Following the below as a guide you can find the most common problems that may arise; please

consult this section before contacting us as most problems are easily cured by following this

information.

Softener fails to regenerate

Electrical service to unit has

been interrupted

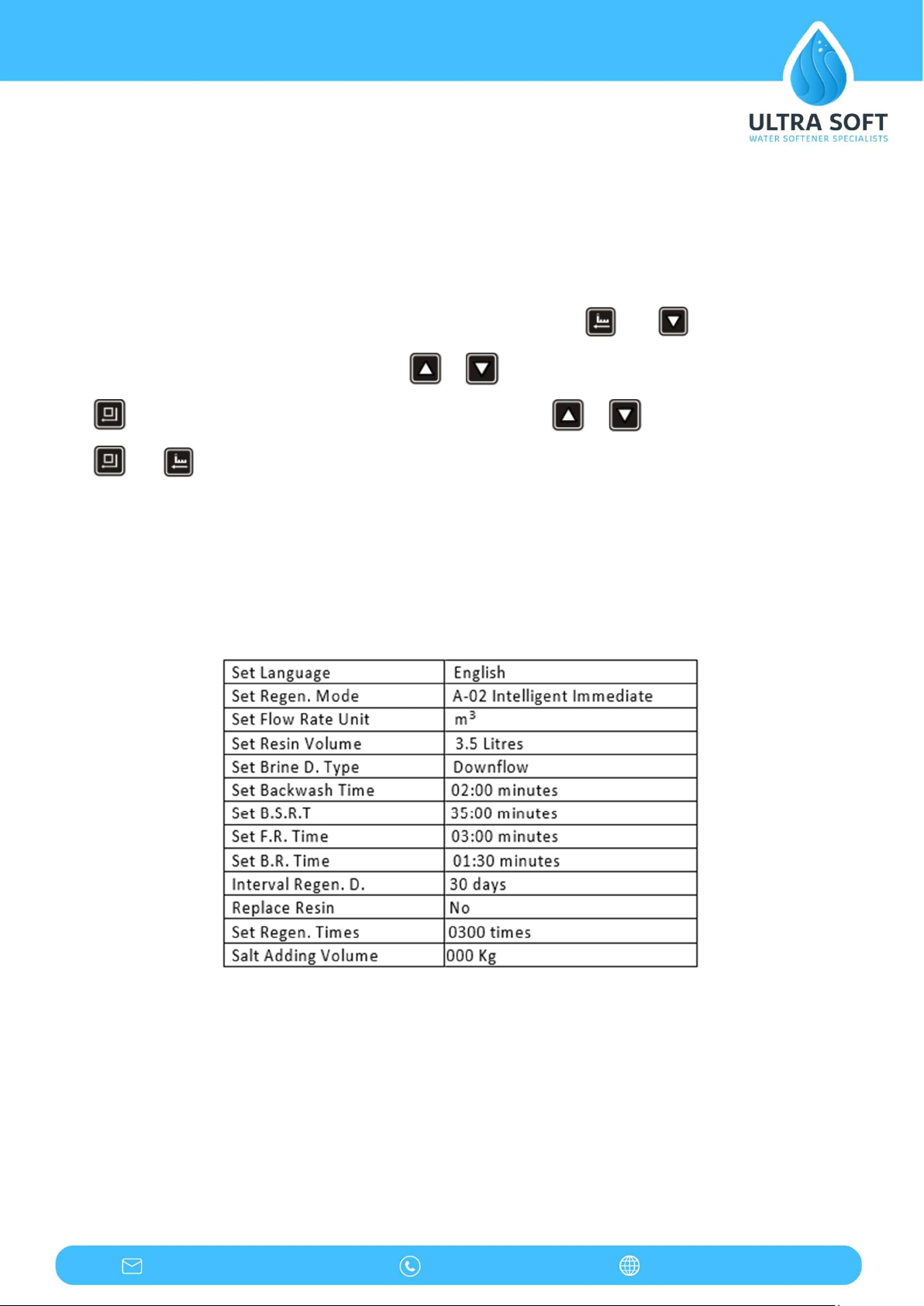

B. Regeneration cycles set

incorrectly

C. Controller is defective

D. Motor fails to work

Assure permanent electrical

service (check fuse, plug,

pull chain or switch)

B. Reset regeneration cycles

C. Replace controller

D. Replace motor

Check turbine is plugged in

Regeneration time is not correct

Time of day is not correct

B. Power failure for more than

3 days

time of day

B. Check program and reset

Softener supplies hard water

leaking (if present)

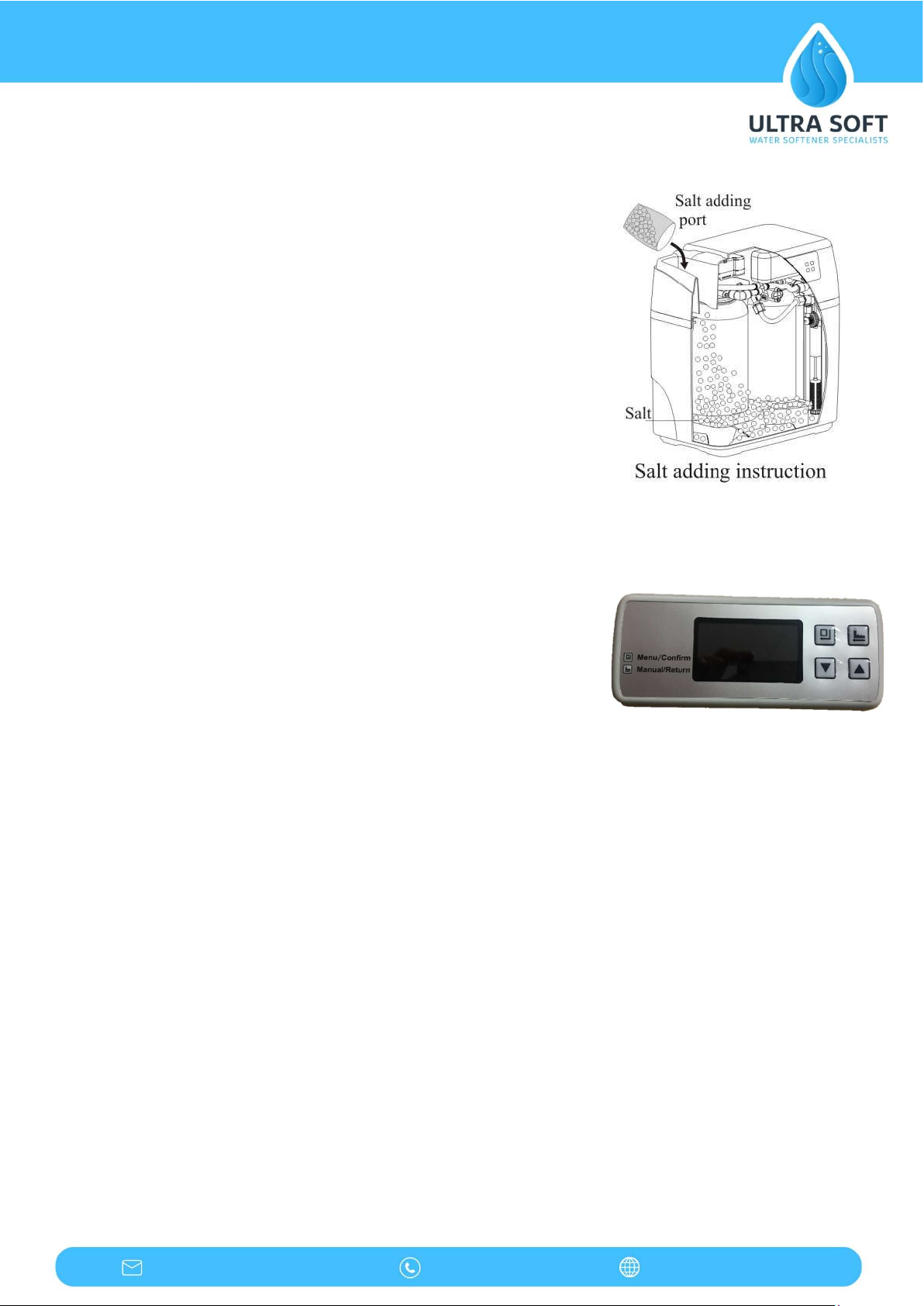

B. No salt in brine tank

C. Injector is plugged

D. Insufficient water is flowing

into brine tank

E. Regeneration cycles not

correct

F. Bad quality of feed water or

turbine blocked

Close or repair bypass valve

B. Add salt to brine tank and

maintain salt level above

water level

C. Change or clean injector

D. Check brine tank refill time

E. Set correct regeneration

cycles in program

F. Reduce inlet turbidity, clean

or replace turbine

B. Excessive water in brine

tank

Check salt usage and salt

setting

B. See below

B. Water remaining after brine

draw

C. Foreign material in brine

valve and/or plugged drain

line

D. Not installed safety brine

valve and/or power failure

whilst salting

E. Safety brine valve

breakdown

Reset correct filling time

B. Check injector and remove

foreign matter from brine

pipe

C. Clean brine valve and brine

pipe

D. Stop water supply and

restart program install with

safety brine valve in salt

tank

E. Repair or replace safety