Cillit Bonaqa Series User manual

DrDr

DrDr

Draftaft

aftaft

aft

BonaqaBonaqa

BonaqaBonaqa

Bonaqa

Single Tank SoftenerSingle Tank Softener

Single Tank SoftenerSingle Tank Softener

Single Tank Softener

Type: S, M, LType: S, M, L

Type: S, M, LType: S, M, L

Type: S, M, L

Changes reserved!Changes reserved!

Changes reserved!Changes reserved!

Changes reserved!

wwwwww

wwwwww

www.cillit.com.cillit.com

.cillit.com.cillit.com

.cillit.com

Installation andInstallation and

Installation andInstallation and

Installation and

operating manualoperating manual

operating manualoperating manual

operating manual GBGB

GBGB

GB

Bonaqa / 2008-10 / © Cillit-Wassertechnik GmbH / Printed in Germany

GBGB

GBGB

GB

22

22

2

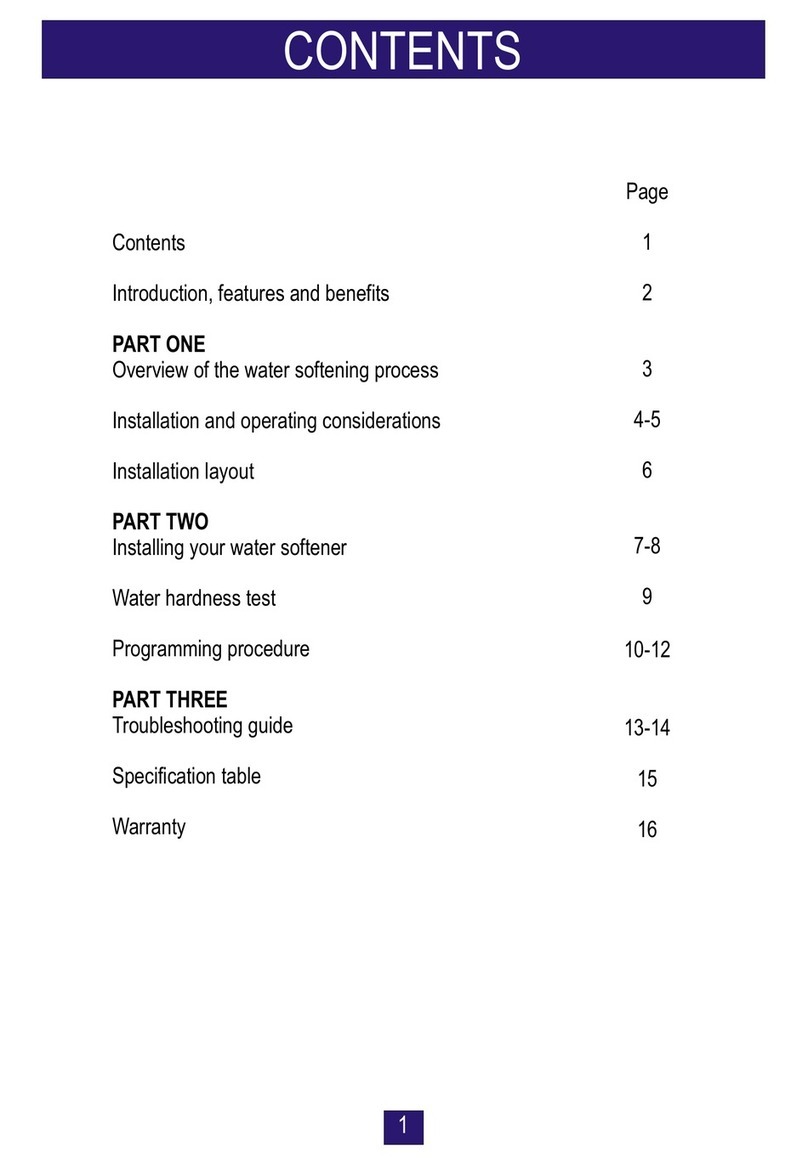

Table of ContentsTable of Contents

Table of ContentsTable of Contents

Table of Contents PagePage

PagePage

Page

Safety InstructionsSafety Instructions

Safety InstructionsSafety Instructions

Safety Instructions 22

22

2

Scope of DeliveryScope of Delivery

Scope of DeliveryScope of Delivery

Scope of Delivery 33

33

3

Intended UseIntended Use

Intended UseIntended Use

Intended Use 33

33

3

FunctionFunction

FunctionFunction

Function 33

33

3

Installation RequirementsInstallation Requirements

Installation RequirementsInstallation Requirements

Installation Requirements 44

44

4

InstallationInstallation

InstallationInstallation

Installation 55

55

5

Quick Guide to OperationQuick Guide to Operation

Quick Guide to OperationQuick Guide to Operation

Quick Guide to Operation 77

77

7

Start-UpStart-Up

Start-UpStart-Up

Start-Up 88

88

8

OperationOperation

OperationOperation

Operation 1313

1313

13

ChecksChecks

ChecksChecks

Checks 1616

1616

16

Warranty

Warranty

WarrantyWarranty

Warranty 1616

1616

16

Operator ResponsibilitiesOperator Responsibilities

Operator ResponsibilitiesOperator Responsibilities

Operator Responsibilities 1616

1616

16

TroubleshootingTroubleshooting

TroubleshootingTroubleshooting

Troubleshooting 1717

1717

17

Standards and Legal RegulationsStandards and Legal Regulations

Standards and Legal RegulationsStandards and Legal Regulations

Standards and Legal Regulations

1717

1717

17

Technical SpecificationsTechnical Specifications

Technical SpecificationsTechnical Specifications

Technical Specifications 1818

1818

18

Machine LogMachine Log

Machine LogMachine Log

Machine Log 1919

1919

19

We thank you for showing yourWe thank you for showing your

We thank you for showing yourWe thank you for showing your

We thank you for showing your

confidence in our products byconfidence in our products by

confidence in our products byconfidence in our products by

confidence in our products by

purchasing a Cillit unit.purchasing a Cillit unit.

purchasing a Cillit unit.purchasing a Cillit unit.

purchasing a Cillit unit.

SafSaf

SafSaf

Safety Instrety Instr

ety Instrety Instr

ety Instructionsuctions

uctionsuctions

uctions

The complete power unit including the cable must

be replaced in event of damage to the mains cable.

Soiled brine tanks can damage the unit and affect

water quality.

Clean the brine tank if it is dirty and at least once a

year using drinking water.

Notify residents of the installation of the unit, explain

how it works and inform them of the regenerative to

be used.

Using softened drUsing softened dr

Using softened drUsing softened dr

Using softened drinking winking w

inking winking w

inking water with plants andater with plants and

ater with plants andater with plants and

ater with plants and

aquatic animalsaquatic animals

aquatic animalsaquatic animals

aquatic animals

Each species of plant and aquatic animal requires

water that contains a special combination of sub-

stances. Users of the unit should therefore consult

the standard literature and check that they can use

retreated drinking water for watering plants or for

filling ornamental lakes, aquariums or fishponds.

If a power failure occurs when regeneration waste

water and overflow are being drained into a pumpinto a pump

into a pumpinto a pump

into a pump,

flooding could occur.

Danger

Note

GBGB

GBGB

GB

33

33

3

22

22

2

11

11

1

33

33

3

Scope of DelivScope of Deliv

Scope of DelivScope of Deliv

Scope of Deliverer

erer

eryy

yy

y

Bonaqa water-softening unit,Bonaqa water-softening unit,

Bonaqa water-softening unit,Bonaqa water-softening unit,

Bonaqa water-softening unit, with:

Cover, removable

11

11

1 Microprocessor controller with low salt

indication

22

22

2 Control valve with chlorine cell for disinfection

33

33

3 Power supply unit with cable and mains plug

44

44

4 Resin tank with exchanger resin

55

55

5 Brine tank

--

--

- Brine valve

- Hard water inlet with check valve

- 2 m flushing water hose

--

--

- 2 m overflow hose 18 x 24

--

--

- Fixing material

55

55

5

44

44

4

FunctionFunction

FunctionFunction

Function

The Bonaqa water softening unit works according

to the ion exchange principle.

Regeneration is triggered volumetrically with time

override.

During regeneration the water supply is maintained

by a flow of hard water through the bypass in the

control valve. Following regeneration, full capacity

is once again available.

The hardness of the water and the desired hard-

ness of blended water on-site and the time of the

regeneration is entered into the electronic system

when the unit is started-up. All other unit parameters

are stored in the electronic system. Unit parameters

can be queried.The remaining capacity is displayed

in litres and as a graph.The flow quantity is displayed

in l/h during operation.

The unit is equipped with a device that disinfects

the exchanger resin during the regeneration

process.

ElectrElectr

ElectrElectr

Electrical poical po

ical poical po

ical poww

ww

wer fer f

er fer f

er failureailure

ailureailure

ailure

In case of an electrical power failure of more than

8h the softener restarts with an automatic

regeneration.

All settings are permanently stored and do not have

to be reentered after an electrical power failure.

Intended UseIntended Use

Intended UseIntended Use

Intended Use

The Bonaqa water softening unit is intended for the

softening or partial softening of drinking and service

water. It is also designed to prevent calcification

damage to water pipes, fittings, boilers and other

equipment and to prevent malfunctioning.

CoverCover

CoverCover

Cover

GBGB

GBGB

GB

44

44

4

Installation RequirementsInstallation Requirements

Installation RequirementsInstallation Requirements

Installation Requirements

Observe all applicable installation regulations, general

guidelines, hygiene requirements, and technical speci-

fications.

Softening units may not be installed in water supply sys-

tems which provide water for fire extinguishing purposes.

The pipe network must be flushed before the unit is in-

stalled.

The total dissolved iron and manganese may not exceed

0.1mg/l in hard water to be fed into the unit. The hard

water to be fed into the unit must always be free of air

bubbles; if necessary, a bleed device must be installed.

Continuous operation of the softening unit with water

containing chlorine or chlorine dioxide is possible if the

concentration of free chlorine/chlorine dioxide does not

exceed 0.5mg/l.

However, continuous operation with water containing

chlorine/chlorine dioxide causes the ion exchanger resin

to age prematurely. A softening unit reduces the con-

centration of free chlorine and chlorine dioxide. In other

words, the concentration in the outflow of a softening

unit is generally considerably lower than in the inflow.

The unit should be sized so that at least daily regenera-

tion is necessary based on the throughput. If water con-

sumption is reduced, e.g. during holidays, a shut-off

device must be fully opened for at least 5 minutes be-

fore water can be used again.

A protective filter must be installed no further than 1m1m

1m1m

1m

upstream from the unit.The filter must be functional be-

fore the water softening unit is installed.This is the only

way to ensure that dirt and corrosive products cannot

enter the softener.

When installing the unit, select a location where the unit

can easily be connected to the water supply network.

A connection to the sewage system (at least DN 50), a

floor drain and a separate mains socket (230V/50Hz)

must be nearby.

The emission of interference (voltage peaks, high-fre-

quency electromagnetic fields, interference voltages,

voltage fluctuations, etc.) by the surrounding electrical

systems may not exceed the maximum values speci-

fied in EN 61000-6-4.

The rated mains power (230V/50Hz) and the requisite

operating pressure must be present at all times.A sepa-

rate means of protection against a lack of water is not

provided and must be installed on-site if required.

If there is no floor drain, a separate safety device

(hydrostop) must be used.

The installation site must be free of frost and kept free of

chemicals, paint, solvents and fumes, and the ambient

temperature must not be too high.

If the softened water is intended for human consump-

tion as defined in the German drinking water regula-

tions, the ambient temperature must not exceed 25°C.

If the softened wIf the softened w

If the softened wIf the softened w

If the softened water is intended fater is intended f

ater is intended fater is intended f

ater is intended for technical pur-or technical pur-

or technical pur-or technical pur-

or technical pur-

poses onlyposes only

poses onlyposes only

poses only, the ambient temper, the ambient temper

, the ambient temper, the ambient temper

, the ambient temperature mature m

ature mature m

ature must not eust not e

ust not eust not e

ust not ex-x-

x-x-

x-

ceed 40°Cceed 40°C

ceed 40°Cceed 40°C

ceed 40°C..

..

.

The hose attached to the overflow of the brine container

and the flushing water hose must be routed at an incline

to the sewage system or connected to a pump. Note:Note:

Note:Note:

Note:

The flushing water hose must be secured at a distance

of at least 20mm from the highest possible waste water

level (free discharge).

If flushing water is fed into a pump, it must be designed

for a water quantity of at least 2m3/h or 35l/min.). If the

pump is used for other units simultaneously, it must be

sized larger by a factor of their water output quantities.

The pump must be salt-water resistant.

The maximThe maxim

The maximThe maxim

The maximum operum oper

um operum oper

um operating pressure of the unit mating pressure of the unit m

ating pressure of the unit mating pressure of the unit m

ating pressure of the unit mustust

ustust

ust

nene

nene

nevv

vv

ver be eer be e

er be eer be e

er be exceededxceeded

xceededxceeded

xceeded (see technical specifications).

If the

network pressure is higher, a pressure reducer must be

installed upstream from the unit.

The unit requires a minimThe unit requires a minim

The unit requires a minimThe unit requires a minim

The unit requires a minimum amount of pressureum amount of pressure

um amount of pressureum amount of pressure

um amount of pressure toto

toto

to

functionfunction

functionfunction

function (see technical specifications)..

..

.

DurDur

DurDur

During pressure fluctuations or surgesing pressure fluctuations or surges

ing pressure fluctuations or surgesing pressure fluctuations or surges

ing pressure fluctuations or surges, the sum of, the sum of

, the sum of, the sum of

, the sum of

the pressure surge and the standing pressure is notthe pressure surge and the standing pressure is not

the pressure surge and the standing pressure is notthe pressure surge and the standing pressure is not

the pressure surge and the standing pressure is not

to eto e

to eto e

to exceed the nominal pressurexceed the nominal pressure

xceed the nominal pressurexceed the nominal pressure

xceed the nominal pressure..

..

.

The positive pres-

sure surge must not be greater than 2 bar and the nega-

tive pressure surge must not be less than 50% of the

self-adjusting flow pressure.

WW

WW

Warrarr

arrarr

arranty eanty e

anty eanty e

anty exclusionxclusion

xclusionxclusion

xclusion

--

--

- Non-compliance with the installation conditions

and/or the operator responsibilities voids the

warranty.

- The wearing parts as outlined in the

“Operator Responsibilities” chapter and the

consequences of failing to replace these parts

on time is not covered by the 2-year legal

warranty.

- Cillit does not assume responsibility if the unit

fails or if the capacity becomes deficient due

to incorrect material selection/combination,

floating corrosive products or iron and mineral

deposits, or any resulting damage thereof.

- Using regenerative that does not comply with

DIN EN 973 type A voids the warranty.

GBGB

GBGB

GB

55

55

5

InstallationInstallation

InstallationInstallation

Installation

Connect the unit according to the adjacent diagram.

Connect the corrugated hose outletoutlet

outletoutlet

outlet with the hardhard

hardhard

hard

ww

ww

water inletater inlet

ater inletater inlet

ater inlet and the corrugated hose inletinlet

inletinlet

inlet with the

softened wsoftened w

softened wsoftened w

softened water outletater outlet

ater outletater outlet

ater outlet.

Be sure to obserBe sure to obser

Be sure to obserBe sure to obser

Be sure to observv

vv

ve the arroe the arro

e the arroe the arro

e the arrows indicating thews indicating the

ws indicating thews indicating the

ws indicating the

direction of flodirection of flo

direction of flodirection of flo

direction of floww

ww

w.

Installation DiagramInstallation Diagram

Installation DiagramInstallation Diagram

Installation Diagram

Hydro-

stop Filter

Pressure reducer

Floor drain

Hardwater-Hardwater-

Hardwater-Hardwater-

Hardwater-

inletinlet

inletinlet

inlet

Softwater-Softwater-

Softwater-Softwater-

Softwater-

outletoutlet

outletoutlet

outlet

GBGB

GBGB

GB

66

66

6

1111

1111

11

1212

1212

12

Insert the flushing water hose (1111

1111

11) into the

connection piece.

Route the flushing water hose (1111

1111

11) at an incline to

the sewage system connection (drain) and secure

the end with the fixing material supplied to prevent

it flapping about when under pressure.

Put the overflow hose (18 x 24) on the overflow (1212

1212

12).

Secure it with zip ties and route it with an incline of

least 10cm to the sewage system connection (drain).

Both hoses connected to the sewage system may

not be connected or constricted at any point.

Note:Note:

Note:Note:

Note:

The flushing wThe flushing w

The flushing wThe flushing w

The flushing water and oater and o

ater and oater and o

ater and ovv

vv

verfloerflo

erfloerflo

erflow hoses mw hoses m

w hoses mw hoses m

w hoses mustust

ustust

ust

be connected to the sebe connected to the se

be connected to the sebe connected to the se

be connected to the seww

ww

wage wage w

age wage w

age water system atater system at

ater system atater system at

ater system at

least 20 mm aboleast 20 mm abo

least 20 mm aboleast 20 mm abo

least 20 mm abovv

vv

ve the highest we the highest w

e the highest we the highest w

e the highest waste waste w

aste w

aste w

aste water leater le

ater leater le

ater levv

vv

velel

elel

el

(unimpeded dr(unimpeded dr

(unimpeded dr(unimpeded dr

(unimpeded drainage).ainage).

ainage).ainage).

ainage).

> 20 mm> 20 mm

> 20 mm> 20 mm

> 20 mm

GBGB

GBGB

GB

77

77

7

OperOper

OperOper

Operation and control unit displaation and control unit displa

ation and control unit displaation and control unit displa

ation and control unit displaysys

ysys

ys

OperOper

OperOper

Operation displaation displa

ation displaation displa

ation displayy

yy

y

After-salesAfter-sales

After-salesAfter-sales

After-sales

serviceservice

serviceservice

service

staff onlystaff only

staff onlystaff only

staff only

ChangeChange

ChangeChange

Change

languagelanguage

languagelanguage

language

Set the timeSet the time

Set the timeSet the time

Set the time

and dateand date

and dateand date

and date

Set theSet the

Set theSet the

Set the

hardness ofhardness of

hardness ofhardness of

hardness of

drinking anddrinking and

drinking anddrinking and

drinking and

blended waterblended water

blended waterblended water

blended water

ManualManual

ManualManual

Manual

regenerationregeneration

regenerationregeneration

regeneration

and quickand quick

and quickand quick

and quick

flushingflushing

flushingflushing

flushing

Selection displaSelection displa

Selection displaSelection displa

Selection displayy

yy

y

The Browse button toggles betweenThe Browse button toggles between

The Browse button toggles betweenThe Browse button toggles between

The Browse button toggles between

the Operating and Selection displaythe Operating and Selection display

the Operating and Selection displaythe Operating and Selection display

the Operating and Selection display

Moves cursor,Moves cursor,

Moves cursor,Moves cursor,

Moves cursor,

changes entrieschanges entries

changes entrieschanges entries

changes entries

Moves cursorMoves cursor

Moves cursorMoves cursor

Moves cursor

ConfirmsConfirms

ConfirmsConfirms

Confirms

entriesentries

entriesentries

entries

Water consumptionWater consumption

Water consumptionWater consumption

Water consumption

since start-upsince start-up

since start-upsince start-up

since start-up

l/h Time

Current softened water supply

Σ m3:

480

GBGB

GBGB

GB

88

88

8

StarStar

StarStar

Start-Upt-Up

t-Upt-Up

t-Up

Check that the unit has been properly

installed.

Measure and note the hardness of the

drinking water upstream of the softener.

PreparPrepar

PreparPrepar

Preparing the bring the br

ing the bring the br

ing the brineine

ineine

ine

Remove cover.

PP

PP

Pour 1 sacour 1 sac

our 1 sacour 1 sac

our 1 sack of regenerk of regener

k of regenerk of regener

k of regenerativativ

ativativ

ativee

ee

e (salt tabsalt tab

salt tabsalt tab

salt tabletslets

letslets

lets

according to DIN EN 973 type A) into the

brine tank (AA

AA

A).

PP

PP

Pour 12 litres of drour 12 litres of dr

our 12 litres of drour 12 litres of dr

our 12 litres of drinking winking w

inking winking w

inking water oater o

ater oater o

ater ovv

vv

ver theer the

er theer the

er the

saltsalt

saltsalt

salt.

CursorCursor

CursorCursor

Cursor

l/h Time

Insert mains plug.

Water supply must remain closed.

The display shows the starstar

starstar

start screent screen

t screent screen

t screen

AlloAllo

AlloAllo

Allow basic fixing (approw basic fixing (appro

w basic fixing (approw basic fixing (appro

w basic fixing (approx.x.

x.x.

x.

4040

4040

40 sec).sec).

sec).sec).

sec).

TheThe

TheThe

The

rr

rr

running noise stopsunning noise stops

unning noise stopsunning noise stops

unning noise stops..

..

.

The regenerregener

regenerregener

regenerationation

ationation

ation diagram appears; a

regenerregener

regenerregener

regenerationation

ationation

ation begins.

Press the BroBro

BroBro

Browsewse

wsewse

wse button.

Set the cursor to ManMan

ManMan

Manualual

ualual

ual

PressPress

PressPress

Press OK

AA

AA

A

00

00

0

GBGB

GBGB

GB

99

99

9

StarStar

StarStar

Start-up flusht-up flush

t-up flusht-up flush

t-up flush

Slowly turn on the water supply.

Set the cursor to StarStar

StarStar

Start-up flusht-up flush

t-up flusht-up flush

t-up flush

Press OKOK

OKOK

OK to confirm.

The StarStar

StarStar

Start-up flusht-up flush

t-up flusht-up flush

t-up flush symbol is inverted.

The StarStar

StarStar

Start-up flusht-up flush

t-up flusht-up flush

t-up flush lasts for approx. 1

minutes.

Caution – no wCaution – no w

Caution – no wCaution – no w

Caution – no water maater ma

ater maater ma

ater may be tapped yy be tapped y

y be tapped yy be tapped y

y be tapped yet.et.

et.et.

et.

Control:Control:

Control:Control:

Control:

The flushing wThe flushing w

The flushing wThe flushing w

The flushing water should beater should be

ater should beater should be

ater should be

clean and there are no bclean and there are no b

clean and there are no bclean and there are no b

clean and there are no bubub

ubub

ubbb

bb

blesles

lesles

les..

..

.

Repeat the processRepeat the process

Repeat the processRepeat the process

Repeat the process until the water

flowing to the sewage connection is clean

and there are no bubbles.

Flushing is completed as soon as the ne-

gative symbol disappears.

NaCL

H

2

O

NaCL

Initial Start-Up

Flus

NaCL

H

2

O

NaCL

NaCL

H2O

NaCL

GBGB

GBGB

GB

1010

1010

10

Setting the hardnessSetting the hardness

Setting the hardnessSetting the hardness

Setting the hardness

The hardness of drinking water measured

on site and the desired hardness of

blended water is entered here.

The bThe b

The bThe b

The blending vlending v

lending vlending v

lending valvalv

alvalv

alve me m

e me m

e must also beust also be

ust also beust also be

ust also be

adjusted later (page 12).adjusted later (page 12).

adjusted later (page 12).adjusted later (page 12).

adjusted later (page 12).

Press the BroBro

BroBro

Browsewse

wsewse

wse button

Set the cursor to SettingsSettings

SettingsSettings

Settings

Press OKOK

OKOK

OK

You can make the following settings here:

The bb

bb

blended wlended w

lended wlended w

lended water supplyater supply

ater supplyater supply

ater supply can be dis-

played in litreslitres

litreslitres

litres, mm

mm

m33

33

3or US gallonsUS gallons

US gallonsUS gallons

US gallons.

Water hardness can be displayed in °dH°dH

°dH°dH

°dH,

°fH°fH

°fH°fH

°fH, °eH, CaCo3°eH, CaCo3

°eH, CaCo3°eH, CaCo3

°eH, CaCo3 (ppmppm

ppmppm

ppm).

ININ

ININ

IN Hardness of drinking water

Enter the measured hardness of the drink-

ing water.

OUTOUT

OUTOUT

OUT Hardness of blended water

Enter desired hardness of the blended

water (recommendation 4° – 8°dH).

DaDa

DaDa

Day (s) 1y (s) 1

y (s) 1y (s) 1

y (s) 1:The softener checks every day

(1) at the time of regeneration the

remaining capacity and decides wether a

regeneration is necessary or not.

Do not change the setting!Do not change the setting!

Do not change the setting!Do not change the setting!

Do not change the setting!

RegenerRegener

RegenerRegener

Regenerationation

ationation

ation TimeTime

TimeTime

Time can be changed.

Move the arrow horizontally to the required

field.

The field is highlighted.

The value or the unit can be changed with

the up/down arrows.

The changed vThe changed v

The changed vThe changed v

The changed values are saalues are sa

alues are saalues are sa

alues are savv

vv

veded

eded

ed

immediatelyimmediately

immediatelyimmediately

immediately..

..

.

The progThe prog

The progThe prog

The progrr

rr

ramming necessaramming necessar

amming necessaramming necessar

amming necessary fy f

y fy f

y for staror star

or staror star

or start-t-

t-t-

t-

ing the unit is completeing the unit is complete

ing the unit is completeing the unit is complete

ing the unit is complete..

..

.

LiterLiter

LiterLiter

Liter °dH°dH

°dH°dH

°dH

ININ

ININ

IN 2525

2525

25 °dH°dH

°dH°dH

°dH

OUTOUT

OUTOUT

OUT 55

55

5°dH°dH

°dH°dH

°dH

Enter hardness of waterEnter hardness of water

Enter hardness of waterEnter hardness of water

Enter hardness of water

Day (s) 1Day (s) 1

Day (s) 1Day (s) 1

Day (s) 1 01 : 00 : 0001 : 00 : 00

01 : 00 : 0001 : 00 : 00

01 : 00 : 00

Time of regenerationTime of regeneration

Time of regenerationTime of regeneration

Time of regeneration

GBGB

GBGB

GB

1111

1111

11

Start a regenerationStart a regeneration

Start a regenerationStart a regeneration

Start a regeneration

Press the BroBro

BroBro

Browsewse

wsewse

wse button

Set the cursor to RegenerRegener

RegenerRegener

Regeneration (NaCL)ation (NaCL)

ation (NaCL)ation (NaCL)

ation (NaCL)

Start the regeneration

Each step of the regeneration process is

displayed with the progressing time.

Regeneration takes 23,5 or 36 minutes.

After the regeneration the display shows

the current softened water supply.

Open water supply behind the Bonaqa.

NaCL

H2O

NaCL

Start

Regeneration

NaCL

H

2

O

NaCL

Regeneration

00 : 22 : 30

H2O

GBGB

GBGB

GB

1212

1212

12

Setting the hardness of bSetting the hardness of b

Setting the hardness of bSetting the hardness of b

Setting the hardness of blended wlended w

lended wlended w

lended waterater

aterater

ater

Close the blending valve (VV

VV

V) clockwise and then in-

crease the blended water hardness by opening

gradually (increasing arrow).

To test the water hardness, allow the nearest cold

water tap to run for a while and check the hardness

of the blended water. Adjust with the blending valve

(VV

VV

V) until the desired value (recommendation 4° – 8

°dH) is reached.

Sodium content of parSodium content of par

Sodium content of parSodium content of par

Sodium content of partially softened wtially softened w

tially softened wtially softened w

tially softened waterater

aterater

ater

The sodium content increases by 8.2mg/l if the hard-

ness of drinking water is decreased by 1°dH.

Hardness of drinking water – hardness of blended

water x 8.2mg/l = increase in the sodium content.

ChecChec

ChecChec

Check connections and pipeline junctions fk connections and pipeline junctions f

k connections and pipeline junctions fk connections and pipeline junctions f

k connections and pipeline junctions for leaksor leaks

or leaksor leaks

or leaks

once again.once again.

once again.once again.

once again.

The unit is now ready for use.

TT

TT

Trr

rr

ransfansf

ansfansf

ansferrerr

errerr

erring the unit to the opering the unit to the oper

ing the unit to the opering the unit to the oper

ing the unit to the operatorator

atorator

ator::

::

:

If there is a delay between the installation/start-up

of the unit and transfer to the operator, a manual

regeneration must be performed.

The operator must be told how the unit works as

well as how to operate and inspect it. Ensure that

the operator receives the installation and operating

manual.

VV

VV

V

GBGB

GBGB

GB

1313

1313

13

NaCL

H

2

O

NaCL

NaCL

H2O

NaCL

00 : 22 : 30

H2O

OperOper

OperOper

Operationation

ationation

ation

Starting regeneration manuallyStarting regeneration manually

Starting regeneration manuallyStarting regeneration manually

Starting regeneration manually

Press the BroBro

BroBro

Browsewse

wsewse

wse button

Set the cursor to ManMan

ManMan

Manualual

ualual

ual

Press OKOK

OKOK

OK

The cursor is set to RegenerRegener

RegenerRegener

Regenerationation

ationation

ation

Press OKOK

OKOK

OK to confirm.

Regeneration is performed.

Press the BroBro

BroBro

Browsewse

wsewse

wse button twice

Each step of the regeneration process is

displayed with the progressing time.

Regeneration takes 23,5 or 36 minutes.

Additional disinfection is not required if the

resin tank is regenerated regularly (by the

quantity controller or time override con-

troller). In unfavourable conditions, e.g. if

the unit is located in a warm room and

has not been used for a long time, it may

need to be disinfected by staff from our

after-sales service in addition to regen-

eration.

Regeneration

GBGB

GBGB

GB

1414

1414

14

Fuse vent1!

date time

Fill saltFill salt

Fill saltFill salt

Fill salt

Refill the salt as soon as laclac

laclac

lack of saltk of salt

k of saltk of salt

k of salt is

indicated on the display. All commercially

available regenerative salts (tablet form

according to DIN EN 973 type A) can be

used.

Open the cover. Fill salt in the brine tank

(AA

AA

A).

Refill the unit in such a way that no dirt

can get into the brine tank (AA

AA

A) (if neces-

sary, clean the salt packages before use).

Clean the brClean the br

Clean the brClean the br

Clean the brine tank with drine tank with dr

ine tank with drine tank with dr

ine tank with drinking winking w

inking winking w

inking waterater

aterater

ater

if dirif dir

if dirif dir

if dirt does get in.t does get in.

t does get in.t does get in.

t does get in.

Press OK.The laclac

laclac

lack of saltk of salt

k of saltk of salt

k of salt display dispears

The first two regenerations after a low-salt

level is detected take an additional 4

minutes to complete.

FF

FF

Fault messagesault messages

ault messagesault messages

ault messages

VV

VV

Valvalv

alvalv

alve/motor 1e/motor 1

e/motor 1e/motor 1

e/motor 1

Press OKOK

OKOK

OK to confirm.

Contact the after-sales service staff if the

malfunction is still displayed.

Electrolysis cell oElectrolysis cell o

Electrolysis cell oElectrolysis cell o

Electrolysis cell ovv

vv

vercurrentercurrent

ercurrentercurrent

ercurrent

Press OKOK

OKOK

OK to confirm.

Contact the after-sales service staff if the

malfunction is still displayed.

Note:Note:

Note:Note:

Note: If there are anIf there are an

If there are anIf there are an

If there are any proby prob

y proby prob

y problemslems

lemslems

lems, pull out, pull out

, pull out, pull out

, pull out

the mains plug and the unit into bthe mains plug and the unit into b

the mains plug and the unit into bthe mains plug and the unit into b

the mains plug and the unit into bypassypass

ypassypass

ypass..

..

.

SerSer

SerSer

Servicevice

vicevice

vice

Service is required after 500 regenerations

or 12 months.

The new counter begins after 1m3has

flown through the unit.

Fuse Elyse

date time

l/h Time

Current softened water supply

ServiceService

ServiceService

Service

Lack of salt !

date time

AA

AA

A

GBGB

GBGB

GB

1515

1515

15

day month yea

h min sek

24 h DS yes

day of week

Deutsch

English

Francaise

Italiano

Espanol

Nederlands

Changing the languageChanging the language

Changing the languageChanging the language

Changing the language

Only change this setting if another

national language is required.

Press the BroBro

BroBro

Browsewse

wsewse

wse button

Set the cursor to ABCABC

ABCABC

ABC....

....

..

Press OKOK

OKOK

OK

Place the cursor on the required language.

Press OKOK

OKOK

OK to confirm.

The language selected is highlighted.The language selected is highlighted.

The language selected is highlighted.The language selected is highlighted.

The language selected is highlighted.

Press the BroBro

BroBro

Browsewse

wsewse

wse button twice.

Display: Current softened water supply

Setting the timeSetting the time

Setting the timeSetting the time

Setting the time

The time is preset and automatically sets

itself for daylight saving time.

Press the BroBro

BroBro

Browsewse

wsewse

wse button

Press OKOK

OKOK

OK

Move the highlighted display field further.

Only the highlighted field can be changed.

Change numbers or display field.

24 h = 24 hour display

DS = Daylight saving time change

yes / no

Press OKOK

OKOK

OK to confirm

GBGB

GBGB

GB

1616

1616

16

ChecChec

ChecChec

Checksks

ksks

ks

The operThe oper

The operThe oper

The operator mator m

ator mator m

ator must perfust perf

ust perfust perf

ust perforor

oror

orm the fm the f

m the fm the f

m the folloollo

olloollo

ollowing checwing chec

wing checwing chec

wing checksks

ksks

ks

regularregular

regularregular

regularly to guarly to guar

ly to guarly to guar

ly to guarantee that the unit functionsantee that the unit functions

antee that the unit functionsantee that the unit functions

antee that the unit functions

properproper

properproper

properlyly

lyly

ly

..

..

.

ChecChec

ChecChec

Check the regenerk the regener

k the regenerk the regener

k the regenerativativ

ativativ

ative and refill after usee and refill after use

e and refill after usee and refill after use

e and refill after use

ChecChec

ChecChec

Check the wk the w

k the wk the w

k the water hardness

ater hardness

ater hardnessater hardness

ater hardness

The hardness of drinking water entering the unit as

well as the set hardness of the blended water must

be checked once a month and corrected if need be

(see Start-Up).

ChecChec

ChecChec

Check fk f

k fk f

k for leaksor leaks

or leaksor leaks

or leaks, visual inspection, visual inspection

, visual inspection, visual inspection

, visual inspection

Check connection lines and connections for leaks.

Check for dirt in the regenerative brine tank and

brine cavity every 2 months and clean and flush with

clear water if necessary.

The intervals between checks are recommended

minimums and must be reduced accordingly for

sensitive consumer systems.

WW

WW

Warrarr

arrarr

arrantyanty

antyanty

anty

If the product malfunctions during the warranty

period, please contact your contract partner, the

installation company, and indicate the model type

and production number (see specifications or the

type plate on the unit).

OperOper

OperOper

Operator Responsibilitiesator Responsibilities

ator Responsibilitiesator Responsibilities

ator Responsibilities

You have purchased a durable and service-friendly

product.

However, all technical equipment requires regular

servicing to guarantee optimal functionality.

Find out about the quality/pressure ratio of the water

to be treated on a regular basis. If the water quality

changes, the settings may need to be changed.

Consult a specialist if this is the case.

Hygienic cleaning of brine container cabinet at least

once per year

Regular checRegular chec

Regular checRegular chec

Regular checks bks b

ks bks b

ks by the opery the oper

y the opery the oper

y the operator are required fator are required f

ator are required fator are required f

ator are required foror

oror

or

the wthe w

the wthe w

the warrarr

arrarr

arranty and proper functioning of the unit.anty and proper functioning of the unit.

anty and proper functioning of the unit.anty and proper functioning of the unit.

anty and proper functioning of the unit.

The unit must be checked regularly in accordance

with the operating and use conditions, but at least

every 2 months.

The replacement of wThe replacement of w

The replacement of wThe replacement of w

The replacement of wearear

earear

earing paring par

ing paring par

ing parts within thets within the

ts within thets within the

ts within the

prescrprescr

prescrprescr

prescribed maintenance interibed maintenance inter

ibed maintenance interibed maintenance inter

ibed maintenance intervv

vv

vals is also requiredals is also required

als is also requiredals is also required

als is also required

ff

ff

for the wor the w

or the wor the w

or the warrarr

arrarr

arranty and proper functioning of theanty and proper functioning of the

anty and proper functioning of theanty and proper functioning of the

anty and proper functioning of the

unit.unit.

unit.unit.

unit.

WW

WW

Wearear

earear

earing paring par

ing paring par

ing parts:ts:

ts:ts:

ts: Retainer seals

MaintenanceMaintenance

MaintenanceMaintenance

Maintenance

Check brine valve Once a year

Check electrolysis cell Once a year

Check water meter Once a year

Check low-salt level Once a year

Check drive motor Once a year

Check/clean/replace

retainer seals Once a year

Injector Every 5 years

Electrolysis cell Every 5 years

Water meter Every 5 years

Brine valve Every 5 years

Waste water hose Every 5 years

Non-return valve Every 5 years

Dilution unit Every 5 years

Control valve Every 10 years

Resin tank Every 10 years

Wearing parts may only be replaced by qualified

personnel (fitter or after-sales service).

We recommend that you enter into a maintenance

agreement with your fitter or the after-sales service

department.

GBGB

GBGB

GB

1717

1717

17

ActionAction

ActionAction

Action

Refill salt and start manual

regeneration.

Establish electrical connection.

Set as described in Start-Up

section “Setting the hardness of

blended water”.

Increase admission pressure

(set pressure reducer if neces-

sary) and start manual regen-

eration.

Repeat start-up flush.

If the fIf the f

If the fIf the f

If the fault cannot be remedied bault cannot be remedied b

ault cannot be remedied bault cannot be remedied b

ault cannot be remedied by fy f

y fy f

y folloollo

olloollo

ollowing these stepswing these steps

wing these stepswing these steps

wing these steps, please contact our after-sales ser, please contact our after-sales ser

, please contact our after-sales ser, please contact our after-sales ser

, please contact our after-sales servicevice

vicevice

vice

depardepar

depardepar

department and quote the sertment and quote the ser

tment and quote the sertment and quote the ser

tment and quote the series and production nies and production n

ies and production nies and production n

ies and production number (see type plate on bacumber (see type plate on bac

umber (see type plate on bacumber (see type plate on bac

umber (see type plate on back of unit).k of unit).

k of unit).k of unit).

k of unit).

TT

TT

Troubroub

roubroub

roubleshootingleshooting

leshootingleshooting

leshooting

FF

FF

Faultault

aultault

ault

Unit not supplying softened or

blended water.

Unit not supplying sufficient

water or the flow is insufficient.

Coloured flushing water at

start-up.

CauseCause

CauseCause

Cause

No salt in the brine tank (33

33

3).

Power supply cut off.

Blending adjusting spindle (VV

VV

V)

not set correctly.

Inlet pressure is too low.

Abraded particles from ex-

changer resin.

Standards and Legal RegulationsStandards and Legal Regulations

Standards and Legal RegulationsStandards and Legal Regulations

Standards and Legal Regulations

The unit conforms to DIN EN 14743 (systems for treating drinking water in buildings).

GBGB

GBGB

GB

1818

1818

18

WW

WW

Water softening unitater softening unit

ater softening unitater softening unit

ater softening unit ModelModel

ModelModel

Model Bonaqa SBonaqa S

Bonaqa SBonaqa S

Bonaqa S Bonaqa MBonaqa M

Bonaqa MBonaqa M

Bonaqa M Bonaqa LBonaqa L

Bonaqa LBonaqa L

Bonaqa L

Nominal connection width DN 32 (G 1¼")

Nominal pressure PN 10

Operating range bar 2 - 8

Peak flow rate* m3/h 1.4 2.0 2.5

Nominal flow rate at 1 bar pressure drop * m3/h 1.0 1.5 1.8

Nominal capacity at 10°d * l 800 1100 1500

Quantity of resin l 3.5 6 6

Regenerative consumed per regeneration* kg 0.5 0.5 1.0

Waste water quantity per regeneration (4 bar)* l 33 33 50

Regenerative storage capacity in the cabinet kg 25 25 25

Mains power V/Hz 230/50 – 60

Energy requirement W/h 15

Unit voltage V ~ 24

Protection class IP 54

Min/max water/ambient temperature °C 5 - 30 / 5 - 40

Dimensions (H x W x D) mm 587x381x518 690x381x518 690x381x518

Connection height A mm 400 530 530

External thread connection G 1¼"

Minimum sewage system connection DN 50

Empty weight excl. packaging, approx. kg 17 19 19

Production nProduction n

Production nProduction n

Production numberumber

umberumber

umber PNRPNR

PNRPNR

PNR 8-5012068-501206

8-5012068-501206

8-501206 8-5012078-501207

8-5012078-501207

8-501207 8-5012088-501208

8-5012088-501208

8-501208

**

**

* provisional data

TT

TT

Technical Specificationsechnical Specifications

echnical Specificationsechnical Specifications

echnical Specifications

GBGB

GBGB

GB

1919

1919

19

Machine LogMachine Log

Machine LogMachine Log

Machine Log

(to be filled in when starting the unit)

Drinking water hardness

inflow ____________°d

Date of initial start-up ____________________ Network pressure ____________________bar

Water meter status ____________________m3

Personnel trained ___________________________________________________________________________________________

Regenerative

refilled

Maintenance performed

Date/name

Regenerative

refilled

Maintenance performed

Date/name

Comments _________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

Cillichemie Italiana SRLCillichemie Italiana SRL

Cillichemie Italiana SRLCillichemie Italiana SRL

Cillichemie Italiana SRL

Via Plinio 59

I - 20129 Milano

Tel. +39 02 2046343

Fax +39 02 201058

E-mail: [email protected]

Cilit S.A.Cilit S.A.

Cilit S.A.Cilit S.A.

Cilit S.A.

C/Silici, 71 - 73

Poligono Industrial del Este

E - 08940 Cornella de LIobregat,

Barcelona

Tel. +34 93 4740494

Fax +34 93 4744730

E-mail: [email protected]

CillitCillit

CillitCillit

Cillit FranceFrance

FranceFrance

France

15, a Avenue de l’Europe

B.P. 80045 Schiltigheim

F - 67013 Strasbourg Cedex

Tel. +33 3 88626064

Fax +33 3 88835 90

E-mail: [email protected]

CillitCillit

CillitCillit

Cillit WassertechnikWassertechnik

WassertechnikWassertechnik

Wassertechnik GmbHGmbH

GmbHGmbH

GmbH

Industriestraße 7

D - 69198 Schriesheim

Tel. +49 6203 73688

Fax +49 6203 73208

E-mail: [email protected]

wwwwww

wwwwww

www.cillit.com.cillit.com

.cillit.com.cillit.com

.cillit.com

Cillit CEE Watertechnology GmbHCillit CEE Watertechnology GmbH

Cillit CEE Watertechnology GmbHCillit CEE Watertechnology GmbH

Cillit CEE Watertechnology GmbH

A-4030 Linz

Dauphinestraße 89

Tel.:+43/732/305233

Fax: +43/732/305233-20

www.cillit-aqua.com

This manual suits for next models

3

Other Cillit Water Dispenser manuals

Popular Water Dispenser manuals by other brands

Follett

Follett Symphony Plus installation instructions

Soleus Air

Soleus Air WD1-02-01 manual

Hasley Taylor

Hasley Taylor HTHBHVR8 owner's manual

Greenway Home Products

Greenway Home Products GWD5570WBC Use & care guide

Mediclinics

Mediclinics FA0028 Installation, use and maintenance handbook

ISE

ISE UW UltraWarm Installation, care & use

Hamilton Beach

Hamilton Beach SA-HB-40-DB-CERT owner's manual

Curtis

Curtis WB5GT Specification sheet

Vidalux

Vidalux SS1700 Installation and operating manual

Judo

Judo i-soft Installation and operating instructions

Greenway Home Products

Greenway Home Products Polar PWD5975BLS specification

Elkay

Elkay EZTL EZSTL8 1D Series Installation, care & use manual