Cincinnati CB Series User guide

OPERATION,

MAINTENANCE

AND

SAFETY

MANUAL

FOR

@D~@D~IN!I~ifD

CB

HYDRAULIC

PRESS

BRAKES

CINCINNATI

INCORPORATED

CINCINNATI,

OHIO

45211

EM-234

(FEB

93)

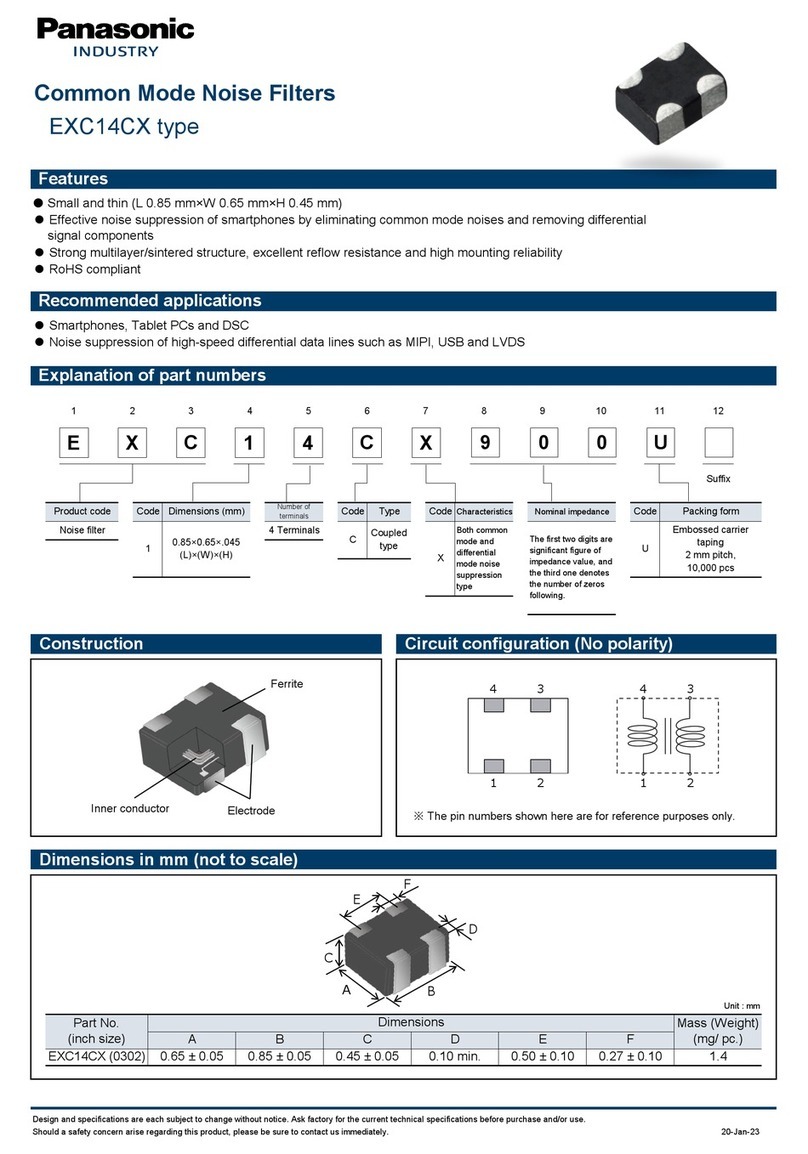

CB HYDRAULIC PRESS BRAKE INDEX

SECTION

1

SECTION 2

SECTION 3

SECTION

4

INSTALLATION 1

LIFTING AND

MOVING

1

FOUNDATION 1

CLEANING 1

LEVELING 1

INITIAL LUBRICATION 2

ELECTRICAL

CONNECTIONS_3

IDENTIFICATION 4

SAFETY

5

OPERATION 10

STANDARD

CONTROLS

10

OPTIONAL

CONTROLS

12

INITIAL

START-UP

OF

NEW

MACHINE

13

DAILY

START-UP

13

SECTION

6

SECTION 7

MAINTENANCE

AND

ADJUSTMENTS

__

23

LUBRICATION

23

HYDRAULIC

OIL

23

OIL

FILLER-BREATHER

23

CHECKING·&SETTING HYDRAULIC

PRESSURE

24

CYLINDERS

24

PUMP

25

VALVES

26

LEVELING

SYSTEM

26

TILT LIMIT

SWITCHES

27

MACHINE

LEVELNESS

28

SWIVEL

END-GUIDE

BEARINGS_28

ELECTRICAL

28

TROUBLESHOOTING

28

MAINTENANCE

CHECK

LIST

__

30

ORDERING REPAIR

PARTS

31,

SECTION 5KNOWING YOUR

PRESS.BRAKE

_14

PERFORMANCE &RATINGS

__

14

PRINCIPLES

OF

OPERATION

_14

TYPES

OF

DIES

15

PUNCHING

CAPACITY

16

STRIPPING CAPACITY

16

ECCENTRIC

LOAD

CAPACITY

_17

OFF-CENTER LOAD CAPACITY

_17

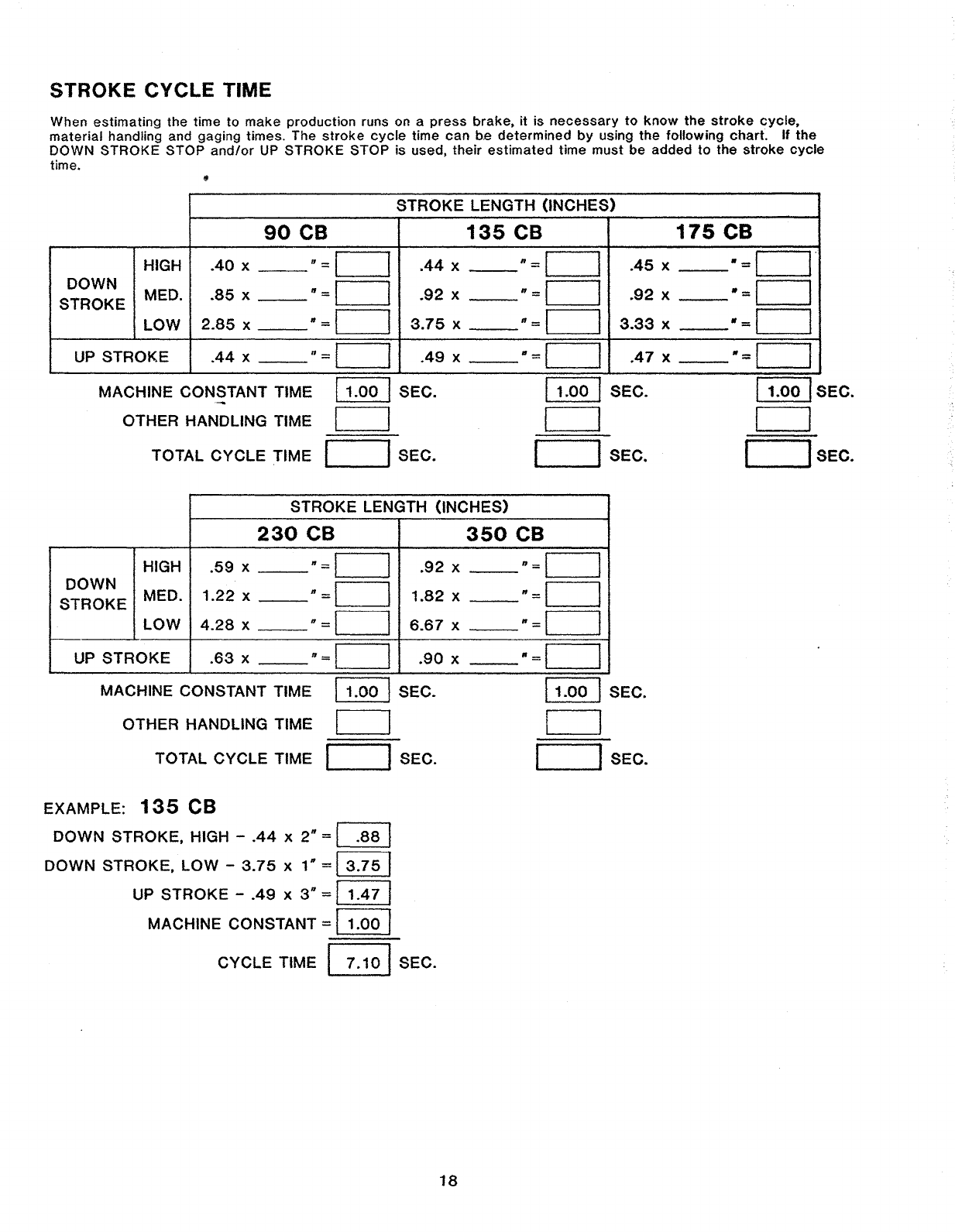

STROKE

CYCLE

TIME

18

SET-UP

AND USE

19

INSERTING

TOOLING

19

SET

MACHINE

CONTROLS_

20

REMOVING

TOOLING

20

BENDING TIPS 21

GAGING 21

BLANK

DEVELOPMENT

22

ORDERING REPAIR PARTS

__

31

RETURNING PARTS FOR

CREDIT

31

SERVICE

31

©

COPYRIGHT

1987

BY

CINCINNATI

INCORPORATED

SECTION 1

Upon

receipt

of

your

CINCINNATI

Hydraulic

Press

Brake

carefully

remove

the

contents

of

the

one

or

more

packing

boxes

shipped

with

the

machine.

All

of

the

machine

options

and

loose

parts)

such.

as

wrenches,

will

be

in

these

boxes.

Check

all

of

the

parts

received

with

the

packing

list.

Claims

for

shortages

or

damaged

parts

should

be

made

within

ten

days.

Remove

all

shipping

paper

from

the

wrapped

parts

of

the

press

brake.

Leave

the

shipping

skids

attached

to

the

machine

until

it

has

been

moved

to

its

final

location.

LIFTING AND MOVING

CINCINNATI CB

Hydraulic

Press

Brakes

are

readily

handled

by

cranes

of

sufficient

capacity

with

chains

or

cables

adjusted

to

the

proper

length

for

even

lifting.

Use

a

timber

brace

bet\veen

the

top

of

the

housings.

A

typical

hitch

is

shown

in

Fi.~re

1.

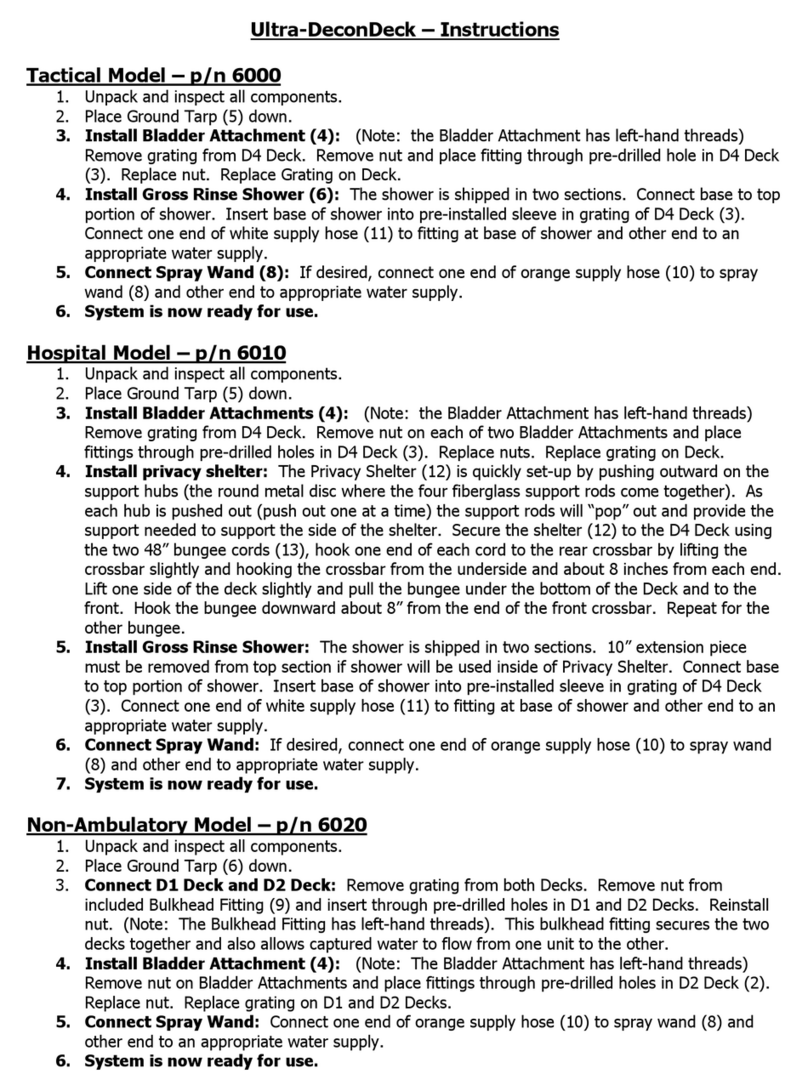

FIGURE 1

Where

crane

facilities

are

insufficient

in

capacity

or

are

not

available,

rig

the

machine

into

final

location.

When

rigging

into

position,

be

extremely

careful

to

keep

the

machine

supported

evenly

and

to

guard

against

tipping.

CINCINNATI

INCORPORATED

recommends

that

professional

riggers

be

employed

to

handle

the

machine

to

ensure

against

damage

or

injury

to

workers.

If

jacks

are

used

to

lo·w·er

the

machine

onto

the

foundation

bolts,

care

should

be

taken

to

prevent

twisting

of

the

machine.

1

INSTALLATION

FOUNDATION

A

CINCINNATI

CB

Hydraulic

Press

Brake

is

not

a

self-

contained

machine;

that

is,

the

machine

must

be

provided

with

a

rigid

foundation

to

ensure

the

preservation

of

alignment

of

the

housing

and

cross

framing

members.

The

foundation

must

support

the

weight

of

the

machine

without

cracking

or

settling

aut

-of

-level.

For

details

of

the

foundation

recommended

for

your

press

brake

refer

to

the

Foundation

Plan

drawing.

It

is

advisable,

particularly

in

localities

where

unusual

soil

conditions

may

exist,

to

have

your

foundation

plan

approved

by

a

local

registered

civil

engineer.

As

a

final

check,

before

locating

the

press

brake

on

the

foundation,

see

that

the

anchor

bolts

in

your

foundation

coincide

with

the

bolt

hole

spacing

in

the

housing

feet.

CLEANING

Thoroughly

clean

protective

grease

from

all

parts

of

the

machine

with

solvent.

Go

over

the

grease

with

a

rag

wet

with

solvent

and

allow

to

soak.

Use

rags

instead

of

waste.

A

stiff

brush

will

get

into

the

corners.

Do

not

use

an

air

hose

-

pressure

may

drive·

dirt

and

grit

into

bearing

surfaces.

After

cleaning

thoroughly,

wipe

dry

and

make

sure

that

no

grease

or

grit

is

left.

With

oil,

clean

and

flush

the

ram

guides

and

slides,

wiping

off

all

excessive

oil.

Periodic

cleaning

of

the

machine

after

installation

is

advisable.

LEVELING

CINCINNATI

Press

Brakes

are

leveled

by

placing

fIat

steel

shims

of

proper

thicknesses

under

the

press

brake

housing

feet

as

required.

Use

a

precision

level

-

not

a

carpenter's

or

machinist's

leveL

See

Figure

2. Always

wipe

level

and

surface

clean

before

placing

level.

Give

the

bubble

of

the

precision

level

a

half

minute

to

come

to

absolute

rest.

FIGURE 2

After

the

machine

is

level,

retighten

foundation

bolt

nuts

securely.

Recheck

guide

and

slide

alignment.. Do

not

remove

shims.

Alignment

may

not

be

permanent.

Recheck

level

in

afew

weeks.

Do

not

use

any

grouting

around

the

machine.

Leave

the

bed

pit

empty

and

cover

with

steel

plate

(175CB x

12,

230CB x

12,

350CB x

10,

12).

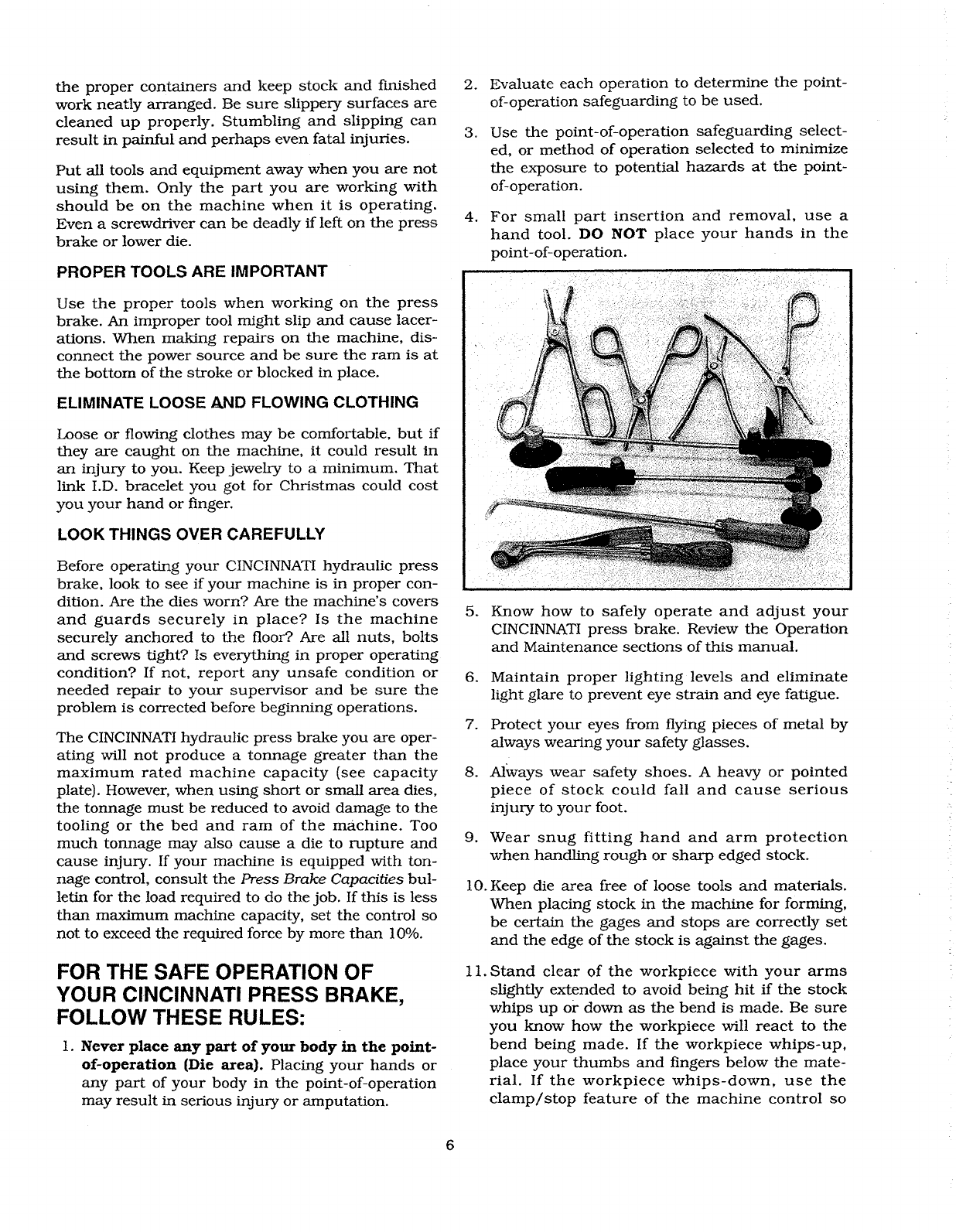

This

condition

is

corrected

by

adding

or

removing

shims

under

one

of

the

rear

housing

feet.

In

the

example,

the

excessive

clearance

was

at

the

right

guide

and

slide.

To

bring

the

alignment

into

tolerance,

shims

could

be

added

under

the

right

rear

housing

foot

or

removed

from

the

left

rear

housing

foot.

The

alignment

must

be

corrected

even

if

it

causes

the

bed

to

be

out-of-leveL

RAM

GUIDE

RAM

CLAMP

(LOOSENED

AND

AWAY

FROM

GUIDE)

o

o

FIGURE 4

RAM

MEASURE

CLEARANCE

AT

TOP

AND

BOTTOM

FIGURE 3

Let

the

machine

down

and

recheck

level.

Repeat

as

often

as

necessary.

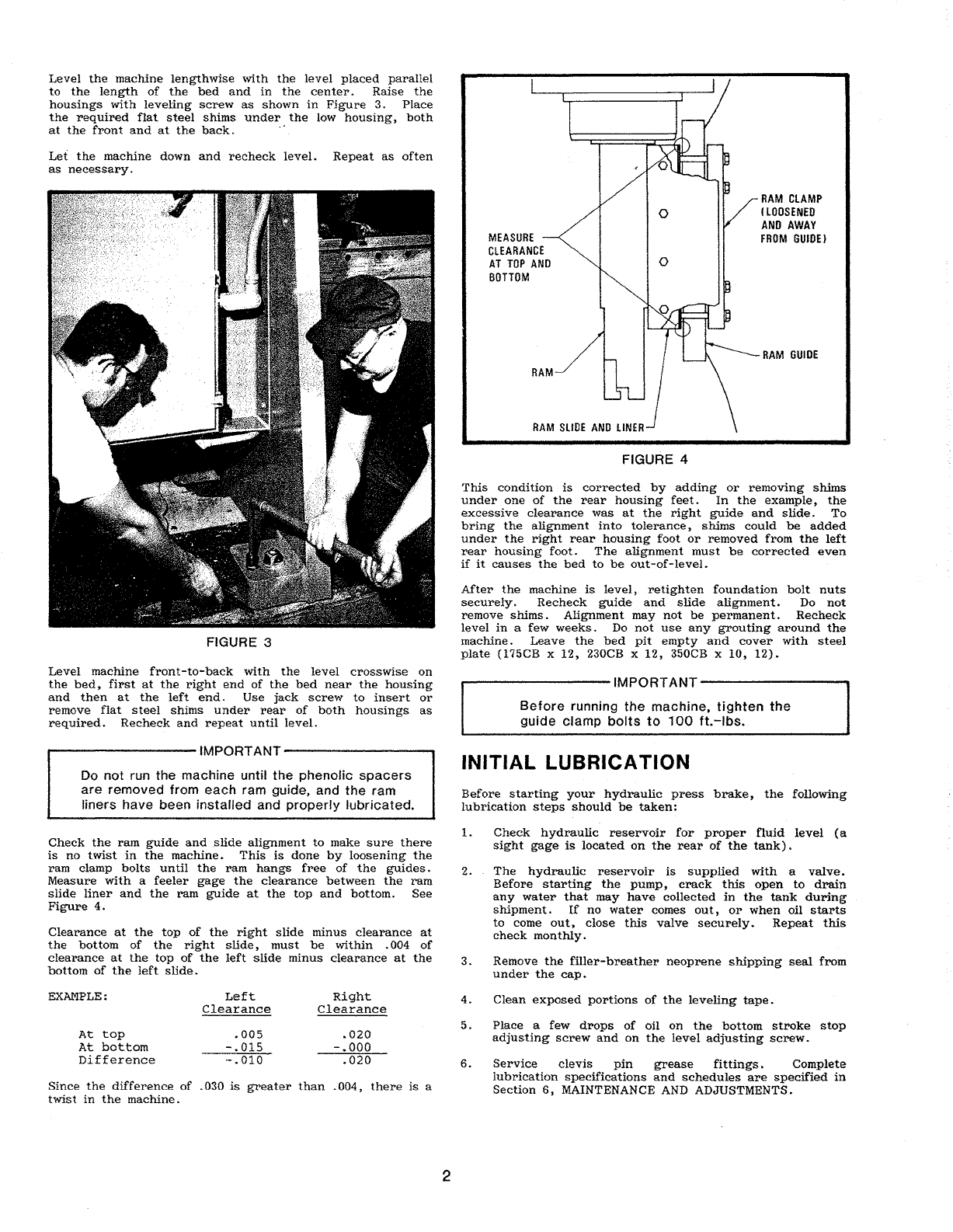

Level

the

machine

lengthwise

with

the

level

placed

parallel

to

the

length

of

the

bed

and

in

the

center.

Raise

the

housings

with

leveling

screw

as

shown

in

Figure

3.

Place

the

required

flat

steel

shims

under

the

low

housing

~

both

at

the

front

and

at

the

back.

.'

Level

machine

front-to-back

with

the

level

crosswise

on

the

bed,

first

at

the

right

end

of

the

bed

near

the

housing

and

then

at

the

left

end.

Use

jack

screw

to

insert

or

remove

flat

steel

shims

under

rear

of

both

housings

as

required.

Recheck

and

repeat

until

level.

r---------IMPORTANT

---------.

Before

running

the

machine.

tighten

the

guide

clamp

bolts

to

100

ft.-Ibs.

....--------IMPORTANT-------

........

Do

not

run the machine until

the

phenolic

spacers

are

removed from

each

ram guide, and

the

ram

liners have been

installed

and

properly

lubricated.

INITIAL LUBRICATION

Before

starting

your

hydraulic

press

brake,

the

following

Iu

brication

steps

should

be

taken:

Check

the

ram

guide

and

slide

alignment

to

make

sure

there

is

no

twist

in

the

machine.

This

is

done

by

loosening

the

ram

clamp

bolts

until

the

ram

hangs

free

of

the

guides.

Measure

with

a

feeler

gage

the

clearance

between

the

ram

slide

liner

and

the

ram

guide

at

the

top

and

bottom.

See

Figure

4.

Clearance

at

the

top

of

the

right

slide·

minus

clearance

at

the

bottom

of

the

right

slide,

must

be

within

.004

of

clearance

at

the

top

of

the

left

slide

minus

clearance

at

the

bottom

of

the

left

slide.

1.

Check

hydraulic

reservoir

for

proper

fluid

level

(a

sight

gage

is

located

on

the

rear

of

the

tank).

2.

The

hydraulic

reservoir

is

supplied

with

a

valve.

Before

starting

the

pump,

crack

this

open

to

drain

any

water

that

.

may

have

collected

in

the

tank

during

shipment.

If

no

water

comes

out,

or

when

oil

starts

to

come

out,

close

this

valve

securely.

Repeat

this

check

monthly.

3.

Remove

the

filler-breather

neoprene

shipping

seal

from

under

the

cap.

EXAMPLE:

Left

Clearance

Right

Clearance

4.

Clean

exposed

portions

of

the

leveling

tape.

Since

the

difference

of

.030

is

greater

than

.004,

there

is

a

twist

in

the

machine.

At

top

At

bottom

Difference

.005

-.015

.-

.010

.020

-.000

.020

5.

Place

afew

drops

of

oil

on

the

bottom

stroke

stop

adjusting

screw

and

on

the

level

adjusting

screw.

6.

Service

clevis

pin

grease

fittings..

Complete

lubrication

specifications

and

schedules

are

specified

in

Section

6,

MAINTENANCE

AND

ADJUSTMENTS.

2

.....

--------CAUTION

--------

...

STANDARD PRESS BRAKES

ARE

DESIGNED

FOR AND SHIPPED WITH PETROLEUM BASED

HYDRAULIC FLUIDS, WHICH

ARE

FLAMMABLE.

CHECK APPLICABLE FIRE CODES FOR SPECIAL

PRECAUTIONS.

ELECTRICAL CONNECTIONS

As

shown

on

the

Foundation

Plan

drawing,

suitable

leads

must

be

brought

to

the

machine

into

the

electrical

control

panel

on

the

right

housing.

This

is

the

only

electrical

connection

that

is

necessary.

Be

certain

that

proper

voltage

is

fed

to

the

press

brake,

that

the

lines

are

of

sufficient

capacity

and·

that

a

suitable

ground

conductor

is

attached.

3

NOTE: CINCINNATI INCORPORATED

CB

Hydraulic

Press

Brakes

are

factory

wired

for

460V/3/60HZ

service.

If

service

is

other

than

this,

do

not

remove

warning

tag

from

the

main

disconnect

or

connect

any

power

to

the

machine

until

aCINCINNATI

INCORPORATED

Service

Representative

inspects

and

services

the

machine.

Do

not

start

the

main

drive

motor

until

thoroughly

reading

the

OPERATION

section

of

this

manual

and

aCINCINNATI INCORPORATED

Service

Represent-

ative

is

present.

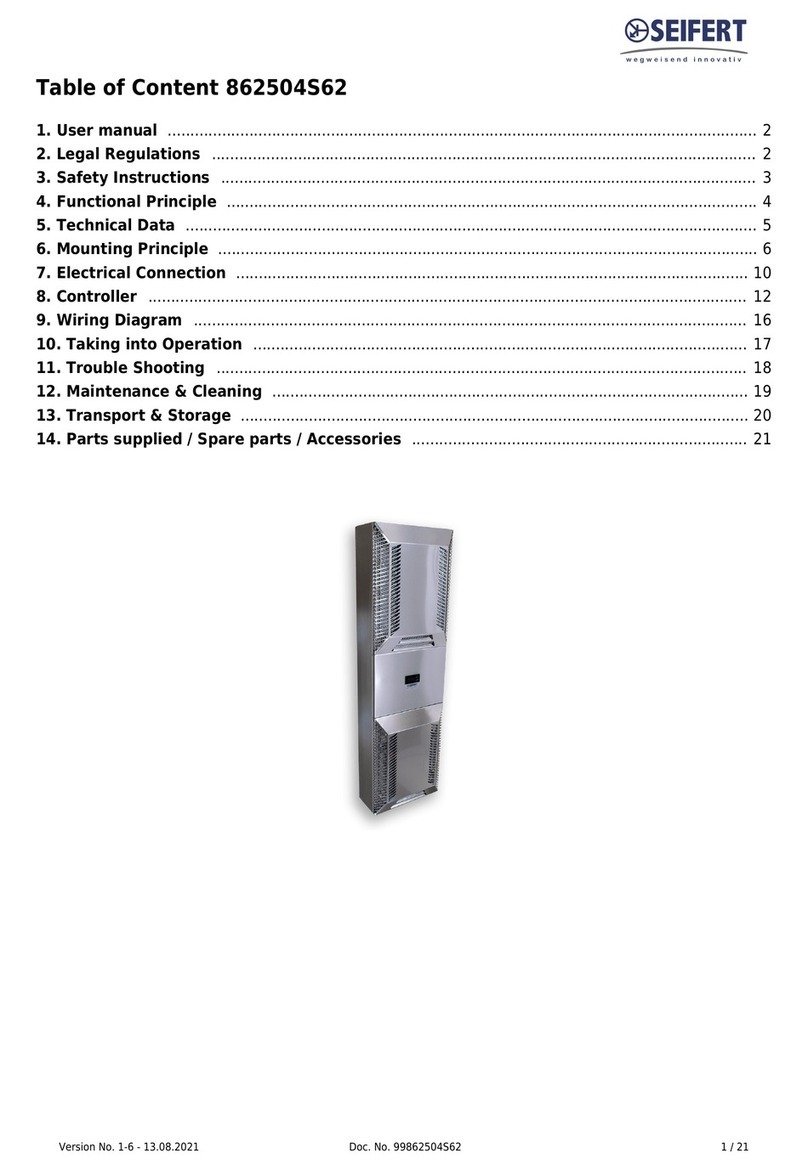

CB HYDRAULIC PRESS BRAKE

MODEL

175CB

SHOWN

SECTION 2

1.

FOOTSWITCH

2.

BED

3. DIE CLAMPS

4. PALMBUTTON STATION

5. RAM

6.

CYLINDER

7. SERVO LEVELING

VALVE

8.

LEVELING BAND

--

9. RAM

TILT

ADJUSTMENT

10. MAIN CONSOLE

11.

SET-UP

LIGHT

12.

STROKE

CONTROL CAMS

13.

FOOTSWITCH

CONTROL

14.

LEVELING SCREW

6

4

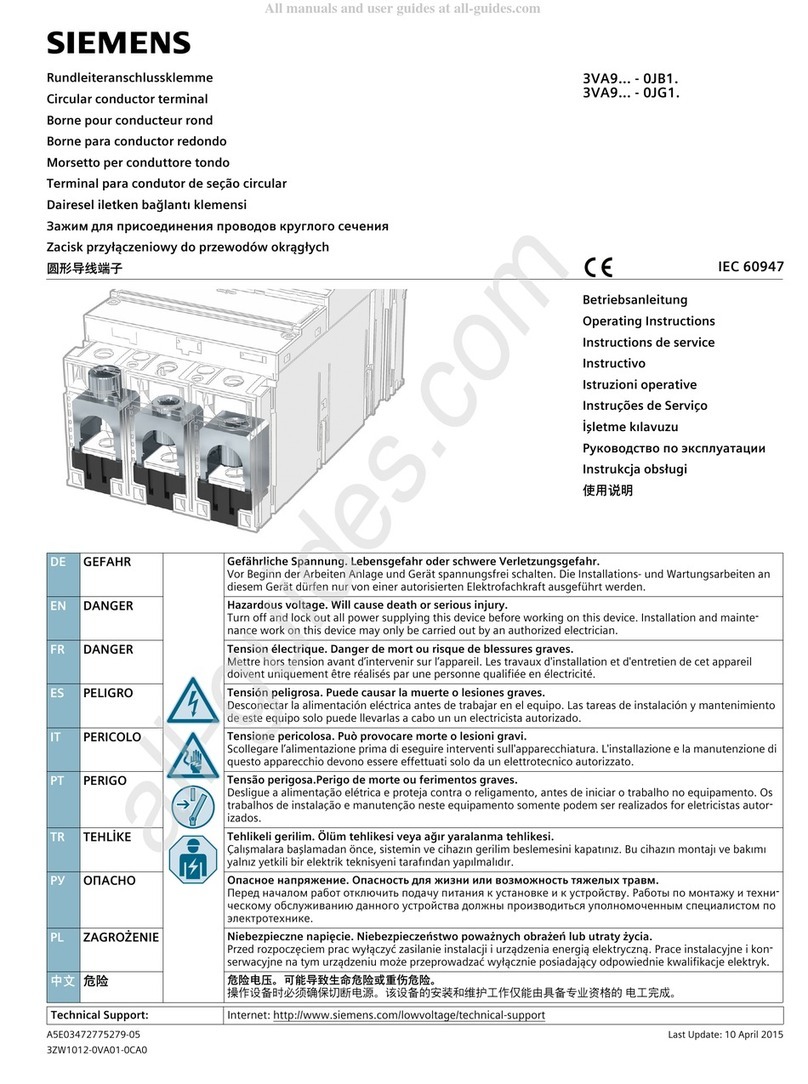

IDENTIFICATION

10

FIGURE 5

1.

RIGHT HOUSING

2.

SWIVEL END-GUIDE

3. DRAIN VALVE

4. FLUID

LEVEL

GAGE

5. FILLER-BREATHER

6. MAIN DRIVE MOTOR &

PUMP

7.

FLOW

DIVIDER

8.

LEFT

HOUSING

9. SLIDE &GUIDE

10.

HYDRAULIC MANIFOLD

11. HYDRAULIC RESERVOIR &

HOUSING BRACE

12.

TILT

LIMIT SWITCHES

SECTION 3

SAFETY RECOMMENDATIONS FOR

HYDRAULIC PRESS BRAKE

OPERATION:

Press

brakes

manufactured

by

CINCINNATI INCOR-

PORATED

comply

with

the

construction

require-

ments

of

the

Occupational

Safety

and

Health

Act

and

the

National

Safety

Standards

of

the

American

National

Standards

Institute.

CINCINNATI

INCORPORATED

also

offers

update

packages

for

older

press·

brakes

to

assist

you

in

your

compliance

and

safety

programs.

The

press

brake

is

a

versatile

and

multi-purpose

machine.

We

recommend

you

evaluate

each

press

brake

operation

in

order

to

determine

the

method

of

point-of-operation

safeguarding

which

best

meets

that

operation.

TIle

press

brake,

tooling,

piece

part

and

method

of

feed

and

removal

must

be

evaluated

for

each

job

before

deciding

on

the·

safeguarding

to

be

used.

CINCINNATI

INCORPORATED

recommends

you

read

and

understand

the

safeguarding,

use

and

care

requirements

of

the

American

National

Standard

for

Press

Brakes,

ANSI

B11.3.

This

is

available

from

the

American

National

Standards

Institute,

11 West

42nd

Street,

New York, New York

10036

and

is

included

with

this

manual.

For

additional

safety

information

we

recommend:

•

Securing

applicable

safety

data

sheets

from

the

National

Safety

CounCil,

1121

Spring

Lake

Drive,

Itasca,

Illinois

60143-3201.

•

Determining

your

responsibilities

under

your

state

and

local

safety

codes

•

Requesting

assistance

from

the

loss

prevention

department

of

your

workmen's

compensation

carrier

Personnel

responsible

for

your

press

brake

operator

training

program,

tooling

set-up,

maintenance,

and

operations

must

read

and

understand

this

Operation,

Safety

and

Maintenance

manual.

No

one

should set-up, operate

or

maintain

this

press

brake

until

they

thoroughly

understand

it

and

know

how

to

do

their

job

safely.

This

safety

information

is

not

intended

as

a

substitute

for

the

Operation

and

Maintenance

sections

of

this

manual.

5

SAFETY

FOR SAFE OPERATION OF YOUR

CINCINNATI PRESS BRAKE

KEEP

CLEAR

OF

THE

POINT-OF-OPERATION

The

purpose

of

a

press

brake

is

to

bend

metal

and

it

is

obvious

that

this

same

capacity

will

sever

arms,

hands,

fingers

or

any

other

part

of

the

body

that

is

in

the

point-of-operation

when

the

ram

is

activated.

During

operation,

all

parts

of

your

body

must

be

completely

clear

of

the

work

area.

NEVER

PLACE

ANY

PART

OF

YOUR

BODY

IN

THE

POINT-OF-

OPERATION

(Die

area).

If

operation

by

more

than

one

person

is

reqUired,

operator

controls

must

be

furnished

for

each

per-

son.

If

foot

controls

are

used~and

your

evaluation

of

that

specific

operation

indicates

safeguarding

is

necessary,

provide

the

necessary

safeguarding

before

any

work

is

performed.

(See ANSI B11.3.)

If

you

use

two-hand

operator

control

station(s)

·as

point-of-operation

safeguarding,

be

certain

that

they

comply

with

ANSI B

11.3.

If

operation

by

more

than

one

person

is

reqUired,

one

person

should

be

responsible

to

see

that

not

only

his·

own

body

is

clear

of

the

point

-of~operation

and

all

moving

parts,

but

also

that

his

co-workers

are

clear

and

entirely

visible

in

a

safe

location,

before

the

press

is

operated.

During

set-up,

maintenance

or

other

work

on

the

machine

which

necessitates

manipulation

Within

the

point-of-operation,

either

the

ram

should

be

at

the

bottom

of

the

stroke

or

it

should

be

blocked

so

the

dies

cannot

close.

The

power

supply

should

be

disconnected

and

locked

OFF.

CONCENTRATE ON YOUR

JOB

Daydreaming,

worrying

about

other

problems

or

other

improper

operation

of

a

machine

could

cripple

you

for life.

Operating

a

press

brake

reqUires

your

complete

attention.

Talking,

joking

or

participating

in

or

watching

horseplay

could

result

in

physical

injury

to

you

...

and

that

is

nothing

to

joke

about.

So

watch

what

you

are

doing

and

concentrate

on

your

job.

NEATNESS IS IMPORTANT

Keep

the

floor

of

your

work

area

clear

of

scrap

and

trash

that

could

cause

you

to

stumble.

Put

scrap

in

the

proper

containers

and

keep

stock

and

finished

work

neatly

arranged.

Be

sure

slippery

surfaces

are

cleaned

up

properly.

Stumbling

and

slipping

can

result

in

painful

and

perhaps

even

fatal

injuries.

Put

all

tools

and

equipment

away

when

you

are

not

using

them.

Only

the

part

you

are

working

with

should

be

on

the

machine

when

it

is

operating.

Even

a

screwdriver

can

be

deadly

if

left

on

the

press

brake

or

lower

die.

PROPER TOOLS ARE IMPORTANT

Use

the

proper

tools

when

working

on

the

press

brake.

An

improper

tool

might

slip

and

cause

lacer-

ations.

When

making

repairs

on

the

machine,

dis-

connect

the

power

source

and

be

sure

the

ram

is

at

the

bottom

of

the

stroke

or

blocked

in

place.

ELIMINATE

lOOSE

AND FLOWING CLOTHING

Loose

or

flowing

clothes

may

be

comfortable,

but

if

they

are

caught

on

the

machine,

it

could

result

in

an

injury

to

you.

Keep

jewelry

to

a

minimum.

That

link. I.D.

bracelet

you

got

for

Christmas

could

cost

you

your

hand

or

finger.

LOOK

THINGS OVER CAREFULLY

Before

operating

your

CINCINNATI

hydraulic

press

brake

t

look

to

see

if

your

machine

is

in

proper

con-

dition.

Are

the

dies

worn?

Are

the

machine's

covers

and

guards

securely

in

place?

Is

the

machine

securely

anchored

to

the

floor?

Are

all

nuts,

bolts

and

screws

tight?

Is

everything

in

proper

operating

condition?

If

not,

report

any

unsafe

condition

or

needed

repair

to

your

supervisor

and

be

sure

the

problem

is

corrected

before

beginning

operations.

The

CINCINNATI

hydraulic

press

brake

you

are

oper-

ating

will

not

produce

a

tonnage

greater

than

the

maximum

rated

machine

capacity

(see

capacity

plate). However,

when

using

short

or

small

area

dies,

the

tonnage

must

be

reduced

to

avoid

damage

to

the

tooling

or

the

bed

and

ram

of

the

machine.

Too

much

tonnage

may

also

cause

a

die

to

rupture

and

cause

injury.

If

your

machine

is

eqUipped

with

ton-

nage

control,

consult

the

Press

Brake

Capacities

bul-

letin

for

the

load

reqUired

to

do

the

job.

If

this

is

less

than

maximum

machine

capacity,

set

the

control

so

not

to

exceed

the

required

force

by

more

than

100/0.

FOR THE SAFE OPERATION

OF

YOUR CI·NCINNATI PRESS BRAKE,

FOLLOW THESE RULES:

1.

Never

place

any

part

of

your

body

in

the

point-

of-operation

(Die

area).

Placing

your

hands

or

any

part

of

your

body

in

the

point-of-operation

may

result

in

serious

injury

or

amputation.

6

2..

Evaluate

each

operation

to

determine

the

point-

of-operation

safeguarding

to

be

used

..

3.

Use

the

point-of-operation

safeguarding

select-

ed~

or

method

of

operation

selected

to

minimize

the

exposure

to

potential

hazards

at

the

point-

of-operation.

4.

For

small

part

insertion

and

removal,

use

a

hand

tooL

DO

NOT

place

your

hands

in

the

point

-of-operation.

5.

Know

how

to

safely

operate

and

adjust

your

CINCINNATI

press

brake.

Review

the

Operation

and

Maintenance

sections

of

this

manual.

6.

Maintain

proper

lighting

levels

and

eliminate

light

glare

to

prevent

eye

strain

and

eye

fatigue.

7.

Protect

your

eyes

from

flying

pieces

of

metal

by

always

wearing

your

safety

glasses.

8.

Always

wear

safety

shoes.

A

heavy

or

pointed

piece

of

stock

could

fall

and

cause

serious

injury

to

your

foot.

9.

Wear

snug

fitting

hand

and

arm

protection

when

handling

rough

or

sharp

edged

stock.

10.

Keep

die

area

free

of

loose

tools

and

materials.

When

placing

stock

in

the

machine

for forming,

be

certain

the

gages

and

stops

are

correctly

set

and

the

edge

of

the

stock

is

against

the

gages.

11.

Stand

clear

of

the

workpiece

with

your

arms

slightly

extended

to

avoid

being

hit

if

the

stock

whips

up

or

down

as

the

bend

is

made.

Be

sure

you

know

how

the

workpiece

will

react

to

the

bend

being

made.

If

the

workpiece

whips-up,

place

your

thumbs

and

fingers

below

the

mate-

rial.

If

the

workpiece

whips-down~

use

the

clamp/stop

feature

of

the

machine

control

so

your

hands

can

be

removed

from

the

workpiece

when

the

bend

is

made.

Set

the

forming

speed

to

avoid

excessive

part

~whip".

12.

Releasing

the

footswitch

of

your

CINCINNATI

press

brake

will

immediately

stop

or

reverse

(depending

upon

the

mode

selection)

downward

travel

of

the

ram

in

case

of

emergency.

13.

When

you

leave

the

machine,

place

the

ram

at

bottom

of

the

stroke

or

place

safety

blocks

in

position

under

the

ram.

Turn

OPERATOR CON-

TROL

selector

to

«OFF"

and

remove

the

key

..

even

if

you

will

be

away

for

only

a

few

minutes.

14.

Have

the

routine

scheduled

maintenance

and

adjustments

performed

as

shown

on

the

Maintenance

Checklist

in

Section

6.

15.

Check

alignm~t

of

the

dies

before

operating

the

machine

after

the

dies

have

been

changed

or

if

the

machine

has

been

idle

overnight..

Improper

alignment

could

cause

chipping

and

flying

chips

can

cause

lacerations

and

eye

injuries.

16.

Report

any

cuts,

bruises

and

all

other

injuries

to

your

supervisor

or

the

medical

department

immediately.

They

are

the

best

judges

of

how

serious

or

minor

the

nature

of

your

injUry

is.

GENERAL GUIDELINES FOR

INSTALLING, REMOVING AND

TRANSFERRING TOOLING (DIES)

Installing,

removing

and

transferring

tooling

is

haz-

ardous

and

should

be

done

with

proper

supervision

by

experienced

set-up

men.

Improper

handling

techniques

can

cause

muscle

,strains,

hernias

or

serious

disabling

injUries.

1.

Transfer

dies

using

the

proper

techniques

for

the

weight

of

the

die{s)

being

handled:

a.

Very

light

dies

(up

to

50

pounds)

can

be

car-

ried

manually

or

transferred

on

a

die

truck.

b.

Dies

weighing

over

50

pounds

or

those

that

are

awkward

to

move

should

be

handled

by

a

hoist.

If

the

punch

or

die

has

tapped

holes

for lifting

attachments,

be

sure

the

proper

size

bolts

are

used.

A

bolt

smaller

in

diameter

than

the

tapped

hole

will

slip

Qut

and

cause

serious

injUry.

If

no

lifting

attachments

are

prOVided

..

use

only

approved

rope

slings

so

the

dies

will

not

be

nicked

or

scratched.

Lift

the

dies

high

enough

to

clear

any

obstruc-

tions

..

but

no

higher.

7

CAUTION

2.

When

installing

and

setting-up

dies:

a.

Clean

the

machine

and

filler

block

surfaces

to

which

the

dies

will

be

fastened.

Always

turn

machine

OFF

and

use

safety

blocks

between

the

bed

and

ram

when

working

in

this

area.

b.

Inspect

the

dies

for

chips,

cracks

or

other

hazardous

conditions.

Wipe

them

off

with

a

clean

cloth.

c.

Always

place

the

machine

control

MODE

selector

in

the

"INCH"

position

so

the

ram

can

only

be

cycled

by

use

of

palmbuttons.

d.

Never

reach

into

or

through

the

die

area

when

.

aligning

the

dies

or

setting

the

gaging.

3.

When

removing

dies

from

the

press

brake:

a.

Clear

the

work

areas

of

all

stock,

containers,

tools

and

other

eqUipment.

b.

After

placing

safety

blocks

between

the

dies

and

turning

OFF

the

machine,

clean

both

upper

and

lower

dies

using

a

bench

brush

and

finally

wipe

clean

with

a

cloth.

c.

Place

the

machine

control

MODE

selector

in

the

"INCH"

position

so

the

ram

can

only

be

cycled

by

use

of

the

palmbuttons.

d.

Never

loosen

the

ram

clamp

bolts

unless

the

dies

are

in

a

closed

position

and

the

drive

motor

has

been

shut

«OFF".

Detailed

step-by-step

instructions

for

installing

and

removing tooling

are

provided

in

the

KNOWING YOUR

PRESS BRAKE

section

of

this

manual.

These

instruc-

tions

should

be

followed

for

safe

installation

and

removal

of

tooling from

your

CINCINNATI

press

brake.

Also

included

in

the

KNOWING

YOUR

PRESS

BRAKE

section

of

the

manual

are

instructions

for

making

bends,

gaging,

blank

development

and

use

of

the

machine

controls.

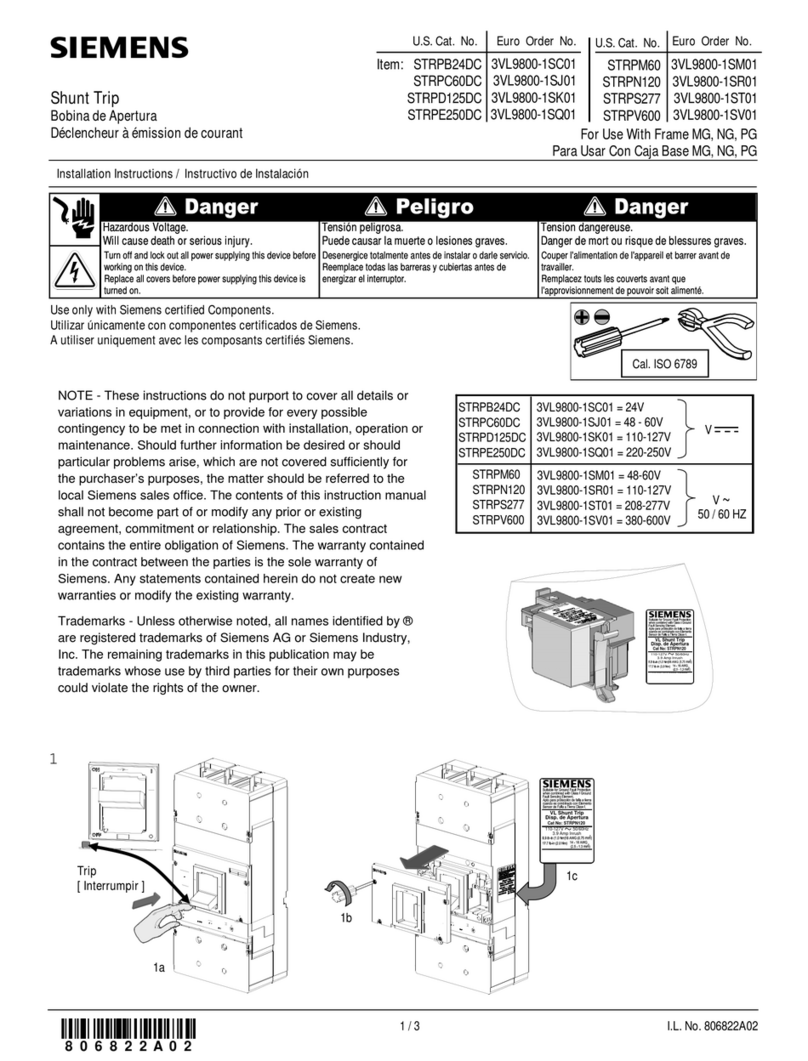

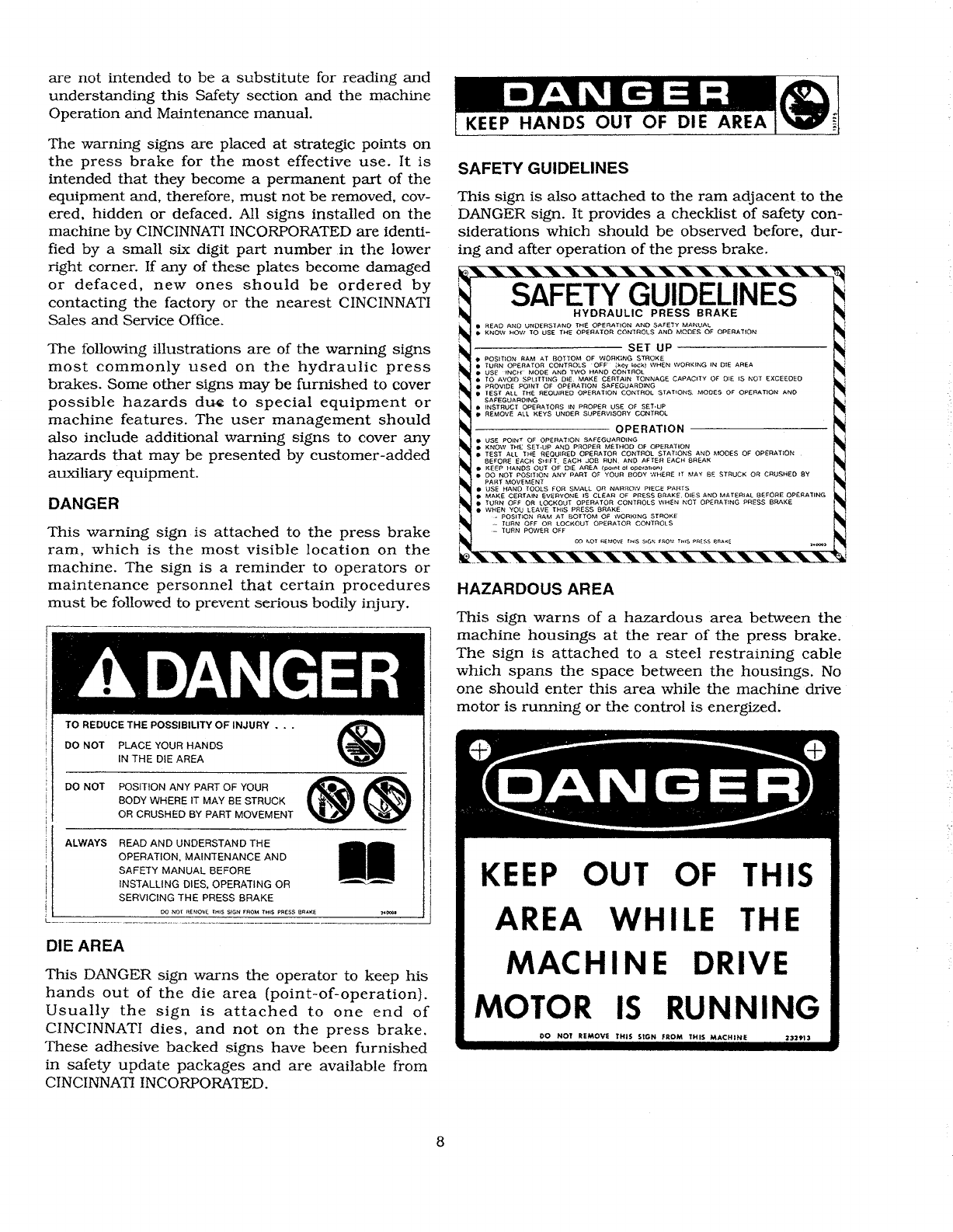

SAFETY SIGNS

In

order

that

press

brake

operators

and

maintenance

personnel

may

be

warned

of

certain

potential

haz-

ards

that

may

exist

-

unless

specified

procedures

are

followed - a

number

of

warning

signs

are

attached

to

CINCINNATI

Hydraulic

Press

Brakes.

Warning

signs

L

__

.

__

.

__

._

_

__

..

_.

. . . .

--'

DANGER

DIE AREA

DO

NOl

REMOVE THIS SIGN FROM THIS

MACHINE

2329U

KEEP

OUT OF THIS

AREA

WHILE

THE

MACHINE

DRIVE

MOTOR

IS

RUNNING

----------

seTUP

----------

•POSITION RAM AT BOTTOM

OF

WORK~NG

STROKE

•TURN OPERATOR CONTROLS

'OFF

!kCy

lock)

WHEN WORKING

IN

DIE AREA

•

USE·'No·r

MODE AND TWO HAND CONTROL

•TO AVOID SPLITTING

DIE.

MAKE

CERTAIN TONNAGE. CAPACITY

OF

DIE IS NOT EXCEEDED

•PROVIDE POINT

OF

OPERA

nON

SAFEGUARDING

•TEST

ALL

THE REOUIRED OPERATION CONTROL STATIONS. MODES OF OPERATION

AND

SAFEGUARDING

•INSTRUCT OPERATORS IN PROPER USE

OF

SET·UP

•REMOvE

All·

KEYS

UNDER SUPERVISORY CONTROL

SAFETY GUIDELINES

---------

OPERATION

---------

•USE POINT

OF

OPERATiON SAFEGUARDING

•KNO\V THt: SET·UP

AND

PROPER

METHOD

Of

OPERATION

•TEST ALL THE REOUIRED OPERATOR CONTROL STATiONS AND MODES OF OPERATION

BEFORE EACH 5r1lFT. EACH

JOB

RUN.

AND

AFTER EACH BREAK

•KEEP HANDS OUT OF

OlE

AREA

(pomt

of

operatlco)

•DO NOT POSITlON ANY PART

OF

YOUR BODY WHERE

IT

MAY

BE

STRUCK OR CRUSHED

BY

PABT MOVEMENT

•USE HAND TOOLS FOR

SMALL

OR NARROW PIECE

PMas

•MAKE CERTAIN EVERYONE IS CLEAR OF PRESS BRAKE. DIES

AND

MATERIAL

BEfORE

OPERATING

•TURN OFF OR LOCKOUT OPERATOR CONTROLS WHEN NOT OPERATING PRESS

BRAKE

•WHEN

you

LEAVE THIS

PRESS

BRAKE

.-POSITION

RAM

AT BOTTOM OF WORKING STROKE

---

TURN OFF OR

LOCKOuT

OPERATOR

COtHROlS

._..

TURN POWER OFF

SAFETY

GUIDELINES

HYDRAULIC

PRESS

BRAKE

•READ AND UNDERSTAND THE OPERATION

AND

SAFETY

MANUAL

•KNOW HOW TO USE THE OPERATOR CONTROLS

AND

MODES OF OPERA

lION

HAZARDOUS

AREA

This

sign

is

also

attached

to

the

ram

adjacent

to

the

DANGER

sign.

It

provides

a

checklist

of

safety

con-

siderations

which

should

be

observed

before,

dur-

ing

and

after

operation

of

the

press

brake.

This

sign

warns

of

a

hazardous

area

between

the

machine

housings

at

the

rear

of

the

press

brake.

The

sign

is

attached

to

a

steel

restraining

cable

which

spans

the

space

between

the

housings.

No

one

should

enter

this

area

while

the

machine

drive

motor

is

running

or

the

control

is

energized.

II

ALWAYS READ AND UNDERSTAND THE

OPERATION,

MAINTENANCE

AND

SAFETY

MANUAL

BEFORE

INSTALLING DIES, OPERATING OR

SERVICING THE PRESS BRAKE

TO REDUCE

THE

POSSIBILITY

OF

INJURY • • •

------------------il

I

I

i

~i

"I

I

DO NOT POSITION ANY PART OF

YOUR

(8

~

"

BODY

WHERE

IT

MAY

BE

STRUCK

~~

",tlt~

..

I

OR

CRUSHED

BY

PART MOVEMENT

'"

-.....~

DO NOT PLACE YOUR HANDS

IN THE DIE AREA

,··A,DANGER

are

not

intended

to

be

a

substitute

for

reading

and

understanding

this

Safety

section

and

the

machine

Operation

and

Maintenance

manual.

The

warning

signs

are

placed

at

strategic

points

on

the

press

brake

for

the

most

effective

use.

It

is

intended

that

they

become

a

permanent

part

of

the

equipment

and,

therefore,

must

not

be

removed,

cov-

ered,

hidden

or

defaced.

All

signs

in&talled

on

the

machine

by

CINCINNATI INCORPORATED

are

identi-

fied

by.a

small

six

digit

part

number

.in

the

lower

right

corner.

If

any

of

these

plates

become

damaged

or

defaced,

new

ones

should

be

ordered

by

contacting

the

factory

or

the

nearest

CINCINNATI

Sales

and

Service

Office.

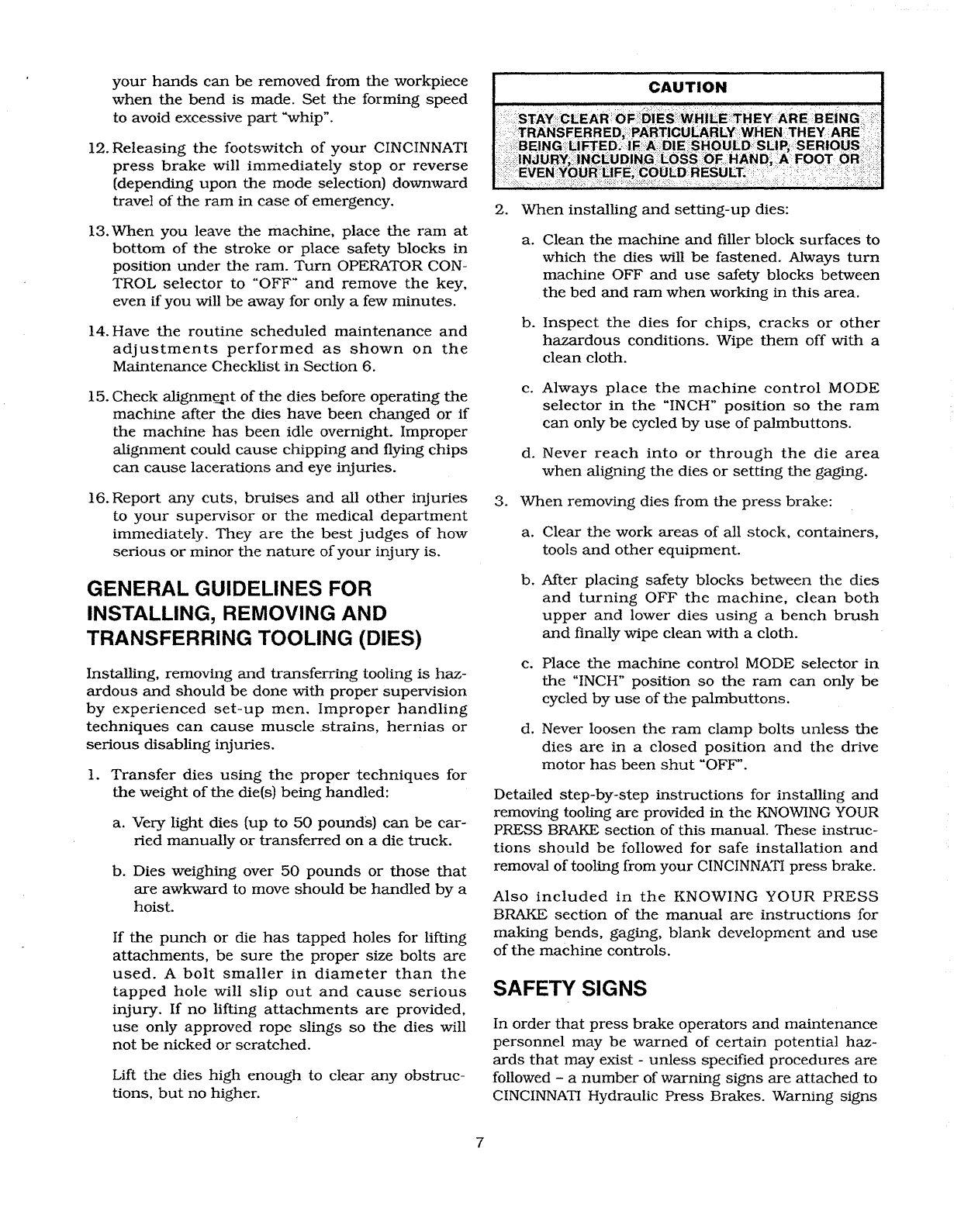

The

following

illustrations

are

of

the

warning

signs

most

commonly

used

on

the

hydraulic

press

brakes.

Some

other

signs

may

be

furnished

to

cover

possible

hazards

d~

to

special

equipment

or

machine

features.

The

user

management

should

also

include

additional

warning

signs

to

cover

any

hazards

that

may

be

presented

by

customer-added

auxiliary

equipment.

This

warning

sign.

is

attached

to

the

press

brake

ram,

which

is

the

most

visible

location

on

the

machine.

The

sign

is

a

reminder

to

operators

or

maintenance

personnel

that

certain

procedures

must

be

followed

to

prevent

serious

bodily

injury.

:

00

Nor

BE

MOVE THIS SiGN FROM

TtilS

PRESS BRAKE

This

DANGER

sign

warns

the

operator

to

keep

his

hands

out

of

the

die

area

(point-of-operation).

Usually

the

sign

is

attached

to

one

end

of

CINCINNATI

dies,

and

not

on

the

press

brake.

These

adhesive

backed

signs

have

been

furnished

in

safety

update

packages

and

are

available

from

CINCINNATI INCORPORATED.

8

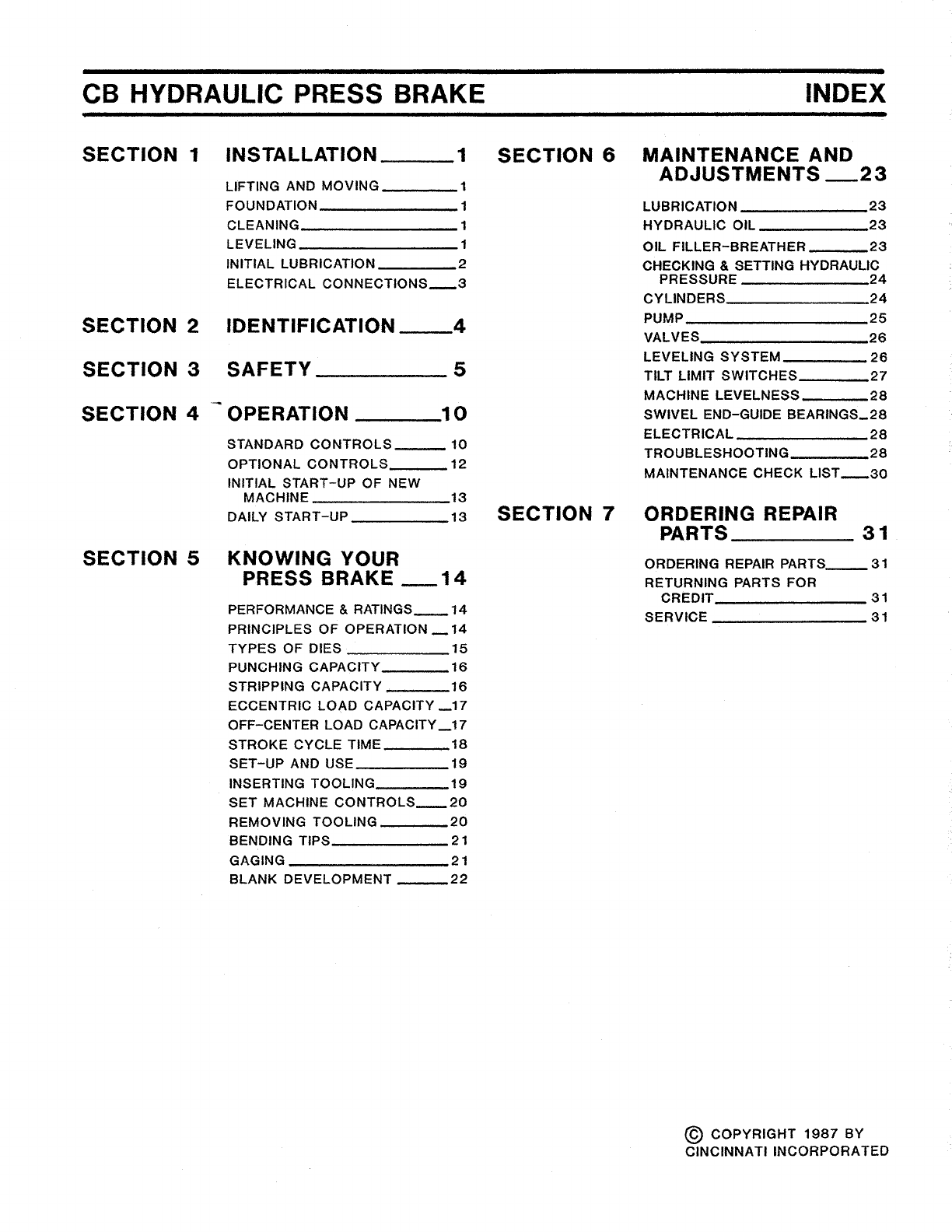

GUARD AGAINST TIPPING

The

design

of

hydraulic

press

brakes

is

such

that

much

of

the

weight

is

concentrated

to

the

front

of

the

machine.

This

sign

cautions

that

the

machine

should

be

guarded

against

tipping

when

moving

or

installing

until

it

is

anchored

to

the

floor.

The

sign

refers

to

the

Operatorts

manual

for

complete

instal-

lation

instructions.

o

CAUTION

0

THIS MACHINE IS HEAVY

IN

FRONT-

GUARD AGAINST TIPPING UNTIL

ANCHOR

BOLTS

ARE SECURED.

COMPLETE

INSTALLATION

INSTRUCTIONS

ARE

IN

"OPERATORS

MANUAL"

PACKED

IN

PLASTIC

POUCH

ON

SIDE

OF

MACHINE.

BEFORE

STARTING

-

LEVEL,

CLEAN,

LUBRICATE

AND

CHECK

RAM

SLIDES

FOR

PROPER

CLEARANCE

AS

DESCRIBED

IN

"OPERATORS

MANUAL"

PRESS

BRAKE

OPERATOR SAFETY

GUIDELINES

•

Be

sure

you

know

your

press

brake

-

capacity,

controls,

operating

modes,

safeguarding

•

Know

and

understand

the

job

you

are

about

to

perform

-material placement, feeding,

movement

of

material

being

formed

•Never place

your

hands

in

the

die

area

•Make

sure

no

one

is

in

backgage

area

at

rear

of

machine

•Tooling,

press

brake

and

gaging

properly

set

for

the

job

•

Always

cycle

the

press

brake

at

least

twice·

with-

out

a

part

in

dies

before

each

shift

and

each

job

•Keep

die

area

free

of

all

unnecessary

material

and

tools

•

Do

not

hang

tools

on

the

ram

•

Adequate

safeguarding

available

and

used

•Keep

your

body

clear

of

workpiece

•Keep

work

area clean

and

orderly

•Keep

alert

-Keep

your

mind

on

the

job

•

Hand

tools

-

personal

protective

devices

avail-

able

and

used

9

•Make

certain

all

persons

are

clear

of

machine

anc'

material

before

operating

•When

you

leave

your

press

brake:

•Place ram

at

bottom

of

stroke

or

block

•Turn

controls

"OFF"

•Turn

power

"OFF"

FAILURE

TO

FOLLOW

SAFE

PRESS

BRAKE

OPERATING

PROCEDURES

MAY

RESULT

IN

SERIOUS

INJURY

TO

YOU

OR

ANOTHER

EMPLOYEE

SAFETY MAINTENANCE CHECK

•SAFEGUARDING

at

point-of-operation

in

proper

adjustment

and

operating

properly

•PINCH POINT

guarding

properly

installed

•OPERATOR CONTROLS

working

O.K.

•OPERATING MODES

functioning

properly

•RAM

starting

and

stopping

properly

•WARNING PLATES clean

and

easily

read

•ELECTRICAL

WIRING

in

good

condition

•CAUTION PAINTING

in

good

condition

•AUXILIARY EQUIPMENT

checked

-

working

properly

•HAND TOOLS

and

personal

protective

equipment

in

good

order

-

readily

available

•

SAFETY

MANUALS

and

OPERATOR

MANUALS

attached

to

machine

•

SCHEDULED

NORMAL

MAINTENANCE

work

completed

SAFETY

IS

PART

OF

YOUR

JOB

•••

THE

MORE

ATTENTION

YOU

PAY

TO

DEVELOPING

SAFE

HABITS,

THE

LESS

THE

CHANCES

OF

INJURY

TO

YOU

AND

YOUR

FELLOW

EMPLOYEES

SECTION 4

Before

starting

your

Press

Brake

the

following

controls

and

their

functions

should

be

thoroughly

understood.

STANDARD CONTROLS

MAIN

CONSOLE

(FIGURE

8)

STROKE

CONTROL

Switch:

This

is

a

two

position

(nON"

-

"OFF")

key

selector

operator

controL

When

in

the

"OFF"

position

the

ram

cannot

be

stroked.

GROUND CONNECTED

Light:-

When

illuminated

this

light

indicates

that

the

low

voltage

A.

C.

control

circuit

is

grounded.

This

is

an

internal

chassis

ground

-

it

does

not

indicate

that

the

machine

is

grounded

..

OPERATION

Switch:

This

is

atwo

position

(flRESET" -

"ON")

key

selector

supervisory

control.

The

normal

position

of

this

switch

is

in

the

"ON

tt

position..

Whenever

a

power

loss

has

occurred-~he

switch

must

be

turned

to

the

"RESET"

position

and

then

to

the

"ON"

position

before

the

main

drive

motor

can

be

energized.

READY

Light:

When

this

light

is

illuminated

it

indicates

that

the

operation

control

has

been

reset

and

the

main

drive

motor

can

be

energized

by

depressing

the

START

button

..

MAIN

DRIVE

START

Button:

This

is

a

guarded

pushbutton

which

is

depressed

to

energize

the

main

drive

motor.

When

illuminated

the

main

drive

motor

is

energized.

MAIN

DRIVE

-

STOP

Button:

This

pushbutton,

'when

depressed,

will

de-energize

the

main

drive

motor.

MODE

Selector:

This

is

a

three

position

key

selector

supervisory

control

consisting

of:

INCH:

This

is

a

set-up

mode

that

can

only

be

operated

by

the

use

of

a

palmbutton

operator's

station.

The

ram

will

run

when

the

operator's

station

is

activated

and

stop

either

on

the

"DOWN"

or

"UP"

stroke

when

the

station

is

deactivated.

The

ram

will

automatically

stop

at

top

of

the

stroke.

Release

the

palmbuttons

and

depress

them

again

to

start

another

cycle.

FIGURE 8

10

OPERATION

SINGLE STROKE -

NO

AUTO

RETURN:

This

is.

a

production

mode

and

can

be

operated

by

the

palm-

button

operator's

station

or

the

footswitch

-operator's

station.

Multiple

paltnbutton

operator's

stations

or

multiple

foots

witch

operator's

stations

can

be

used

in

this

production

mode

but

a

combination

of

palmbutton

and

footswitch

operator's

stations

cannot

be

used.

The

ranl will

run

when

the

operator's

station

is

activated

and

stop

either

on

the

"DOWN"

or

"UP"

stroke

when

the

station

is

deactivated.

If

multiple

operator's

stations

are

in

use)

all

operator's

stations

must

be

deactivated

and·

then

reactivated

before

the

ram

will

resume

trnOWN"

stroking.

The

ram

will

au

tomatically

stop

at

the

top

of

the

stroke.

All

operator's

stations

must

be

deactivated

and

then

reactivated

to

start

another

cycle.

SINGLE

STROKE -AUTO RETURN:

This

is

a

produc-

tion

mode

that

can

only

be

operated

by

use

of

the

three

position

footswitch

operator's

station.

Multiple

footswitch

operator's

stations

can

be

used

in

this

production

mode.

On

the

"DOWN"

or

closing

stroke,

the

ram

will

continue

to

run

as

long

as

the

station

or

stations

are

depressed.

Upon

releasing

the

footswitch

to

the

"CENTER"

position,

the

ram

will

stop.

Upon

releasing

the

footswitch

to

the

"UP"

position)

the

ram

will

return

to

the

top

stroke

control

setting

and

stop.

After

the

ram

has

passed

through

the

bottom

stroke

control

setting,

with

the

footswitch

fully

depressed

or

completely

released

to

the

"UP"

position,

the

ram

will

automatically

return

to

the

top

of

the

stroke

and

stop.

Releasing

the

footswitch

to

the

nCENTER

tt

position

will

stop

the

ram.

All

stations

must

be

deactivated

and

then

reactivated

before

the

ram

will

start

another

cycle~

DOWN STROKE -SPEED

Selector:

This

is

a

three

position

key

selector

supervisor)

control.

The

machine

is

provided

with

three

"DOWN"

or

closing

speeds

(HIGH,

PvlEDIUM

and

LOW).

A

combination

of

any

two

of.

the

three·

speeds

can

be

made

with

this

selector.

(NOTE:

Full

tonnage

is

available

in

MEDIUM

or

LOW

speed

and

approximately

45%

of

maximum

tonnage

is

available

in

HIGH

speed.)

DOWN

STROKE -STROKE

STOP

Switch:

This

is

atwo

position

("ON"-

If

OFF

lt

)

key.

selector

supervisory

control.

With

the

STROKE

STOP

in

the

"ONn

position

the

ram

will

descend

when

the

operator's

station

is

activated,

automatically

stopping

at

a

preselected

height

above

the

bottom

of

the

stroke.

The

operator's

station

must

be

deactivated

and

reactivated

to

complete

the

ram

cycle.

PALMBUTTON OPERATOR

StATION

(FIGURE

9)

FIGURE 9

Two

guarded

palmbuttons,

which

must

be

depressed

about

the

same

time,

are

provided

to

activate

the

ram

in

either

the

"INCHttor

"SINGLE

STROKE

-NO

AUTO

RETURN"

modes.

Releasing

either

palmbutton

will

stop

the

ram.

Both

buttons

Inust

be

released

and

redepressed

to

restart

ram

motion.

EMERGENCY STOP

Button:

Depressing

this

push-

button

deactivates

the

main

drive

motor.

RAM

UP

Button:

This

pushbutton,

when

depressed,

will

cause

the

ram

to

go

up

regardless

of

the

motion,

position

or

previous

direction

of

the

ram.

The

ram

will

stop

when

the

button

is

released

or

when

the

top

stop

position

is

reached.

RAM

UP -.

RAM

DOWN

Directional

Lights:

These

lights

indicate

the

direction

of

motion

(

green

-

UP

or

red-DOWN)

that

the

ram

is

moving

or

will· move

should

an

operator

station

be

activated.

OPERATOR

STATION

Switch:

This

is

a

two

position

("ONU_HOFF")

key

selector

for

activating

the

palm-

buttons.

When

in

the

ttOFF

fJ

position,

ram

cannot

be

cycled

by

pressing

the

palm

buttons.

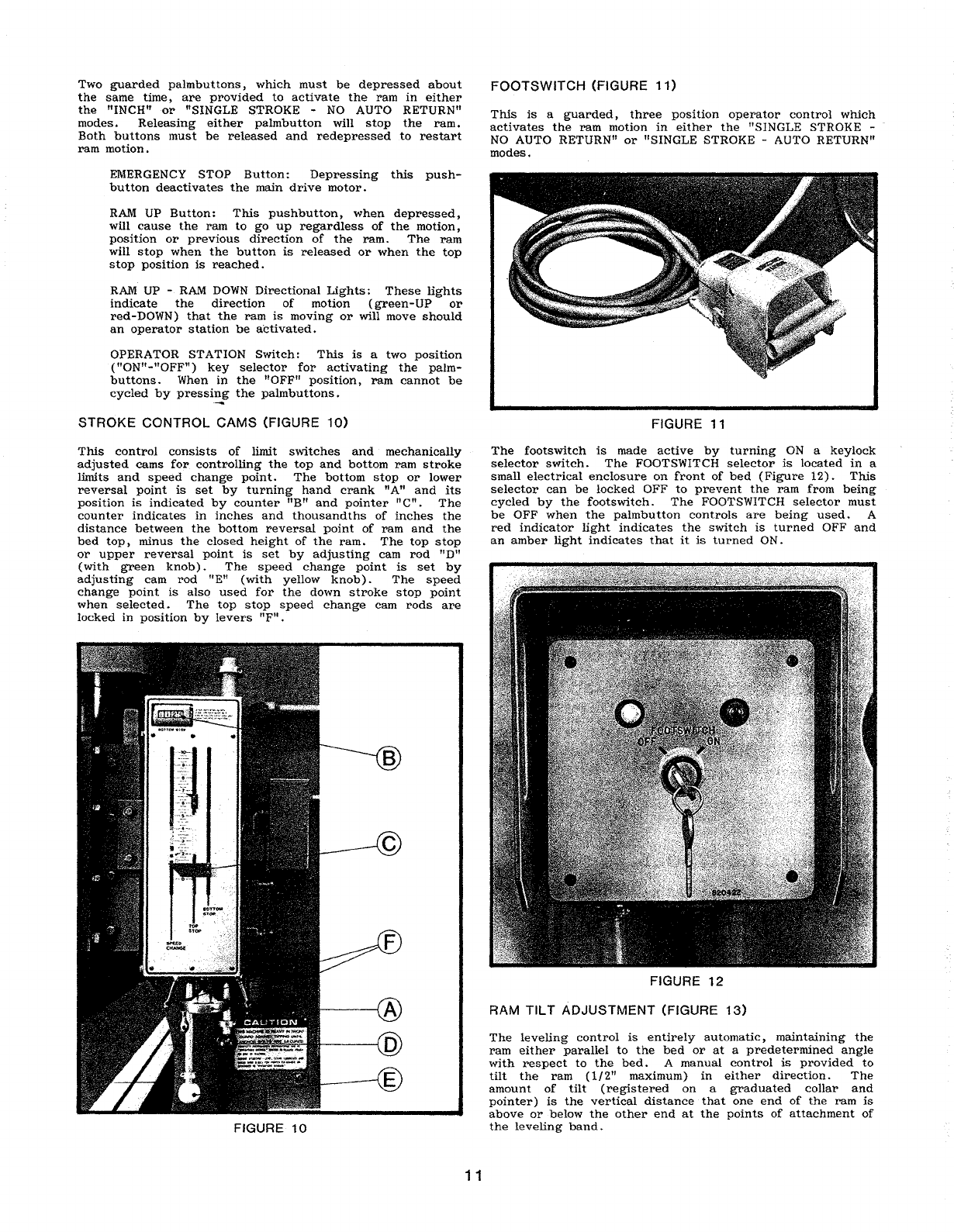

STROKE

CONTROL

CAMS

(FIGURE

10)

This

control

consists

of

limit

switches

and

mechanically

adjusted

cams

for

controlling

the

top

and

bottom

ram

stroke

limits

and

speed

change

point.

The

bottom

stop

or

lower

reversal

point

is

set

by

turning

hand

crank

nAft

and

its

position

is

indicated

by

counter

nB"

and

pointer

"en.

The

counter

indicates

in

inches

and

thousandths

of

inches

the

distance

between

the

bottom

reversal

point

of

ram

and

the

bed

top,

minus

the

closed

height

of

the

ram.

The

top

stop

or

upper

reversal

point

is

set

by

adjusting

cam

rod

uD"

(with

green

knob)

.

The

speed

change

point

is

set

by

adjusting

cam

rod

"En

(with

yellow

knob).

The

speed

change

point

is

also

used

for

the

down

stroke

stop

point

when

selected.

The

.top

stop

speed

change

cam·

rods

are

locked

in

position

by

levers

"F

n•

FIGURE·

10

11

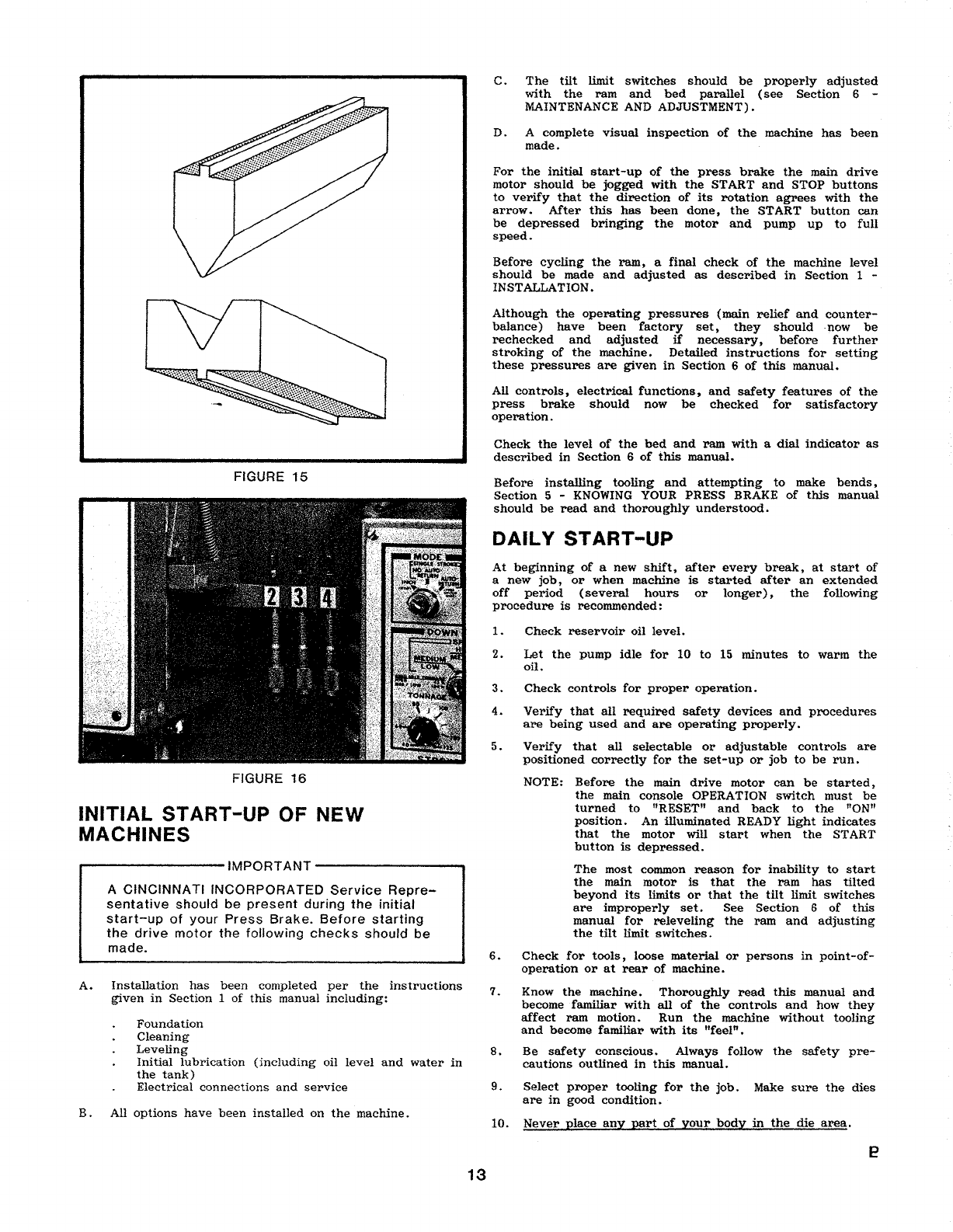

FOOTS

WITCH

(FIGURE

11)

This

is

a

guarded,

three

position

operator

control

which

activates

the

ram

motion

in

either

the

"SINGLE

STROKE -

NO

AUTO

RETURNu

or

"SINGLE

STROKE

-AUTO

RETURN"

modes.

FIGURE 11

The

footswitch

is

made

active

by

turning

ON

a

keylock

selector.

switch.

The

FOOTSWITCH

selector

is

located

in

a

small

electrical

enclosure

on

front

of

bed

(Figure

12).

This

selector

can

be

locked

OFF

to

prevent

the

ram

from

being

cycled

by

the

footswitch.

The

FOOTSWITCH

selector

must

be

OFF

when

the

palmbutton

controls

are

being

used.

A

red

indicator

light

indicates

the

switch

is

turned

OFF

and

an

amber

light

indicates

that

it

is

turned

ON.

FIGURE

12

RAM

TILT

ADJUSTMENT

(FIGURE

13)

The

leveling

control

is

entirely

automatic,

maintaining

the

ram

either

parallel

to

the

bed

or

at

a

predetermined

angle

with

respect

to

the

bed.

A

manual

control

is

provided

to

tilt

the

ram

(1/2"

maximum)

in

either

direction.

The

amount

of

tilt

(registered

on

a

graduated

collar

and

pointer)

is

the

vertical

distance

that

one

end

of

the

ram

is

above

or

below

the

other

end

at

the

points

of

attachment

of

the

leveling

band.

To

operate

the

press

brake

with

the

bed

and

ram

parallel,

the

graduated

collar

and

pointer

should

be

set

to

their

"ZERO"

marks.

Servicing

and

adjusting

the

tilt

control

is

covered

in

the

MAINTENANCE

section

of

this

manual.

FIGURE

13

...----------CAUTION---------..

WHEN

OPERATING

AT

THE

EXTREME

LIMITS

OF

STROKE,

THE

FULL

LENGTH

OF

STROKE

SHOULD·

BE

REDUCED

BY

THE

AMOUNT

,OF

THE

RAM

TIL

T

FOR

OPERATION

IN

A

TILTED

POSITION

TO

PREVENT

LEFT

PISTON

FROM

STRIKING

THE

TOP

OR

BOTTOM

OF

THE

CYLINDER.

The

maximum

allowable

tilt

is

112

ft

in

the

length

between

the

tape

anchor

points.

If

this

tilt

is

exceeded,

the

out-of-Ievel

limit

switches

will

stop

the

ram

by

de-energizing

the

main

pump

motor.

SET-UP

LIGHTS (FIGURE

5)

This

light'is

mounted

on

front

side

of

the

main

electrical

enclosure.

The

green

Ughtcomes

on

whenever

the

ram

is

at

the

bottom

reversal

position.

OPTIONAL CONTROLS

UP

STROKE

-

STROKE

STOP

Switch

(FIGURE

14)

This

is

a

two

position

("ON"-"OFF

n)

key

selector

supervisory

control

located

on

the

main

console.

When

in

the

nON"

position

the

ram

will

automatically

stop

immediately

after

passing

through

the

bottom

reversal

point.

All

operator

controls

being

used

must

be

released

and

reactivated

to

restart

the

return

stroke

of

the

ram.

This

con

trol

can

be

used

in

all

modes.

TONNAGE

CONTROL

The

tonnage

control

consists

of

an

adjustable

selector

mounted

on

the

main

console.

The

maximum

tonnage

for

"centered

tf

loads

is

limited

by

the

setting

of

this

selector.

Upon

building

up

to·

the

pre-selected

tonnage,

the

ram

will

automatically

reverse

from a

downward

to

an

upward

direction.

12

Actual

forming

tonnage

in

high

speed

is

approximately

45%

of

the

tonnage

control

setting.

FIGURE

14

IMPORTANT

---------..

The

hydraulic

components

and

machine

frame

members

are

safeguarded

against

overload

by

both

a

pressure

transducer

and

a

relief

valve

in

the

circuit.

However,

care

must

be

taken

to

provide

enough

area

under

upper

and

lower

dies

to

prevent

them

from

sinking

into

the

bed

top

or

ram

nose

due

to

highly

concentrated

loads.

ThiS

is

the

shaded

area

shown

in

Figure

15.

The

minimum

area

(sq.

in.)

for

each

die

to

prevent

sinking

may

be

calculated

by

this

formula:

MAXIMUM

TONNAGE

Die

Area

=

15

An

example

for

a

135

ton

machine:

the

minimum

die

area

is

135

divided

by

15,

or

9

square

inches

..

ADDITIONAL

FOOTSWITCHES

AND/OR

PALMBUTTONS

The

operation

of

these

controls

is

the

same

as

the

standard

controls.

Additional

selector

switches

are

provided

for

selecting

left,

right

or

both

controls.

MULTIPLE DEPTH

STOPS

(FIGURE

16)

With

this

option

a

total

of

four

distinct

pre-set

bottom

reversal

points

are

available.

The

No. 1

stop

is

the

standard

bottom

stop.

Stops

No.2,

3

and

4

are

set

by

adjusting

micrometer

barrels

which

are

added

to

the

bottom

s

top

cam

on

the

right

hand

side

of

the

machine.

T,he

press

brake

operator

can

select

which

of

the

four

stops

he

wants

by

a

portable

s~lector

switch,

which

can

be

moved

any

place

along

the

front

of

the

press

brake.

FIGURE

15

FIGURE

16

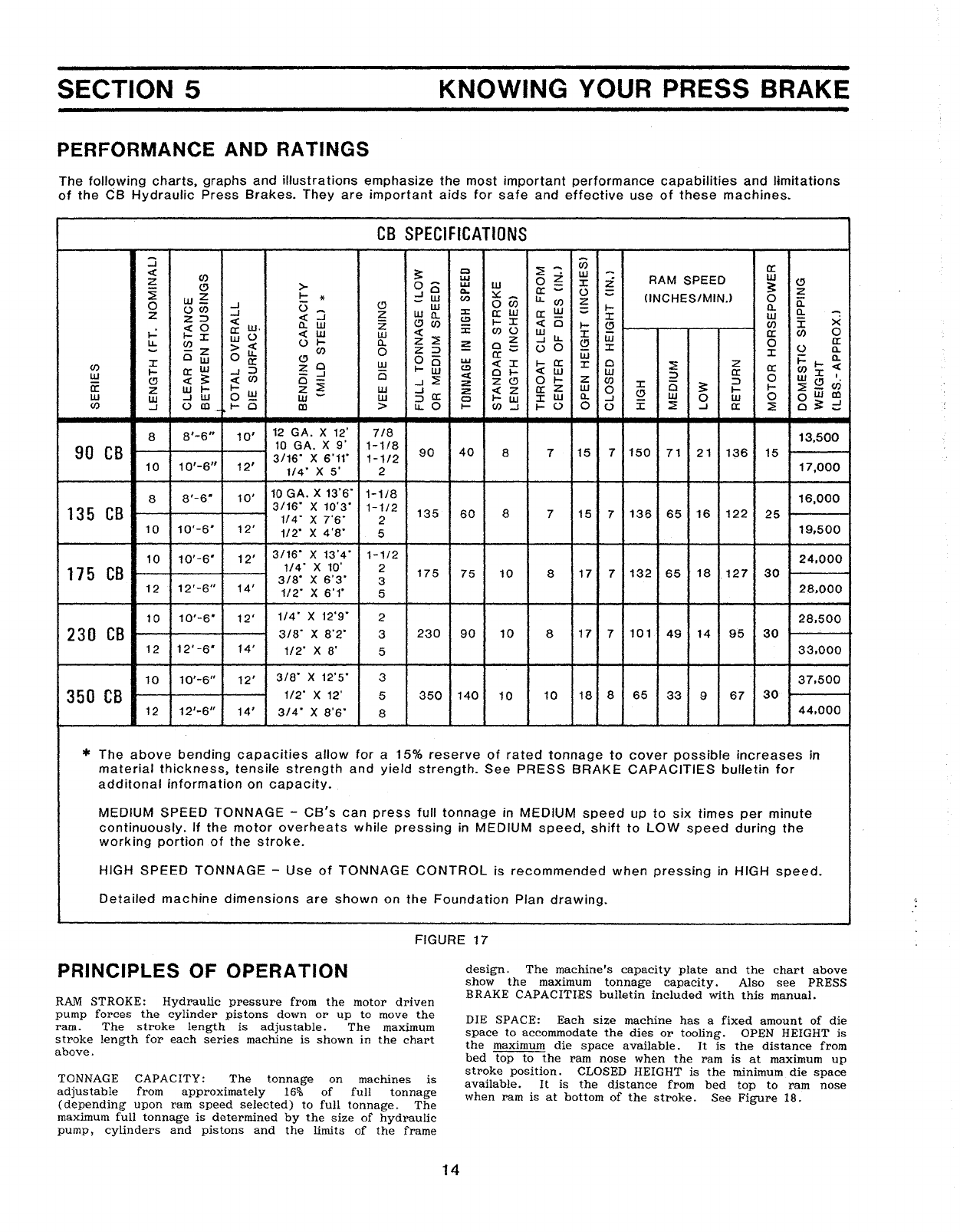

INITIAL

START-UP

OF NEW

MACHINES

.......

-------IMPORTANT

---------a

A

CINCINNATI

INCORPORATED

Service

Repre-

sentative

should

be

present

during

the

initial

start-up

of

your

Press

Brake.

Before

starting

the

drive

motor

the

following

checks

should

be

made.

A.

Installation

has

been

completed

per

the

instructions

given

in

Section

1

of

this

manual

including:

Foundation

Cleaning

Leveling

Initial

lubrication

(including

oil

level

and

water

in

the

tank)

Electrical

connections

and

service

B.

All

options

have

been

installed

on

the

machine.

13

C.

The

tilt

limit

switches

should

be

properly

adjusted

with

the

ram

and

bed

parallel

(see

Section

6 -

MAINTENANCE

AND

ADJUSTMENT).

D.

A

complete

visual

inspection

of

the

machine

has

been

made.

For

the

initial

start-up

of

the

press

brake

the

main

drive

motor

should

be

jogged

with

the

START

and

STOP

buttons

to

verify

that

the

direction

of

its

rotation

agrees

with

the

arrow.

After

this

has

been

done

t

the

START

button

can

be

depressed

bringing

the

motor

and

pump

up

to

full

speed.

Before

cycling

the

ram,

a

final

check

of

the

machine

level

should

be

made

and

adjusted

as

described

in

Section

1 -

INSTALLATION.

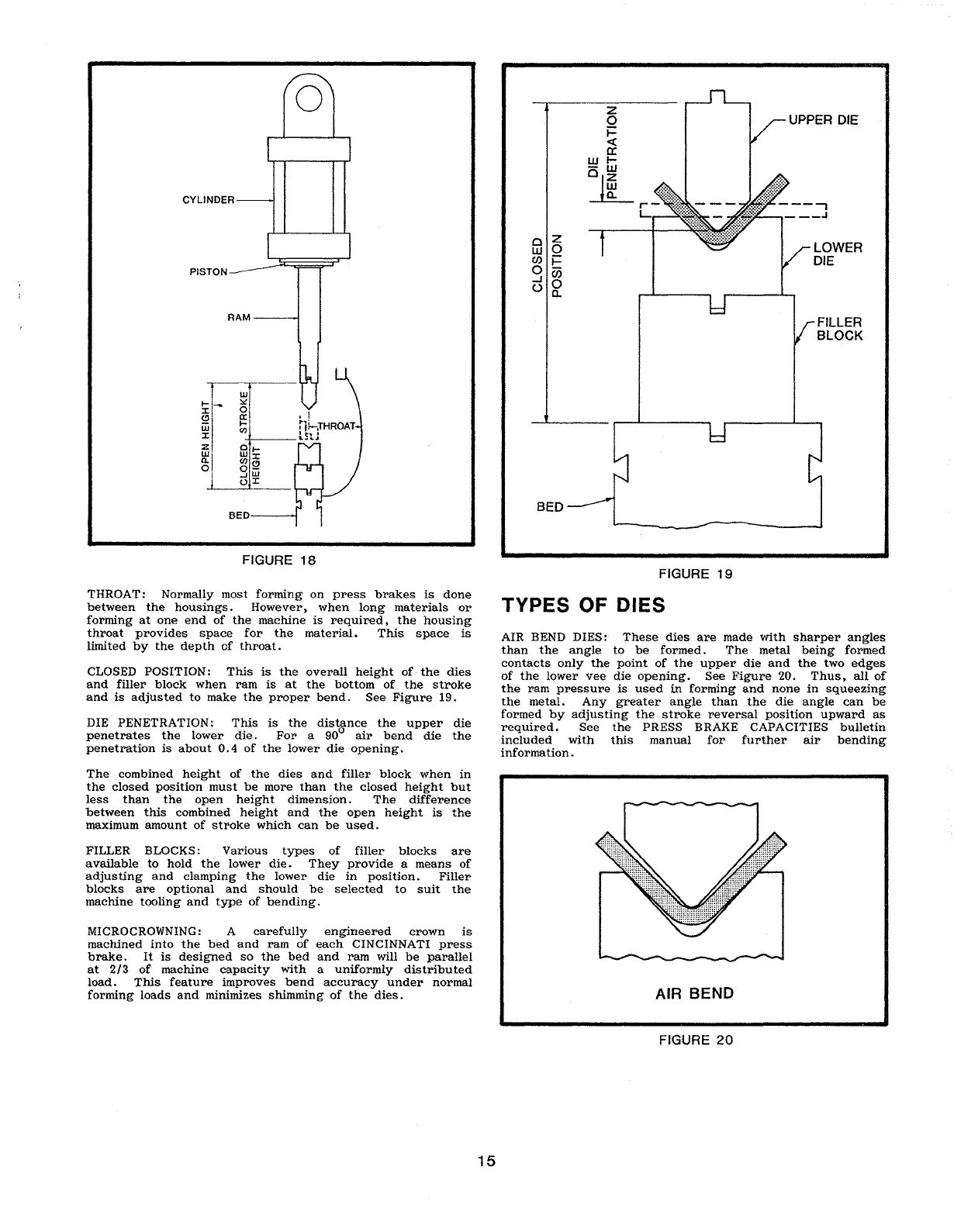

Although

the

operating

pressures

(main

relief

and

counter-