CIAC Outdoor Series User manual

VERSION: A

DATA:Aug,12th,2016

SEVICE MANUAL

AHU VALVE BOX

Contents

1. General Information................................................................................................................................ 1

2. Specication ........................................................................................................................................... 4

3. Dimension............................................................................................................................................... 5

4. Wiring diagram ....................................................................................................................................... 7

5. Installation .............................................................................................................................................. 8

6. PCB photo ............................................................................................................................................ 26

7. Dip switch setting.................................................................................................................................. 27

8. Failure code.......................................................................................................................................... 29

9. Troubleshooting.................................................................................................................................... 30

APPENDIX Sensor resistance table........................................................................................................ 34

1

1. General information

1.1 Function:

Thought AHU valve box, can realize the CIAC IMVF outdoor unit connect with third party DX air handling units. As the folowing gure

1.2 Feature:

(1) EXV part and control part integration, easy for translation and installation. Gas pipe is integrated into

the valve box.

(2) Optional insttion location: can choose lting or nailed to the wall

(3) Control box location changeable :

Control box can be separately with EXV box.(2 meter)

Control box can be front or back of EXV box, easy installation.

(4) Broad capacity: 5-20HP

(5) High Compatible:

Same PCB board with IMVF indoor, easy operation and service.

Same wired controller can be used with IMVF indoor unit such as YR-E16,YR-E17 and YR-E14

(6) Reliable EEV : EEV is supplied by FUJIKOKI.

2

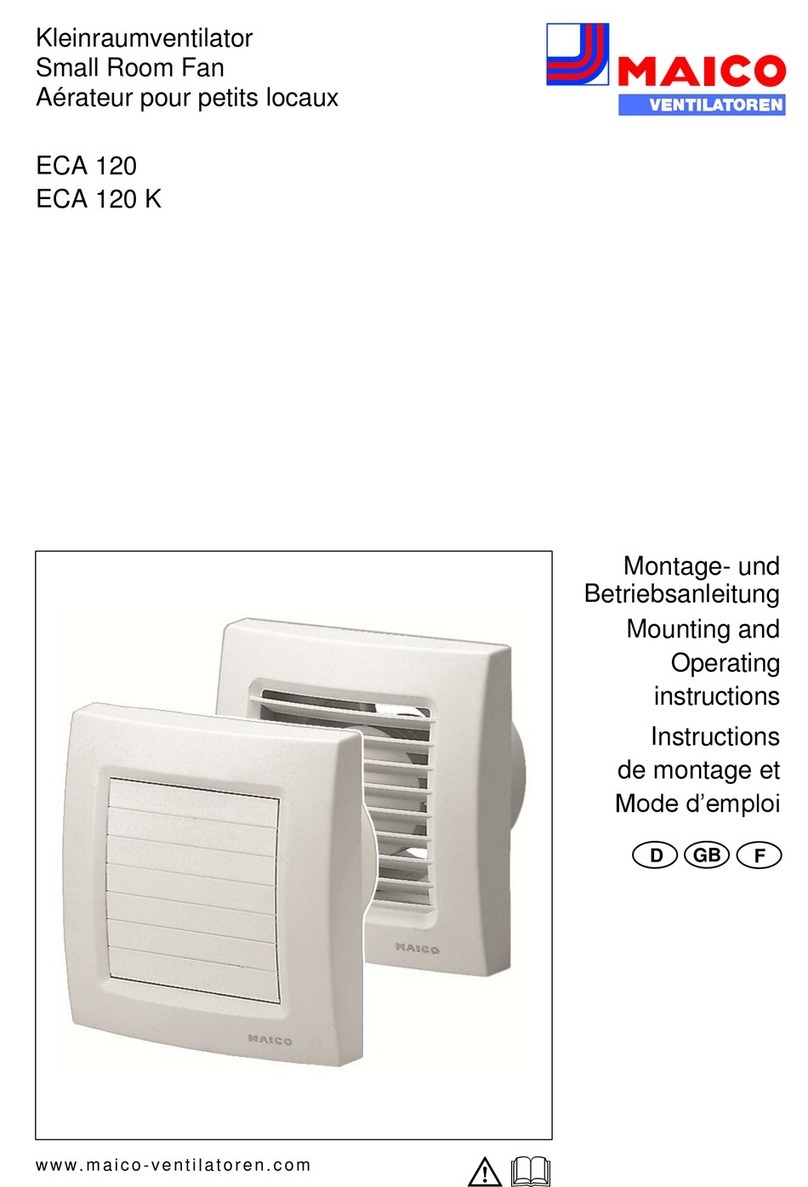

1.3 System lineup

MRV III-C

MRV Outdoor

Valve Box

AHU &

MRV indoor

MRV III-S

8/10/12HP

AH1-280A

AHU need purchase in Market

5HP(14KW) <Connected AHU capa. ≤10HP(28KW) 10HP <Connected AHU capa. ≤20HP(56kw)

AH1-560A

MRV III-C PLUS MRV IV-C

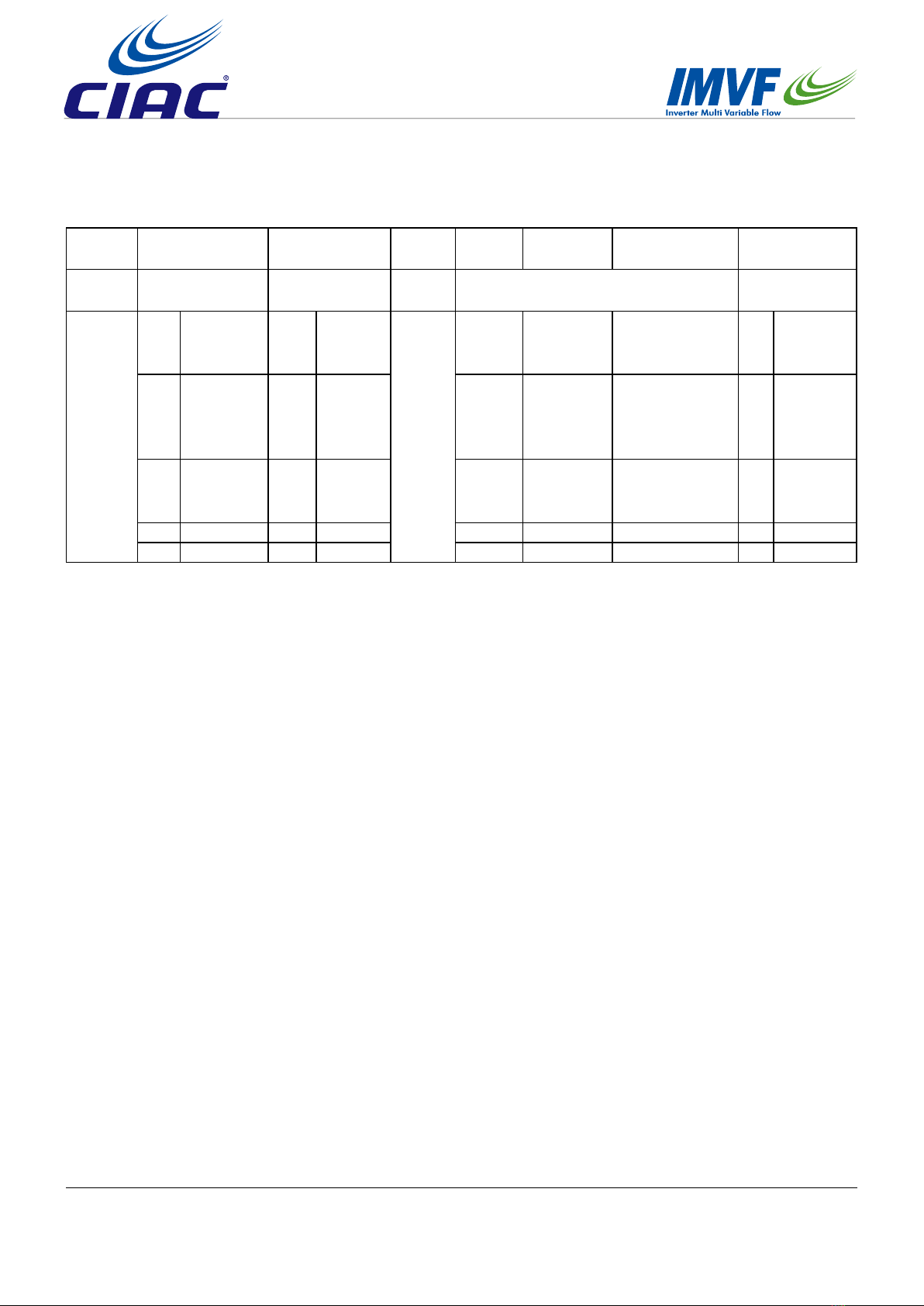

1.4 Conguration

AH1-280A

Different Valve Same Control Parts

EXV part Control Part Sensor and wire Controller

OR

AH1-560A

OR

Outdoor series Outdoor model

IMVFIII-C (2200V) CA43BV***-V5J1H

IMVFIII-C (460V) CA43BV***-V6J1H

The AHU valve box can connect with the following outdoor units:

3

1.5 Nomenclature

Code

position 1,2 3 4 5 6 7 8

Code

meaning Valve box series Valve box type Space

mark

Indoor capacity which Valve box can be

connected Series number

Code and

contents

VP 3-pipe valve

box 1 1 to 1

-

Cooling

capacity

Cooling

capacity<

99KW

Three digits***(unit:

100W) AFirst

generation

MS

IMVF

+SUPER

MATCH

valve box

2 1 to 2 Cooling

capacity

Cooling

capacity>

99KW

Three digits 000

(unit

:

HP) B Second

generation

AH

IMVF +

AHU valve

box

3 1 to 3 Cooling

capacity

Cooling

capacity is

not dened

Three digits 000 C Third

generation

4 1 to 4 … …

… … … …

4

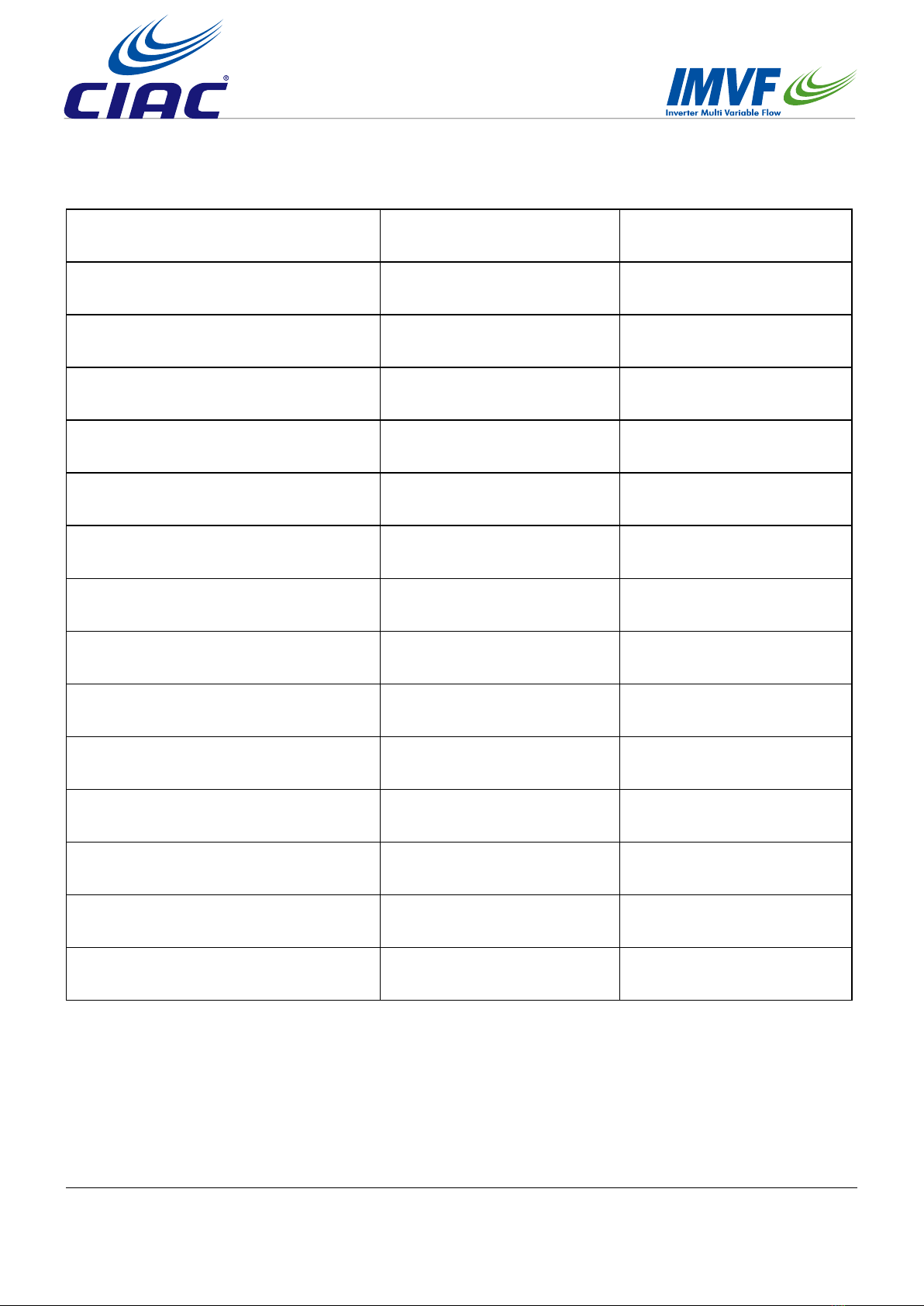

2. Specication

Model AH1-280A AH1-560A

Connected AHU capacity 14≤x ≤28KW(5-10HP) 28 <x ≤56KW(10-20HP)

Power supply 220-240V/50/60Hz 220-240V/50/60Hz

Dimention(W/D/H) 350/226/155 433/296/193

Shipping dimensions 606*295*209 667*365*249

Material Galvanized steel Galvanized steel

Color Grey Grey

Weight/kg 6 9

Shipping Weight/kg 8 12

Liquid pipe (mm) 9.52(Main)/12.7 12.7(Main)/9.52/15.88

Gas pipe (mm) 25.4(Main)/22.2 /19.05 28.58(Main)/25.4/22.22

Pipe connection method Flare connection and welding Flare connection and welding

Branch box-Indoor Max Single pipe length/m 5 5

Branch box- indoor max drop/m 5 5

Height Drop between branch box /m 15 15

5

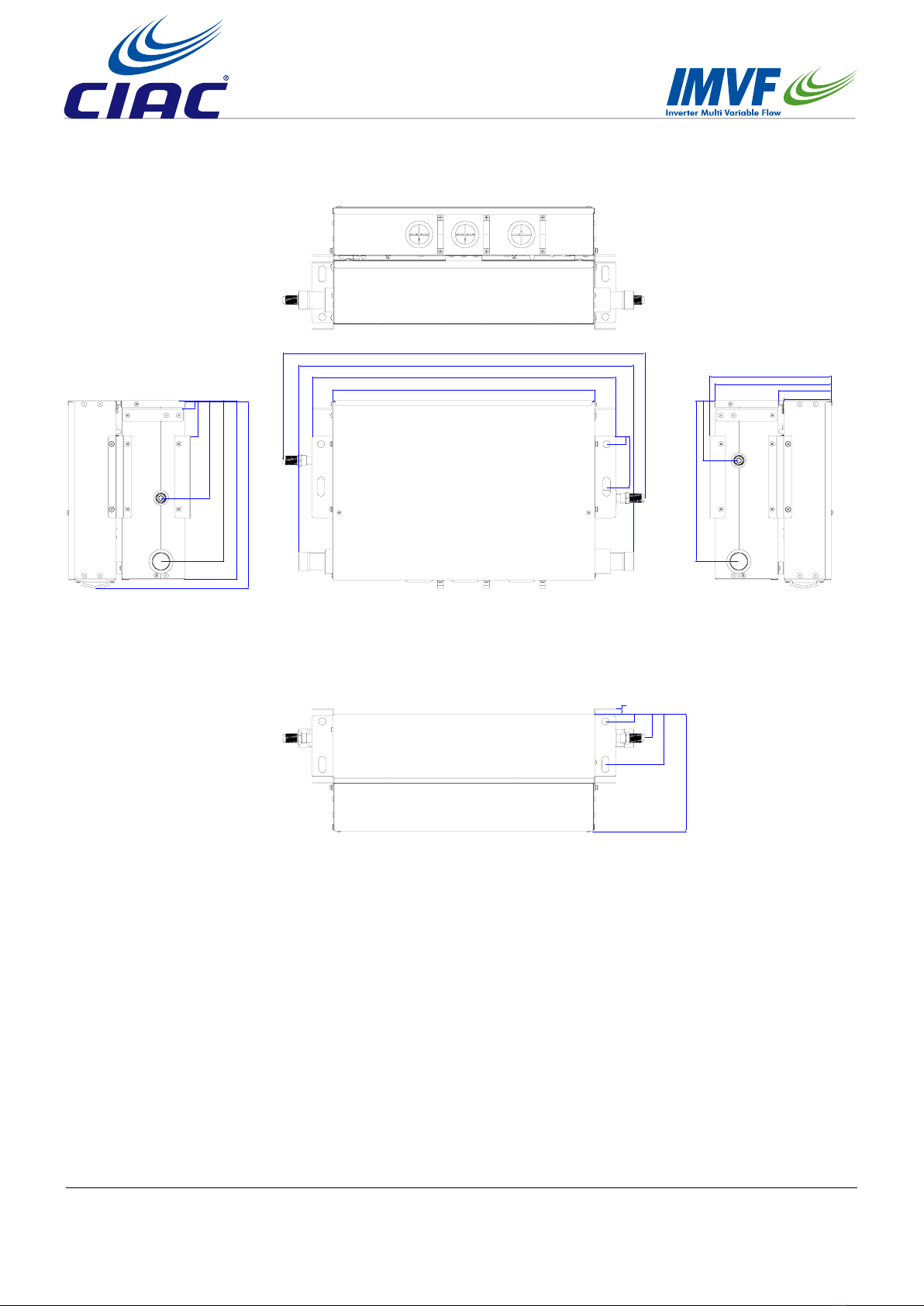

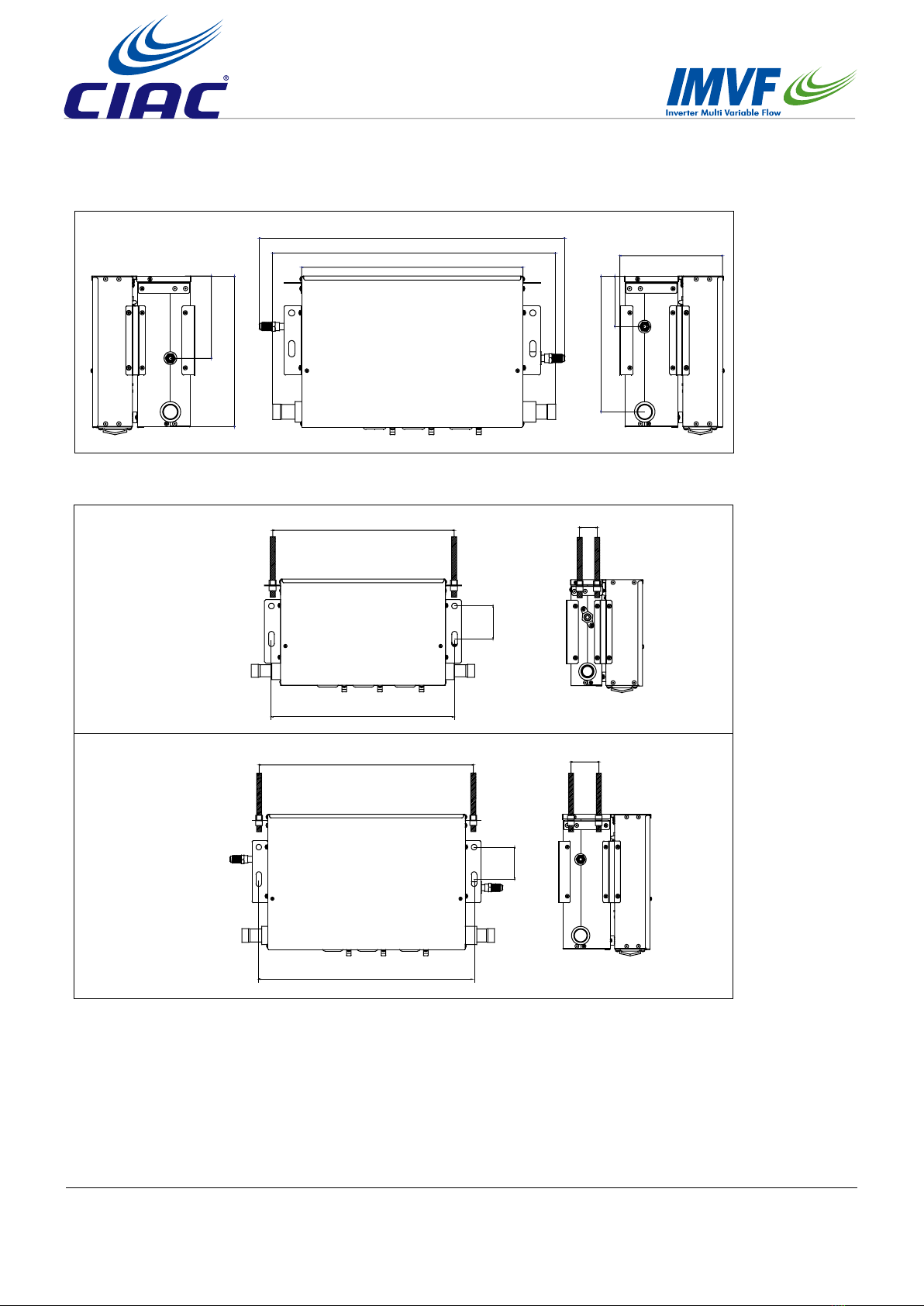

3. Dimension

AH1-280A

240

226

179

166

56

44

13

195

147

12

36

49

82

9

155

476

419

350

15

14

84

86

152

80

195

163

78

6

AH1-560A

13

59

161

266

296

309

433

501

597

553

14

84

78

87

192

201

99

266

193

12

39

83

9

7

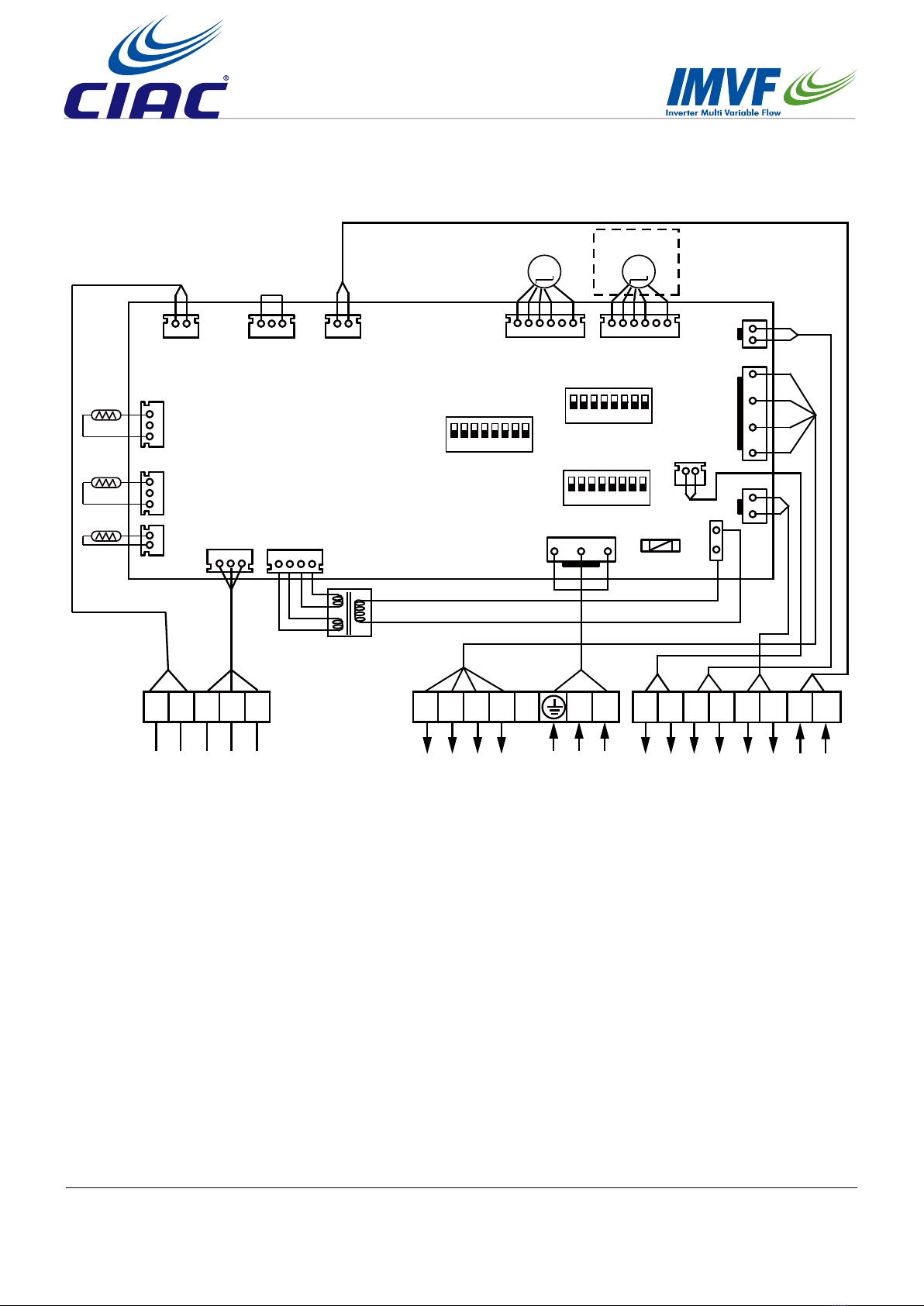

4. Wiring diagram

SW01 ON

12345678

CN10CN15

CN18

CN19

CN20

CN16

CN3

CN7

CN1

TC2

TC1 ON

SW07

Outdoor

unit

Controller

12345678

ON

SW03

Power

Input 220V

FAN Speed

AC 220V

Output

DC 12V

12345678

6.3A 250VAC

FUSE1

PMV1

M

P Q A B C LH M L N V1 V2 D1D2 P1 P2N

CN24CN22

TA

CN31

CN33

CN8

{

{

{

{

Input

ON/OFF

{

Output

Dry

contact

{

Output

AC 220V

{

{

K1 K2

CN13 CN12

PMV2

M

8

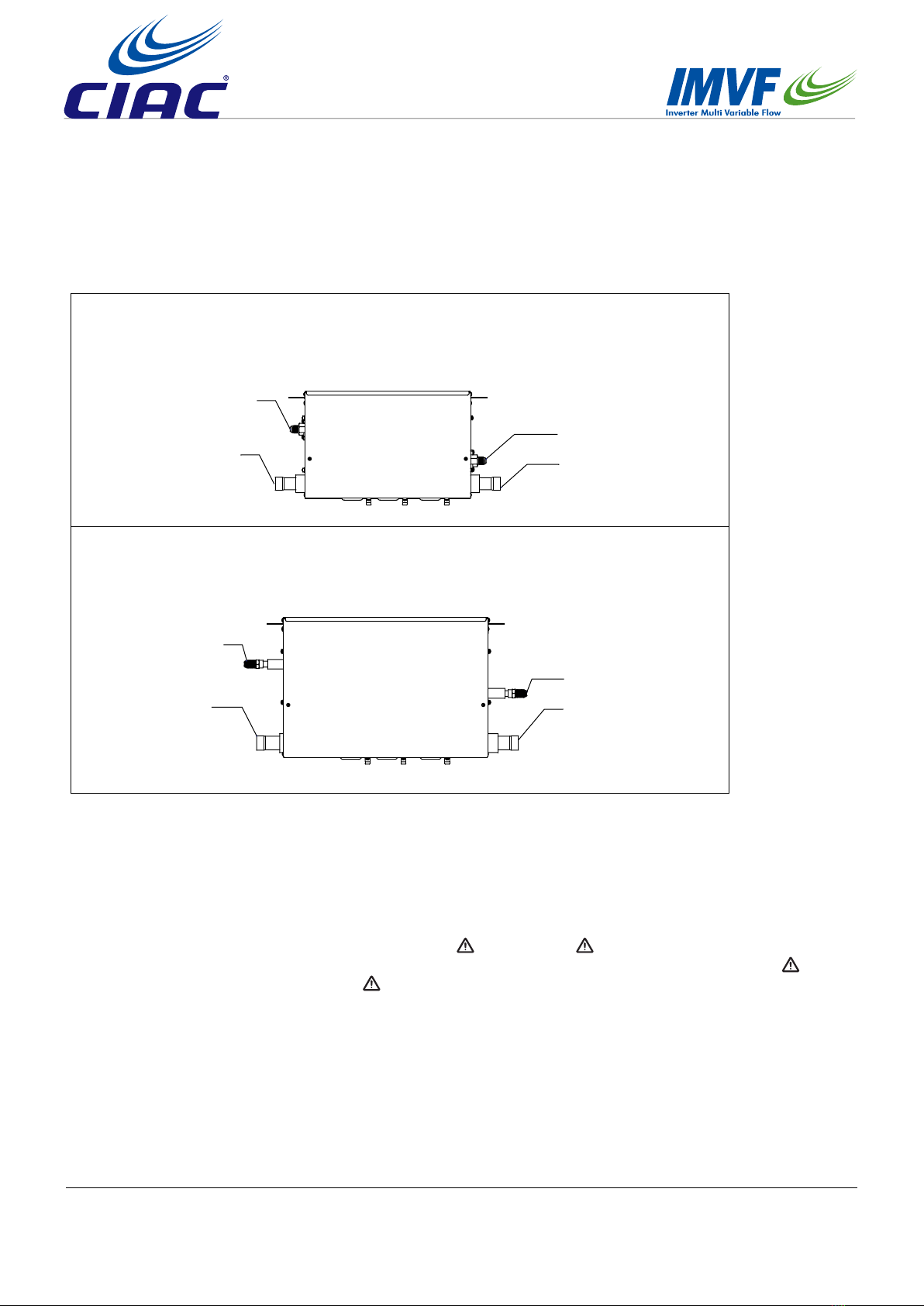

5. Installation

5.1 Parts and function

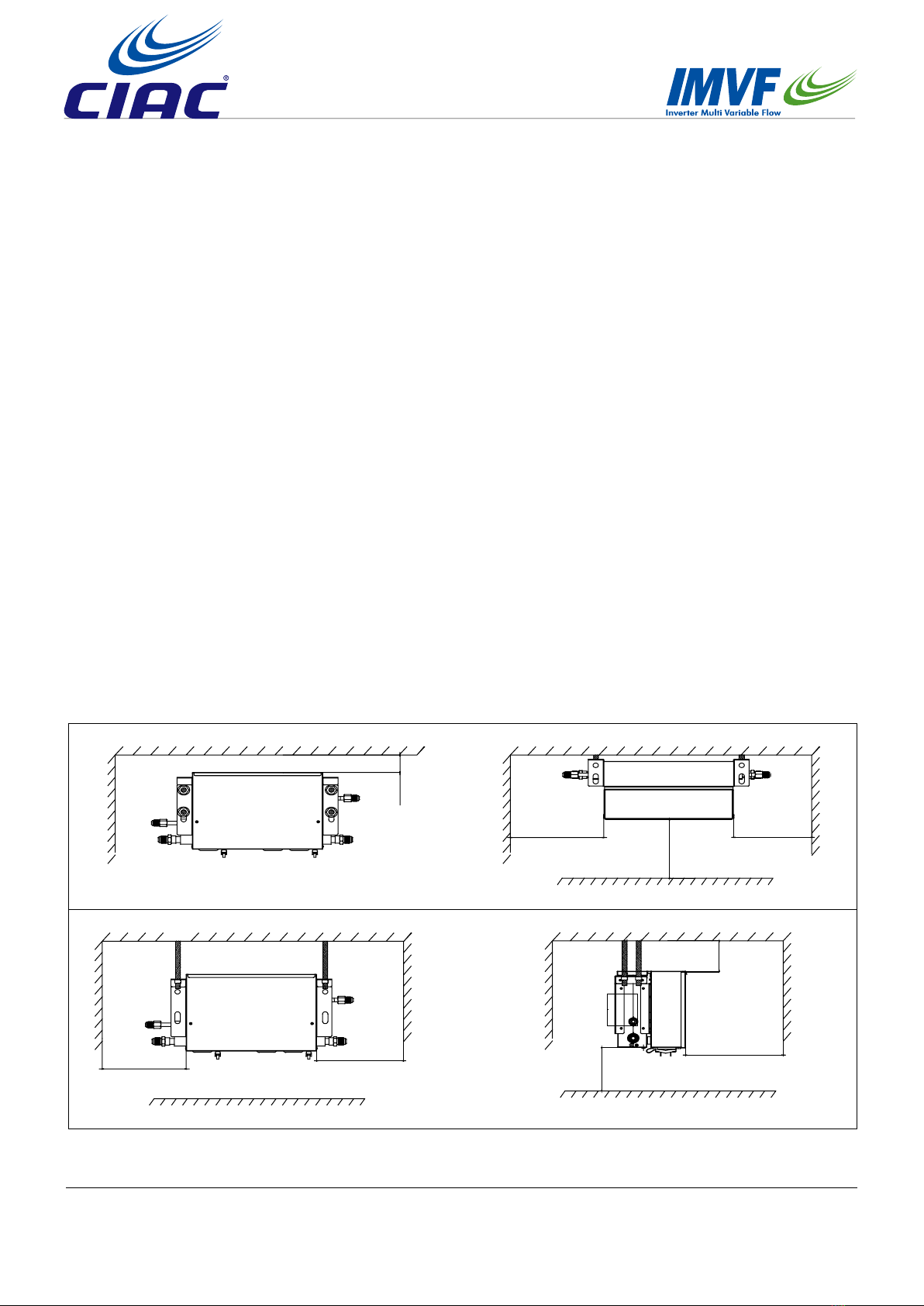

Outdoor unit side (2 pipes)

Outdoor unit side (2 pipes)

Indoor unit side (2 pipes)

Indoor unit side (2 pipes)

Liquid Pipe (Ø9.52)

Liquid Pipe (Ø12.7)

Liquid Pipe (Ø12.7)

Liquid Pipe (Ø9.52)

Gas Pipe (Ø25.6)

Gas Pipe (Ø28.8) Gas Pipe (Ø28.8)

Gas Pipe (Ø25.6)

AH1-280A

AH1-560A

5.2 Safety

• If the connection kit is transferred to a new user, this manual shall be transferred to the user, together with the

conditioner.

• Before installation, be sure to read Safety Considerations in this manual for proper installation.

• The safety considerations stated below is divided into “ Warning” and “ Attention”. The matters on severe

accidents caused from wrong installation, which is likely to lead to death or serious injury, are listed in “

Warning”. However, the matters listed in “ Attention” are also likely causing the severe accidents. In general,

both of them are the important items related to the security, which should be strictly abided by.

• After the installation, perform test run to make sure everything is in normal conditions, and then operate and

maintain the connection kit in accordance with the user manual. The user manual should be delivered to the user

for proper keeping.

9

• Please ask the special maintenance station for installation and repair. Water leakage, electric shocks or re

accidents might be caused from improper installation if you conduct the installation by your own.

• The installation should be conducted properly according to this manual. Water leakage, electric shocks or re

accidents might be caused from improper installation.

• Please make sure to install the connection kit on the place where can bear the weight of the connection kit. The

connection kit can’t be installed on the grids such as the non-special metal burglar-proof net. The place with

insufcient support strength might cause the dropdown of the machine, which may lead to personal injuries.

• The installation should be ensured against typhoons and earthquakes, etc. The installation unconformable to the

requirements will lead to accidents due to the turnover of the machine.

• Specic cables should be used for reliable connections of the wirings. Please x the terminal connections reliably

to avoid the outside force applied on the cables from being impressed on the cables. Improper connections and

xings might lead to such accidents as heating or re accidents.

• Correct shapes of wirings should be kept while the embossed shape is not allowed. The wirings should be reliably

connected to avoid the cover and the plate of the electrical cabinet clipping the wiring. Improper installation might

cause such accidents as heating or re accidents.

• While placing or reinstalling the connection kit, except the specic refrigerant (R410A), don’t let the air go into the

refrigeration cycle system. The air in the refrigeration cycle system might lead to the cracking or personal injuries

due to abnormal high pressure of the refrigeration cycle system.

• During installation, please use the accompanied spare parts or specic parts. If not, water leakage, electric

shocks, re accidents or refrigerant leakage might be caused.

• During installation, if refrigerant leakage occurs, ventilation measures should be taken, for the refrigerant gas

might generate harmful gases upon contacting the ame.

• After installation, check if any refrigerant leakage exists. If the refrigerant gas leaks in the room, such things as

air blowing heaters and stoves, etc. may generate harmful gases.

• Don’t install the connection kit at the places where the ammable gases may leak. In case the gas leakage

occurs around the machine, such accidents as re disasters may be caused.

• The refrigerant gas pipe, HP gas pipe and liquid pipe should be heat insulated to preserve heat. For inappropriate

heat insulation, the water caused from the condensation will drop to get the article at home wet.

• The electrical construction shall be implemented by the correspondingly qualied personnel in accordance with

electrical construction standards, local electrical laws as well as specications. Moreover, dedicated circuit must

be used, rather than the wire pin. Insufcient capacity of the wire circuit and unprepared construction (if any) may

cause electric shock, res, etc.

• During the process of grounding, the ground wire cannot be connected to the gas pipe, water pipe, lightning rod

and ground wire of the telephone. Incomplete grounding may cause electric shock, res, etc.

• Install residual-current circuit breaker, or electric shock, res, etc. will occur.

• When contacting electrical components, ensure they are powered off. Contacting the live part may result in the

danger of electric shock.

• If there is leakage of the refrigerant gas ow during operation, refrigerant gas is required. If the refrigerant gas

contacts any re, poisonous gases will be produced.

• If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualied

persons in order to avoid a hazard.

Warning

10

• This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety.

• Children should be supervised to ensure that they do not play with the appliance.

• This appliance can be used by children aged from 8 years and above and persons with reduced physical, sensory

or mental capabilities or lack of experience and knowledge if they have been given supervision or instruction

concerning use of the appliance in a safe way and understand the hazards involved. Children shall not play with

the appliance. Cleaning and user maintenance shall not be made by children without supervision.

• The appliances are not intended to be operated by means of an external timer or separate remote-control

system.

• Keep the appliance and its cord out of reach of children less than 8 years.

Attention

• The connection kit should be effectively grounded. Electric shocks may occur if the connection kit is ungrounded

or inappropriately grounded. The wire for earthing shouldn’t be connected to the connections on the gas pipe,

water pipe, lightning rod or telephone.

• The breaker for electricity leakage should be mounted. If not, accidents such as electric shocks may happen.

• The installed connection kit should be checked for electricity leakage by being powered.

• After installation, all cassette concealed connection kites should be trial-tested. After the proper operation of the

machine, other tments can be made.

• When installing the connection kit, please x the box and connecting pipes in an efcient way to avoid shaking

when changing connection kit.

• If the ambient humidity bigger than 80%, when the water discharge hole be blocked or the lter becomes dirty,

or airow speed change, there may be leads to condensing water drop down, and at the same time there maybe

some drops of water spit out.

• Keep the connection kit, power supply wiring, conductor, etc. at least 1 m away from the TV and radio to avoid

image interference and noise. However, sometimes there is still noise when the distance is over 1 m due to the

different states of radio waves.

• Try to install connection kit where the uorescent lamp is far away.

• When wireless devices are being installed, the distance that the signal from the controller will reach may be

shortened in a room with a uorescent lamp that is turned on in an electric way (frequency conversion or rapid

start).

Prohibitions

• Do not use components other than the fuse of proper capacity, such as metal wire and copper wire, which will

cause res and other faults if used instead of the fuse.

• When doing the cleaning and maintenance, make sure that the operation has been stopped and the manual

power switch is in the off position.

• Do not use appliances such as water heater near the connection kit. Using appliances producing steam near the

connection kit may lead to accidents such as water leakage, electric leakage and short circuit when the cooling

system is in operation.

11

5.3 Installation instruction

Do not install at such places

Attention item

Accessories

1. A place that is lled with mineral oil, a kitchen which has oil and steam everywhere, etc., which may cause

degradation, falling off and water leakage of the resinous components.

2. A place with corrosive gases such as sulphurous acid gas, which will lead to the corrosion of the copper tube,

welding joint, etc., causing refrigerant leakage.

3. A place where machines give out electromagnetic waves, which will lead to abnormality and improper function of

the control system.

4. A place with possible leakage of combustible gases, oating of carbon ber and combustible dust and use of

volatile combustible substances such as diluents, the accumulation of which around the machine set will lead to

res.

5. A place where small animals inhabit, whose contacting the inner electrical components may cause faults,

smoking, outbreak of a re, etc.

6. A coastal place with high salinity and a place with great variation in voltage such as a factory, which may cause

faults to vehicles and ships.

Install after making sure that the type of the refrigerant used is R410A. If any other type of refrigerant is used, the

machine cannot run.

• Before and after the unpacking, if connection kit is to be moved, the hoisting handles (totally 4) shall be held

rmly. Do not apply force to other parts, especially a refrigerant tube and an electrical cabinet.

• Concerning the installation of the outdoor and indoor units, refer to the installation specication of each unit.

Conrm that the accessories below are packed together.

AH1-

280A Variable diameter suspending clip

Thermal

insulation

pipe

Nut Specication

Quantity 2 2 2 2 8 2 2 2 1

Shape

Ø12.7

Ø9.52

inner diameter Ø19.3

inner diameter Ø22.4

outer diameter Ø25.4

12

<Entrustment>

Before the installation is completed, do not abandon the accessories needed in installation.

Combinations

• The connection kit is special used for third party air handling units. Cannot connect to other indoor unit.

• Please according to the following table to select the connection kit model.

Table1: Total capacity of indoor unit:

Connection kit The capacity of the air handing unit (kW) The quantity of the air handing unit

AH1-280A ≤28kW 1

AH1-560A 28kW<Capacity≤56kW 1

(2) Inspection upon delivery

Inspection item Inspection column

If the electric box cover is installed

If the installation specication is transferred to the customer

Inspection item

Pay much attention to the following during installation. Check them again after completion.

(1) Inspection items after installation

Inspection item Defect Inspection column

If the installation of connection kit is secure ? Falling off, vibration and noise

If gas leakage inspection is completed ? No heating/cooling

If complete insulation is achieved

(refrigerant piping and tubing connections) ? Water leakage

If the voltage of the power supply is

consistent with that on the nameplate ? Out of service, burnt

If there is improper wiring or piping ? Out of service, burnt

If there is construction without grounding ? Danger in electric leakage

If the thickness of the wire is as specied ? Out of service, burnt

AH1-

560A Variable diameter suspending clip screw

Thermal

insulation

pipe

Nut Specication

Quantity 2 2 2 2 8 8 2 2 2 1

Shape

Ø15.88

Ø12.7

inner

diameter

Ø22.4

inner

diameter

Ø25.6

outer

diameter

Ø28.58

13

5.4 Installation procedure

5.4.1 Pre-installation

The installation location selected shall meet the following conditions and be approved by users.

• The strength shall be sufcient to withstand the weight of the connection kit

• There is no signicant tilt on the plane.

• Ensure that there is enough space for installation and maintenance.

• There is space for inspection on the side and top of the electric box

• The length of piping between the indoor and outdoor units shall be within the permissible range (referring to the

specication attached to the outdoor unit).

• Please install the connection kit in places where noise will not inuence the customers too much (such as

washroom, passageway, warehouse, equipment room, etc.). Places with high requirement for quiet are not

suggested for installation, such as bedroom, drawing room, meeting room, ofce, etc.

Note:

• the electrical box can be changed as show in 3 connection kit installation.

• When starting up, stop, defrosting, and oil-returning in heating mode , the 4-way valve will veer and create noise.

This kind of noise is normal for the running of connection kit.

• A noise may be emitted by the connection kit as a result of control during operation or stopping of an indoor unit.

If it is installed in the ceiling where it is exposed, take adequate precautions with the installation location.

<Notice item>

• Inspect whether the installation location can sufciently withstand the weight of connection kit and set the hoisting

bolts by reinforcing the beam if necessary. Use hoisting bolts in installation (referring to 2 for the preparation

before installation).

• Install the power wiring and power line of the connection kit at more than 1 m away from TV and radio to prevent

the image clutter and noise. But, there may be noise even if it is more than 1 m according to the different waves.

Min100

Front view

Min200 Min200

Min300

Top view

Wall mounted (mm)

Celing mounted (mm)

Front view Side view

Min200

Min200

Min300

Min50

Min50

14

Electrical box

Manhole must

be arranged

on the side of

the electrical

box

500

500

5.4.2 Preparation before installation

(1) Connection kit dimension (mm)

Max 5000

Electrical box Connection kit

Dividually mounted (mm)

AH1-280A

147

226

163

195

80

476

419

350

15

(2) Lifting dimension of connection kit (mm)

AH1-280A

AH1-560A

37

71

AH1-560A

161

296

201

99

266

597

553

433

385

70

389

467

70

472

Fig.1

16

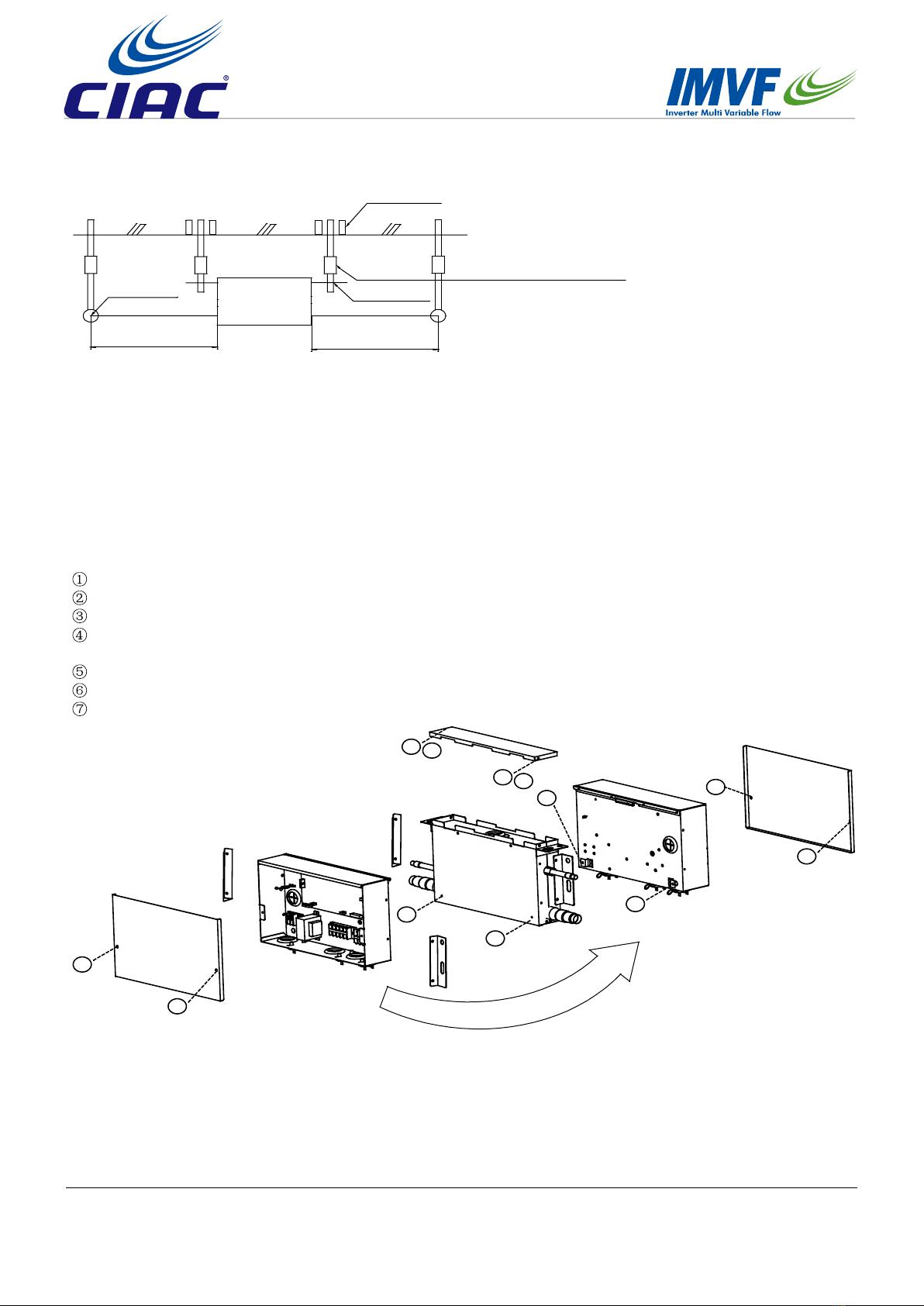

5.4.3 Installation of connection kit

Use parts and components specied for installing the installation components.

(1) Change the installation direction of electric box according to requirements following the steps below; (see

Fig.1)

Remove the cover of the electrical appliance box; (2 screws)

Remove the electrical appliance box; (2 screws)

Remove the top plate; (4 screws)

Change the outgoing direction of wiring (electric valve coil) between the equipment and the electrical appliance

box;

Rotate 180° to install the top plate;

Install the electrical appliance box;

Install the cover of the electrical appliance box.

Fig.1

④Electrical appliance removal

1

1

3

3

2

2

5

5

7

7

6

6

Thick cement plate

Foundation bolt

Long nuts or turnbuckle

Lifting bolt

Connection

kit

Lifting tools

Less than 1m Less than 1m Note: All the parts in the gure are purchased locally.

See the Fig.1 & Fig.2 to install the lifting bolts and hoisting tools.

• Use the lifting bolts with the size of M8~M10

• Press insert for new settings. Press hole in anchor if set. Ensure that it can sufciently withstand the weight of

the connection kit before installation.

Fig.2

17

5.4.4 Refrigerant pipe Installation

• Pipes between the outdoor unit and connection kit, selection of refrigerant branching suite, and the Pipe between

refrigerant branching suites and the indoor units, please refer to the installation instructions or equipment design

data attached to the outdoor unit.

• Before Installation, make sure the type of the refrigerant to be used is R410A. (If a refrigerant other than this type

is used, It cannot run properly)

• Please provide thermal insulation at the high-pressure gas pipe, suction gas pipe,, liquid pipe and oil equalizing

pipe (pipes for outdoor units in case of multi-split system) and the connections between these pipes. In the

absence of thermal insulation, liquid leakage and scalding may happen. Particularly when the high-pressure

gas pipe delivers indrawn air under full-refrigeration condition, it needs the same thermal insulation as does the

suction gas pipe. Besides, high-pressure gas pipe and suction gas pipe are to deliver high-pressure gas, thus

please provide thermal insulation material that can sustain temperature over 120 °C.

• Enhance the thermal insulation material based on the installation environment. The indicators are shown below.

For RH75%–80% at 30°C: over 15 mm thick.

For over 80% at 30°C: over 20 mm thick.

If not reinforced, the thermal insulation material surface is prone to condensation. Please refer to the equipment

design data for further details.

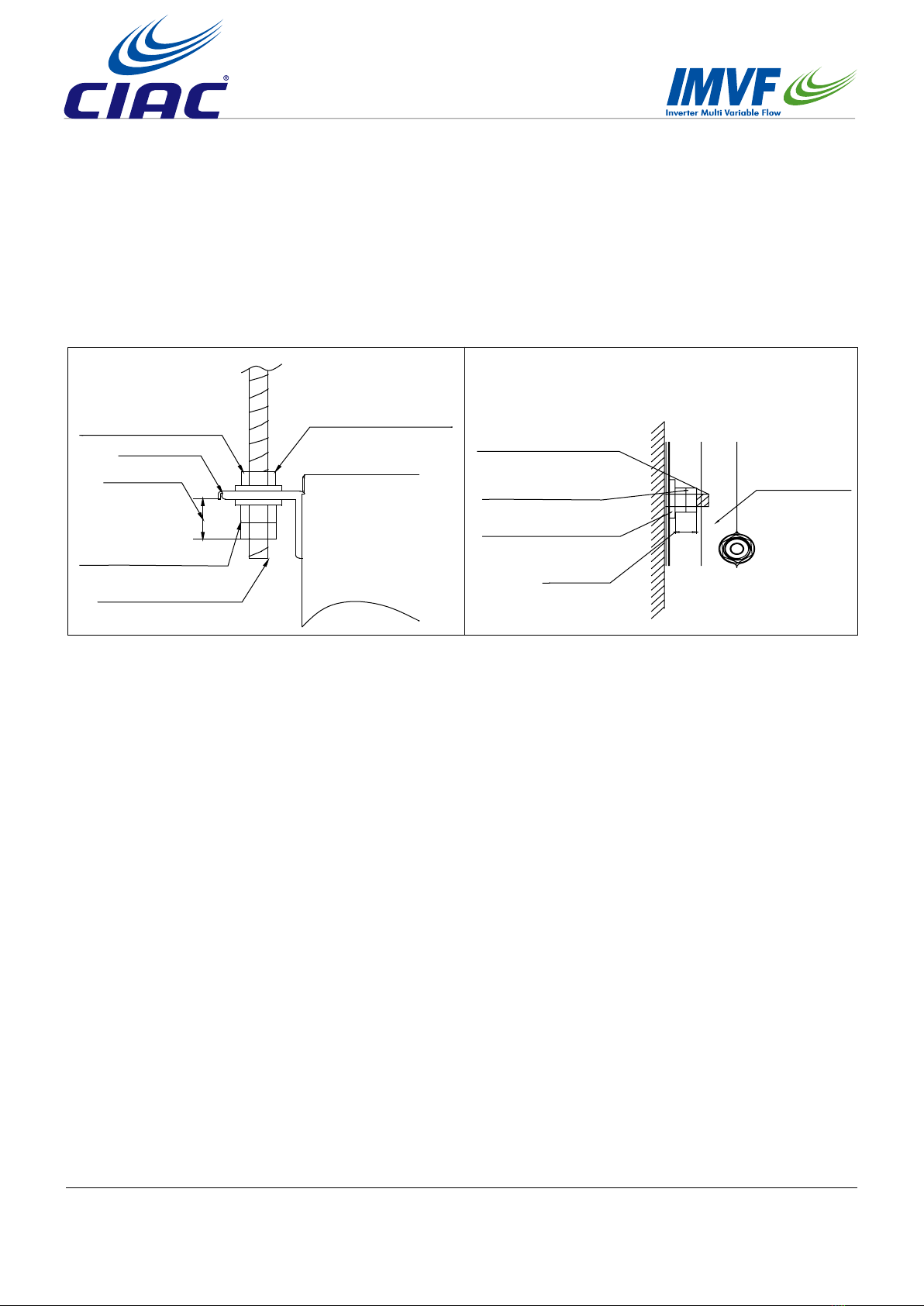

Fig.2

Wall mounted

Gasket

(purchased locally)

Double nuts

(purchased locally)

Lifting bolt

(purchased locally)

Nut

(purchased locally)

Connection kit

10-15mm

Lifting tool

Lifting bolt

(purchased locally)

Double nuts

(purchased locally)

Gasket

(purchased locally)

10-15mm

Connection kit

Ceiling mounted

Install the lifting tools on the lifting bolts according to the instruction of the Fig.2

Be sure to follow the stipulations on products locally purchased to use nuts (M8 or M10 of 3 pieces for 4 positions)

and gaskets (M8 with the outer diameter of 24~28 mm and M10 with that of 30~34 mm of 2 pieces for 4 positions)

on the upper and lower sides of the lifting tools.

<Note>

Be sure that the product must be installed with the top surface (the oblique surface in the Fig.2) upward, or it will

not work well and increase the working noise.

18

<Notes>

• Please do not let any type of gas other than the specied refrigerant go into the refrigeration system;

• In case of refrigerant leakage during operation, please replace the gas. (Fill the refrigerant at the outdoor unit)

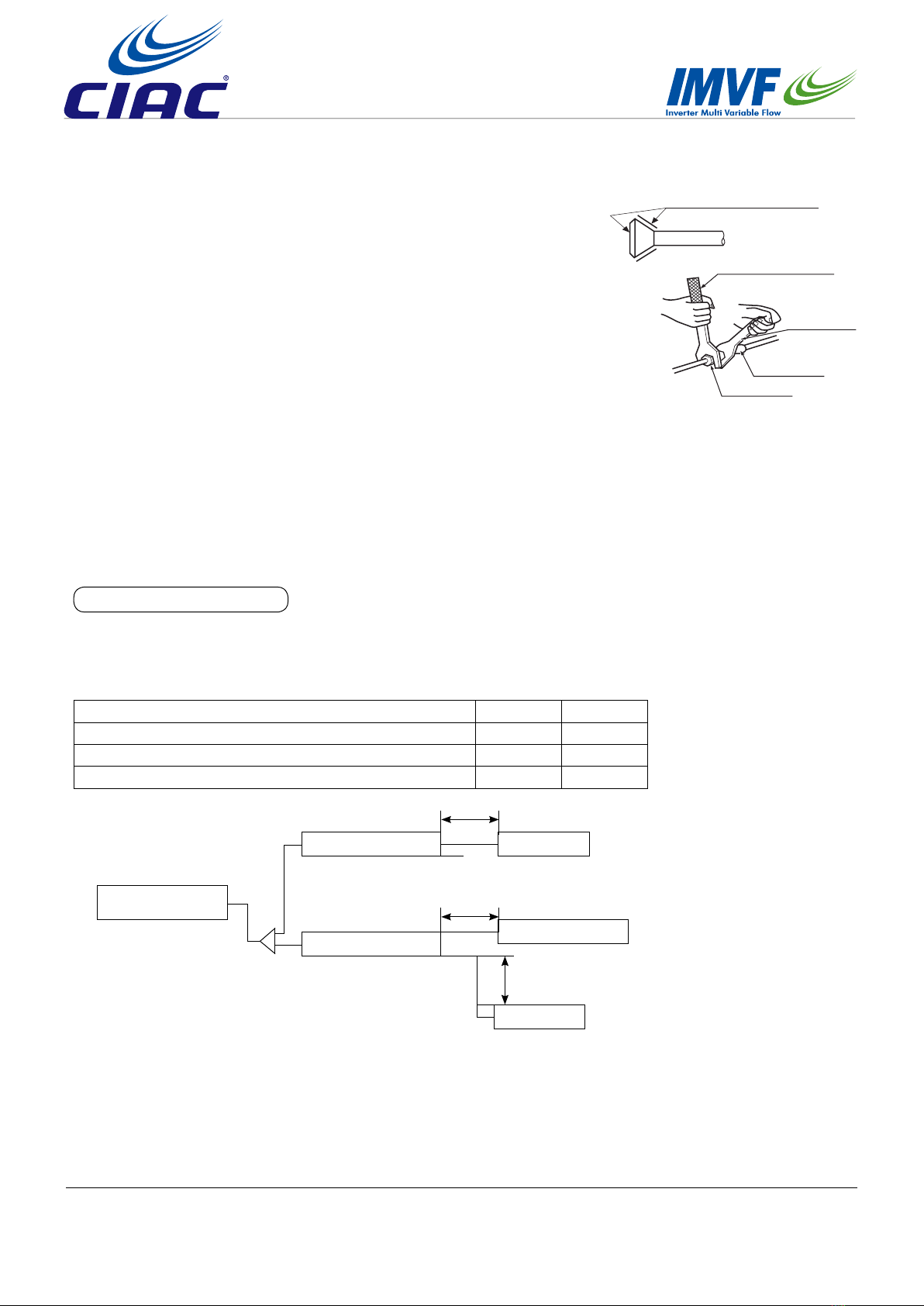

Paste the refrigerant oil here

Torque spanner

Spanner

Pipe joint

Cone nut

Fig.1

Select piping material

• Make sure both the internal surface and external surface of the pipes are intact and are free from harmful

contaminants such as sulphur, oxide, foreign matter, cutting powder, grease and water.

• Please use the following materials for refrigerant pipe.

connection kit AH1-280A AH1-560A

Connection kit-indoor max. single pipe length /m 5 5

Connection kit- indoor max. drop /m 5 5

Connection kit- electrical box max. distance 5 5

• The branching pipe for the pipe must have refrigerant branching suite. For selection of refrigerant branching

suite and max. height drop between indoor units, please refer to the installation instructions or technical data

attached to the outdoor unit.

Outdoor

Connection Kit

Connection Kit

Indoor

Electrical box

Max. length 5m

Max. length 5m

The high-pressure gas pipe, suction gas pipe, liquid pipe must be provided

with reliable thermal insulation. In the absence of thermal insulation, liquid

leakage may happen.

The outdoor unit is already lled with refrigerant.

To connect the pipes to connection kit or remove them from connection kit,

do use both spanner and torque wrench, as shown in the Fig.1.

Apply refrigerant oil to inside and outside of the are. Screw it for 3 to 4

rounds with hands and then tighten it.

Determine the tightening torque. (Excessive tightening may damage the nuts

and hence cause leakage)

Check the connecting pipes for gas leakage and then x the thermal

insulation, as shown in the in the Fig.2

Only use sealing gasket to wrap the part jointing between the gas pipe and

thermal insulation.

For pipe cutter and are tool, please use R410A special tools.

Indoor

Max. height drop 5m

This manual suits for next models

4

Table of contents

Popular Fan manuals by other brands

Maico

Maico ECA 120 SERIES Mounting and operating instructions

Makita

Makita CLX303 owner's manual

U.S. FAN

U.S. FAN UVQL900 quick start guide

ARDES

ARDES AR5PR40PR2 Instructions for use

Ebmpapst

Ebmpapst W6E500-CJ03-81 operating instructions

MrCool

MrCool UNIVERSAL MDUCC150 Series Owners & installation manual