Cimarron ARCONTROL BASE User manual

USER MANUAL

ARCONTROL™ BASE

2020©Copyright Cimarron Energy

hps://www.arcontrolbms.com

Revision B

March 2020

Table of Contents

1.0 Introducon............................................................................................................... 1

1.1 Hardware Installaon ........................................................................................................1

1.2 Wiring for Operaon .........................................................................................................3

1.3 Applicaon Informaon.....................................................................................................6

1.4 Ignion Module ................................................................................................................. 7

2.0 System Overview ....................................................................................................... 7

2.1 User Interface .................................................................................................................... 7

2.2 System Splash Window...................................................................................................... 8

2.3 System Menu.....................................................................................................................8

2.4 System Menu Symbols.......................................................................................................9

2.5 Thermocouple 1 (TC1) ..................................................................................................... 10

2.5 System Info Menu............................................................................................................10

2.6 Data Logs .........................................................................................................................11

2.7 Modbus Protocol ............................................................................................................. 13

3.0 System Sengs.........................................................................................................16

3.1 Sengs Overview............................................................................................................16

3.2 Sengs Menu.................................................................................................................. 17

3.3 Changing System Sengs................................................................................................ 18

3.4 Seng the Date and Time ............................................................................................... 19

4.0 System Operaon .............................................................................................................. 20

4.1 AUTOMATIC Mode ..........................................................................................................21

4.1.1 AUTOMATIC Mode Overview .............................................................................21

4.1.2 AUTOMATIC Mode Operaon States..................................................................22

4.1.3 AUTOMATIC Mode Alarm States ........................................................................24

4.2 CONTINUOUS Mode........................................................................................................27

4.2.1 CONTINUOUS Mode Overview...........................................................................27

4.2.2 CONTINUOUS Mode Operaon States...............................................................28

4.2.3 CONTINUOUS Mode Alarm States......................................................................30

4.3 MANUAL Mode ............................................................................................................... 31

4.3.1 MANUAL Mode Overview ..................................................................................32

4.3.2 MANUAL Mode Operaon States.......................................................................33

4.3.3 MANUAL Mode Alarm States .............................................................................35

5.0 Troubleshooting.................................................................................................................... 37

6.0 Maintenance & Service......................................................................................................... 38

7.0 Approvals ............................................................................................................................. 38

8.0 Equipment Ratings................................................................................................................ 39

WARNING!

1

1 Introducon

Thank you for purchasing the ARControl, our most popular ignion package. This manual will provide you with

important informaon that will help you understand the system, setup the system and how the system operates. Please

keep the manual in an accessible locaon for future reference. At Cimmaron Energy Inc. we are always here to assist

you with any service or spare part needs. Contact us at:

Phone: 1-844-746-1676

Website: hps://www.arcontrolbms.com

1.1 Hardware Installaon

The ARControl should be installed according to the direcons provided in this manual and always be in compliance

with local electrical codes and the specicaons of the operang company. This secon will cover general instrucons

regarding safety as well as specic wiring and materials required for the safe and successful operaon

of the ARControl.

Failure to comply with the following safety warning(s) may result in serious personal injury or death.

•Ensure the power is not connected unl the nal step of installaon.

•Failure of the grounding system integrity can result in personal injury, damage, or failure of operaon.

Theequipmentmustbegroundedinaccordancewithinstruconsanddevicesandwiringconnectedtothe

controller must be according to the appropriate electrical code

•Ensure that no personnel nor any objects come into contact with the ignion module, terminals, or damaged

coilwiring.Theignioncoilcangenerate38kVandisconsideredahazard.

•If using an external power supply, do not power the ARControl with a supply rated for more than 24VDC.

Failure to comply with the following safety warning(s) may result in damage to the product.

•When installaon is complete, ensure that the enclosure is properly sealed and the fasteners are ght. The

enclosurewillensurethattheinternalcomponentsarenotaectedbymoisture,ice,ordebris.

•Disconnect and remove the baery during transportaon or when the ARControl will not be operated for

aperiodofme.

Follow these guidelines when installing the ARControl:

•A switch or circuit breaker must be included in the installaon; it must be suitably located and easily reached. It

mustbemarkedasthedisconnecngdevicefortheequipment.

•Proper earth grounding per local electrical codes must be ulized in the installaon.

•If the ARControl is used in a manner not specied by Cimarron Energy, Inc., the protecon provided by the

equipment may be impaired.

•If the BMS Module (1870-511) is used in conjuncon with the ARControl it must be mounted externally of the

ARControl in order for the ARControl to remain regulatory compliant.

•Use the hardware supplied with the ARControl. The hardware kit supplied with the ARControl contains an

aluminumpre-drilledmounngbracket,and(4)3/4-inchboltsandnuts.

•Locate the unit out of trac and working areas, away from excessive heat, and above areas where water and

liquids may accumulate. Visibility of the display will be enhanced if not facing direct sun.

•Measure the wiring distance. The ignion cable is restricted to a length of 25 feet maximum.

NOTICE

5

VLV B

DIN

GND

PS3

GND

PS2

GND

PS1

PWR

A B PWR GND

MODULE PORT

IN+

IN-

GND

R-

B-

A+

Y+

GND

Y+

R-

THERMO-

COUPLE

PORT

RS485

PORT

ALARM

OUTPUT

DOUT-

DOUT-

AUXIO

GND

DOUT+

GND

OPN-G

GND

CLS-R

OPN-G

GND

CLS-R

MAIN

VALVE

BATTERY-IN

GND

SOLAR

GND

PWR-OUT

BATTERY-OUT

PILOT

VALVE

POWER

PORT

DIGITAL

OUTPUTS

GND GND

GROUND

GND GND

DIGITAL

INPUTS

TRANS-

DUCER

PORT

TC2

TC1

MAIN

VLV A

PILOT

5 A

Notes: Factory Jumpers

•Remove jumper if installing outside wiring

•BMS module must be set to address 1 (Dip switch 1 on)

2

Follow these steps to install the

ARControl:

1. Locate and open the hardware kit.

2. Aach the mounng anges to

the back of the ARControl with

the supplied hardware.

3. Holes will need to be drilled in

theboomoftheenclosureto

accommodate the cables and

conduit to the unit. It is

recommended to use a step

drill bit to drill the holes.

4. Mount the ARControl via the

angestoasecurelocaon

and away from heat sources.

5. Mount provided ignion rod

assembly to pilot or burner

assembly.

6. Aach provided cable

conduit using provided glands

to enclosure and burner chamber.

7.

8.

9.

Mount ignition module to the DIN

rail inside of enclosure. WARNING:

Mounting ignition module inside

enclosure VOIDS the 1960-155

ARControl Class I Division 2 rating.

Connect ignition wire to tab of the

ignitionmodulesparktransformer,

run it through the conduit and

attachittoignitionrodassembly.

Wire the Ignition Module to the

ARControl’s Module Port using the

provided wiring harness.

10. Aach the free end of the

grounding wire (green wire

with yellow trace) to the

burner’s chassis.

11. Connect the power source

to the power and ground

terminal blocks.

12. Navigate to START IGNITION

and press OK. The system will

starttheignioncyclein

automacmode.

The solar power package includes a

baery in a DIN-mountable baery

tray, solar panel, and 9 feet of cable for

connecon to the ARControl. Mount the

bracket and panel facing sunlight in a

suitable locaon.

To Pilot / Burner Chassis

Provided Wiring Harness

To Ignion Rod

Ignion Wire

To Solar Panel, if Baery

powered

To power source or Baery

Permissive

Input

Mounted on DIN rail inside

enclosure

Ignion Module

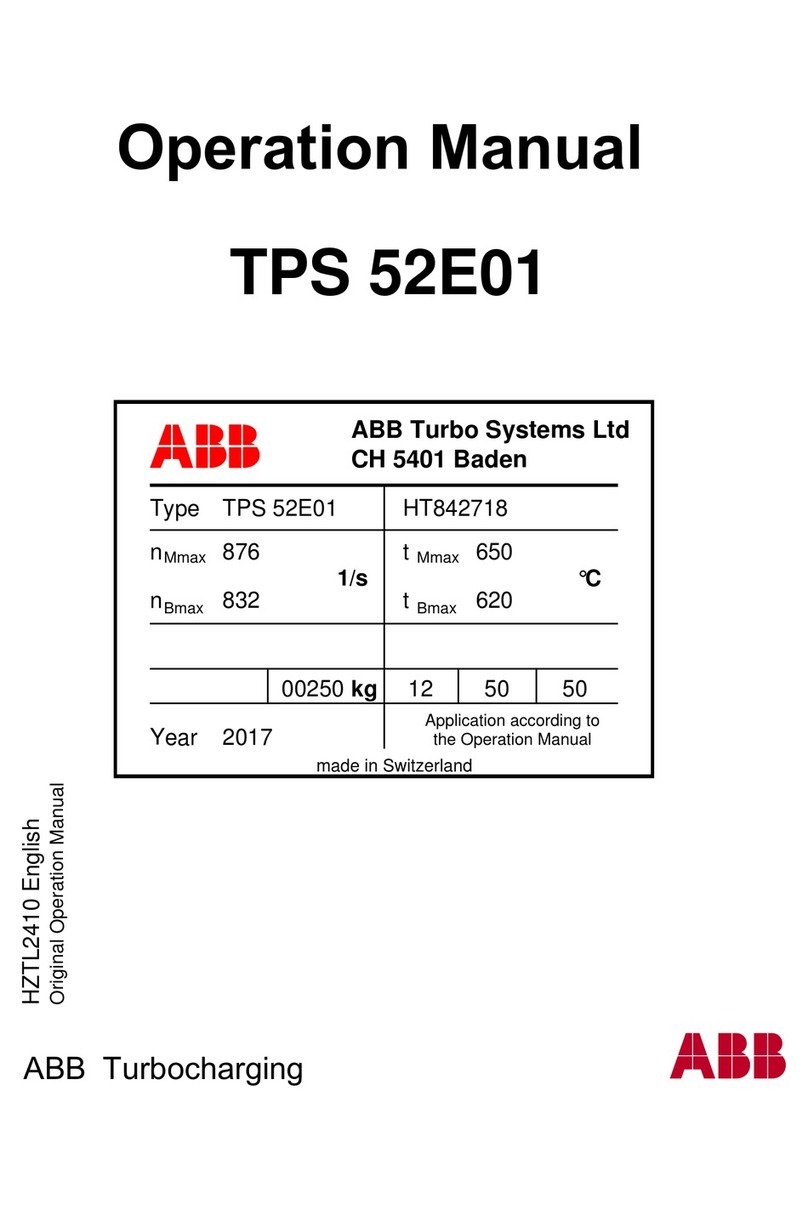

Image 1.1.1 · Hardware installaon

TC1

RS-485 Modbus

Alarm Output

Status Output

3

1.2 Wiring for Operaon

This secon covers general wiring for most common applicaons. Important! All wiring should be done in accordance

with local regulaons and within the specicaons of the site or equipment owner. If there are quesons not answered

by this manual or the wiring diagrams, please call Cimarron Energy at 1-844-746-1676 for assistance.

1.2.1 Connecng the Power

The ARControl is designed to operate from either 12 or 24 volt power supplies or baeries. Power supplies should

be rated Class II and capable of sourcing a minimum of 2 amps. Baeries should be either 12 or 24 volt and have a

DIN

GND

PS3

GND

PS2

GND

PS1

PWR

A B PWR GND

MODULE PORT

IN+

IN-

GND

R-

B-

A+

Y+

GND

Y+

R-

THERMO-

COUPLE

PORT

RS485

PORT

ALARM

OUTPUT

DOUT-

DOUT-

AUXIO

GND

DOUT+

GND

OPN-G

GND

CLS-R

OPN-G

GND

CLS-R

MAIN

VALVE

BATTERY-IN

GND

SOLAR

GND

PWR-OUT

BATTERY-OUT

PILOT

VALVE

POWER

PORT

DIGITAL

OUTPUTS

GND GND

GROUND

GND GND

DIGITAL

INPUTS

TRANS-

DUCER

PORT

5 Watt Solar

Panel

minimum 12 Ah (amp-hour) capacity.

1.2.2 Connecng a Solar Panel and Baery

(if required)

Solar Charing

The ARControl contains an integrated solar charger. The

solar charger is capable of charging a 12 volt 12 Ah SLA

(sealed lead acid) baery. A solar panel rated for 12 volt

systems with a maximum current output of 2 amps is

recommended. Installaons that require more charging

current than provided by the internal solar charger should

ulize a properly sized external solar charger and baery.

Power Pack

The standard ARControl Power Pack (PN: 1960-160)

contains a 12 volt 12 Ah SLA baery in a sturdy DIN-

mountable bracket and a 5 wa 12 volt solar panel with

9 feet of cable and a mount ng bracket. The battery and

bracket clips onto the bottom DIN rail in the ARControl

enclosure. The solar panel can be mounted with a U-bolt

to a pole or to any other structure that can accommodate

the mount ng holes. Be sure to locate the solar panel

south facing in an area free from obstruction of the sun

throughout the ent rety of the day.

Fusing

The ARControl has three user-replaceable fuses. The fuse

on the DIN mounted terminal block that connects to

BATTERY IN on the ARControl utilizes a 5 amp ATC or ATO

fuse. The ARControl board is fused at both the POWER

PORT and MODULE PORT with 2 amp ceramic fuses (PN:

3181-002). The POWER PORT fuse protects all of the

valve outputs and the digital outputs. The MODULE PORT

fuse protects the power output to the Ignition Module.

There are two spare 2 amp ceramic fuses located in the

SPARE FUSES location on the ARControl board.

DIN

GND

PS3

GND

PS2

GND

PS1

PWR

A B PWR GND

MODULE PORT

IN+

IN-

GND

R-

B-

A+

Y+

GND

Y+

R-

THERMO-

COUPLE

PORT

RS485

PORT

ALARM

OUTPUT

DOUT-

DOUT-

AUXIO

GND

DOUT+

GND

OPN-G

GND

CLS-R

OPN-G

GND

CLS-R

MAIN

VALVE

BATTERY-IN

GND

SOLAR

GND

PWR-OUT

BATTERY-OUT

PILOT

VALVE

POWER

PORT

DIGITAL

OUTPUTS

GND GND

GROUND

GND GND

DIGITAL

INPUTS

TRANS-

DUCER

PORT

Chassis

Ground

Sealed Lead Acid

Battery (SLA)

Positive terminal can be

connected from the

power source to the

fused DIN rail mounted

terminal block

5 A

Image 1.2.1 · Solar panel wiring

Image 1.2.2 · Baery pack wiring

4

1.2.3 Connecng a

Thermocouple (if used)

TC1 is the only thermocouple input. The

input has a readout on the system main

screen and the thermocouple value gets

recorded in the data logs (Image 1.2.3).

DIN

GND

PS3

GND

PS2

GND

PS1

PWR

A B PWR GND

MODULE PORT

IN+

IN-

GND

R-

B-

A+

Y+

GND

Y+

R-

THERMO-

COUPLE

PORTS

RS485

PORT

ALARM

OUTPUT

DOUT-

DOUT-

AUXIO

GND

DOUT+

GND

OPN-G

GND

CLS-R

OPEN-G

GND

CLS-R

MAIN

VALVE

BATTERY-IN

GND

SOLAR

GND

PWR-OUT

BATTERY-OUT

PILOT

VALVE

POWER

PORT

DIGITAL

OUTPUTS

GND GND

GROUND

GND GND

DIGITAL

INPUTS

TRANS-

DUCER

PORT Thermocouple

+

-

1 2 3 4

ROCKER DOWN

O

F

F

VALVE

OUTRET

POWER RS485

B

A

TC1

R-

Y+

TC2

R-

Y+

1870-511

DIN

GND

PS3

GND

PS2

GND

PS1

PWR

A B PWR GND

MODULE PORT

IN+

IN-

GND

R-

B-

A+

Y+

GND

Y+

R-

THERMO-

COUPLE

PORTS

RS485

PORT

ALARM

OUTPUT

DOUT-

DOUT-

AUXIO

GND

DOUT+

GND

OPN-G

GND

CLS-R

OPEN-G

GND

CLS-R

MAIN

VALVE

BATTERY-IN

GND

SOLAR

GND

PWR-OUT

BATTERY-OUT

PILOT

VALVE

POWER

PORT

DIGITAL

OUTPUTS

GND GND

GROUND

GND GND

DIGITAL

INPUTS

TRANS-

DUCER

PORT

To pilot

assembly

Ignition Module

DIN

GND

PS3

GND

PS2

GND

PS1

PWR

A B PWR GND

MODULE PORT

IN+

IN-

GND

R-

B-

A+

Y+

GND

Y+

R-

THERMO-

COUPLE

PORT

RS485

PORT

ALARM

OUTPUT

DOUT-

DOUT-

AUXIO

GND

DOUT+

GND

OPN-G

GND

CLS-R

OPN-G

GND

CLS-R

MAIN

VALVE

BATTERY-IN

GND

SOLAR

GND

PWR-OUT

BATTERY-OUT

PILOT

VALVE

POWER

PORT

DIGITAL

OUTPUTS

GND GND

GROUND

GND GND

DIGITAL

INPUTS

TRANS-

DUCER

PORT

Customer External PLC

1.2.4 Communicaon via

Modbus RS-485

To use Modbus communicaon, use the

RS-485 PORT on the board, aaching

the A+ and B- wiring as well as the GND

to the external PLC or communicaon

device. Nocaons of alarms can also

be retrieved via Modbus (Image 1.2.4).

1.2.5 Connecng the

Ignion Module

The wiring from the Ignion Module

is connected to the MODULE PORT at

the top of the ARControl board. Both

thermocouple inputs are jumpered

short. The DIP switch must be set to

address posion 1 (Image 1.2.5).

Image 1.2.3 · Thermocouple (TC1) wiring

Image 1.24 · Modbus RS-485 wiring

Image 1.2.5 · Ignion module wiring

5

DIN

GND

PS3

GND

PS2

GND

PS1

PWR

A B PWR GND

MODULE PORT

IN+

IN-

GND

R-

B-

A+

Y+

GND

Y+

R-

THERMO-

COUPLE

PORTS

RS485

PORT

ALARM

OUTPUT

DOUT-

DOUT-

AUXIO

GND

DOUT+

GND

OPN-G

GND

CLS-R

OPEN-G

GND

CLS-R

MAIN

VALVE

BATTERY-IN

GND

SOLAR

GND

PWR-OUT

BATTERY-OUT

PILOT

VALVE

POWER

PORT

DIGITAL

OUTPUTS

GND GND

GROUND

GND GND

DIGITAL

INPUTS

TRANS-

DUCER

PORT

Permissive IN

GND

IN

GND

5VDC 1MΩ

10KΩ

DIN

GND

PS3

GND

PS2

GND

PS1

PWR

A B PWR GND

MODULE PORT

IN+

IN-

GND

R-

B-

A+

Y+

GND

Y+

R-

THERMO-

COUPLE

PORT

RS485

PORT

ALARM

OUTPUT

DOUT-

DOUT-

AUXIO

GND

DOUT+

GND

OPN-G

GND

CLS-R

OPN-G

GND

CLS-R

MAIN

VALVE

BATTERY-IN

GND

SOLAR

GND

PWR-OUT

BATTERY-OUT

PILOT

VALVE

POWER

PORT

DIGITAL

OUTPUTS

GND GND

GROUND

GND GND

DIGITAL

INPUTS

TRANS-

DUCER

PORT

Status OUT

2A

12 or 24

VDC

OUT

GND

GND

1.2.6 PERMISSIVE (DIN) Input

The PERMISSIVE (DIN) input comes

with a jumper installed from the

factory. To use the PERMISSIVE

(DIN) input, remove the jumper and

connect to an external PLC’s dry

contact switch output or some other

external switch. The PERMISSIVE

(DIN) is acve when the circuit is

open (Image 1.2.6).

1.2.7 Status Output

The status output indicates if the

system is detecng ame at the pilot.

This output sources power and can

drive an indicator light or interface

with an external PLC (Image 1.2.7).

Image 1.2.7 · Status output wiring

Image 1.2.6 · PERMISSIVE (DIN) input wiring

FROM MCU

DOUT+

DOUT-

36R0 50mA

PTC

DIN

GND

PS3

GND

PS2

GND

PS1

PWR

A B PWR GND

MODULE PORT

IN+

IN-

GND

R-

B-

A+

Y+

GND

Y+

R-

THERMO-

COUPLE

PORT

RS485

PORT

ALARM

OUTPUT

DOUT-

DOUT+

AUXIO

GND

DOUT+

GND

OPN-G

GND

CLS-R

OPEN-G

GND

CLS-R

MAIN

VALVE

BATTERY-IN

GND

SOLAR

GND

PWR-OUT

BATTERY-OUT

PILOT

VALVE

POWER

PORT

DIGITAL

OUTPUTS

GND GND

GROUND

GND GND

DIGITAL

INPUTS

TRANS-

DUCER

PORT

DIN

GND

PS3

GND

PS2

GND

PS1

PWR

A B PWR GND

MODULE PORT

IN+

IN-

GND

R-

B-

A+

Y+

GND

Y+

R-

THERMO-

COUPLE

PORT

RS485

PORT

ALARM

OUTPUT

DOUT-

DOUT+

AUXIO

GND

DOUT+

GND

OPN-G

GND

CLS-R

OPEN-G

GND

CLS-R

MAIN

VALVE

BATTERY-IN

GND

SOLAR

GND

PWR-OUT

BATTERY-OUT

PILOT

VALVE

POWER

PORT

DIGITAL

OUTPUTS

GND GND

GROUND

GND GND

DIGITAL

INPUTS

TRANS-

DUCER

PORT

2000mA

DOUT+

GND

BATTERY-IN

GND

6

1.3 Applicaon Informaon

1.3.1 Alarm Output

The alarm output is active when the ARControl is in an

alarm state. The alarm behaves as an open switch when

it is active. External alarm circuitry should be limited to

less than 50mA (Image 1.3.1).

1.3.2 STATUS OUTPUT (DOUT+)

When the STATUS OUTPUT (DOUT+) output is acve

the output behaves as a closed switch bridging the units

baery input to the STATUS OUTPUT (DOUT+)

(Image 1.3.2).

Therefore, if the system is powered by 12V then when the

STATUS OUTPUT (DOUT+) is acve one can expect 12V at

the output. However, due to reverse polarity blocking and

fusing the output is slightly below 12V at

the output.

When the STATUS OUTPUT (DOUT+) is inacve then it

behaves as if switch bridging the units baery input to the

STATUS OUTPUT (DOUT+) is open.

OUT TO

AUTOMATION

PLC

Alarm output inacve/closed switch circuit diagram

Image 1.3.1 · Alarm output inacve

OUT TO

AUTOMATION

PLC

Image 1.3.2 · STATUS OUTPUT (DOUT+) acve - closed switch

Digital input open circuit diagram

STOP

OK

BACK

ARCONTROLBMS.COM

7

2 System Overview

2.1 User Interface

The system user interface (Image 2.1.1) consists of a text display and seven keys (Table 2.1.1) that are used for menu

navigaon, selecng opons on menu items and entering or exing menus.

The text display provides informaon regarding menus, submenus, system modes, selectable opons, current mode

operaon states and alarms. The text display features automac shuto aer 60 seconds without user interacon

through the keyboard. The automac shuto feature helps save power which is especially important in remote

installaons that are solar powered.

Pressing any key will wake up the text display and bring it to the top of the Main menu. If the STOP key is pressed while

the text display is o, it will both send the unit in to the STOP state and wake up the text display. Addionally, if the

system enters in any of the alarm states (see secon 4 System Operaon for further informaon on alarm states) this

will also wake up the text display if the text display is o and it will bring the alarm state screen.

Text Display

Right Key

Down Key

Up Key

Le Key

OK Key

BACK Key

STOP Key

Image 2.1.1 ·System user interface

Table 2.1.1 ·User interface keys

KEY USE DESCRIPTION

Up Use to scroll up menu items

Down Use to scroll down menu items

Le Use to toggle through selectable opons Selectable opons are shown between angle brackets < >

Right Use to toggle through selectable opons Selectable opons are shown between angle brackets < >

OK Use to enter a submenu and select or

enter menu item choice

The OK key allows the entering of menu item acons

and choices, and to and accept or deny system

conrmaon screens.

BACK Use to exit a selected submenu or cancel /

deny prompts

STOP Use to put the system in STOP state The STOP key interrupts any current operaon and sends the

system to the STOPPED state.

E T T I N S

I

M

N

E N

S

S

E R V I C E

G

F O

U

→M O D E : [ C U R R E N T M O D E ]

S T A T E : [ C U R R S T A T E ]

[ S T A T E A D D T L I N F O ]

B V : X X . X V S V = X X . X V

T C 1 = X X X X X ° F

≡

≡

A R C O N T R O L ™

A R C S P A R K ™

F I R M W A R E 5 4 0 0 - 5 2 0 - X X

8

2.3 System Menu

The System Menu is shown in the text display (Image 2.3.1). It will show the following:

•Current mode

•Current state

•Addional informaon about the current state and prompts for aconable menu items

•Thermocouple 1 temperature (F)

•The current baery voltage

•The current solar input voltage

•Sengs submenu

•Service informaon submenu

2.2 System Splash Window

When the system powers up the System Splash window (Image 2.2.1) will appear for 2 seconds. The splash window

contains the company name, system name and nally the system’s rmware idencaon version number and

revision level.

Current mode

Image 2.3.1 ·System menu

Current state

Sengs submenu

Service submenu

Addional Info

Baery voltage Solar input

voltage

Thermocouple 1

temperature

Firmware revision level

Image 2.2.1 ·System splash window

STOP

OK

BACK

ARCONTROLBMS.COM

E T T I N S

I

M

N

E N

S

S

E R V I C E

G

F O

U

→

M O D E :

S T A T E :

[ S T A T E A D D T L I N F O ]

B V : X X . X V S V = X X . X V

T C 1 = X X X X X ° F

A U T M A T I C

O

P P ES T O D

≡

≡

E T T I N S

I

M

N

E N

S

S

E R V I C E

G

F O

U

→M O D E :

S T A T E :

[ S T A T E A D D T L I N F O ]

B V : X X . X V S V = X X . X V

T C 1 = X X X X X ° F

O N T N U O U S

IC

P P ES T O D

≡

≡

→

[ ]

X X X X X X . X

≡

< >

→

[ ]

X X X X X X . X

≡

< >

→

[ ]

X X X X X X . X

≡

< >

→

[ ]

X X X X X X . X

≡

< >

→

[ ]

X X X X X X . X

≡

< >

→

[ ]

X X X X X X . X

≡

< >

9

Example B: Changing the ignion mer from 10s to 30s (Note: Only aects AUTOMATIC mode).

1. Use the UP or DOWN key to SETTINGS MENU.

2. Press the OK key.

3. In the submenu, use the UP or DOWN key to IGNITE.

4. Use the LEFT or RIGHT key and scroll to the 30s menu entry.

5. Use the UP or DOWN key to COMMIT SETTINGS.

6. Press the OK key.

7. Use the LEFT or RIGHT key and scroll to the YES menu entry.

8. Press the OK key to conrm / commit.

2.4 System Menu Symbols

The symbols shown in the System Menu signify the following:

Indicates current menu selecon

Indicates a submenu

Indicates an aconable menu item

Indicates dynamic text related to user selecon

Indicates a user selectable opon

Indicates placeholders for numerical values

The following are some examples of using the System Menu.

Example A: Changing the operaon mode from AUTOMATIC to CONTINUOUS.

1. Use the UP or DOWN key and select MODE.

2. Press the OK key.

3. Using LEFT and RIGHT key scroll to the CONTINUOUS menu entry.

4. Press the OK key. The system will now be in the CONTINUOUS mode. Note: The current state of the mode is

shown in the STATE row.

Use the UP or DOWN key

and move arrow to MODE

Scroll to CONTINUOUS

13

2

4

Example A · Change operaon mode

STOP

OK

BACK

ARCONTROLBMS.COM

E T T I N S

I

M

N

E N

S

S

E R V I C E

G

F O

U

→

M O D E :

S T A T E :

[ S T A T E A D D T L I N F O ]

B V : X X . X V S V = X X . X V

T C 1 = X X X X X ° F

A U T M A T I C

O

I D L E

≡

≡

M O D E : A U T O M A T I C

I G N I T E : 3 0 s

D E L A Y : 1 8 0 0 s

C O M M I T S E T T I N G S

→

M O D E : A U T O M A T I C

I G N I T E : 3 0 s

D E L A Y : 1 8 0 0 s

C O M M I T S E T T I N G S

→

C O M M I T T I N G S E T T I N G S

C A U S E S U N I T T O R E S E T

C O N F I R M C O M M I T ? < Y E S >

10

2.5 Thermocouple 1 (TC1)

TC1 is the temperature readout of thermocouple 1. It is always in degrees Fahrenheit. If a jumper is connected the read-

out will display the ambient temperature. If TC1 is not connected and the jumper is not in place the display will show

the Overow condion (Table 2.5.1). This helps idenfy a possible open TC1.

2.6 Service Info Menu

The Service Info Menu (Image 2.6.1) displays contact informaon for ARControl sales and service department, the

rmware ID number and CRC (cyclic redundancy check), the current operang mode and its sengs, the status of

pernent IO, and acons to clear the data logs or set the date and me.

The ignion and delay duraons of the current mode are displayed in seconds. These can be changed under the Sengs

Menu. The state of PERMISSIVE (DIN) input is displayed, along with the baery and solar voltages.

Use the UP or DOWN key and

move arrow to SETTINGS MENU

14

2

6

Example B · Change ignion mer seng

Move arrow

to IGNITE and

scroll to 30s

Move arrow to

COMMIT SETTINGS

Scroll to YES and

press the OK key

3

5

7

8

Table 2.5.1 · TC1 condions

CONDITION TEXT

Overow TC1= + ∞ oF

Underow TC1= - ∞ oF

Normal TC1= XXXXX oF

→F O R S E R V I C E C A L L

1 - 8 4 4 - 7 4 6 - 1 6 7 6

F W = 5 4 0 0 - 5 2 5 - X X

M O D E = [ S E T T I N G ]

I G N I T E = [ S E T T I N G ]

D E L A Y = [ S E T T I N G ]

D I N = [ C U R R S T A T E ]

B A T T E R Y = X X . X V

S O L A R = X X . X V

C R C = X X X X - X X X X

C L E A R AD T A L O G

S E T D E A N D

A T T E

I M

S

11

2.7 Data Logs

The system can create and store two types of data logs:

Time-based: logsaregeneratedinmeintervalsof15minutes.

Event-based: logs are generated when events of special interest happen in the system. Below is the list of events that

are logged by the system (Table 2.7.1).

Image 2.6.1 ·Service info menu

Table 2.7.1 ·Event data log types

Current mode

Baery voltage

PERMISSIVE

(DIN) input

Ignion duraon

seng

Firmware ID

number

Firmware CRC

value

Delay duraon

seng

Solar input

voltage

LOG TYPE EVENT

LOGS ERASED All previously logs erased

POWER ON Unit has been powered on

POWER OFF Unit was powered o

INTERVAL 15 minutes interval has occurred

DATA DOWNLOAD Previous data has been downloaded

SETTINGS CHANGE System sengs have changed

FIRMWARE UPDATE Firmware has been updated to a new revision

STATE CHANGE System current state has changed

12

Data is broken down into three groups, System data, Digital data and Analog data. Both log types contain the same data

as follows: (Tables 2.7.2, 2.7.3, 2.7.4)

2.7.1 Retrieving the Data Logs

The data logs are easily retrieved by inserng a USB drive (FAT formaed) into the USB drive port of the system. The

system will write the data logs to a CSV le under a folder named ARControl on the root of the USB drive. The CSV log

le is named aer the me the log was generated in the format YYYYMMddhhmmss.

Table 2.7.2 ·System data

Table 2.7.3 ·Digital data

Table 2.7.4 ·Analog data

GROUP HEADER DESCRIPTION

SYSTEM DATA TIME STAMP Time stamp in the format YYYYMMddhhmmss. This me stamp format

facilitates data manipulaon and plong.

DATE Records date of the occurred logged data.

TIME Records me of the occurred logged data.

LOG TYPE Records the event that triggered data to be logged.

MODE Denotes the mode seng at the me when the logged was recorded.

STATE Denotes the mode seng at the me when the logged was recorded.

LOCKOUT Denotes the current lockout code from the ignion unit at the me when the

logged was recorded.

GROUP HEADER DESCRIPTION

DIGITAL DATA FLAME INDICATOR Denotes the state of the Flame indicator output (DOUT) as either inacve or

acve at the me when the logged was recorded.

ALARM Denotes the state of the Alarm output as either inacve or acve at the me

when the logged was recorded.

PERMISSIVE (DIN) Denotes the state of the Permissive (DIN) input as either inacve or acve at

the me when the logged was recorded.

GROUP HEADER DESCRIPTION

ANALOG DATA TEMPERATURE

UNITS

Denotes the temperature units for the ambient temperature record and

thermocouple 1 record.

AMBIENT

TEMPERATURE

Records the ambient temperature reading from the system at the me when

the log was recorded.

THERMOCOUPLE 1 Records the thermocouple 1 reading from the system at the me when the

log was recorded.

BATTERY VOLTAGE Records the baery voltage reading from the system at the me when the

log was recorded.

SOLAR VOLTAGE Records the solar voltage reading from the system at the me when the log

was recorded.

F O R S E R V I C E C A L L

1 - 8 4 4 - 7 4 6 - 1 6 7 6

F W = 5 4 0 0 - 5 2 5 - X X

M O D E = [ S E T T I N G ]

I G N I T E = [ S E T T I N G ]

D E L A Y = [ S E T T I N G ]

D I N = [ C U R R S T A T E ]

B A T T E R Y = X X . X V

S O L A R = X X . X V

C R C = X X X X - X X X X

C L E A R AD T A L O G

S E T D E A N D

A T T E

I M

S

→

13

2.7.2 Clearing the Data Logs

The Clear Data Logs command is located in the Service Info sub-menu. Pressing OK will prompt a conrmaon screen

conrming whether or not to delete all of the previously log data (Image 2.7.2).

2.8 Modus Protocol

The system’s RS-485 port supports a limited subset of the Modbus protocol for communicaons. The system supports

Modbus RTU mode and only supports funcon 3, giving an external PLC the ability to read several conguraon

sengs and system variables.

2.8.1 Modbus Communicaon Parameters

The communicaon parameters for the system are xed as follows (Table 2.7.1):

Follow these steps to clear the

Data Logs:

1. Press the OK key.

2. Use the LEFT or RIGHT key to

select Yes or No (Image 2.7.3).

3. Press the OK key to conrm

/ commit.

A L L D A T A P ER V I O U S L Y

L O G W I L L B E L O S T

C O N F I R M C O M M I T ? < Y E S >

G E D

Select Clear Data

Logs

Image 2.7.2 ·Clear data logs

Table 2.8.1 · Modbus communicaon parameters

Image 2.7.3 ·Select Yes or No

SETTING VALUE

ADDRESS 56

BAUD RATE 19200 bps

WORD ORDER LSW

SERIAL DATA SETUP 8-N-1

14

2.8.2 Modbus Conguraon Registers

Modbus conguraon registers are as follows (Table 2.8.2):

2.8.3 Modbus Variable Registers

Modbus variable registers are as follows (Table 2.8.3):

Table 2.8.2 · Modbus conguraon registers

Table 2.8.3 ·Modbus variable registers

REGISTER

NUMBER NAME DESCRIPTION DEFAULT TYPE R/W

0UNUSED Unused/Reserved for expansion.

Always reads 0. 0N/A R

1FIRMWARE VERSION Current version of the rmware 525 UINT16 R

2FIRMWARE REVISION Current revision of the rmware 2UINT16 R

3FIRMWARE CRC

MSW

Cyclic Redundancy Check most

signicant word 41825 UINT32 R

4FIRMWARE CRC LSW Cyclic Redundancy Check least

signicant word 16147 UINT32 R

5MODE

Opon Register Value

0UINT16 R

AUTOMATIC 0

MANUAL 1

CONTINUOUS 2

7IGNITION TIME

Opon Register Value

30 UINT16 R10s 10

30s 30

9WAIT TIME

Opon Register Value

0UINT16 R

0s 0

1800s 1800

REGISTER

NUMBER NAME DESCRIPTION TYPE R/W

Range Value

210 TC 1 VALUE Min -32768 INT16 R

Max 32767

218 DIN/PERMISSIVE STATE Acve 1UINT16 R

Inacve 0

226 ALARM STATE Acve 1UINT16 R

Inacve 0

230 BATTERY VOLTAGE Min 0UINT16 R

Max 65535

231 SOLAR VOLTAGE Min 0UINT16 R

Max 65535

232 TEMPERATURE Min -32768 INT16 R

Max 32767

15

Table 2.8.3 · Modbus variable registers (connued)

REGISTER

NUMBER NAME DESCRIPTION TYPE R/W

Mode State vs Register Value

200 CURRENT SYSTEM STATE State Register Value

AUTOMATIC UNKNOWN 0UINT16 R

STOPPED 1

PILOT ON 2

IGNITE 3

PILOT FAILED 4

PERMISSIVE (DIN)

OPEN 5

LOW BATTERY 6

DELAY 7

BMS LOCKOUT 8

CONTINUOUS UNKNOWN 0

STOPPED 1

PILOT ON 2

IGNITE 3

FLAME LOST 4

PERMISSIVE (DIN)

OPEN 5

LOW BATTERY 6

IGNITE WARNING 7

BMS LOCKOUT 8

MANUAL UNKNOWN 0

STOPPED 1

PILOT ON 2

IGNITE 3

UNKNOWN 4

PERMISSIVE (DIN)

OPEN 5

LOW BATTERY 6

IGNITE WARNING 7

BMS LOCKOUT 8

16

3 System Sengs

The Sengs Menu allows the user to see the current system sengs, modify the sengs and commit them to the

system. This secon will explain what each seng is, how to enter the Sengs Menu and how to change the

seng opons.

3.1 Sengs Overview

The ARControl has three system sengs, these include mode (MODE), ignion duraon (IGNITE) and delay

duraon (DELAY). The MODE seng is used to select the mode of operaon: AUTOMATIC, CONTINUOUS or

MANUAL (Table 3.1.1).

The IGNITE seng is used to set the length of me that the system will spark. The seng has two opons, 10 seconds

(10s) and 30 seconds (30s) . Note: The IGNITE seng has no eect when in the CONTINUOUS or MANUAL modes

(Table 3.1.2).

The DELAY seng is used to set the length of me allowed for the system to aempt to establish the presence of ame,

from the moment the ignion period is over to the point the system transions into the PILOT FAILED alarm state. The

seng has two opons, 0 seconds (0s) and 1800 seconds (1800s). Note: The DELAY seng has no eect when in the

CONTINUOUS or MANUAL modes (Table 3.1.3).

When set to the 0 seconds (0s) opon, the system transions immediately from the end of the ignion period to the

PILOT FAILED alarm state. When set to the 1800 seconds (1800s) opon, there is a 30 minute delay, between the end of

the ignion period and the transion to the PILOT FAILED alarm state.

Table 3.1.1 · MODE seng

Table 3.1.2 · IGNITE seng

Table 3.1.3 · DELAY seng

MODE SETTINGS SUMMARY

AUTOMATIC Provides med ignion and seable delay period before going in to a pilot failed state.

CONTINUOUS Provides connuous ignion without ming out.

MANUAL Provides the user manual control of the ignion ming.

IGNITE SETTINGS SUMMARY

10s 10 seconds (only applicable in the AUTOMATIC mode)

30s 30 seconds (only applicable in the AUTOMATIC mode)

DELAY SETTINGS SUMMARY

0s 0 seconds (only applicable in the AUTOMATIC mode)

1800s 1800 seconds (only applicable in the AUTOMATIC mode)

→M O D E : < [ O P T I O N S ] >

I G N I T E : < [ O P T I O N S ] >

D E L A Y : < [ O P T I O N S ] >

C O M M I T S E T T I N G S

E T T I N S

I

M

N

E N

S

S

E R V I C E

G

F O

U

→

M O D E : [ C U R R E N T M O D E ]

S T A T E : [ C U R R S T A T E ]

[ S T A T E A D D T L I N F O ]

B V : X X . X V S V = X X . X V

T C 1 = X X X X X ° F

≡

≡

STOP

OK

BACK

ARCONTROLBMS.COM

17

→M O D E : A U T O M A T I C

I G N I T E : 1 0 s

D E L A Y : 1 8 0 0 s

C O M M I T S E T T I N G S

3.2 Sengs Menu

To change the sengs you must enter the Sengs Menu. Follow these steps to enter the Sengs Menu:

1. Use the UP or DOWN key and select SETTINGS MENU (Image 3.2.1).

2. Press the OK key.

Once in the Sengs Menu the system sengs will be displayed (Image 3.2.2).

The default system sengs are (Image 3.2.3):

•MODE (AUTOMATIC)

•IGNITE (10s)

•DELAY (1800s)

Image 3.2.3 · Default system sengs

MODE sengs

Ignion duraon

sengs Delay duraon

sengs

Commit

sengs

Image 3.2.2 · System sengs menu

Image 3.2.1 · Select sengs menu

12

STOP

OK

BACK

ARCONTROLBMS.COM

M O D E : A U T O M A T I C

I G N I T E : 3 0 s

D E L A Y : 1 8 0 0 s

C O M M I T S E T T I N G S

→

STOP

OK

BACK

ARCONTROLBMS.COM

M O D E : A U T O M A T I C

I G N I T E : 3 0 s

D E L A Y : 1 8 0 0 s

C O M M I T S E T T I N G S

→

C O M M I T T I N G S E T T I N G S

C A U S E S U N I T T O R E S E T

C O N F I R M C O M M I T ? < Y E S >

18

4. When sased with the seng changes use the UP and DOWN key and navigate to the COMMIT SETTINGS

command (Image 3.3.2).

5. Press OK, this will bring up the conrmaon screen (Image 3.3.3). Note: Use the LEFT and RIGHT key to scroll

andchangetheconrmaontoeitherYES or NO. Alternavely, the user can press the BACK key to enter NO

astheconrmaonandgobacktoSengs Menu. Important! Once the user has commied the seng the

system will reset and reboot.

6. Press the OK key to conrm.

3.3 Changing System Sengs

Follow these steps to change system sengs:

1. Using the UP and DOWN key to move the arrow on the le hand side of the menu and navigate to desired seng.

2. Using LEFT and RIGHT key scroll through the possible opons for the seng. For example, change the ignion

duraonto30seconds(Image3.3.1)

3. If needed, repeat steps 1 and 2 for the remaining sengs.

Image 3.3.1 · Select seng

Move arrow to

seng

Scroll to

desired seng

12

Image 3.3.2 · Select commit sengs

Image 3.3.3 · Conrmaon screen

45

Other manuals for ARCONTROL BASE

1

Table of contents

Popular Industrial Equipment manuals by other brands

technotrans

technotrans manroland beta.d 40 Original instruction manual

EXCELSENSE

EXCELSENSE SensorShield-1600 user manual

Costa

Costa WD7 Series Instruction, use and maintenance manual

Montech

Montech GTB Assembly instructions

Barudan

Barudan BENS Operation guide

Siemens

Siemens SIMOGEAR BA 2730 operating instructions