EXCELSENSE SensorShield-1600 User manual

SensorShield-1600™

User Manual, V1.1

Table of Contents

Table of Contents 1

Overview 3

IMPORTANT SAFETY INSTRUCTIONS 4

Warning 4

Caution 5

Specifications 6

Mechanical Drawings 7

Ordering Options 8

Typical Installations 8

Sensor Mounting 10

Clear Glass Area Dimensions 11

Enclosure Mounting Instructions 12

Accessories 13

Triggering the SensorShield-1600™ 13

Manual Trigger 13

Manual Trigger using External Button 14

Automatic Trigger 15

Thermal Subsystem 15

SensorShield-1600 Thermal Subsystem 16

SensorShield-1600™ Modbus-RTU Interface 16

SensorShield-1600 Modbus Interface 17

Modbus-RTU Settings 19

Modbus Settings 19

Device ID Address 19

Modbus Data Addresses 19

Internal Modbus Server Update Rate 19

RS-232 Settings 19

Supported Function Codes 20

Data Memory Mapping 21

Holding Registers 21

Coils 23

Data Descriptions 24

Holding Register Data 24

DIDR - Device ID Register 24

SREG - System State Register 24

1

EREG - System Error Status Register 25

LCCH - Lifetime Cycle Count High Word Register 28

LCCL - Lifetime Cycle Count Low Word Register 28

LSCR - Lifetime Stall Count Register 29

CTOR - Cycle Timeout Register 29

TCIR - Timed Clean Interval Register 30

LCTR - Last Cycle Time Register 30

CCLR - Cycle Completion Level Register 30

MBTR - Main Board Temperature Register 31

WITR - Window Internal Temperature Register 31

DITR - Device Internal Temperature Register 31

Data Coils 32

PTPC - Power Type Coil 32

PLVC - Power Level Coil 32

RDYC - System Ready Coil 33

THSC - Thermal Heating Status Coil 33

TCEC - Timed Clean Enable Coil 34

LCSC - Last Cycle Status Coil 34

2

Overview

SensorShield-1600™ follows the same self-cleaning principles as the ToughEye-1700™ line of

cameras, providing industry-leading, zero maintenance, self-cleaning operation for

rear-mounted optical sensors and cameras, suitable for any industrial application where a clear

view is critical to the success of the operation.

It incorporates a rugged single-piece design, equipped with our field-proven and innovative

ClearSight™ technology. One can simply integrate this shield into a sensor enclosure by

replicating the indicated panel cutout and the hole pattern.

The SensorShield™ family of optical shields excels at three things: reliability,

zero-maintenance operation and clarity.

ExcelSense can customize SensorShield-1600™ installations for almost any application. Please

3

IMPORTANT SAFETY INSTRUCTIONS

Warning

1. This is an ITE class A device. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

2. All electrical connections must be made by qualified personnel in accordance with local

and national electrical codes and regulations. Electrical power is not to be applied to

conductors at any point during this process.

3. Connecting the SensorShield - 1600TM incorrectly poses a risk of injury due to electric

shock to the user, and can damage the device.

4. Damaged or faulty connections may leave electrical conductors bare and/or

short-circuited. Extra care must be taken during installation in order to avoid this

scenario. In such a circumstance, do not attempt to handle conductors before removing

power.

5. The SensorShield-1600™ viewing region is made with hardened glass. The user should

take necessary precautions when handling the system. If excessive, direct force is

induced, the glass may break, causing system failure and potential injury to the user.

6. Operating the SensorShield-1600™ in icy conditions, without the Thermal Subsystem

option in place may lead to damage and void the warranty.

4

Caution

1. Alterations or modifications carried out without appropriate authorization may invalidate

the user’s right to operate the equipment.

2. If powering the device using DC voltage, a Class 2 24VDC 3A power supply is

recommended to ensure stable operation. With its internal protection and regulation,

SensorShield-1600™ can be operated with an unregulated 24VDC power supply. In this

scenario, voltage fluctuation limits will be dependent on setup. Refer to the Electrical

Specifications section on SensorShield-1600™ operational limits.

3. Do not attempt to disassemble SensorShield-1600™ in order to access internal

components. Consult ExcelSense for technical support as required.

4. Never face the SensorShield-1600™ directly towards the sun or any bright or reflective

light, which may cause damage to any internal sensors mounted behind it, such as

cameras.

5. Do not remove the SensorShield-1600™ label containing P/N and S/N information for

warranty service.

6. Never expose SensorShield-1600™ to conditions outside those specified in the

Specifications section. Doing this can cause permanent damage to the device.

7. Damaged SensorShield-1600™ equipment must be replaced through an ExcelSense

representative. Failure to do this may cause incompatibilities and permanent damage to

the system.

8. Always clean the SensorShield-1600™ lens by performing cleaning cycles (see

Triggering the SensorShield-1600™ section for details). Do not clean the glass manually.

SensorShield-1600™ may also be pressure washed as an alternative, when fully

enclosed in an IP69 rated enclosure.

5

Specifications

GENERAL

Dimensions

167mm width x 216mm height x 143mm depth [6.57” x 8.5” x 5.63”]

Weight

2.0Kg (4.5 lbs), 4.0Kg (8.8 lbs) with Bracket and Sunshield

Power

18~32VDC

Clean Cycle

Automatic: Configurable Timer or Schedule-Based

Manual: Network Command or Electrical Trigger

Temperature Range

-40°C to 60°C (operation and storage)

IP Rating

IP69

Vibration

11g (JIS-D-1601-1995)

Sensor Mounting Holes

M3 x 0.5

External Mounting Holes

M6 x 1.0

ELECTRICAL

Parameter

Min

Typ

Max

Input Voltage, VIN (DC port)

18V

24V

32V

Power Consumption, PIN

5W (Idle)

25W (Heating)

Input Protection (DC port)1

Clamping Voltage, VC

116V

Peak-pulse Power, PPP

6.4kW (28ms pulse duration)

Peak-pulse Current, IPP

35A

Overvoltage Lockout, VOVLO

Engage lockout (rising)

33.3V

Disengage lockout (falling)

33.0V

Undervoltage Lockout, VUVLO

Engage lockout (falling)

17.0V

Disengage lockout (rising)

19.0V

Overcurrent Threshold, IOVC

3A (internal PTC fuse)

Reverse-Polarity, VRVP

[Pulse defined by ISO 7637-2]

Max Cable Length2, LMAX

40m (DC), 100m (PoE+)

Trigger Input, VTRIG

0V / Open

0V (internal

pull-down)

VIN

1Tested as per ISO 16750-2. Designed for complete load isolation during damaging input conditions.

6

Ordering Options

Temperature Rating

X- Extreme: -40oC to 60oC

S- Standard: -10°C (non-freezing) to

60oC

Environmental Resistance

S- Standard Corrosion Resistant

Cycle Rating

S- Standard Cycle Rating 50,000

cycles

Hazardous Locations Certification

NR - Not Rated for Explosive Environments

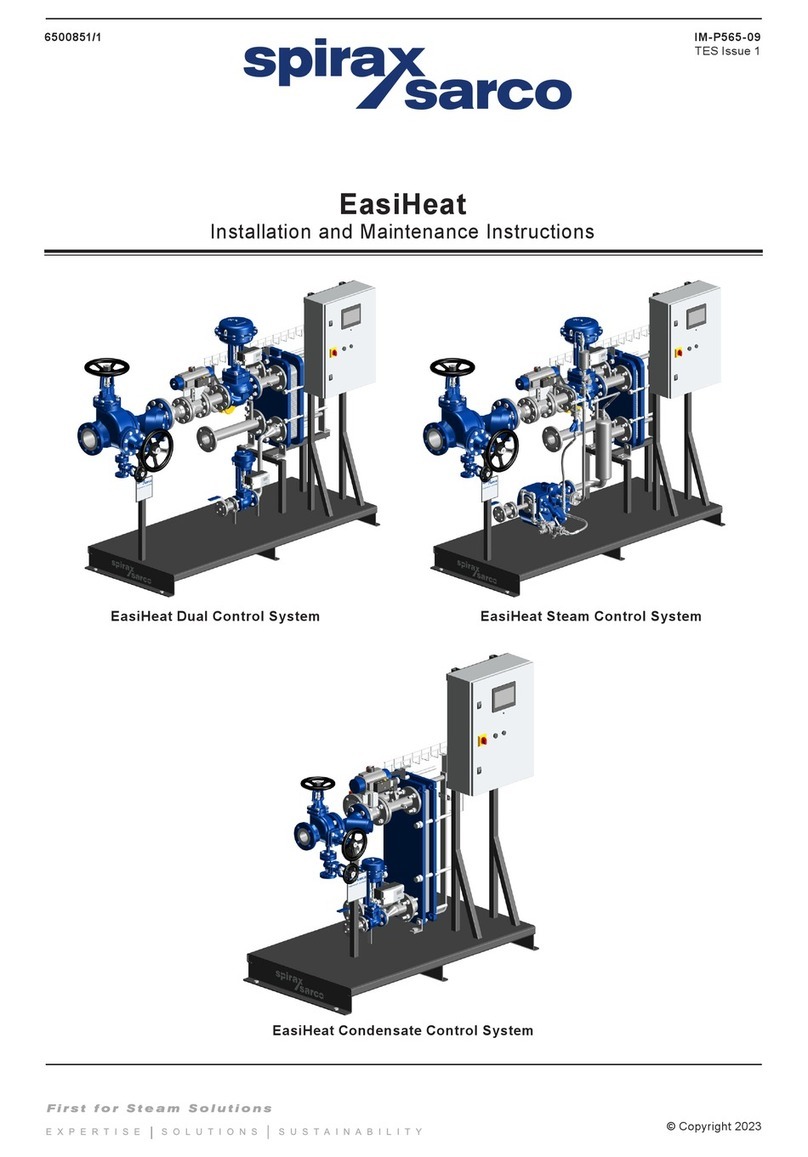

Typical Installations

Important Note: As per rule 2-024(2) of the Canadian Electrical Code Part I,

SensorShield-1600TM does not require approval in order to be installed. However, it must be

connected to a Class 2 output, as permitted by the Canadian Electrical Code Part I. (See rule

16-222 and relevant appendices).

SensorShield-1600TM is relatively simple to install, requiring only 2 connections with an optional

3rd connection for digital triggering of the self-cleaning functionality:

1. Power the unit with a 30W or larger 24 VDC power supply. Connect 24 VDC and GND to

the appropriate terminals of the blue terminal block on the power board:

8

a. The recommended wire gauge for the screwless terminal connections (+V, GND,

TRIG) is 18-22 AWG.

b. The recommended wire finishing method is ferrule application. Wire may be

tinned, where ferrule application is not available.

c. For long cable runs, voltage loss must be taken into account in order to ensure

the voltage at the device does not fall below its minimum voltage (see

Specification table)

2. [Optional] Connect the trigger wire to the trigger terminal of the blue terminal block on

the power board

3. Incoming wires/cables may be fastened to a suitable slot (as highlighted below in blue)

with one or more zip ties:

9

Sensor Mounting

Blue shaded area indicates available space for mounting sensors

10

Clear Glass Area Dimensions

The blue shaded rectangle indicates area extents [mm] for available viewing space, through the

SensorShield-1600™.

11

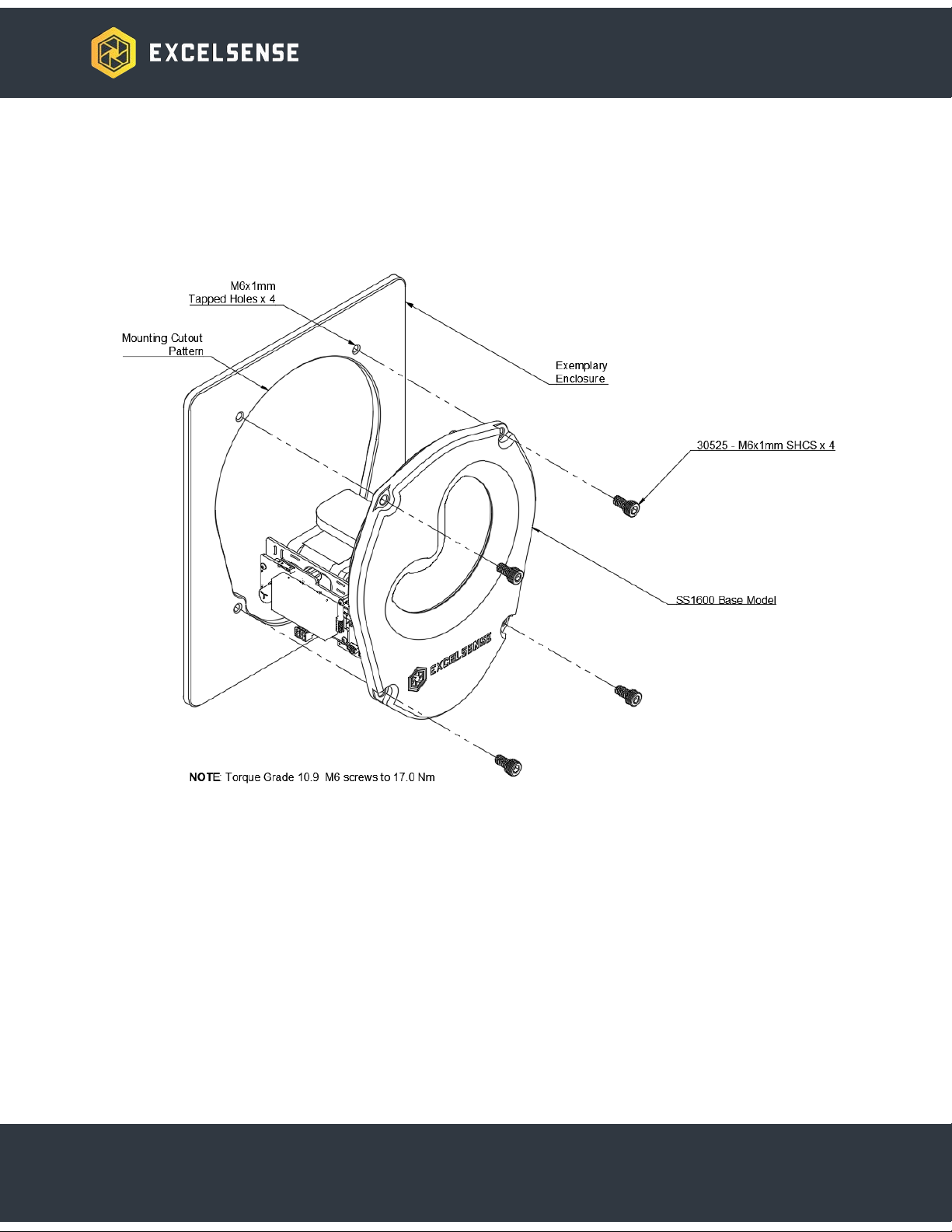

Enclosure Mounting Instructions

See below diagram for overview of mounting process:

Note: Mounting cut pattern is available upon request.

Note: It is recommended to design the 4 M6 mounting holes to be blind tapped holes. This

ensures no ingress of moisture or dust through the mounting points.

12

Accessories

Programming Cable: PA-SS16-USB

Serial communication cable provides a USB interface for the SensorShield-1600™’s Modbus

RTU service. Through this service it is possible to change the self-cleaning frequency, read the

number of cleaning cycles performed and read other diagnostic data.

Trigger Box: TB-FW-05M

Trigger Box provides a convenient method for manual triggering of a self-cleaning cycle. It

requires an input voltage between 5V-24V and the SensorShield-1600’s trigger wire.

Custom Enclosure

SensorShield-1600™ is sold un-enclosed. Contact an Excelsense representative to discuss the

option of having a customized enclosure designed

Triggering the SensorShield-1600™

The SensorShield-1600™ performs cleaning cycles in response to a trigger event. The

triggering event method is an important consideration at the time of specifying your system

topology. The decision is based on many factors, including availability of a digital switch, remote

triggering requirements, and the general nature of the application. Below are the recommended

options for triggering the device:

Manual Trigger

The manual trigger method is based on an external digital input (see Electrical Specifications for

acceptable input voltage range). The device accepts a positive signal pulse as a trigger input

and responds with a single, complete cleaning cycle, initiating its clean at the rising edge of the

pulse. A cleaning cycle is defined as a 360° glass lens rotation. Only when the device has

completed this cleaning cycle will it respond to subsequent trigger events. Note that due to its

edge-sensitive triggering behavior, the device will not perform multiple cleaning cycles if the

trigger wire is held at a logic high state. The pulse sequence shown below will initiate a

SensorShield-1600™ cleaning cycle.

13

Manual Trigger Pulse Diagram

Logic Level

Trigger Voltage

Step 1

Logic Low

0V or Open

Step 2

Logic High

5V ~ VIN (DC voltage)

Step 3

Logic Low

0V or Open

The recommended minimum hold time at a logic level state, tMIN, is 0.5 seconds. Using this

control, the SensorShield-1600TM can be configured for the use case seen below.

Manual Trigger using External Button

In manual trigger applications where on-demand vision is required, the trigger can be simply

wired to a normally-open momentary button as shown below.

14

Connect the TRIG wire of a Trigger Box to the trigger terminal of the power board (shown

above), and the Vin wire of the Trigger Box to a suitable voltage supply.

Automatic Trigger

The SensorShield-1600™ can be configured to perform self-cleaning cycles at a regular

interval. Please refer to the Modbus section for details on this configuration.

Thermal Subsystem

SensorShield-1600™ can be configured to provide a thermal subsystem for defrosting

capabilities, as an option. When ordering, specify SS16XSS-NR for this option. The defrost

subsystem directly heats the inner surface of the glass shield, in order to help remove built-up

ice or frost on the outer surface of the glass.

15

SensorShield-1600 Thermal Subsystem

Units equipped with the thermal defrost system (SS16-X__-__) have a thermal control algorithm.

This algorithm is designed to defrost ice build-up on the lens and prevent the system from

operating prior to defrosting.

The thermal subsystem protection will engage when the system reaches 7°C and will continue

heating until the inner glass temperature reaches a threshold of 15°C. Cleaning will be disabled

while the thermal subsystem is below 7°C, then will become enabled once the system is at or

above 7°C.

Note: For units which are not equipped with the thermal defrost system (SS16-S__-__), it is not

recommended to operate SensorShield-1600™ in icy conditions. Doing so may cause damage

and void the warranty.

16

SensorShield-1600™ Modbus-RTU Interface

This section outlines the SensorShield-1600™ Modbus-RTU interface, implemented through the

RS-232 protocol, including register definitions and functionality, as well as triggering and

operation.

SensorShield-1600 Modbus Interface

ExcelSense provides a simple graphical interface for viewing and modifying key settings.

The tool can be installed as follows:

1. Download the tool:

https://drive.google.com/drive/folders/1E_w-JkIgclwSMgNu5A-LXEUICokxBnzd?usp=sh

are_link

2. Unpack SensorShield1600ModbusClientAppPackage_v1.0_2023-04-28.zip to an

accessible location on your computer

3. Run the file SensorShield1600ModbusClientApp.exe

The SensorShield-1600 can then be configured as follows:

1. Ensure the device is powered, according to the instructions in the Typical Installations

section

2. Connect the PA-SS16-USB adapter cable to the 4 pin connector shown below:

17

3. Once connected, use Windows Device Manager to determine which USB COM port is in

use for this connection.

4. In the Serial Port dropdown shown below, enter the current COM port, then click the

Connect button.

18

Full details of the Modbus registers can be found in the following section. Modifying the

self-clean timeout can be easily done using the controls on the left side of the graphical

interface.

Modbus-RTU Settings

Modbus Settings

Device ID Address

The default Modbus-RTU device ID address is 0x01. This is modifiable through the DIDR

holding register on the Modbus server.

Modbus Data Addresses

All data addresses in Modbus messages are referenced to zero. The first occurrence of a data

item is addressed as item number zero. For example, the coil known as “coil 1” in a

programmable controller is addressed as coil 0x0000 in the data address field of a Modbus

message.

Internal Modbus Server Update Rate

Data stored in the Modbus registers and coils is scanned by the host system’s running program

approximately every 20 milliseconds. The maximum recommended scanning rate by a

Modbus-RTU client is 100ms.

RS-232 Settings

The SensorShield-1600™ device will host a Modbus-RTU server, running with the following

settings:

Baud Rate (bps)

38400

Data Bits

8

Stop Bits

1

Parity

None

Flow Control

None

19

Table of contents

Popular Industrial Equipment manuals by other brands

Zehnder Rittling

Zehnder Rittling ComfoFond-L Eco Series Installer manual

Texas Automation Products

Texas Automation Products ES-32 quick start guide

Pepperl+Fuchs

Pepperl+Fuchs LS611 Series manual

ABB

ABB ACS880-607LC Hardware manual

York

York P XU Series User's information, maintenance and service manual

ABB

ABB HT567437 Operation manual