DO NOT connectcontrol terminals (exceptterminals marked"TA","TB"

and "TC") toAC 220Vpower supply,which may causedamage to theinverter.

DO NOT connectAC powersupply to theoutput terminals marked"U", "V"

and "W". Otherwise,it may causedamage to theinverter, as shownin the

Figure 1-2.

Three-phase

AC

Power Supply

FORBIDDEN

Figure 1-2

COMPULSORY

Figure 1-1

DO install ano-fuse circuit breakeror leakage protectivecircuit

breaker in theside of inverterinput power supplyto prevent

expanding of accidentdue to aninverter problem.

Chapter 1 Safety Instructions Chapter 1 Safety Instructions

CAUTION

It is notadvisable to installan electromagnetic contactorin the sideof

output power supply, because theoperation of openand close tothe

contactor when themotor is runningmay cause damageto the inverter

arising from over-voltageproduced during thisprocess. But itis still

necessary to installa contactor ifone of thefollowing three pointsoccurs:

1.The system offrequency converting governorused to controlenergy-

saving usually worksat a ratedrotation speed. To run thegovernor

economically, thereis a mustto remove theinverter.

2.The inverter participatesin some importprocedure and cannotstop

operating for along period oftime. Torealize free shiftin various control

systems and improvethe reliability ofthese systems, thereis a mustto

install a contactor.

3.When an invertercontrols several motors,there is amust to installa

contactor.

Caution: DO NOToperate the contactorif there isoutput of theinverter.

1.5 Cautionsfor Operation

HAZARD

Do not operateelectrical equipment withwet hands.

An inverter storedfor a yearor longer shouldbe given

powerup test beforeuse so thatthe main circuitfilter capacitor

could be recovered.When the inverter is inthe state ofpowerup,

it is necessaryto raise thevoltage gradually tothe rated value

with a voltageregulator. Generally, the chargingtime should be

controlled within 1~2hours. Otherwise, thereis the dangerof

electric shock orexposure.

Do not touchthe inner sideof the inverterwhile the poweris

ON, nor putany foreign matter, i.e., rodor other matterinside the

inverter. Otherwise,it may resultin serious damageto the

equipment or deathto personnel.

Do not openthe front coverwhile the inverteris powered ON.

Otherwise, there isthe danger ofelectric shock.

Be careful toselect the RestartMode. Otherwise, thereis

the danger ofpersonnel death.

WARNING

If the inverterruns at afrequency higher than50Hz, DO confirm

it is withinthe speed rangeacceptable by yourmotor bearing and

mechanical device. Otherwise, there isthe danger ofdamage to the

motor.

It is notadvisory to runthe reduction box,gear and other

mechanism that needlubricating at lowspeed for along period.

Otherwise, it mayreduce the servicelife of theseequipment or

even damage theequipment.

A generalmotor should bederated before usedue to less

effective ofheat dissipation whenit runs ata low frequency. If itis

a constant torqueload, then aforced method ora special variable

frequency motor shouldbe used torelease heat.

DO cut off the powersupply of aninverter set asidefor a long

time to avoidforeign matter orother things enterin it whichmay

cause damage tothe inverter oreven lead tofire.

The output voltageof inverter isPWM impulse wave.DO NOT

install a capacitoror surgecurrent sink (i.e.,a varistor) inthe

inverter output port.Otherwise, there isthe danger offault tripping

of the inverteror damage toits power elements.DO remove such

kind of thingsif already installed.See the Figure1-3 below.

Forbidden

Forbidden

Inverter

Power factor

compensation

capacitor

Surge current sink

Figure 1-3

Chapter 1 Safety InstructionsChapter 1 Safety Instructions

CAUTION

Motor insulation shouldbe checked beforethe inverter isused

for the firstuse or reusedafter a long-termidle. Be surethe

insulation resistance measuredis no lowerthan 5MÙ.

If the inverteris used beyondthe range ofallowable working

voltage, then anextra step-up orstep-down voltage transformer

shall be configured.

Due to thinair in aplace where thealtitude is higherthan

1,000m, the heatdissipation of inverterwill be lesseffective.

Hence derating shouldbe done beforeuse. In general,when the

height rises by1,000m, the ratedvoltage of theinverter shall

reduce by 10%.Refer to theFigure 1-4 fordetails of thederating

curve.

M

Figure 1-4 Diagramof Inverter DeratingCurve

FORBIDDEN

DO NOT touchthe radiator orcharging resistor ofthe inverter

with hand(s). Otherwise, thereis the possibilityof getting scalded.

DO NOT proceeddirect start-stop operation frequentlywith a

contactor or anyother switch devicesin the inverterinput side.As

large charging currentexists in themain circuit ofthe inverter,

frequent power-on/off mayproduce cumulative effectresulting in

heat fatigue ofinverter components and greatreduction of service

life of theinverter. Seethe detail inthe Figure 1-5.

Three-phaseAC PowerSupply

Inverter

Forbidden

On

Off

COMPULSORY

In case abnormalitiesoccur, such as smoke, offodor, strange

sound, DO cutoff the powersupply immediately,overhaul the

equipment or turn to the agent for help via phone call.

1.6 Cautionsfor Disposing

WARNING

CAUTION

Exposure may happenwhen the electrolyticcapacitor (ELCC)

of the inverterburns. Be carefulto cope withit.

The plastic partson the operatorpanel will giveoff toxic gas

when getting burned.Be careful tocope with it.

Dispose damaged inverteras industrial waste.

M: Integration Module

S: Schism Module

Chapter II Introduction tothe Product Chapter II Introduction tothe Product

Figure 2-5 ModelB Outside Drawing

1. Operator Panel 2. Control Panel 3. External ControlTerminal 4. Power Terminal

5. Lower Cover 6. Casing

Figure 2-6 ModelB Structural Representation

Figure 2-7 ModelC Outside Drawing

1.Fan 2. ControlPanel 3.Cabnet Body 4. WiringCopper Bar 5.PowerTerminal

6. Electrolytic Capacitor(ELCC) 7. OperatorPanel 8. CabinetDoor

Figure 2-8 ModelC Structural Representation

Chapter II Introduction tothe Product Chapter II Introduction tothe Product

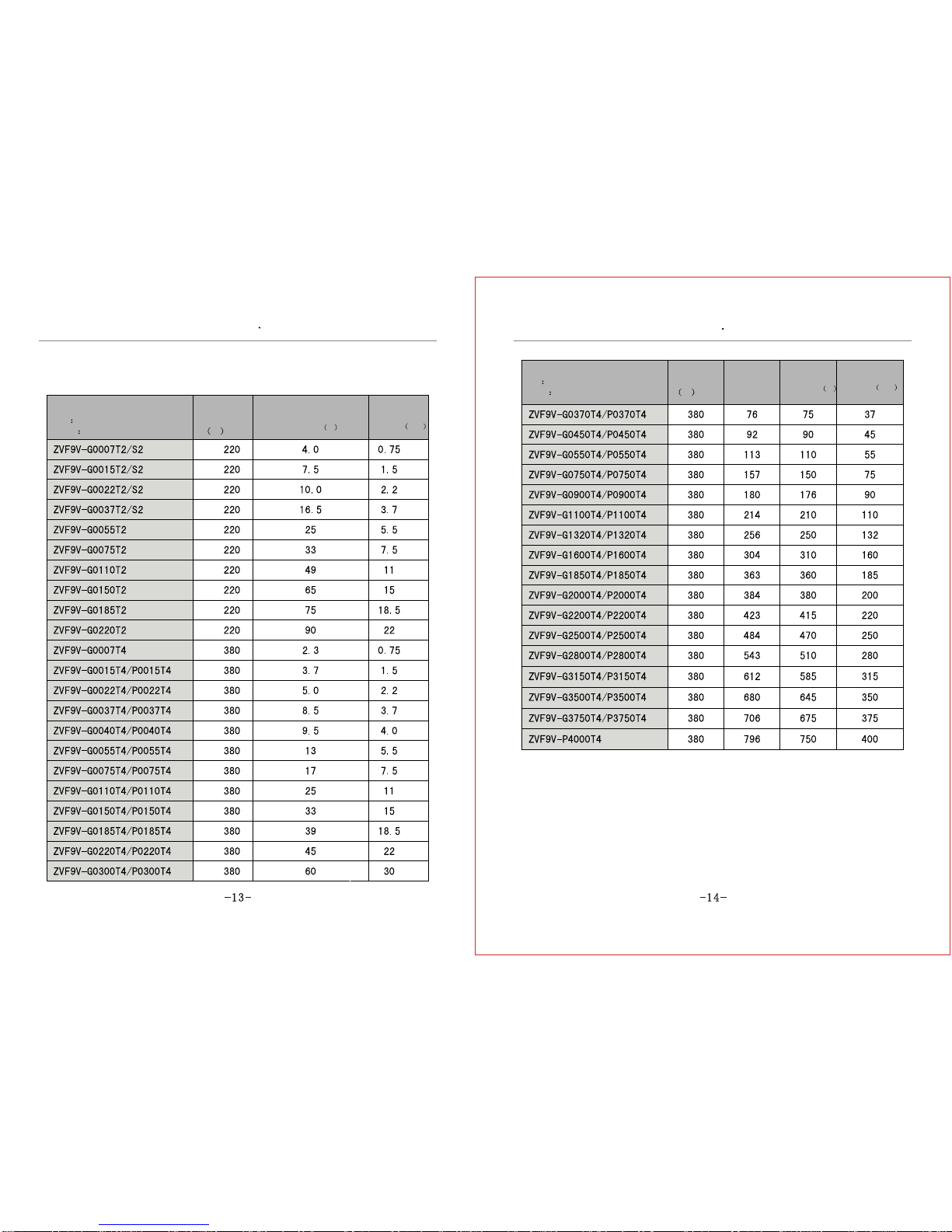

2.5 Models andSpecifications

Table 2-1Inverter Models andSpecifications

Inverter Models

(G Constant TorqueLoad)

(P Fan or PumpLoad)

Input

Voltage

V

Rated

Output

Current A

Adaptive

Motor

Power KW

Inverter Models

(G Constant TorqueLoad)

(P Fan or PumpLoad)

Input

Voltage

V

Rated

Output

Current A

Adaptive

Motor

Power KW

Rated

Input

Current (A)

Jog acceleration/deceleration

time, 0.1~3600.0 can beset.

current

Leap frequency,Jog function,counter,trace to rotatingspeed, instant

shutdown restarting, Frequecnyupper/lower limitation ,acceleration/

deceleration mode regulating,frequency meter andvoltmeter output,

multiple speed/program operation, two-wire/three wire control,

vibration frequency control,Multi-function input terminal selection,

Failure auto resetand 485COM.

Chapter 3Inverter Installationand Wiring Chapter 3Inverter Installationand Wiring

3.1.3 InstallationInstructions

WARNING!

Do not installor operate ifthe inverter isdamaged or hasparts

missing to preventinjury to personnelor loss ofproperty.

Be sure themain loop terminalsshould be tightlyconnected to

the cable. Otherwise,the inverter maybe damaged arisingfrom

loose connection.

Be sure theground terminals ofthe inverter andthe motor must

be properly grounded.Multi-piece inverter shouldbe grounded at

one shared point.

COMPULSORY!

Be sure toinstall a no-fusecircuit breaker orleakage protective

circuit breaker inthe side ofinverter input powersupply to

prevent expanding ofaccident due toan inverter problem.

CAUTION!

Install the inverterin a properplace with moderatetemperature. The

higher the ambienttemperature is, theshorter the servicelife of theinverter

is.Keep any otherheat-producing equipment asfar away fromthe inverter

as possible. Wheninstalling the inverterin an enclosure,maintain the

clearance around theinverter and verifythe temperature iswithin the

allowable range.

3.2 PartsDismantling andInstallation

3.2.1 Dismantle theupper cover.

1 Dismantle the uppercover of theinverter ModelA.

Put a fingerinto the heave of the lowerpart of theinverter and pressit (as shownin the

figure 3-4 wherethe arrow points),stretch forward for30~50mm (as shownin the

figure 3-5), thenraise upward toopen the uppercover of theinverter.

Fig. 3-4 Demonstrationof dismantling

the upper coverof the inverterModel A Fig. 3-5 Demonstrationof dismantling the

upper cover ofthe inverter ModelA

2 Dismantle the uppercover of theinverter Model B.

Unscrew two screwsof the lowerpart of theinverter (as shownin the figure3-6 where thearrow

points), pull thelower cover down for 10~20mm (asshown in thefigure 3-7), thenraise upward toopen the

lower cover ofthe inverter.

Fig. 3-6Demonstration of dismantlingthe

upper cover ofthe inverter ModelB

Fig. 3-7 Demonstrationof dismantling the

upper cover of the inverter Model B

Chapter 3Inverter Installationand Wiring

Chapter 3Inverter Installationand Wiring

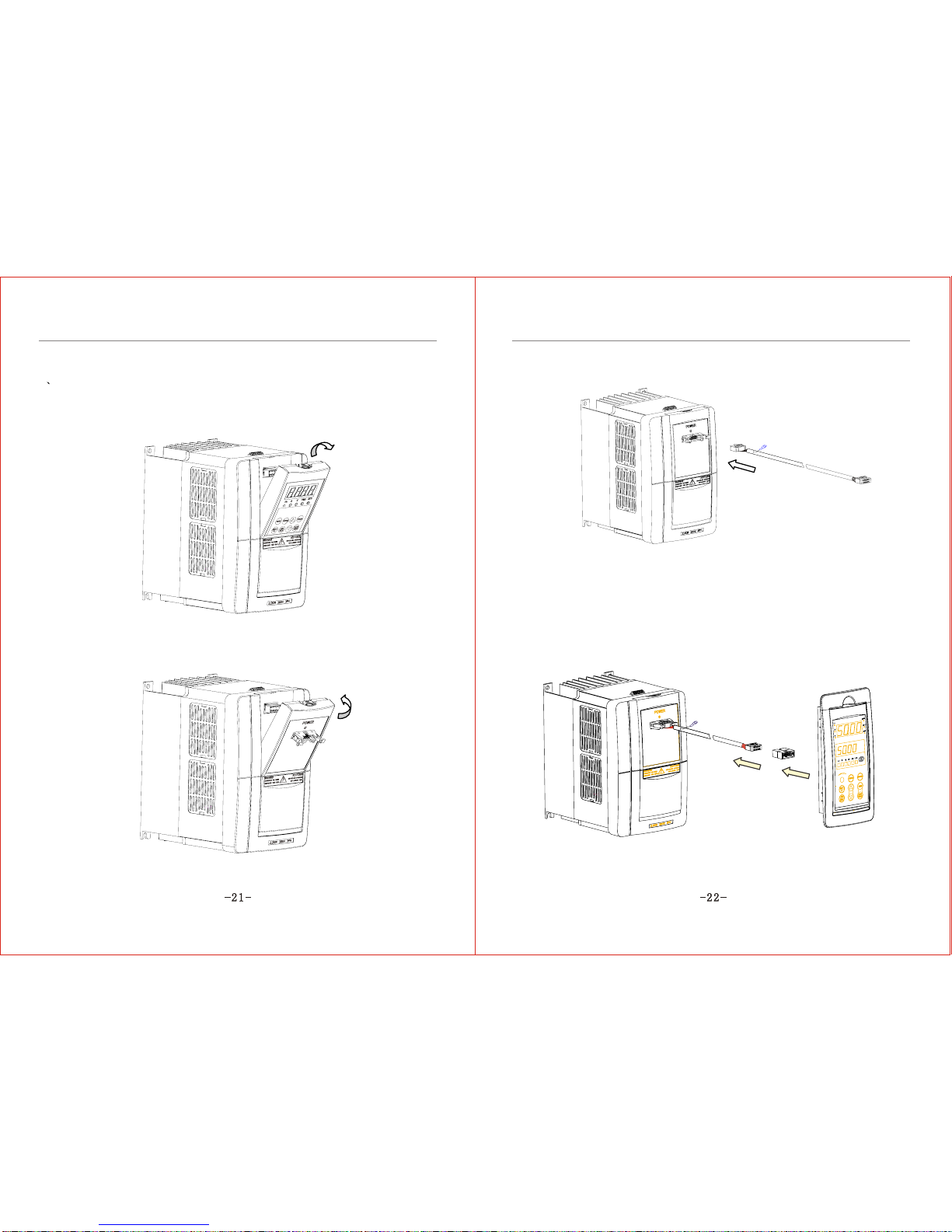

3.2.2 Installation ofthe remote-controlledoperator panel andconnecting wire

1 Installation of theoperator panel andconnecting wire ofthe inverter ModelA

Step 1. Buttonup with ahand at thenotch of the upperpart of operatorpanel and removethe

operator panel (asshown in thefigure 3-8).

Fig. 3-8 MountingDemonstration of theoperator panel

and connecting wireof the inverterModel A

Step 2. Fixthe jack panelprovided in theoptional components inthe installation positionof

operator panel (asshown in thefigure 3-9).

Fig. 3-9 MountingDemonstration of theoperator panel

and connecting wireof the inverterModel A

Step 3. Plugthe ground endof connecting wireprovided in theoptional components

into the slotof jack panel(as shown inthe figure 3-10).

Fig. 3-10 MountingDiagram for theoperator panel and

connecting wire ofthe inverter ModelA

Step 4. Putthe dismantled operatorpanel into theinstallation frame providedin the

optional components, fixand fasten it.Plug the otherend of connectingwire into the

jack panel slot,then plug theslot into theoperator panel (asshown in thefigure 3-11).

Fig. 3-11Mounting Diagram forthe operator panel

and connecting wireof the inverterModel A

Chapter 3Inverter Installationand Wiring

Chapter 3Inverter Installationand Wiring

2 Installation of theoperator panel andconnecting wire ofthe inverter ModelB

Step 1. Buttonup with ahand at thenotch of the upperpart of operatorpanel and removethe panel

(as shown inthe figure 3-12).

Fig. 3-12 MountingDiagram for theoperator panel and

connecting wire ofthe inverter Model

Step 2. Plugthe connecting wiresof the controlpanel and operatorpanel into thejack panel

provided in theoptional components, thenfix the jackpanel in theinstalling location of

operator panel (asshown in Figure3-13).

Fig. 3-13 MountingDiagram for theoperator panel and

connecting wire ofthe inverter ModelB

lug the groundingend of connectingwire into theslot of jackpanel (as shownin the

figure 3-14).

Step 4. Fixand fasten thedismantled operator panel, andput the otherend of connectingwire

into the socketof operator panel(as shown inthe figure 3-15).

Fig. 3-14 MountingDiagram for theoperator panel andconnecting

wire of theinverter Model B

Fig. 3-15 MountingDiagram for theoperator panel andconnecting

wire of theinverter Model B

Chapter 3Inverter Installationand Wiring Chapter 3Inverter Installationand Wiring

3.3.2 Cautions forWiring

Hazard!

Wait atleast 10 minutesafter power OFFbefore opening the frontcover

of the inverter.

Verifythe charge indicatorlamp is OFFbefore proceeding thework,

and be surethat the voltagevalue of themain loop terminalP and DCis

less than 36VDC.

The internal wiringof the invertershould be operatedonly by

authorized qualified personnel.

WARNING!

Verifythe rated inputvoltage of theinverter is matched

with ACpower supply. Otherwise, thereis the possibilityof

damage to theinverter.

Install in orderand only operatewiring after finishing

main parts installation.Otherwise, there isan electric

shock or damageto the inverter.

Do not performover-voltage withstandto the inverter,

for this hadbeen done properlybefore EX-factory.

Be sure toinstall a non-fusecircuit breaker inthe input

power supply sideof the inverterto prevent expanding of

accident due toan inverter problem,which may cause

damage to thedistribution equipment orlead to fire.

Be sure toconnect the groundterminal and themotor

casing to theground wire whichmust be coppercore. The

diameter of thecopper core shouldconform to therelevant

national standard.The ground resistanceshould be less

than 10 .

FORBIDDEN!

DO NOT connectAC powersupply to theoutput terminals marked

"U", "V" and"W". Otherwise, therewill be damageto the inverter.

DO NOT connectcontrol terminals (exceptterminals marked

"TA","TB" and "TC")to AC220V power supply, which maycause

damage to theinverter.

When the open-ended output terminal of thecollector

connects to anyinductive load, i.e., the relaycoil, do inserta

diode at eachend of theload in parallel.

The control wirein the inverteror the controlcabinet should

be at least100mm away fromthe power cable.DO NOTput

them in thesame metallic channel. If thesignal wire andthe

power cable needto intersect, theyshould intersect atan angle

of 90 . The control wire mustadopt STP(shielded twisted pair

wire); the shielded layer mustconnect to theterminal GND;

and the powerwire is recommended to usemetallic shielded

cable

The unavoidable strongelectromagnetic interference ofthe

inverter may havebad influence onall the electricalequipment

and meters inthe same environment.Toreduce interference, the

output cable ofthe inverter canbe inserted inthe metal pipe

connecting to theground or inthe metallic shieldedcable, and

connect the metallicshielded layer tothe ground. Inaddition, a

magnetic loop puton the outputcable is alsoeffective to reduce

interference.

Tips

Tips

Chapter 3Inverter Installationand Wiring Chapter 3Inverter Installationand Wiring

3.3.3 Instruction onMain CircuitTerminals

1 The main circuitterminals are shownas in thefigure 3-18~3-23.

Connect to

ground

Connect to

ground

Single-phase

220V power

supply input

Connect to

braking

resistance

Connect to

braking

resistance

Connect to

three-phase

AC motor

Connect to

three-phase

AC motor

Fig.3-18 Diagram 1for Main CircuitTerminals

Applicable

to Model

Applicable

to Model

Three-phase 380V

(or three-phase 220V)

power supply input

Connect

to ground

Three-phase 380V

power supply input

Braking

resistance

Braking unit Connect to

three-phase

AC motor

Fig.3-20 Diagram 3forMain Circuit Terminals

Applicable

to Model

Applicable

to Model

Three-phase

380V input

power supply

Connect

to reactor

Connect to

braking unit Connect to

three-phase

AC motor

Connect to

ground

Fig.3-19 Diagram 2for Main CircuitTerminals Fig.3-21 Diagram 4for Main CircuitTerminals

Chapter 3Inverter Installationand Wiring Chapter 3Inverter Installationand Wiring

Three-phase

380V input

power supply

Three-phase

380V input

power supply

Connect to

braking unit

Connect to

braking unit Connect to three-

phase AC motor

Connect to three-

phase AC motor

Connect

to ground

Connect

to ground

Fig.3-22 Diagram 5for Main Circuit Terminals

Applicable

to Model

Applicable

to Model

2 Function Description Main CircuitTerminalson

Terminal Symbols Function Description

Power supply input terminalsconnecting to three-phase 380Vor 220V ACinput

power supply

Power supply input terminalsconnecting to single-phase 220VAC input powersupply

Inverter output terminalsconnecting to three-phaseAC motor

External braking resistance terminalsconnecting to both endsof the external

braking resistance

External braking unit terminals;terminal P connectsto the positive endof the

braking unit and DC-connects to the negativeend.

External AC reactorterminals connecting to bothends of theAC reactor

Ground terminal connecting tothe ground

Tips

The three-phase inputpower supply terminals(R, S andT)

do not differ on phasesequence and canbe connected

arbitrarily.

If the motorcounter rotates (reverses)when the output

terminals U,V andW connectto three-phase motor, just

exchange two phasesof U, Vand Warbitrarily.

A brakingunit is requiredto be installedinside the inverter

under 15KW. If anexternal braking resistance is required,just

connect to theexternal braking resistancebetween terminal P

and terminal DB.

An inverter higherthan 18.5KWhas no internalbraking

unit, so ithas no DBterminal. If abraking torque isneeded,

please connect tothe external brakeassembly including

braking unit andbraking resistance between Pand DC-.

ZVF9V-G1600T4/P1850T4or even updatedmodel is

matched with DCreactor. Ifan inverter hasno internal DC

reactor, justfix a DCreactor between Pand DC+.When

performing this step,it is requiredto remove theshort-circuit

ring, then connectto the reactor(applicable to theinverter of

18.5KW orhigher power).

Fig.3-23 Diagram 6for Main CircuitTerminals

Chapter 3Inverter Installationand Wiring Chapter 3Inverter Installationand Wiring

3.3.4 Description onControl CircuitTerminals

1 Control circuit terminalsare shown inthe figure 3-24and 3-25

Fig.3-24 Control CircuitTerminals(1)

Fig.3-25 Control CircuitTerminals(2)

2 Description on ControlCircuit Terminals

Table 3-2Function Description onControl CircuitTerminals

Types Terminal

Symbols Function Description Electrical Specifications

Public

Port Digital signal publicterminal

Forward when FWD-COM shortcuts,

decelerate and stop whenFWD-

COM is open.

Running

Control

Terminal Reverse when FWD-COM shortcuts,

decelerate and stop whenFWD-COM

is open.

INPUT, 0~24 power level,

low level valid,5mA

Multi-function Input

Terminal

Validonly when there isa short

circuit between Xn (n=1,2, 3, 4,

5, 6) andCOM. The functions

can be setby the parameter

F4.00~F4.05 separately.

INPUT, 0~24 power

level, low levelvalid,

5mA

Multi-function

OutputTerminal

Multi-function open-

collector output isdefined as

on-off output terminal,whose

function is setby the

parameter F4.07~F4.08 with

reference of COM.

OUTPUT, MaximumCurrent

Load

Ground Terminal

VacantTerminal

Others

Table of contents

Other Chziri Inverter manuals