3.5 ATTACH THE LOWER FRONT CROSS PIECE (F) TO THE SIDE

PANELS (B) & (C).

3.5.1 Referring to fig.1, open the two side panels (B) and (C) just

enough to introduce the lower front cross piece (F) at the

bottom, front edge of the side panels. Allow the hooks at either

end of the lower front cross piece to enter the slots in the inside

edges of the side panels. Close the side panels onto the cross

piece and then firmly push down on the cross piece to lock it in

place.

3.6 ATTACH THE TOP PANEL (D) TO THE BACK AND SIDE PANELS.

3.6.1 Referring to fig.1 place the top panel (D) onto the assembled side

and back panels. When placing the panel first ensure that the

locking pin on the back of the lock enters the hole in the

upstanding lock tab at the front of the right hand side panel. The

panel will now be self aligning. Ensure that the channel on the

inside of the back edge sits on the top edge of the back panel and

the front corners of the top panel lap over the front corners of

each side panel. Use four self tapping screws (Ø11mm) in the

positions indicated to fix the top panel in position.

3.7 ATTACH UPPER FRONT CROSS PIECE TO THE SIDE PANELS.

3.7.1 Each side panel has a box section that forms the front edge of the

panel. On the back edges of these box sections, just below the top

drawer runners are keyway slots to accept the pressed tabs on the

fixing plates at either end of the upper front cross piece (E). Hold

the cross piece within the cabinet and bring it up to the keyway

slots. It may be necessary to ease each drawer runner away from

the cabinet slightly in order to get the tabs to enter the keyway.

Once the tabs are in on both sides, push down on each end of the

crosspiece to lock it in place.

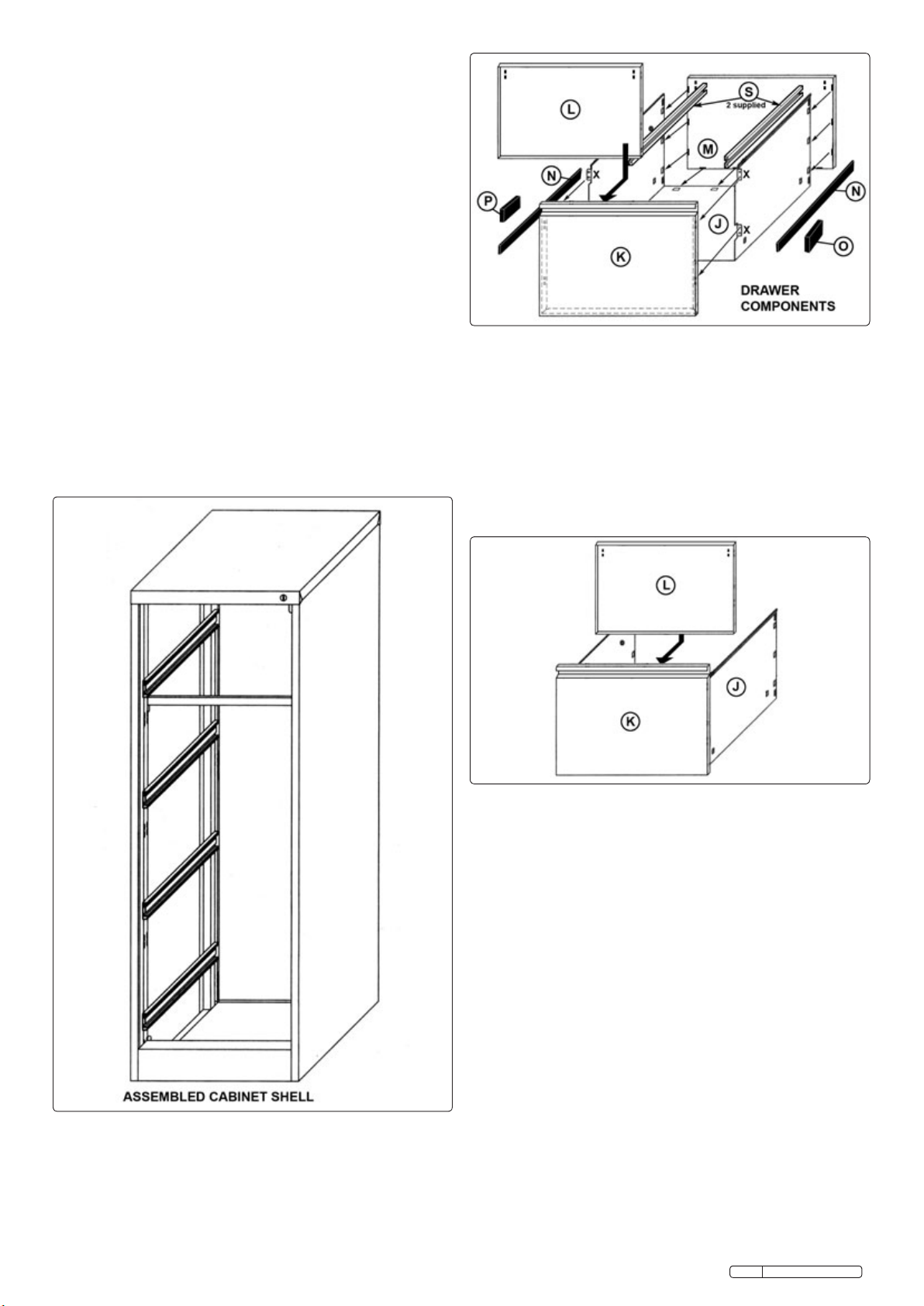

3.8.2 Check that the two tabs (X) on the vertical front edges of the 'U'

shape are bent outwards as shown above. Insert the base and

sides (J) into the open back of the front panel (K) and flex the

vertical sides inwards so that the four tabs go behind the returned

edges at the back of the front panel. Fix the assembly together

with four self tapping screws (Ø9mm) to hold the tabs firmly

behind the back edges of the front panel.

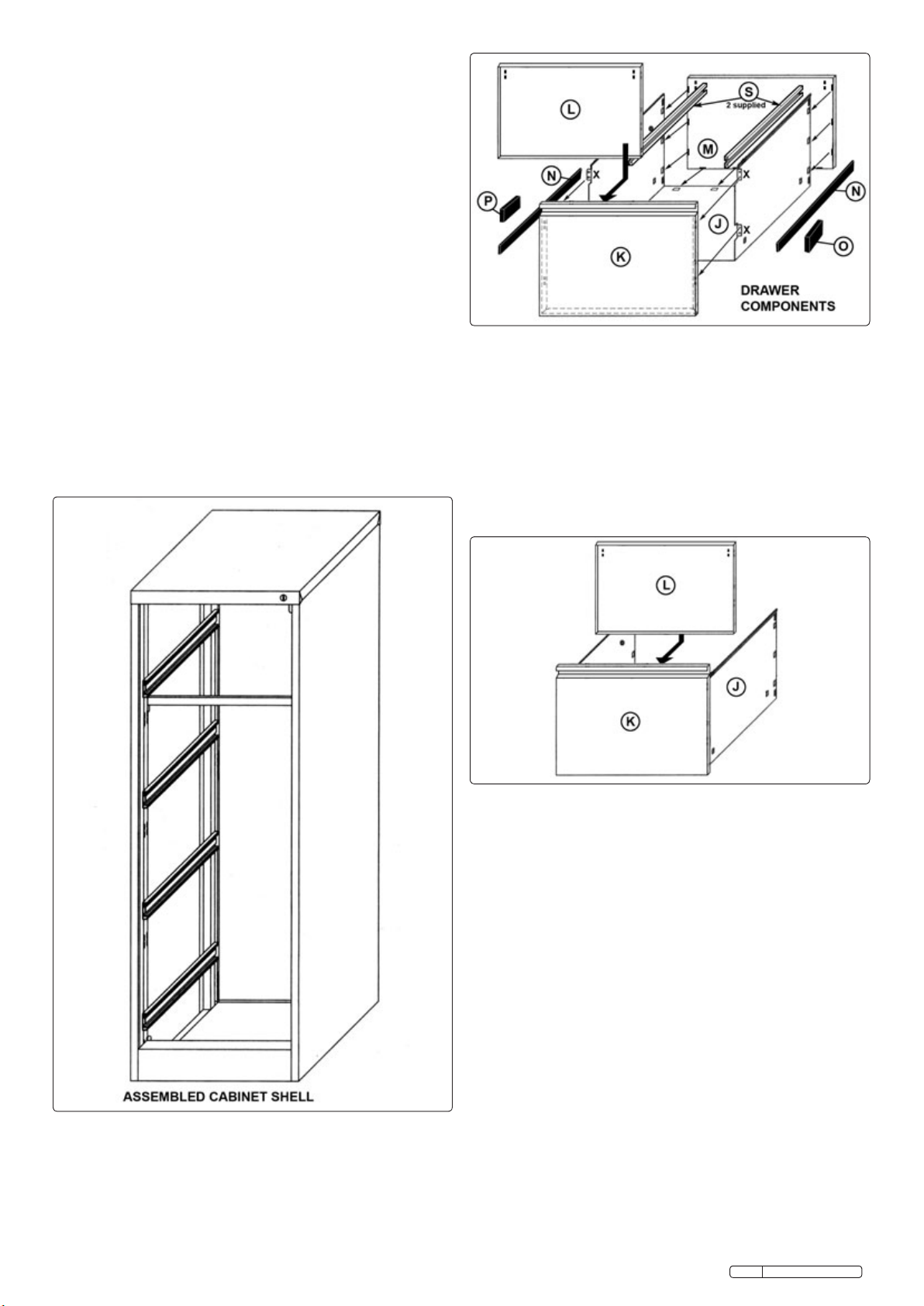

3.8.3 Referring to fig.4 slide the drawer front inner panel (L) down into

the drawer, just behind the front panel (K). Ensure that the

returned edges of the inner panel are facing towards the back of

the front panel. Slide the inner panel (L) into the back of the front

panel (K) so that the tabs on the sides of the inner panel lock into

the slots in the sides of the drawer .

SFC4 Issue No: 1 - 22/02/10

Original Language Version

Fig.2

Fig.3

Fig.4

3.8.4 Now attach the back panel (M) to the drawer. NOTE: If you want

to use the two A4 file runners (S) they should be fitted at the same

time. See fig.5. The rear edges of the 'U' shape have raised hooks

punched into them which line up with slots in the edges of the

back panel (M). Lay the drawer assembly on its front face. If fitting

the file runners (S), push them into the slots at the top of the

drawer inner panel. Then lower the back panel (M) into the 'U'

shape ensuring that the file runners enter the slots in the back

panel and the hooks at the top of the drawer sides also enter the

matching slots in the back panel. The back panel (M) is now tying

together the drawer sides (J) at the top. Gradually ease the rest of

the back panel down into the 'U' shape ensuring that each side

hook engages into the matching slot in the back panel. When all

hooks are engaged push firmly down on to the panel to ensure

that all the hooks are fully inserted into the slots.

3.8.5 At each corner of the assembled back panel is a slot which gives

access to a pair of tabs punched into the 'U' shape. Bend these

tabs into the slots to lock the back panel onto the draw. See fig.6.

3.8.6 The drawer runners (N) attach to the sides of the drawers in a

similar manner to the cabinet runners. Sort the 8 runners into 4 left

hand ones and four right hand ones. Each runner has two hooks

on the rear face which slot into holes in the sides of each draw.

The horizontal hook at the back end of each runner slides

horizontally into the hole at the back of the drawer sides. Once

fully inserted, the hook at the other end of the runner will drop into

the hole at the front of the panel. Pull firmly upwards on the front

end of the runner to engage the hook and the locking tab.

3.8.7 Attach a safety block (P) to the left hand side of each drawer in

the orientation shown in fig.5 using two self tapping screws (Ø9mm).

There are two moulded pins on the back of the moulding which

align with pre-drilled holes in the side of each drawer.

3.8 ASSEMBLE THE DRAWERS.

3.8.1 The bottom and sides of each drawer (see J in fig.3) are supplied

as a flat piece of metal with punched slots creating 'fold' lines'

between the base and sides of the drawer. Place the panel on a

flat surface ensuring that the four tabs (X) on the front edge of the

panel are facing downwards. Place something flat in the centre

portion of the panel and get a second person to firmly hold it in

place. Then bend each side upwards until it is at 90º to the base.

Check the angle with a set square.